Wood block drilling machine for wooden toy

A technology of drilling machine and drilling mechanism, which is applied in the direction of fixed drilling machine, etc., which can solve the problems of troublesome operation and low drilling efficiency, and achieve the effect of stable and fast drilling

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

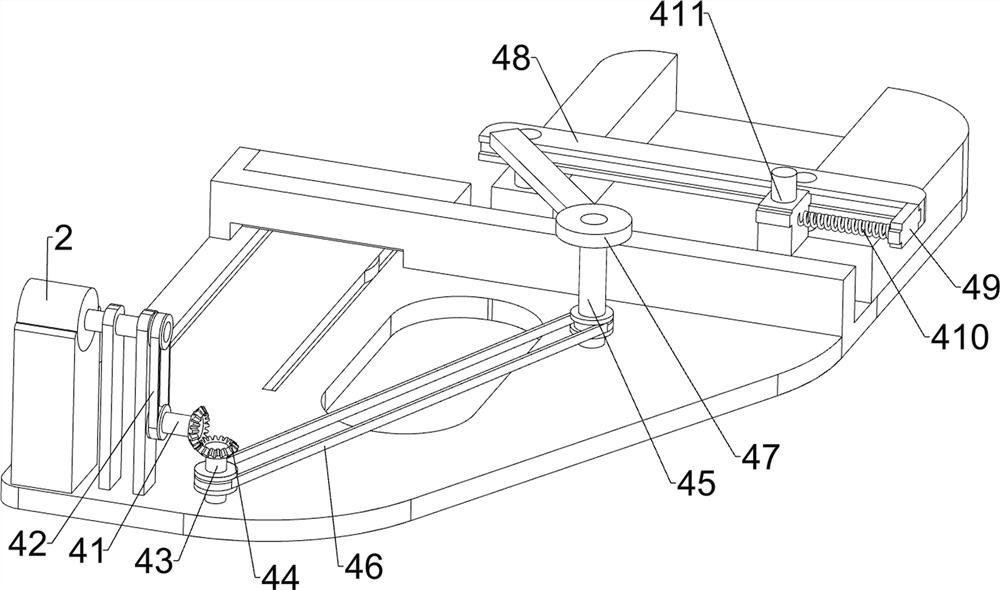

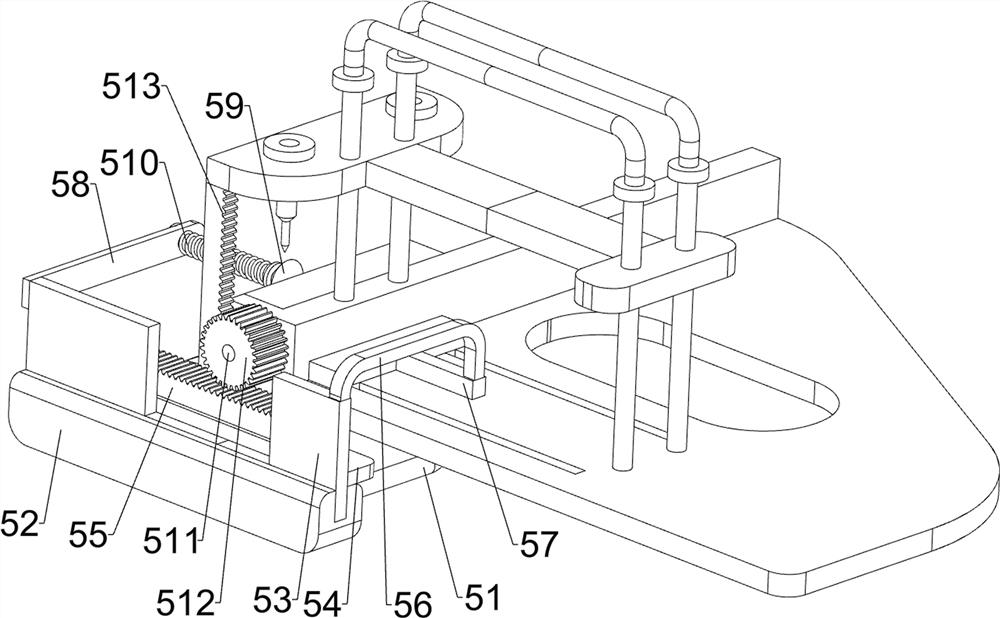

[0023] A block drilling machine for wooden play such as Figure 1-5 As shown, it includes a workbench 1, a motor 2, a drilling mechanism 3, a feeding mechanism 4 and a pressing and unloading mechanism 5. The motor 2 is installed on the left front side of the top of the workbench 1, and the workbench 1 is provided with a drilling mechanism 3. , The workbench 1 is provided with a feeding mechanism 4, and the workbench 1 is provided with a pressing and unloading mechanism 5.

[0024] When people need to use this machine, people first place the wooden block on the workbench 1, and then they can start the motor 2 and the drilling mechanism 3, so that the motor 2 drives the drilling mechanism 3 to operate, and at the same time the drilling mechanism 3 drives the upper The material mechanism 4 and the pressing and returning mechanism 5 operate, and the operation of the feeding mechanism 4 drives the wooden block to move to the right, so that the wooden block moves to the bottom of th...

Embodiment 2

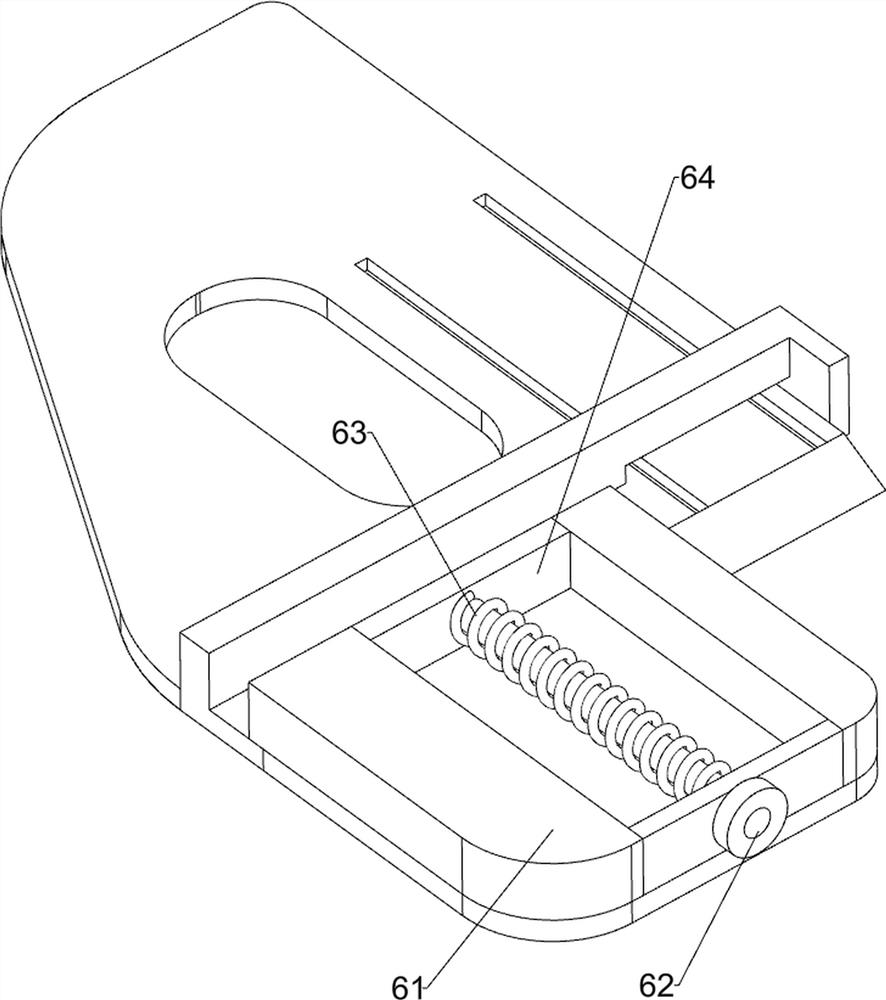

[0032] On the basis of Example 1, such as Figure 6 Shown, also comprise feeding mechanism 6, feeding mechanism 6 limit block 61, the second push rod 62, the 5th spring 63 and the second push block 64, workbench 1 top right rear side is provided with limit block 61, limit The bit block 61 is connected with the first guide plate 48 on the rear side. The rear side of the workbench 1 is provided with a second push rod 62 in a sliding manner. The second push rod 62 is covered with a fifth spring 63. The front end of the second push rod 62 A second push block 64 is provided, the fifth spring 63 is connected with the second push block 64 and the workbench 1 , and the second push block 64 slides between the limit block 61 and the workbench 1 .

[0033] First people pull the second push rod 62 backward, the second push rod 62 drives the second push block 64 to move backward, the fifth spring 63 is compressed, and then the wooden block can be placed on the workbench 1 and the stop bloc...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com