Ultra-low temperature austenite stainless steel solid core welding wire

A technology of austenitic stainless steel and solid wire, applied in the direction of welding medium, welding equipment, welding/cutting medium/material, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0015] Embodiment 1, the stainless steel welding wire composition of welding 304L:

[0016] C: ≤0.03%, Si: ≤0.60%, Cr: 19.0~22.0%, Ni: 10~12%, Mo: 0%, Mn: 2.0~4.0%, N: 0.05~0.10%, S≤0.015, P ≤0.015%, RE: 0.10% (added amount), the balance is Fe.

Embodiment 2

[0017] Embodiment 2, the stainless steel welding wire composition of welding 316LN:

[0018] C: ≤0.03%, Si: ≤0.60%, Cr: 22.0~26.0%, Ni: 12~15%, Mo: 2.5~3.5%, Mn: 4.0~6.5%, N: 0.12~0.18%, S≤0.015 , P≤0.015%, RE: 0.10% (added amount), the balance is Fe.

[0019] The welding wire of embodiment 2 of this technical solution was used in the overlay welding test project of the international thermonuclear fusion experiment, and the welding performance is good, and its weld metal can fully meet the use of 316LN in an ultra-low temperature environment.

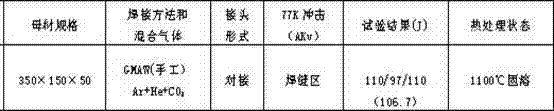

[0020] Below is 316LN stainless steel material, the technical data welded with technical achievement of the present invention:

[0021]

[0022] According to the fourth part of GB150-2011 "Pressure Vessels", the impact energy index of stainless steel at low temperature -100 ℃ is ≥31J. However, the impact energy index of the welding material of the present invention reaches 106.7J at -196°C, indicating that its low-tempera...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com