High-purity ferrite stainless steel material and manufacturing method thereof

A manufacturing method, stainless steel technology, applied in the direction of manufacturing tools, temperature control, casting equipment, etc., can solve the problems that the size of nitrided precipitates cannot be effectively controlled, the fluidity of molten steel is deteriorated, and the rate of billet forming of molten steel is low. Effects of improving grain coarsening, improving processing, and improving welding performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

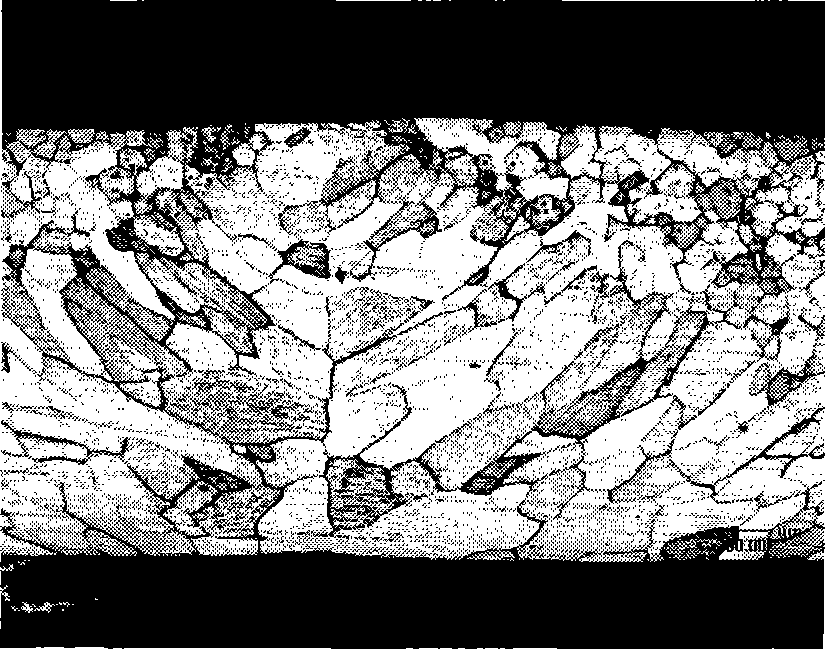

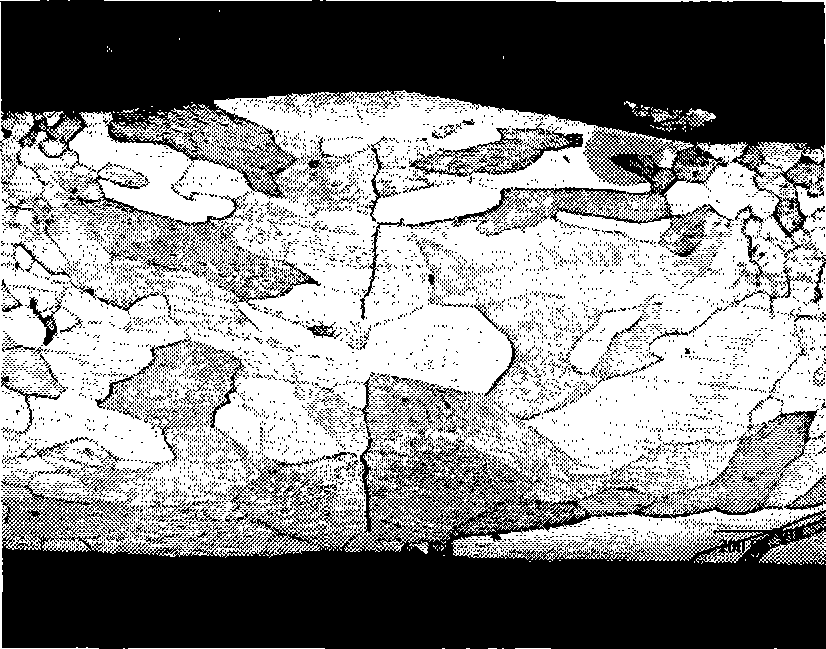

Image

Examples

Embodiment Construction

[0052] The present invention will be described in detail below through examples.

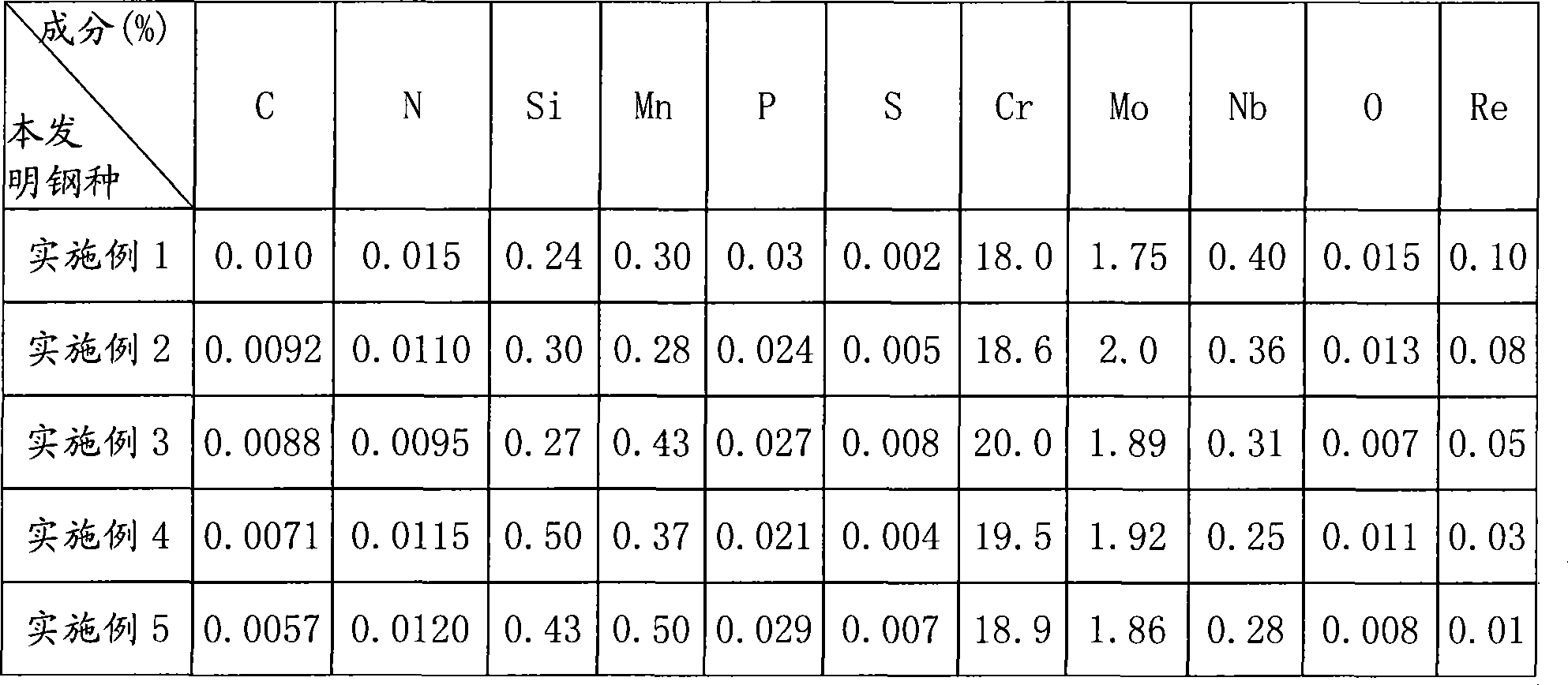

[0053] Table 1 is the chemical composition of stainless steel with good weldability of medium-chromium rare earth-containing high-purity ferrite in various embodiments of the present invention;

[0054] Table 2 is the manufacturing process parameters such as steel smelting, hot rolling, heat treatment of the present invention;

[0055] Table 3 shows the mechanical properties of the welded seam and the cupping value reflecting the plasticity of the welded seam.

[0056] Table 1

[0057]

[0058] Table 2

[0059]

serial number

Casting temperature

(℃)

rare earth feeding

enter time

(Second) hot rolled out

steel temperature

(℃) Finish rolling

temperature

(℃) hot and cold

fire temperature

(℃) Cumulative cold rolling

Deformation rate

% Example 1 1530 48 1100 850 1045 70 Example 2 1535 37 1...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com