Full-automatic punching die

A fully automatic, punching technology, applied in the field of punching dies, can solve the problem of inaccurate positioning

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

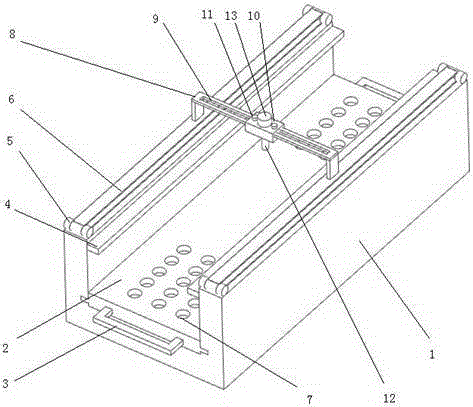

[0014] Below in conjunction with accompanying drawing and embodiment the invention is described in detail:

[0015] The invention provides a fully automatic punching die, which drives the bracket to move through the transmission, and drives the punching equipment to move horizontally through the motor of the bracket, thereby realizing fully automatic punching. After using the punching die, the punching is accurate and continuous punching can be realized. hole.

[0016] As an embodiment of the present invention, the present invention provides a fully automatic punching die, including a chassis 1, a pull plate 2, a main motor 5, a transmission belt 6, a bracket 8, a moving bracket 10, a punch 12 and a moving motor 13, The section of the underframe 1 is U-shaped, the inner walls of the two side ends of the underframe 1 have guide rails, the two side ends of the pull plate 2 are clamped in the guide rails, and the upper parts of the two side ends of the underframe 1 Each has a pa...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com