Drilling machine for furniture board material

A technology for sheet metal and furniture, applied in manufacturing tools, stationary drilling machines, wood processing appliances, etc., can solve problems such as affecting flatness, errors, and affecting workshop cleanliness, and achieves improved drilling results, improved accuracy, and protected cleanliness. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

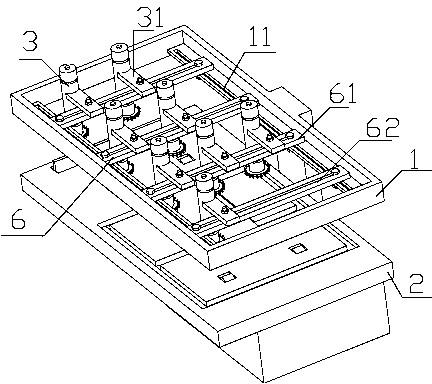

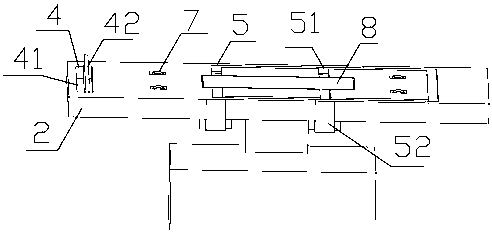

[0030] Example 1, such as figure 1 figure 2 and image 3 Shown: a drilling machine for furniture boards, including a drilling device 3, the drilling machine for furniture boards includes a lower machine 2 for holding the boards, located in parallel above the lower machine 2 and connected to the drill The upper machine 1 of the hole device 3, the sliding device 6 for connecting the drilling device 3 so that the drilling device 3 moves along the X axis and the Y axis on the plane of the upper machine 1 and the lower machine 2 for cleaning The removal device 5 of sheet scrap.

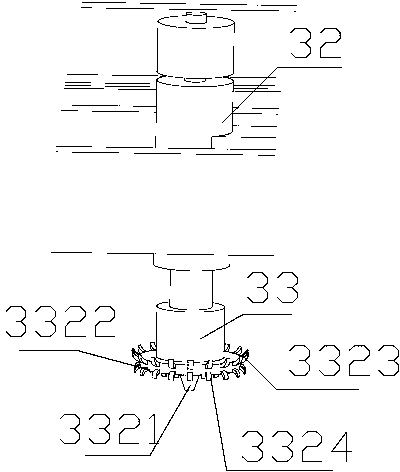

[0031] The upper machine platform includes a chute 11; the sliding device 6 includes a plurality of sleds 61 perpendicular to the chute 11 and can slide parallel to each other on the chute 11. The second chute 62; the drilling device 3 includes a fixed plate 31 that can slide on the second chute 62 and can be fixed on the second chute 62, is connected with the fixed plate 31 and can expand and contract...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com