Nanpsheet-shaped SAPO-34 molecular sieve as well as ultrafast preparation method and application thereof

A SAPO-34, flake-shaped technology, applied in the field of molecular sieves, can solve the problems of difficult operation and difficult industrial scale-up, and achieve the effects of small solvent consumption, short crystallization time and high yield

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

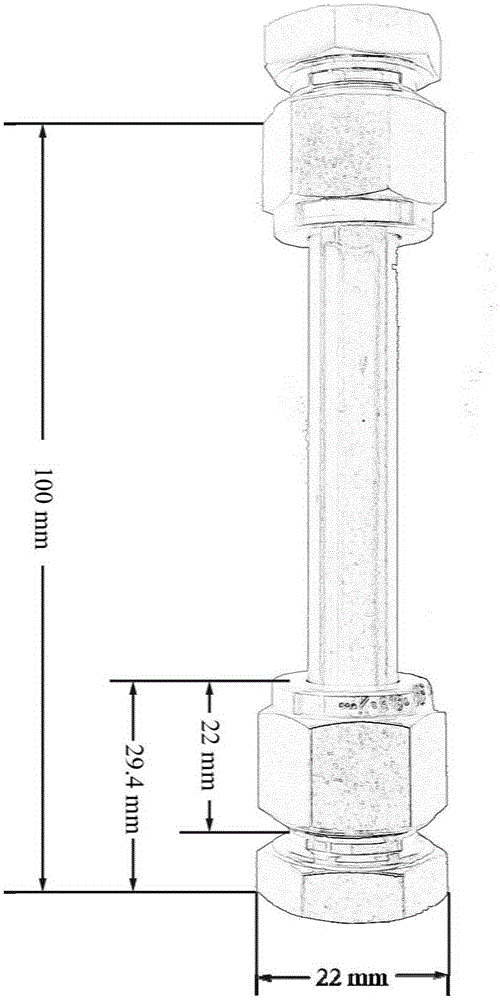

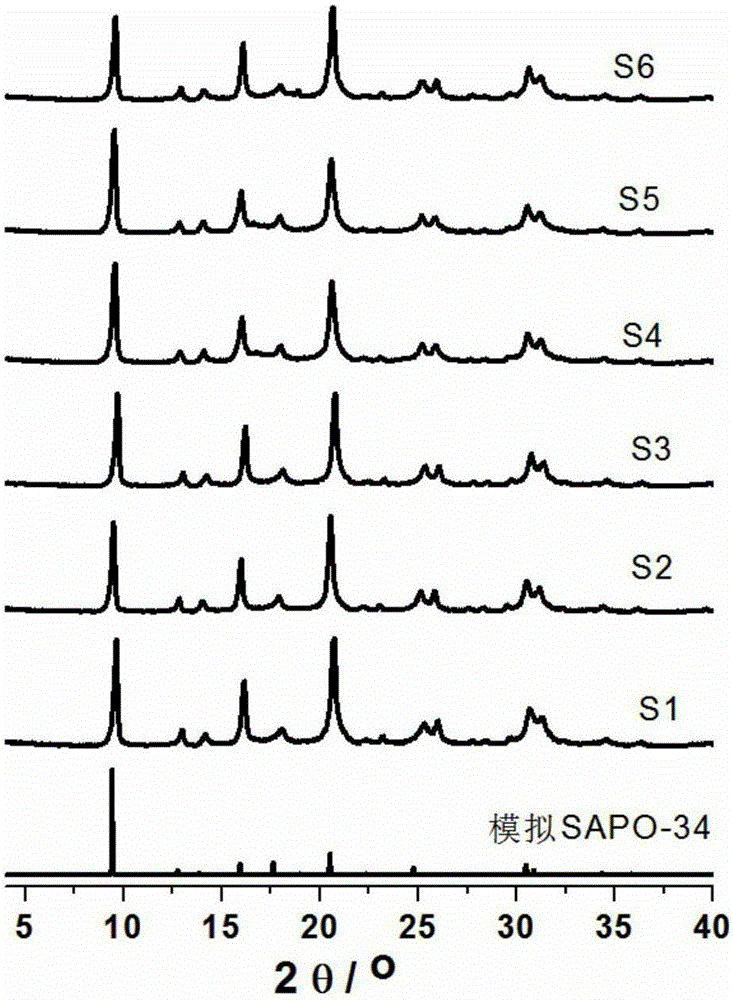

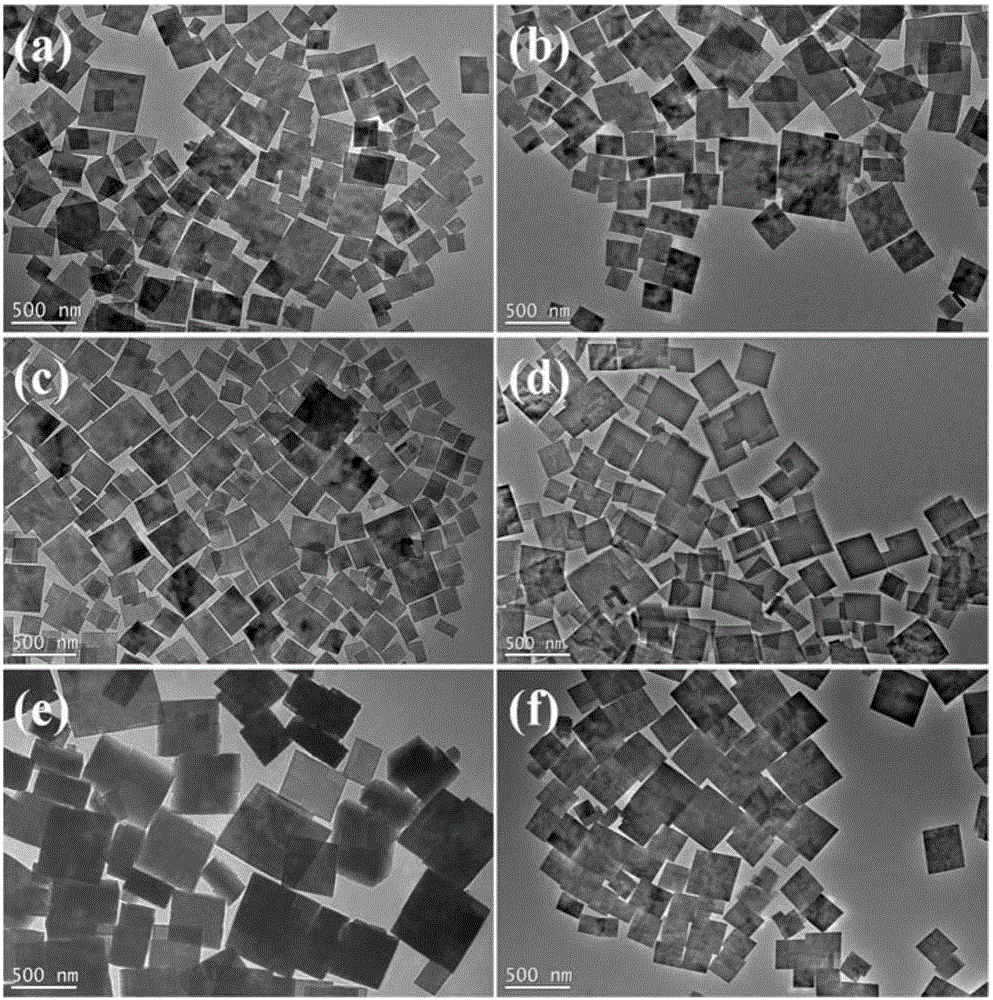

[0038] Add 0.98g of aluminum isopropoxide to a mixed solution of 2.0g of tetraethylammonium hydroxide and 0.26g of water, and stir at 30°C for 5 hours to obtain a mixture; add 0.03g of white carbon black and 1.10g of phosphoric acid to In the above mixture, the stirring process was continued at 30°C for 3 hours to obtain the initial gel mixture of SAPO-34 molecular sieves; after that, the obtained initial gel mixture of SAPO-34 molecular sieves was stirred for another 3 hours in a water bath at 50°C, and the reaction system The molar ratio of each component oxide, tetraethylammonium hydroxide and solvent in the initial gel mixture is 1.0TEAOH: 0.1SiO 2 : 1.0P 2 o 5 : 0.5Al 2 o 3 : 20H 2 O; Finally, 0.01 g of a SAPO-34 molecular sieve seed crystal with a mass fraction of 1% was added to the obtained gel. The resulting gel mixture was stirred for a further 3 hours in a 50°C water bath. The resulting gel mixture was loaded with an attached figure 1 For the stainless steel ...

Embodiment 2

[0040] Add 0.1g of aluminum oxide to a mixed solution of 0.82g of tetraethylammonium hydroxide and 0.16g of methanol (MeOH), and stir at 50°C for 2 hours to obtain a mixture; 0.018g of active silicon dioxide, 0.11g Phosphoric acid was added to the above mixture in turn, and the stirring process was continued at 30°C for 1 hour to obtain the initial gel mixture of SAPO-34 molecular sieve; after that, the obtained initial gel mixture of SAPO-34 molecular sieve was stirred again in a water bath at 80°C for 6 hour, the molar ratio of each component oxide, tetraethylammonium hydroxide and solvent in the initial gel mixture in the reaction system is 4.0TEAOH: 0.6SiO 2 : 1.0P 2 o 5 : 2.0Al 2 o 3 :10MeOH:60H 2 O; Finally, 0.012 g of a SAPO-34 molecular sieve seed crystal with a mass fraction of 10% was added to the obtained gel. The resulting gel mixture was stirred for a further 6 hours in an 80°C water bath. The obtained gel mixture was put into a special stainless steel react...

Embodiment 3

[0042] Add 0.32g of aluminum hydroxide to a mixed solution of 1.26g of tetraethylammonium hydroxide and 0.55g of ethanol (EtOH), and stir at 40°C for 3 hours to obtain a mixture; 0.062g of ethyl silicate, 0.23g of phosphoric acid Add to the above mixture in turn, and continue to stir at 40°C for 2 hours to obtain the initial gel mixture of SAPO-34 molecular sieve; after that, stir the obtained initial gel mixture of SAPO-34 molecular sieve in a water bath at 60°C for another 4 hours, The molar ratio of each component oxide, tetraethylammonium hydroxide and solvent in the initial gel mixture in the reaction system is 3.0TEAOH: 0.3SiO 2 : 1.0P 2 o 5 : 2.0Al 2 o 3 : 12EtOH: 48H 2 O; Finally, 0.012 g of SAPO-34 molecular sieve seed crystals with a mass fraction of 5% were added to the obtained gel. The resulting gel mixture was stirred for a further 4 hours in a 60°C water bath. The obtained gel mixture was put into a special stainless steel reactor, and the reactor was heat...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com