Forming and punching device

A technology of punching device and molding die, which is applied in metal processing and other directions, can solve the problems of many processes, labor and time consumption, and increase production cost, and achieve the effects of improving work efficiency, reducing errors, and reducing production costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0033] In order to make it easy to understand the technical means, creative features, objectives and effects achieved by the present invention, the present invention will be further explained below in conjunction with specific drawings.

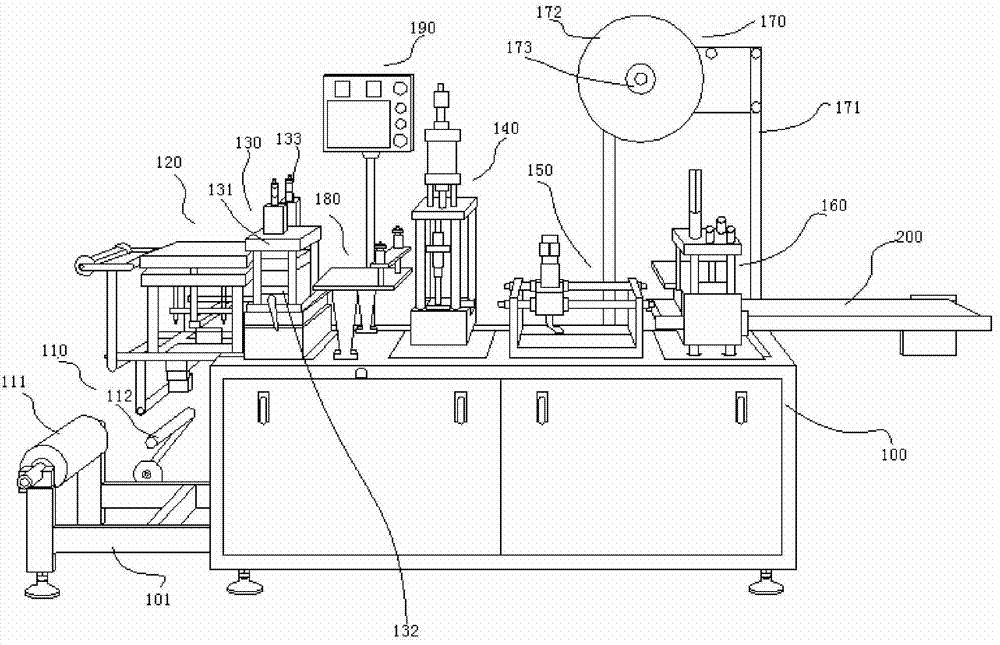

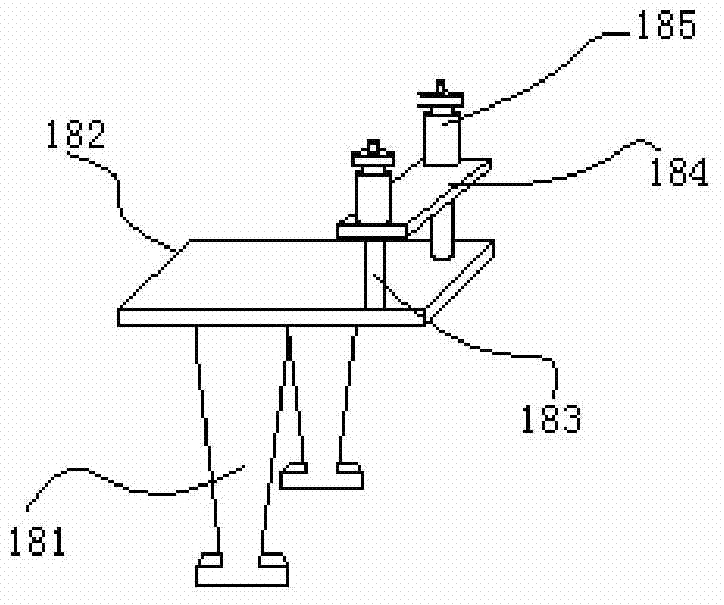

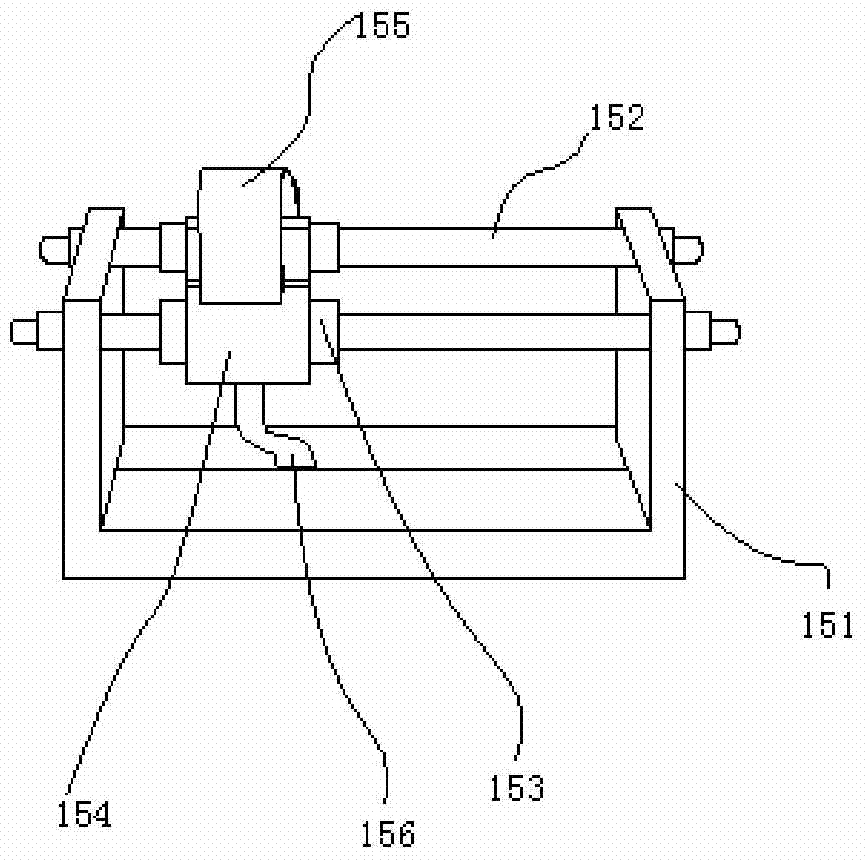

[0034] See figure 1 , The present invention provides a forming and punching device, which is used to produce milk tea cup lids, and includes a cabinet body 100. The cabinet body is sequentially provided with a first rolling device 110 and a heating device 120 from left to right. , The forming die 130, the punching device 140, the mechanical clamping device 150, the punching device 160 and the second roll shaking device 170.

[0035] The present invention forms a conveying mechanism through the mutual cooperation between the first roll shaking device 110 and the second roll shaking device 170, and the sheet on the first roll shaking device 100 passes through the heating device 120, the forming die 130, and the punching device in sequence. The devic...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com