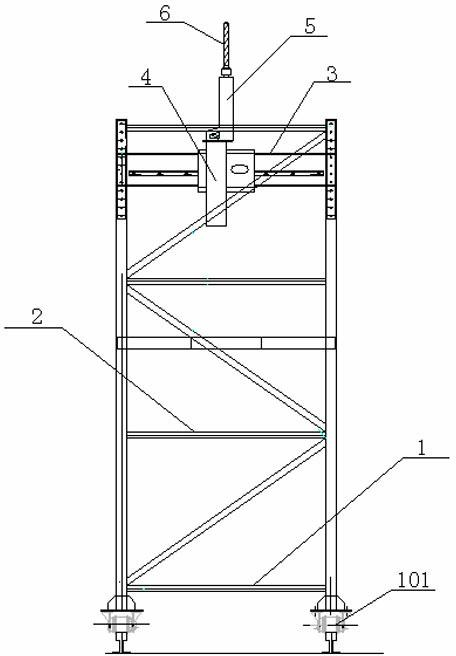

Tunnel drilling machine

A technology for punching machines and tunnels, which is applied to rotary drilling machines, drilling equipment and methods, and construction, etc., can solve the problems of difficult quality control, low work efficiency, and high labor intensity, and achieve high drilling accuracy and efficiency. , the effect of reducing labor intensity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

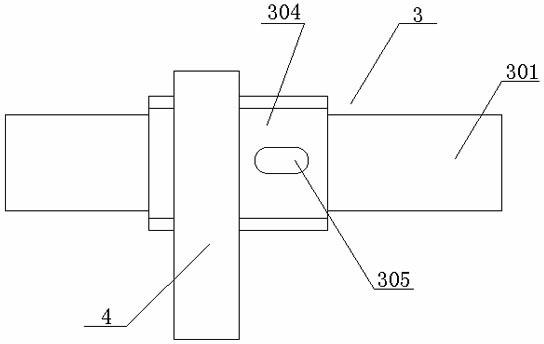

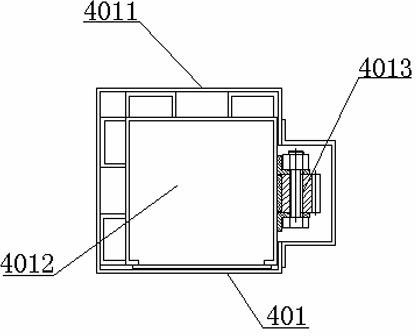

[0031] The tunnel drilling machine includes the following parts: the base part, which is composed of steel structure and steel wheels, implements the operation of the tunnel drilling machine on the track. At the same time, it supports the weight of the entire drilling machine; the frame part is made of high-strength aluminum alloy profiles to effectively reduce its own weight. It is easy to assemble and disassemble, and the entire impact height can be adjusted arbitrarily according to the actual use requirements; for the electric control part, the electric control adopts two control modes, continuous punching and inching punching. At the same time, it is equipped with a socket for lighting or other purposes during operation; the tunnel drilling machine is equipped with a vacuum device, which is installed near the drill bit. When drilling, the dust drilled by the drill bit can be effectively sucked by the vacuum device. absorb. It can effectively improve the working environmen...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com