Insulation cup with titanium composite inner tank and manufacturing process thereof

A manufacturing process and technology for thermos cups, which are applied to thermos cups with titanium composite inner liner and their manufacturing processes, can solve the problems of easy deterioration and high production costs, reduce manufacturing costs, ensure health and environmental protection, and ensure thickness and safety. The effect of stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

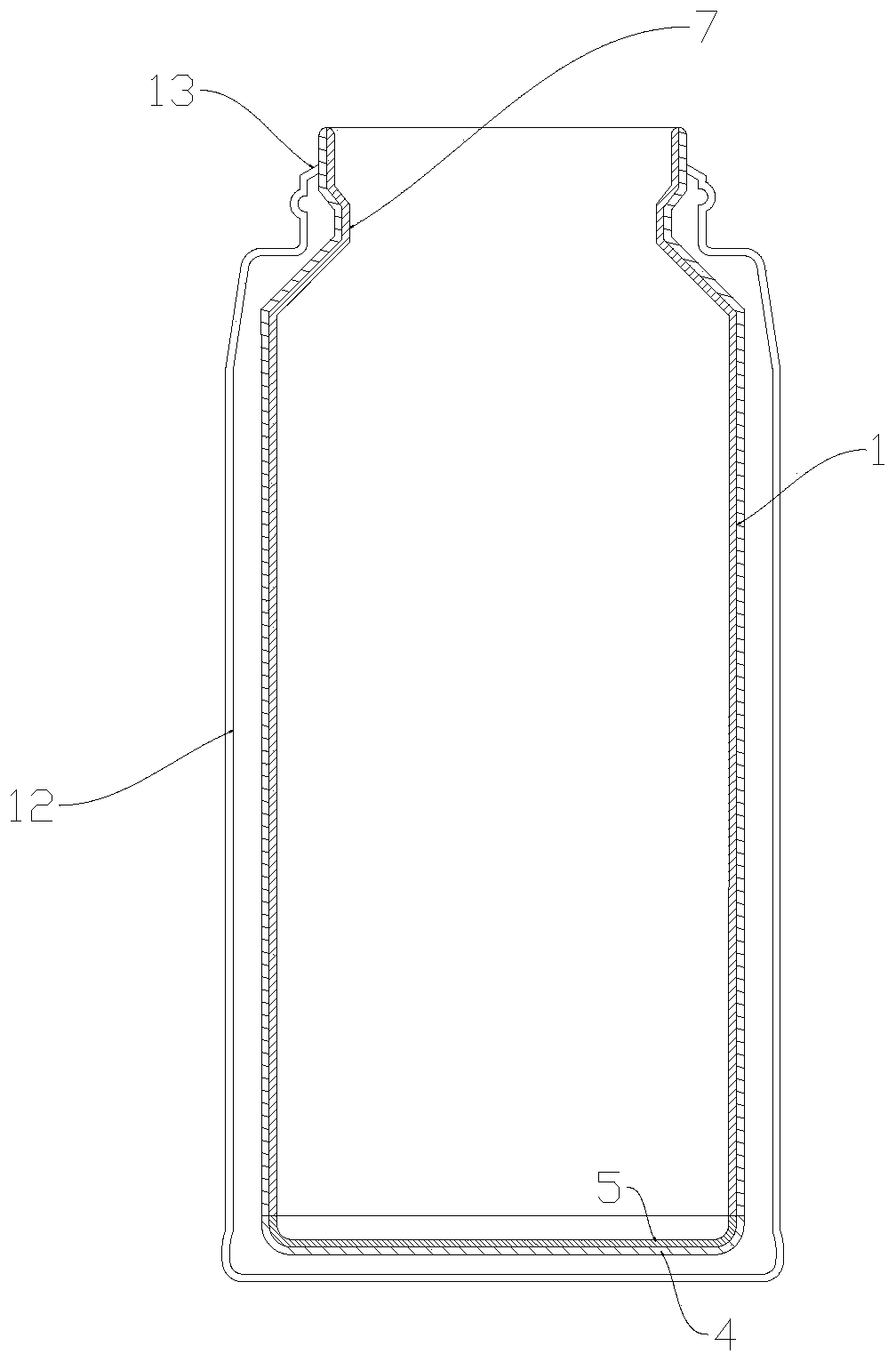

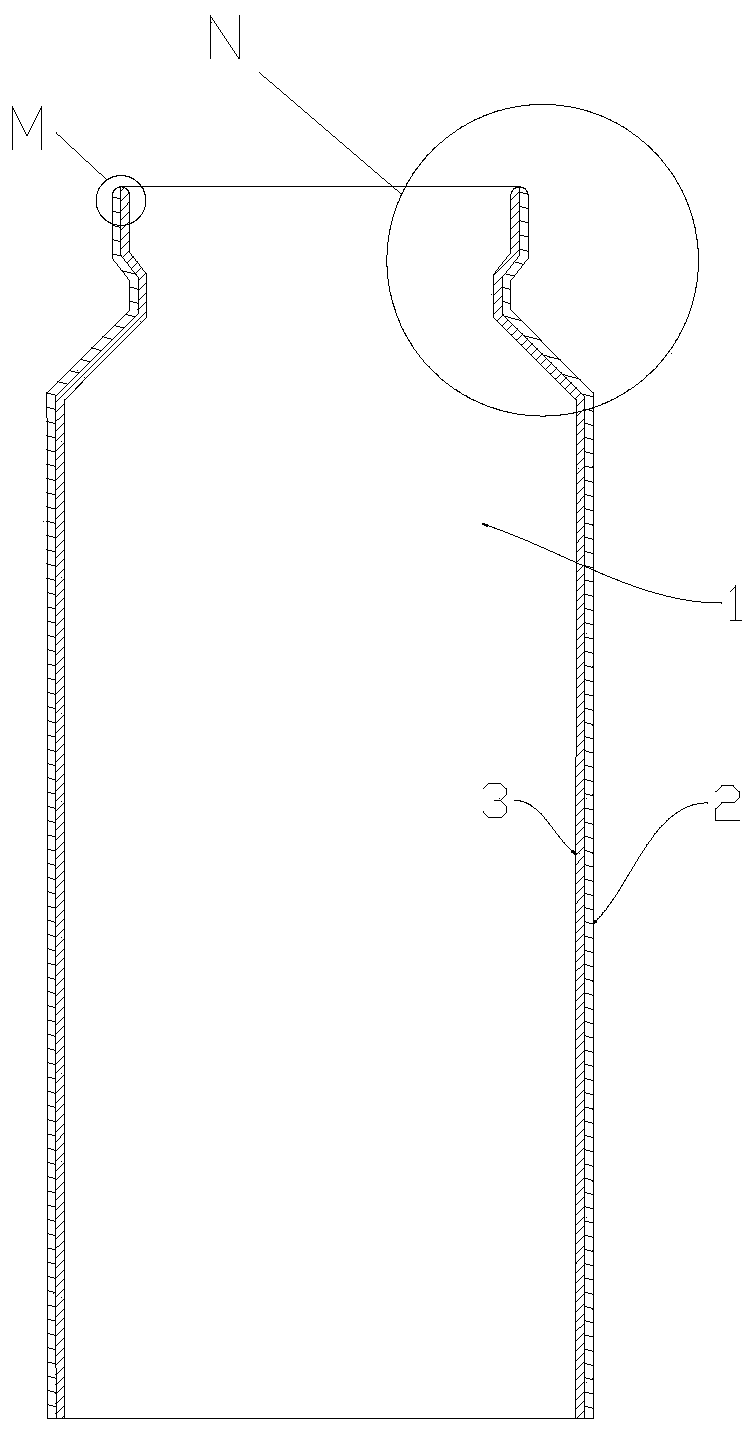

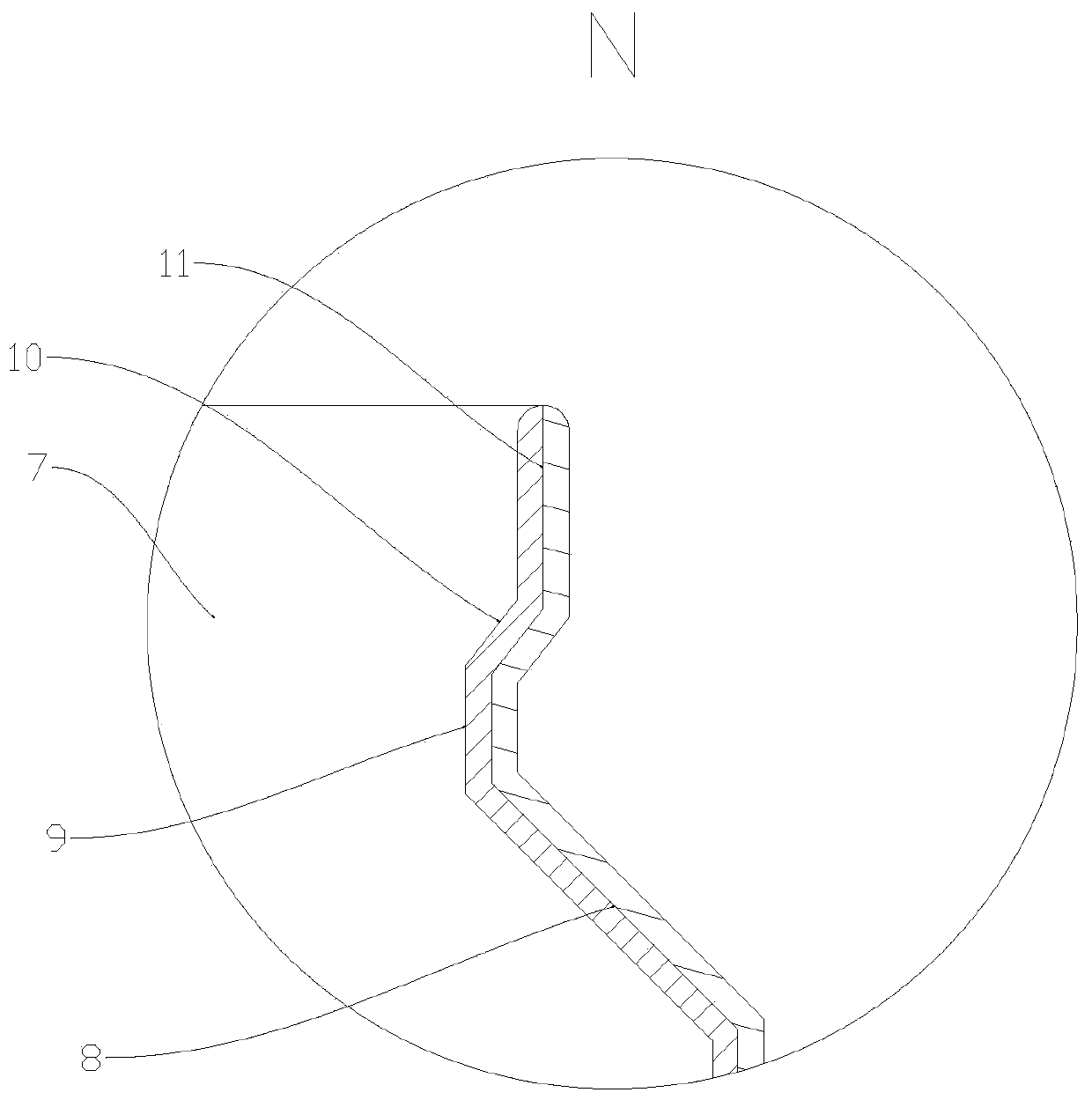

[0035] Thermos mugs with a titanium composite liner, such as Figure 1 to Figure 4As shown, the liner body 1 is included, the liner body 1 includes a first liner layer 2 and a second liner layer 3, the first liner layer 2 and the second liner layer 3 are concentrically arranged, and the first liner layer 2 Made of stainless steel or copper or iron or aluminum, the second inner liner layer 3 is made of titanium material, the upper end of the second inner liner layer 3 is provided with an outwardly flanging transition arc 6, the transition arc 6 It has an integral structure with the second inner liner layer 3, the upper end of the first inner liner layer 2 is set in the transition arc 6, the lower end of the inner liner body 1 is provided with a first bottom layer 4 and a second bottom layer 5, and the first bottom layer The thickness of 4 is the same as the thickness of the first liner layer 2, the thickness of the second bottom layer 5 is the same as the thickness of the secon...

Embodiment 2

[0039] A manufacturing process of a thermos cup with a titanium composite liner, such as Figure 1 to Figure 4 shown, including

[0040] The thermos cup with titanium composite liner described in embodiment 1 also includes the following manufacturing steps:

[0041] Step 1, take pipes made of stainless steel or copper or iron or aluminum and pipes made of titanium of the same length, and wear the pipes made of titanium on the stainless steel or copper or iron or aluminum The pipe made of the material is arranged concentrically to form a composite pipe;

[0042] Step 2: Spinning the composite pipe to form the inner tank body 1, the thickness of the pipe made of stainless steel or copper or iron or aluminum is spun to 0.3-0.6 mm, and the thickness of the pipe made of titanium is Pipe thickness spinning to 0.03 ~ 0.5mm;

[0043] In step 3, the upper end of the liner body 1 is narrowed to form the cup mouth 7, and the end of the cup 7 and the lower end of the liner body 1 are t...

Embodiment 3

[0048] Thermos mugs with a titanium composite liner, such as figure 1 , figure 2 , image 3 , Figure 6 As shown, the difference from Embodiment 1 is that the upper end of the first inner bag layer 2 and the upper end of the second inner bag layer 3 are provided with a semicircular arc 14 extending toward the middle of the inner bag body 1, the first inner bag The semicircular arc 14 of the layer 2 and the semicircular arc 14 of the second liner layer 3 form the transition arc 6 in combination.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com