Automatic material fetching, hole punching and fastening machine for ceiling

An automatic reclaiming and ceiling technology, applied in metal processing, work accessories, metal processing equipment, etc., can solve the problems of not being able to achieve fully automatic operation, requiring manual operation, low efficiency, etc., saving manpower and material resources, reducing burden, The effect of speeding up the renovation process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0036] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

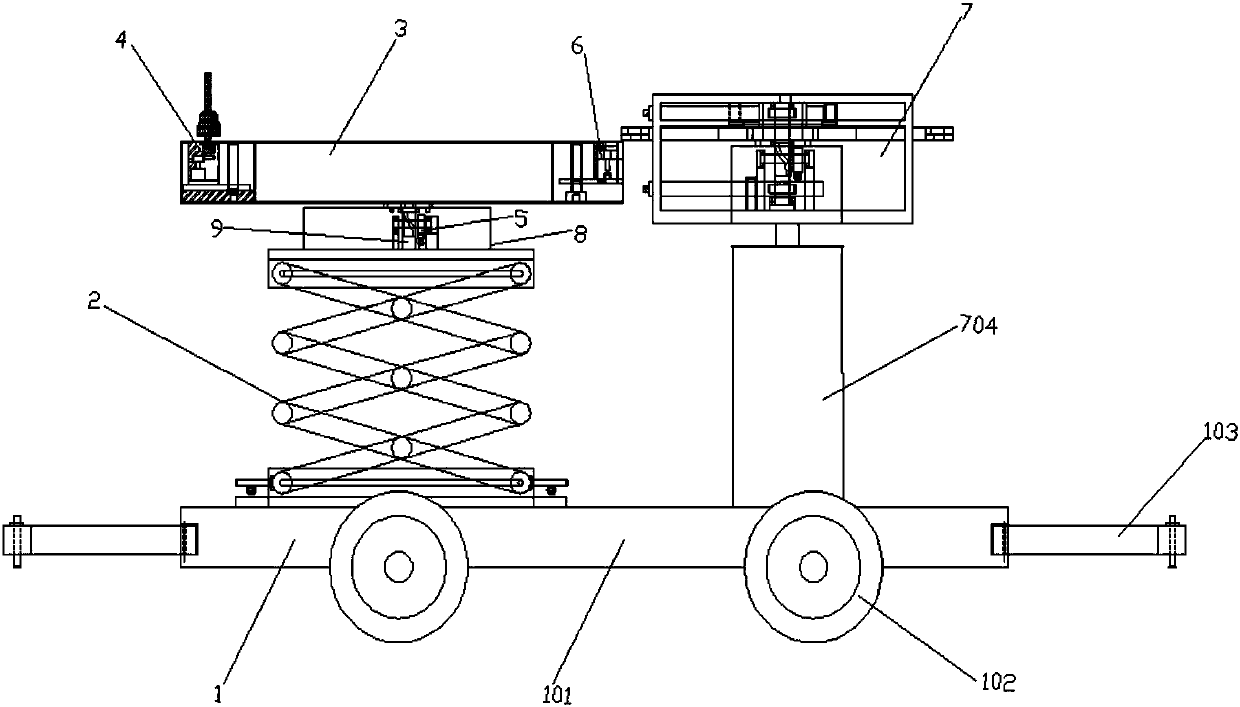

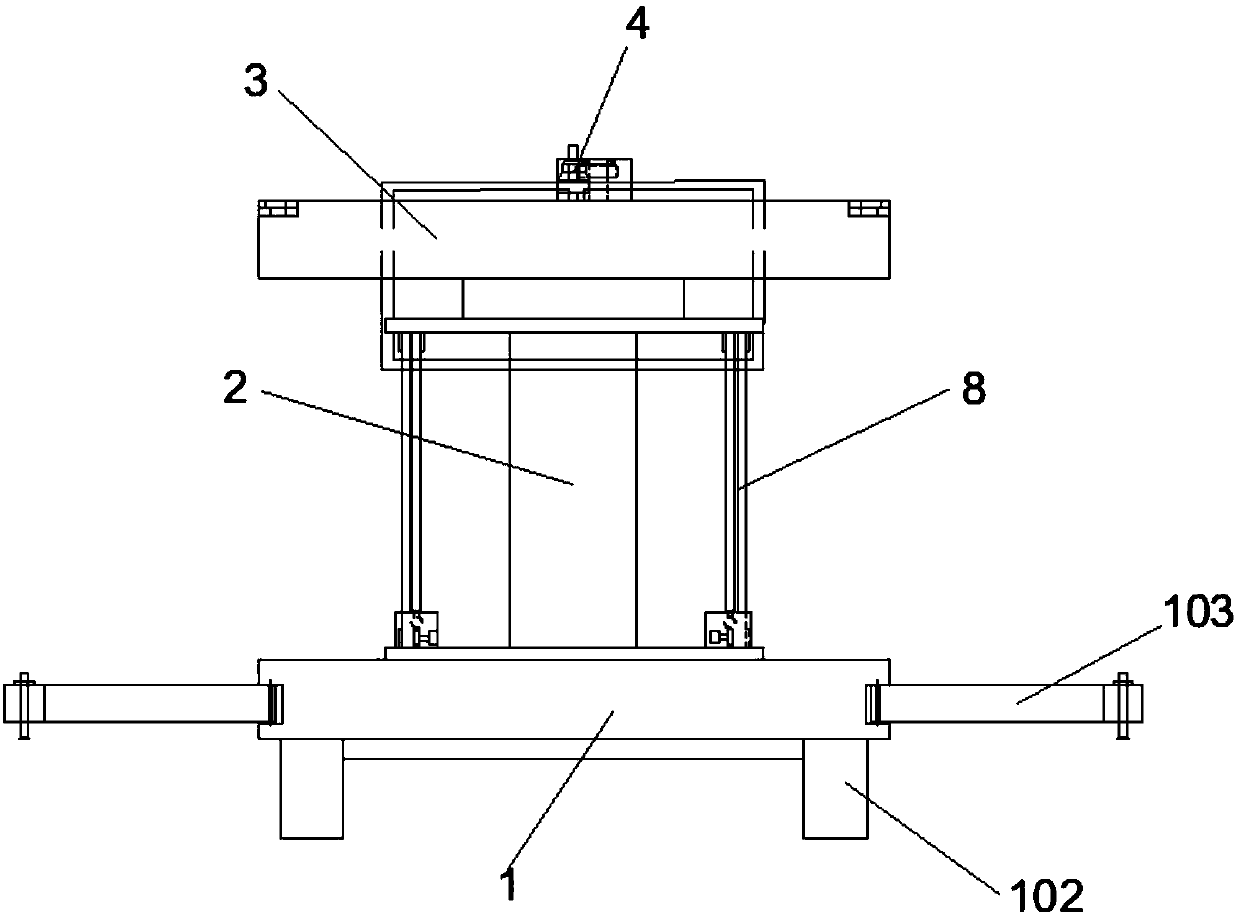

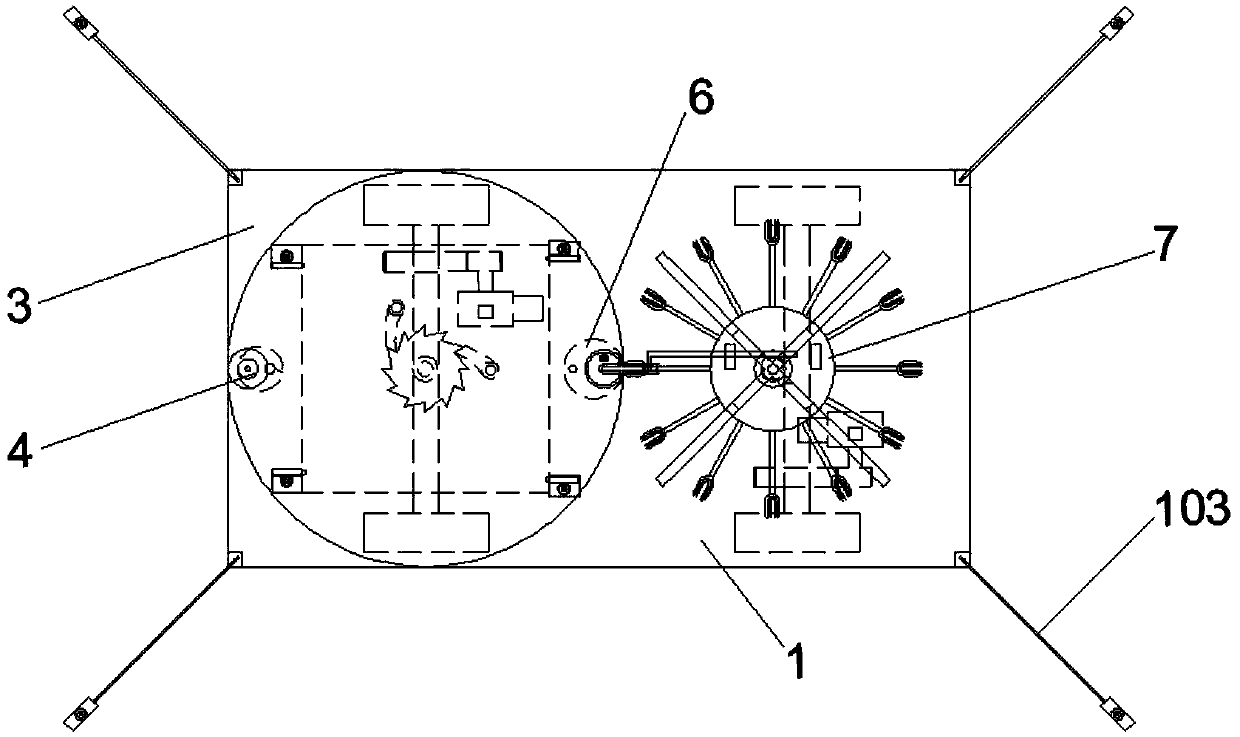

[0037] Such as Figure 1-3 As shown, a ceiling automatic retrieving, punching and fastening machine in this embodiment includes a load-bearing trolley 1, a fixed scissor lift 2, a first motion intermittent mechanism 5, a circular rotatable platform 3, Upliftable punching mechanism 4, upliftable screw-in expansion screw mechanism 6, multi-wrench rotary refueling machine 7, casing 8, fixed shaft 9, bearing and support frame; hole and the bottom of the fastening machine, the fixed scissor lift 2 is set on the side above the load-bearing trolley 1 and is connected with the car body 101 of the load-bearing trolley 1, and the multi-wrench rotary refueling machine 7 is set on the load-bearing trolley The other side above the trolley 1 is connected to the car body 101 of the load-bearing trolley 1. The housing 8 is arranged on the pressure-bearing platform of ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com