Stainless steel magnetic field regulating device

A technology of stainless steel and magnetic modulation, applied in the direction of electromechanical devices, electromechanical transmission devices, permanent magnet clutches/brakes, etc., can solve the problems of poor creep resistance, complicated manufacturing process, low degree of polymerization, etc., and achieve good machining performance and welding performance, enhance the magnetic field modulation effect, and expand the effect of the application field

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

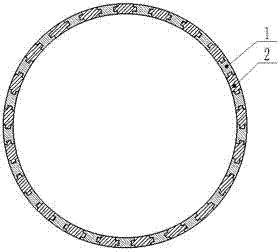

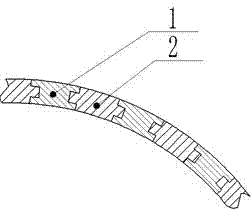

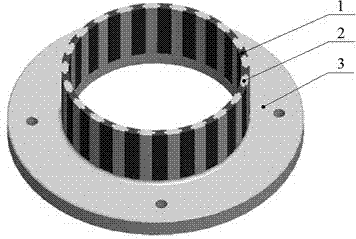

[0053] Example 1: The stainless steel magnetic adjustment device can be used in the cylindrical magnetic transmission device. The magnetic adjustment device is nested with the main and driven rotors, and is located between the main and slave rotors to form a uniform internal and external air gap to achieve radial adjustment. Magnetism, the magnet adjustment pieces 13 are stacked axially or tangentially to form the magnet adjustment block 1 (see Figure 4 , 5 , Figure 9 and Figure 14 ); (1) Applied to the barrel-type magnetic adjustment asynchronous magnetic coupling (see Figure 28 ) in the working principle: the active rotor 9 drives the P 1 Opposite permanent magnet 6 with n 1 rotate at a rotational speed, forming a rotational speed of n 1 , number of pole pairs P 1 Rotating magnetic field, the number of passes is P 2 After the magnet block 1 is modulated, its rotational speed and distribution will change to form a pole pair number P 3 , speed is n 2 The new rotat...

Embodiment 2

[0054] Embodiment 2: The stainless steel magnetic adjustment device can be used in the disc type magnetic adjustment asynchronous magnetic coupling (see Figure 30 ), the magnetic adjustment disk is parallel to the main and driven disks, and a uniform left and right air gap is formed between the main and driven disks to realize axial magnetic adjustment. The magnetic adjustment pieces 13 are stacked radially or tangentially to form a magnetic adjustment block 1 ( See Figure 21 , 22 , Figure 25 and Figure 27 ); the magnetic modulation principle of this magnetic modulation device is similar to the magnetic modulation device in Embodiment 1, the difference is that the former is axial magnetic modulation, and the latter is radial magnetic modulation.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com