Stone cutting machine

A cutting machine, stone technology, applied in the direction of stone processing tools, stone processing equipment, work accessories, etc., can solve the problems of insufficient lightweight, heavy weight, and difficult to move.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

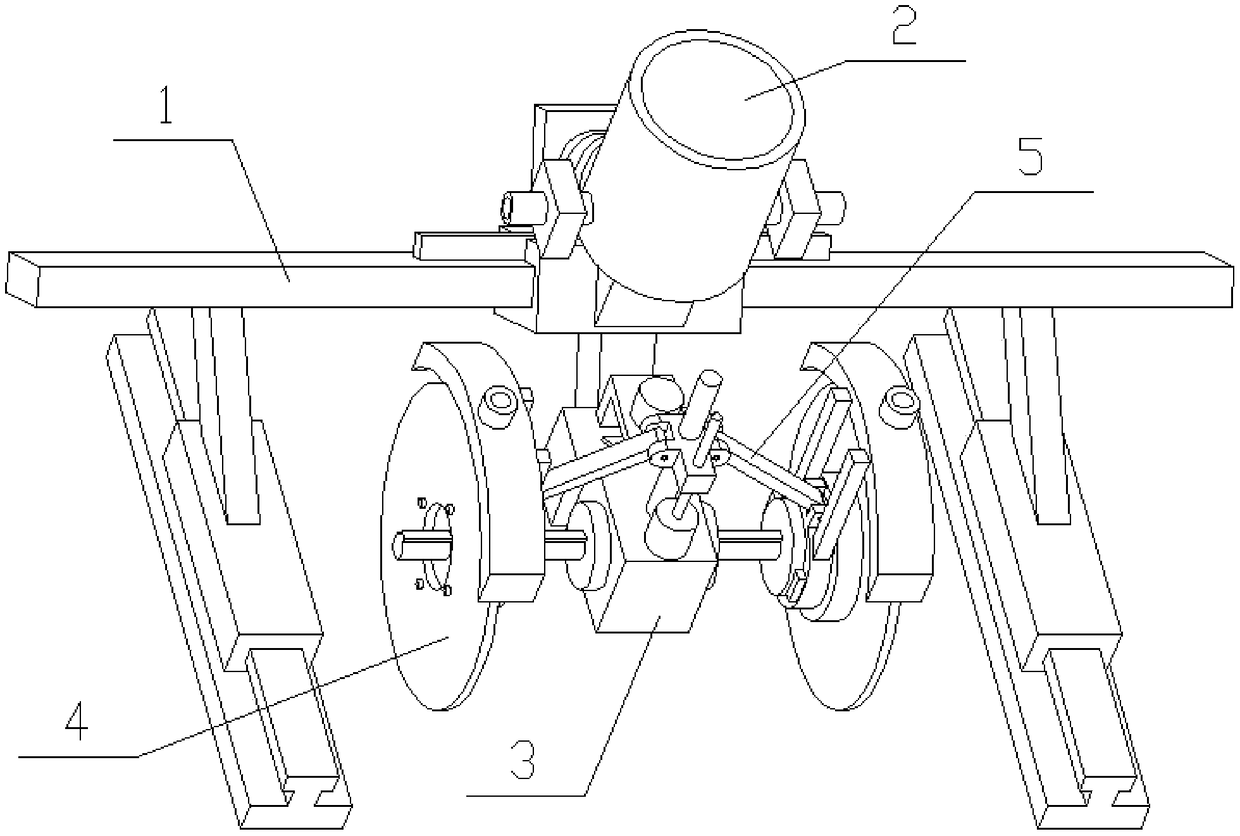

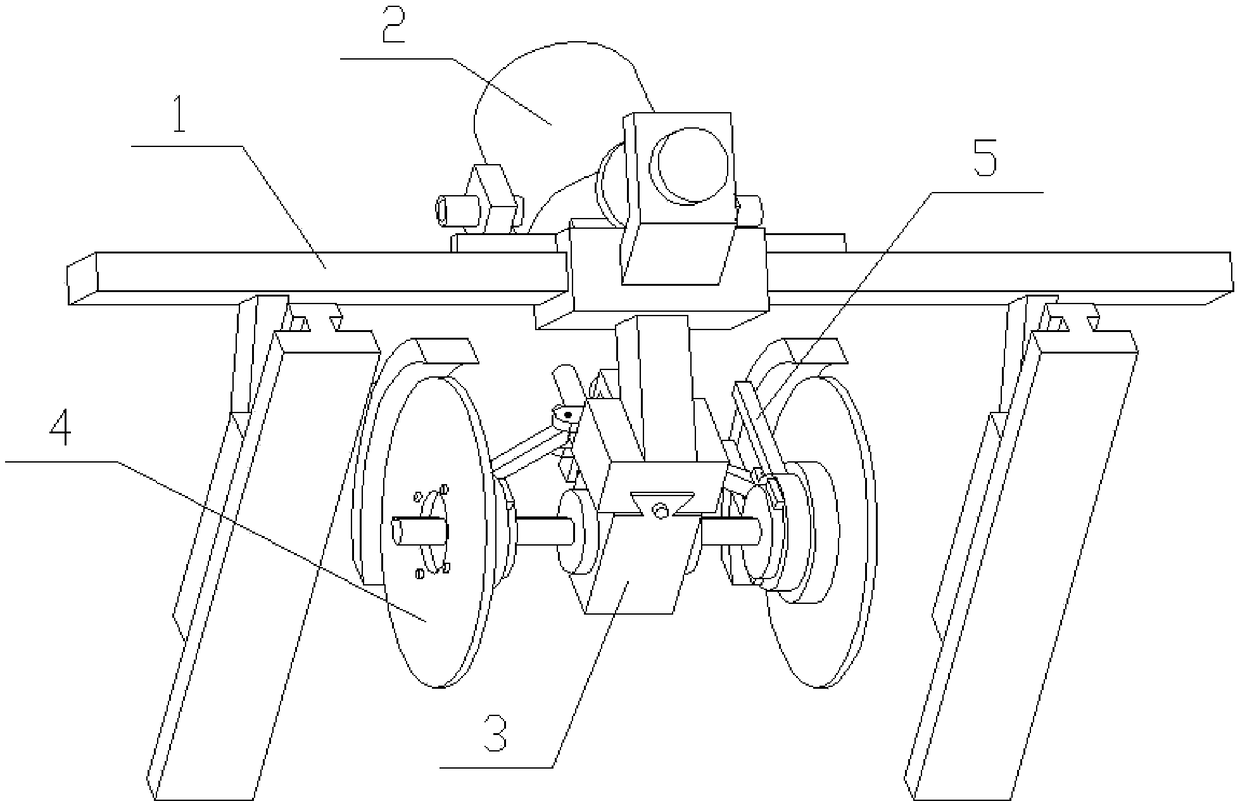

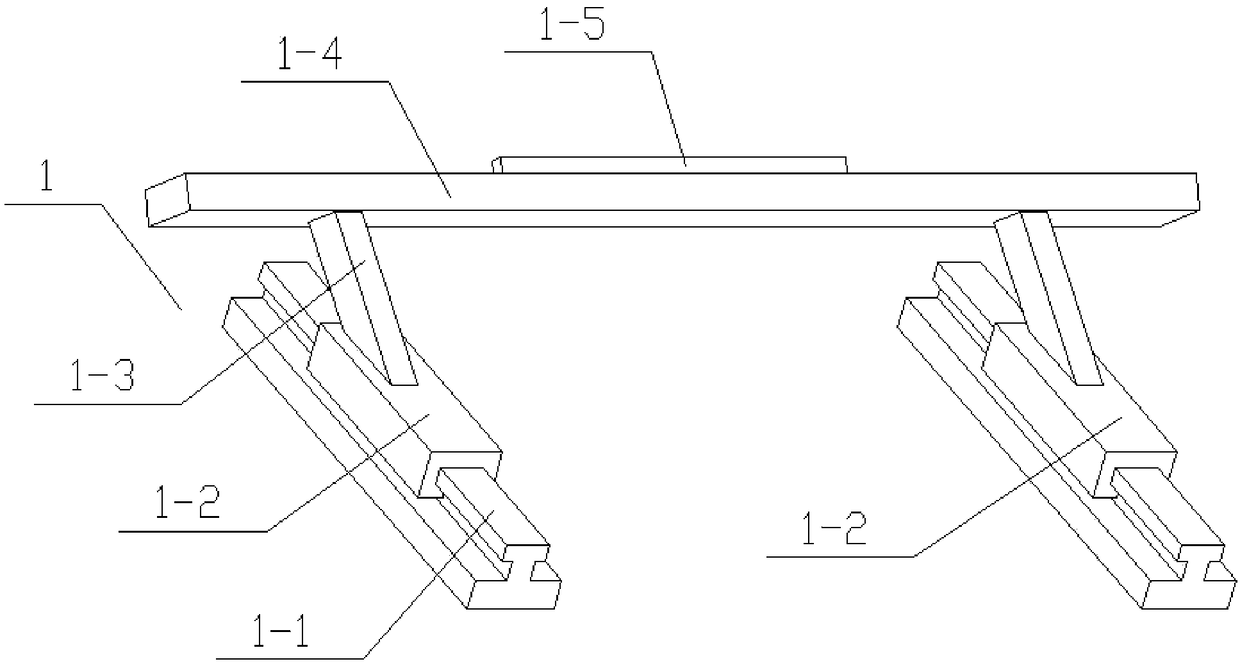

[0025] Combine below Figure 1-10 Describe this embodiment, the present invention relates to the field of stone processing, more specifically a stone cutting machine, including a sliding frame 1, a sliding seat 2, a middle seat 3, a cutting piece 4 and a distance adjustment mechanism 5, the present invention can once Two cuts are cut out of the stone, and the distance between the two circular saws 4-6 can be adjusted; the height of the two circular saws 4-6 can also be adjusted to facilitate the cutting of stones with different thicknesses; the two circular saws The left and right positions of 4-6 can also be adjusted, which is convenient for the user to adjust the positions of the two circular saws 4-6 according to the needs, so as to avoid moving heavy stones to cut different positions of the stones.

[0026] The sliding seat 2 is slidably connected to the upper end of the sliding frame 1, the sliding seat 2 and the sliding frame 1 are meshed for transmission, the middle sea...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com