High-efficient punching equipment for producing chairs

A kind of drilling equipment and high-efficiency technology, which can be used in stationary drilling machines, wood processing appliances, bark areas/debris/dust/waste removal, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments.

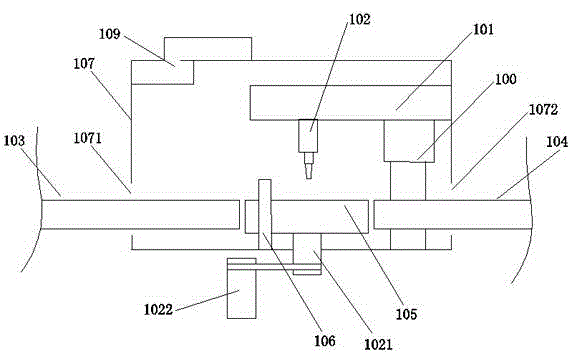

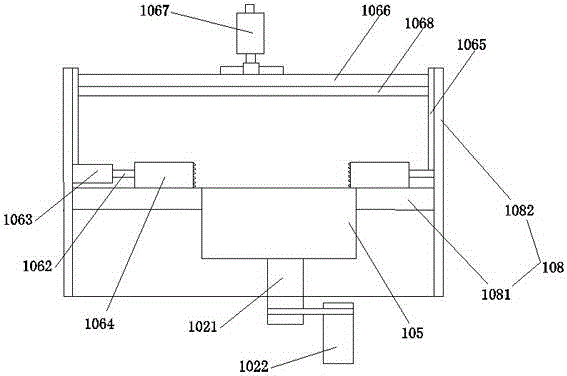

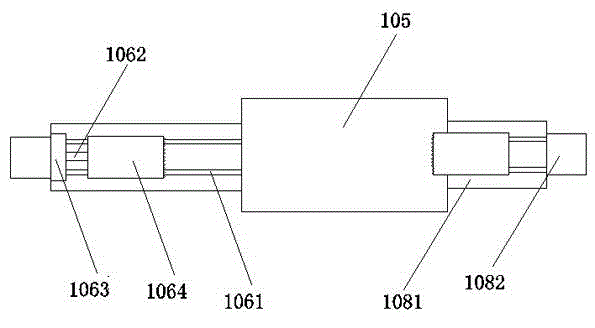

[0022] Efficient punching equipment for the production of chairs, as attached figure 1 As shown, it includes a frame 101 and a punching device 102 arranged on the frame 101, a hydraulic lifting device 100 for driving the frame 101 up and down, and an input rail 103 and an output rail 104 arranged below the punching device 102, A punching table 105 is arranged between the input track 103 and the output track 104. The punching table 105 is located directly below the punching device 102, and a rotating shaft 1021 and Drive motor 1022, for different punching positions, when needing to be punched object carries out the placement of different angles, can drive punching table 102 to rotate by drive motor 1022, meets requirement; The cover 107 is provided with the front passing hole 1071 for the input rail 103 and the rear passing hole 1072 for the ou...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com