Electron servo feed system

A feeding system and electronic technology, applied in feeding nozzles, glass manufacturing equipment, manufacturing tools, etc., can solve the problems affecting product quality and output, low product yield, poor control accuracy, etc., and achieve convenient and accurate operation. Punching, easy adjustment effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

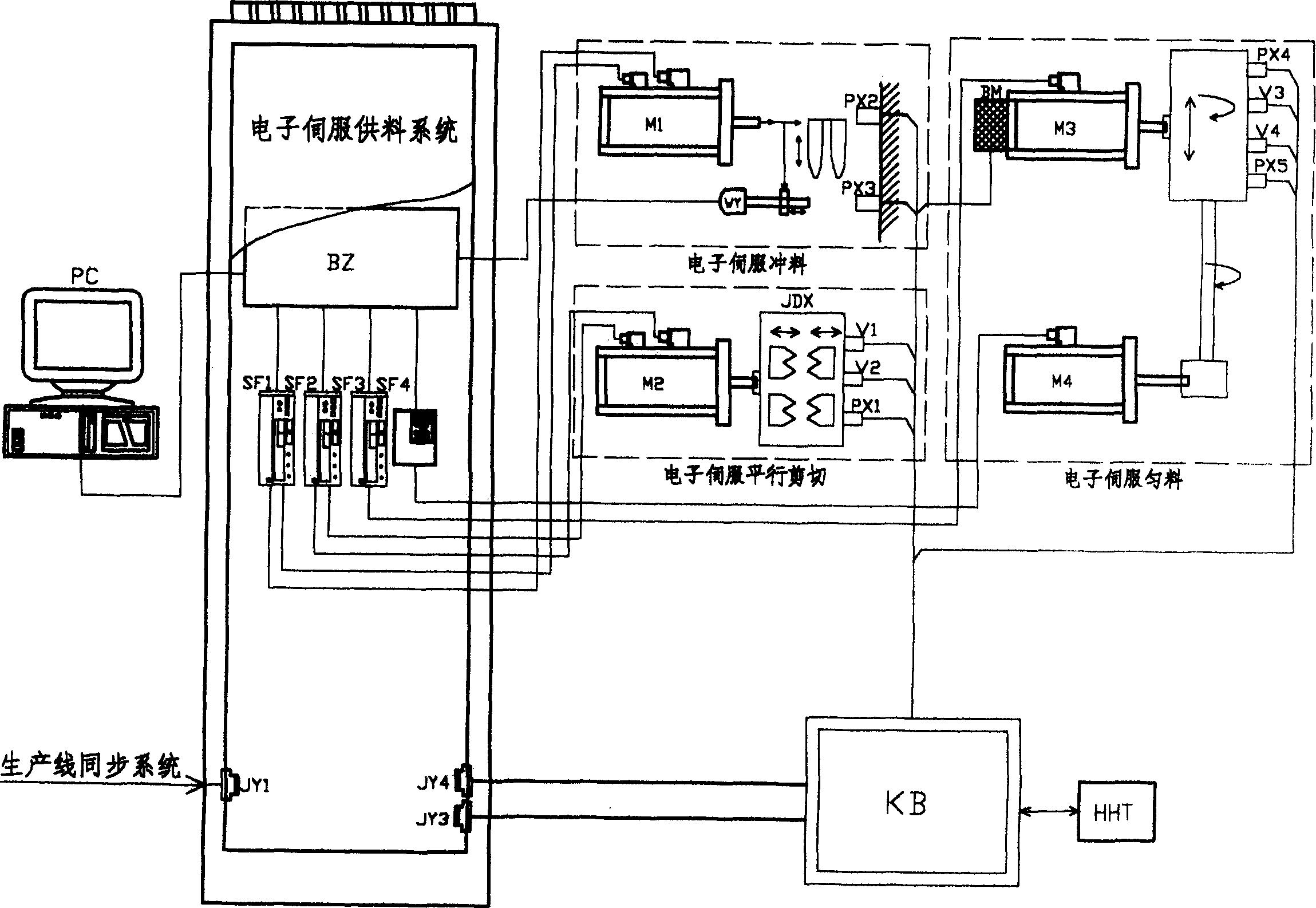

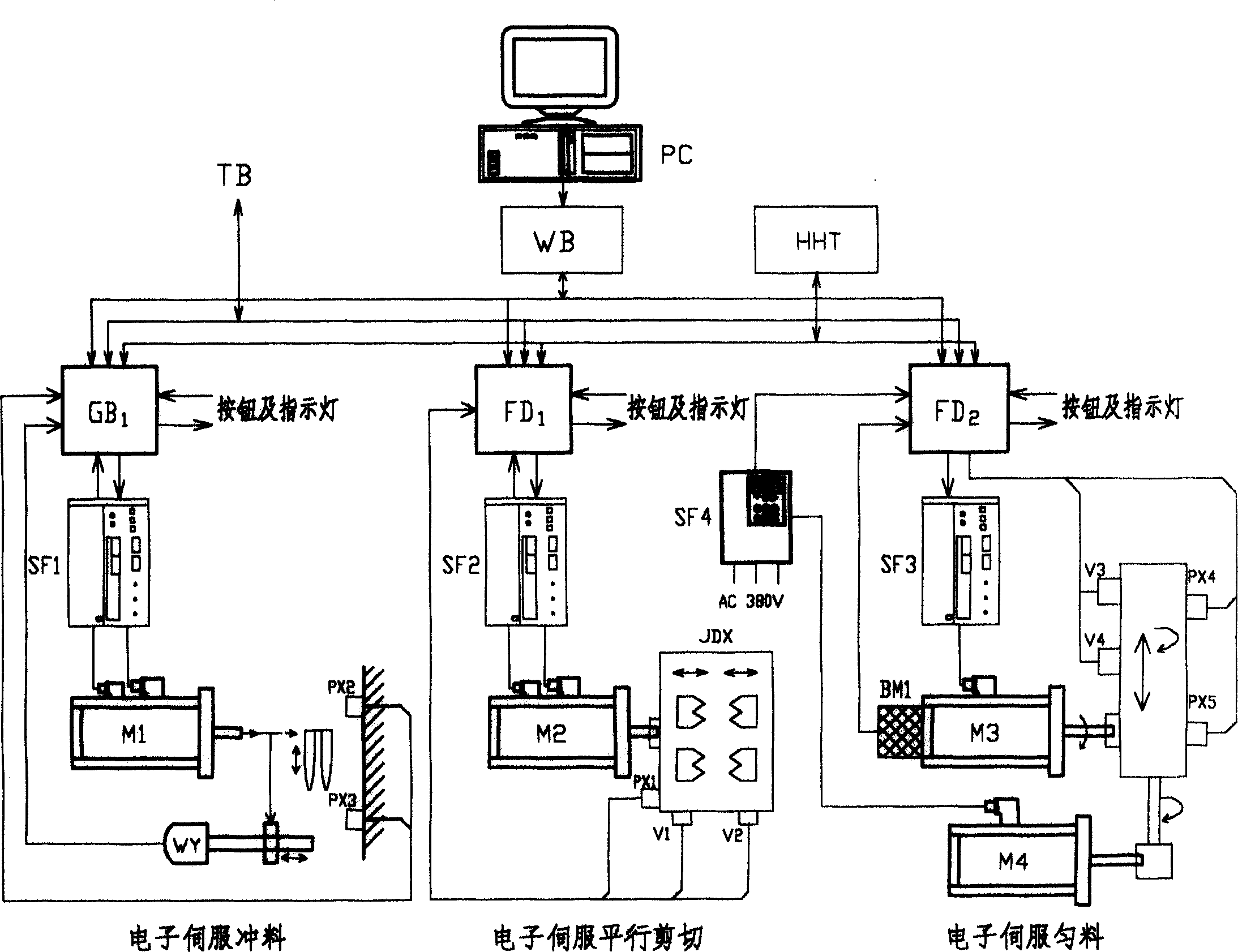

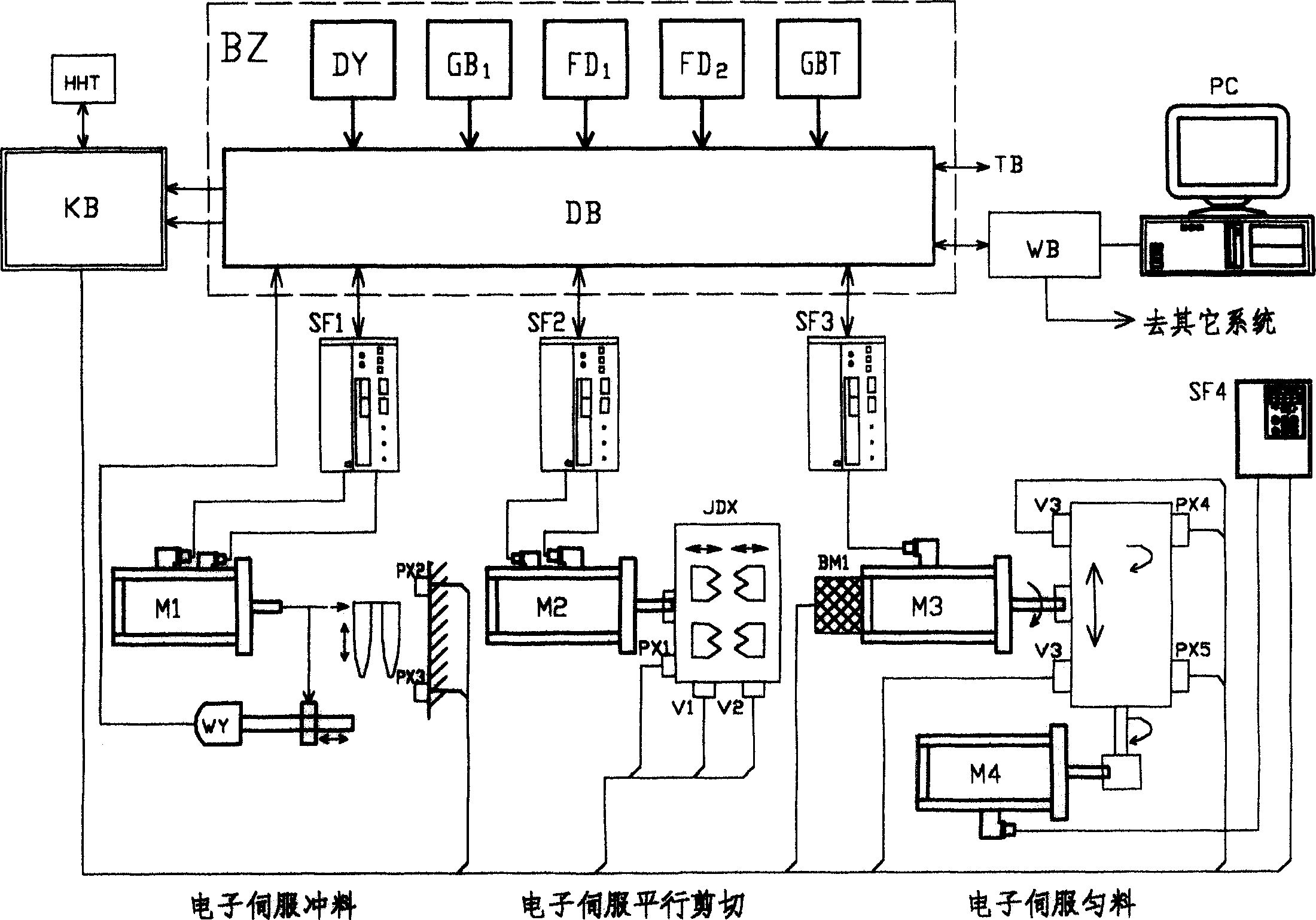

[0029] figure 1 Among them, the servo motor M1 driving the punch mechanism is connected to the punch microprocessor controller GB1 through the servo motor driver SF1 and the lower microprocessor controller unit BZ, the punch displacement sensor WY, the punch upper punch limit switch PX2, the punch The lower punch limit switch PX3 is installed on the punch device, and is connected with the microprocessor control unit GB1 of the punch mechanism through the microprocessor control unit BZ. Servo motor M1, under the control of punch mechanism microprocessor controller GB1 and servo driver SF1, drives the punch mechanism to perform punching operation according to the set electronic cam curve. If the punch exceeds the upper limit or At the lower limit position, the system first pulls the punch to the set position, alarms and stops.

[0030] The lower microprocessor controller GB1, the servo motor M1, the servo driver SF1, the punch mechanism and the displacement sensor WY driven by ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com