Boiler with annular upper furnace body deashing chamber

A furnace body and ash cleaning technology, which is applied in the boiler field, can solve the problems of waste of resources, long time, delay in heating, etc., and achieve the effects of safe and reliable use, extended service life, and extended service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

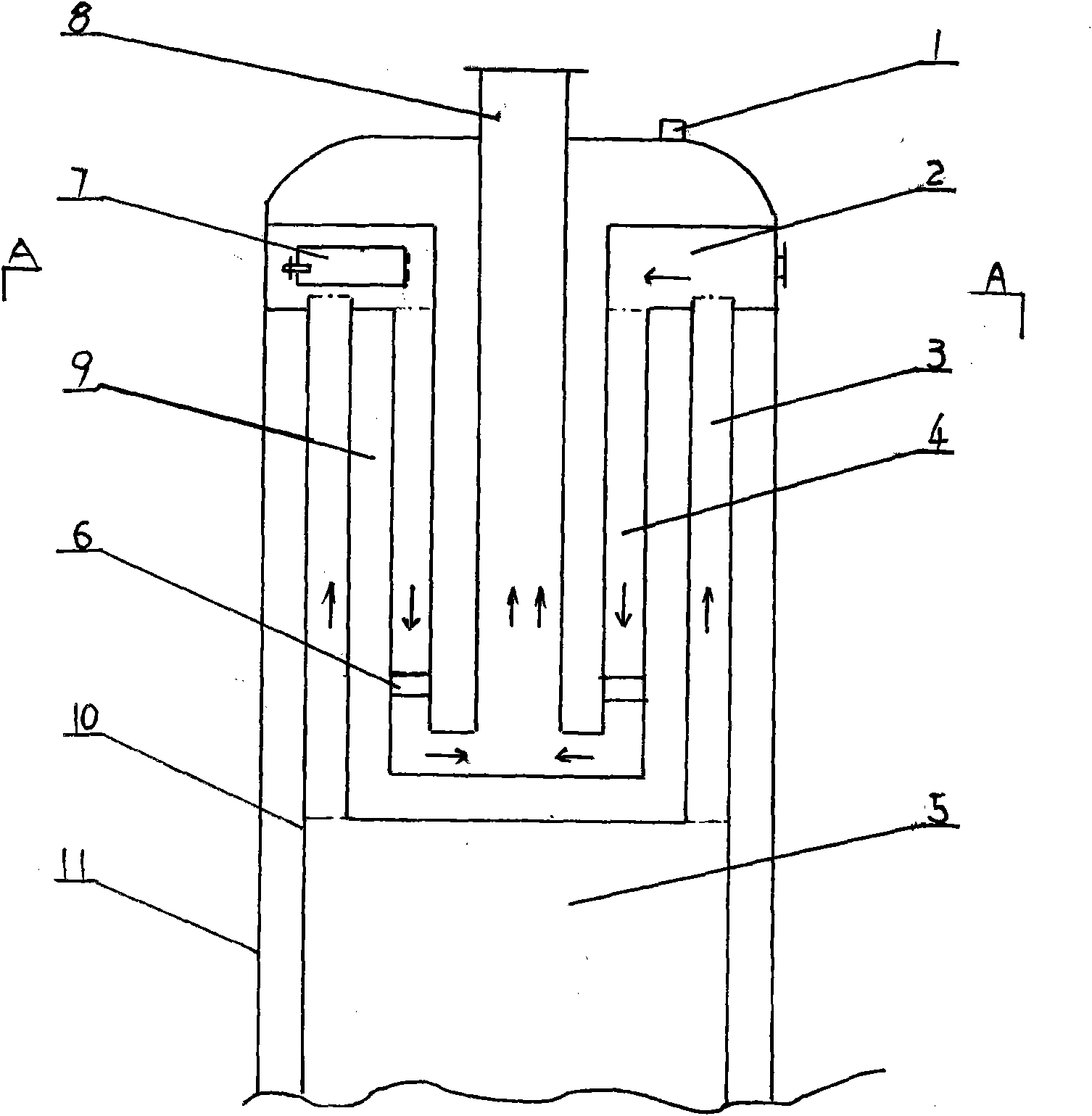

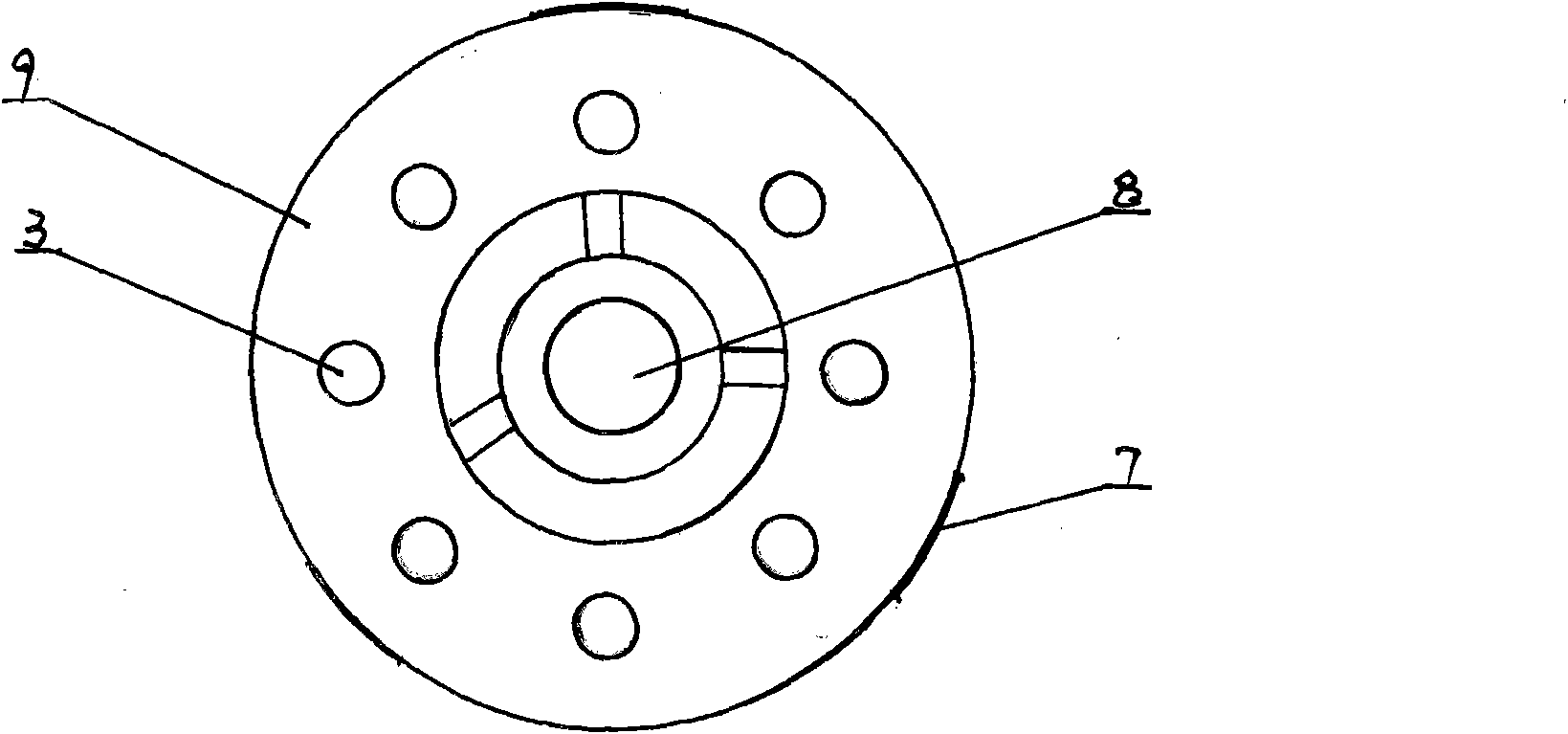

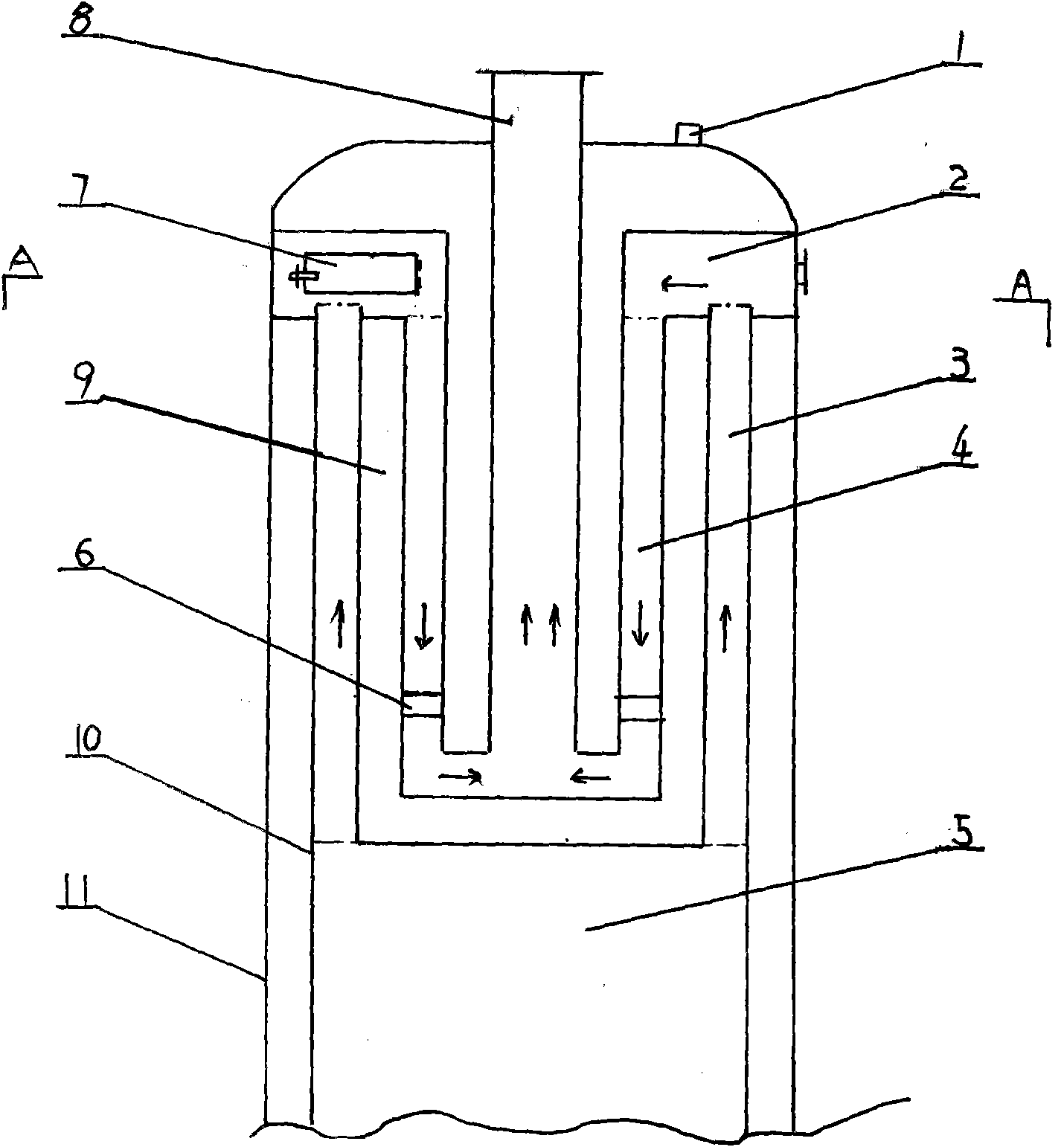

[0008] Such as Figure 1 to Figure 2 As shown, since the design of the present invention is mainly at the intersection of the upper and lower flue passages on the top of the furnace body, the rest of the furnace body is omitted. The water outlet 1, the ascending flue 3, the descending flue 4, the water liner 9, the furnace body 11, the furnace 5, the water pipe 6, the flue pipe 8 and the water liner layer 10 of the present invention are traditional reciprocating flue type boiler structures , so it will not be described in detail.

[0009] The present invention is composed of a furnace body, a furnace and a water outlet. An annular upper furnace body ash cleaning chamber 2 is arranged in the water bladder at the upper end of the furnace body. The flue is usually a fire pipe. The upper end of the descending flue communicates with the ring-shaped upper furnace body cleaning chamber, and the descending flue is usually an annular body descending flue. At least one soot-cleaning ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com