Bridge type stone cutter with polishing function

A stone cutting machine, grinding and polishing technology, applied in grinding/polishing equipment, grinding machines, manufacturing tools, etc., can solve the problem of not having the ability to grind and polish stone, and it is urgent to improve processing efficiency, save labor costs, and reduce moving procedures. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

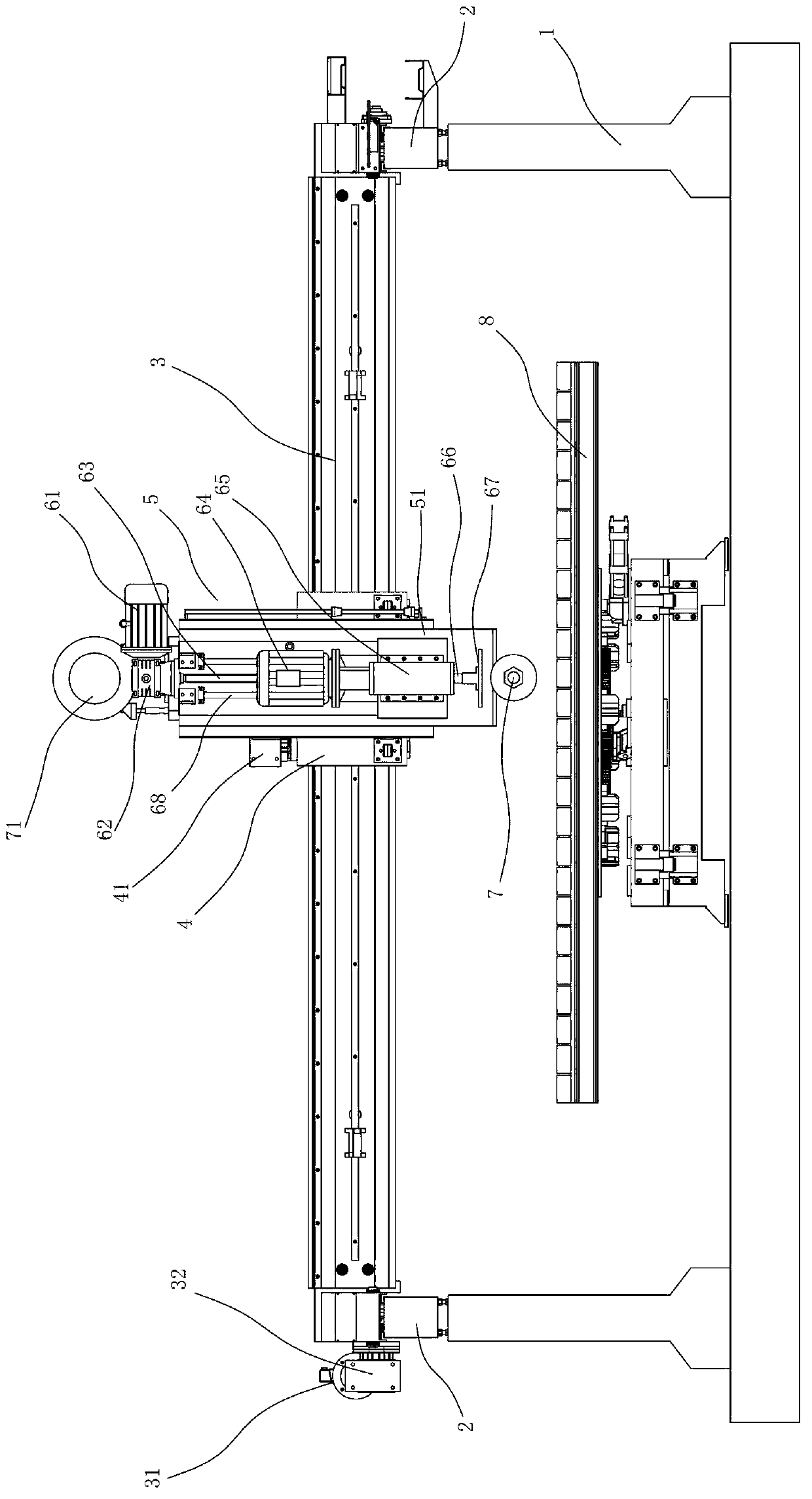

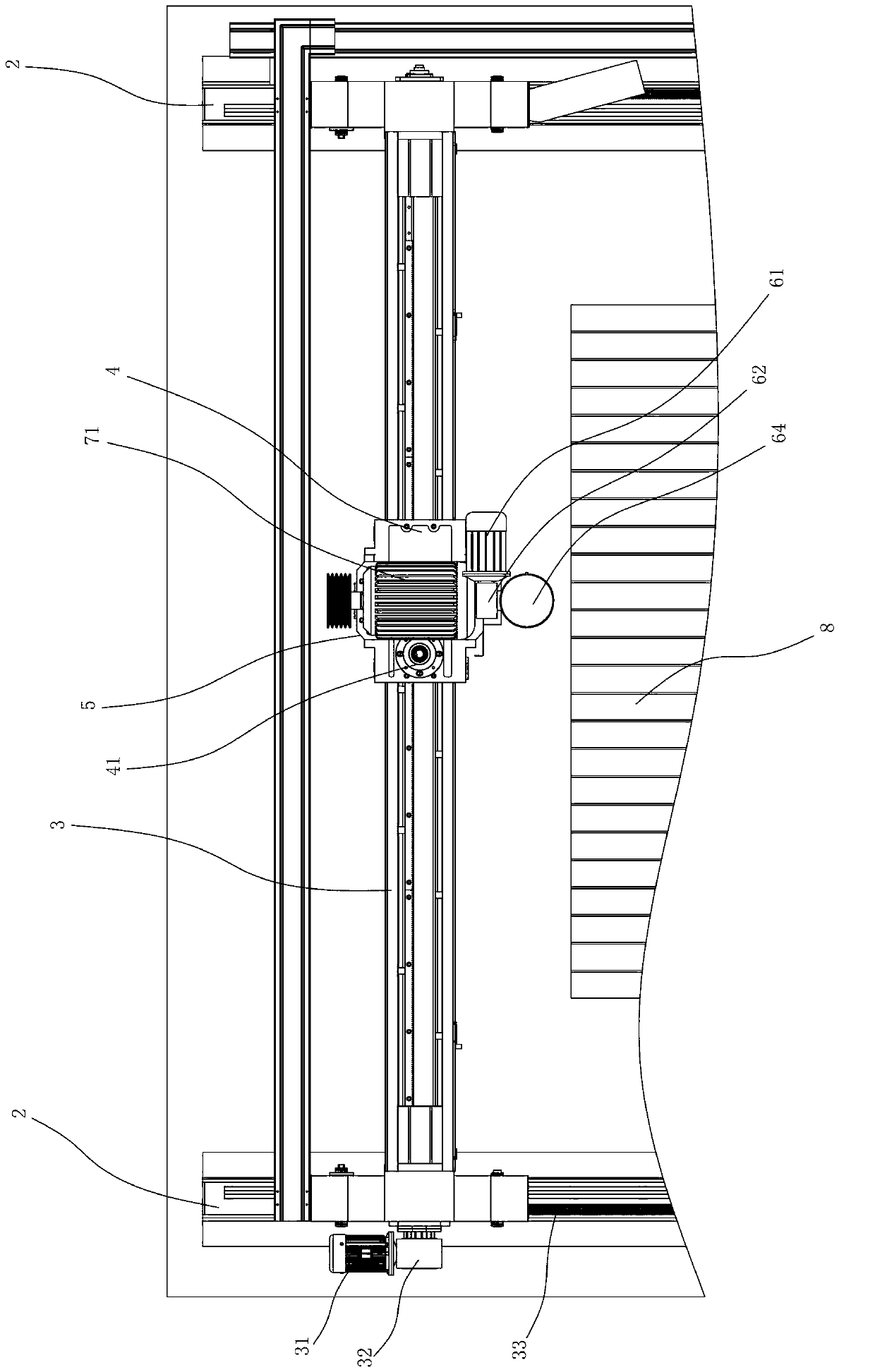

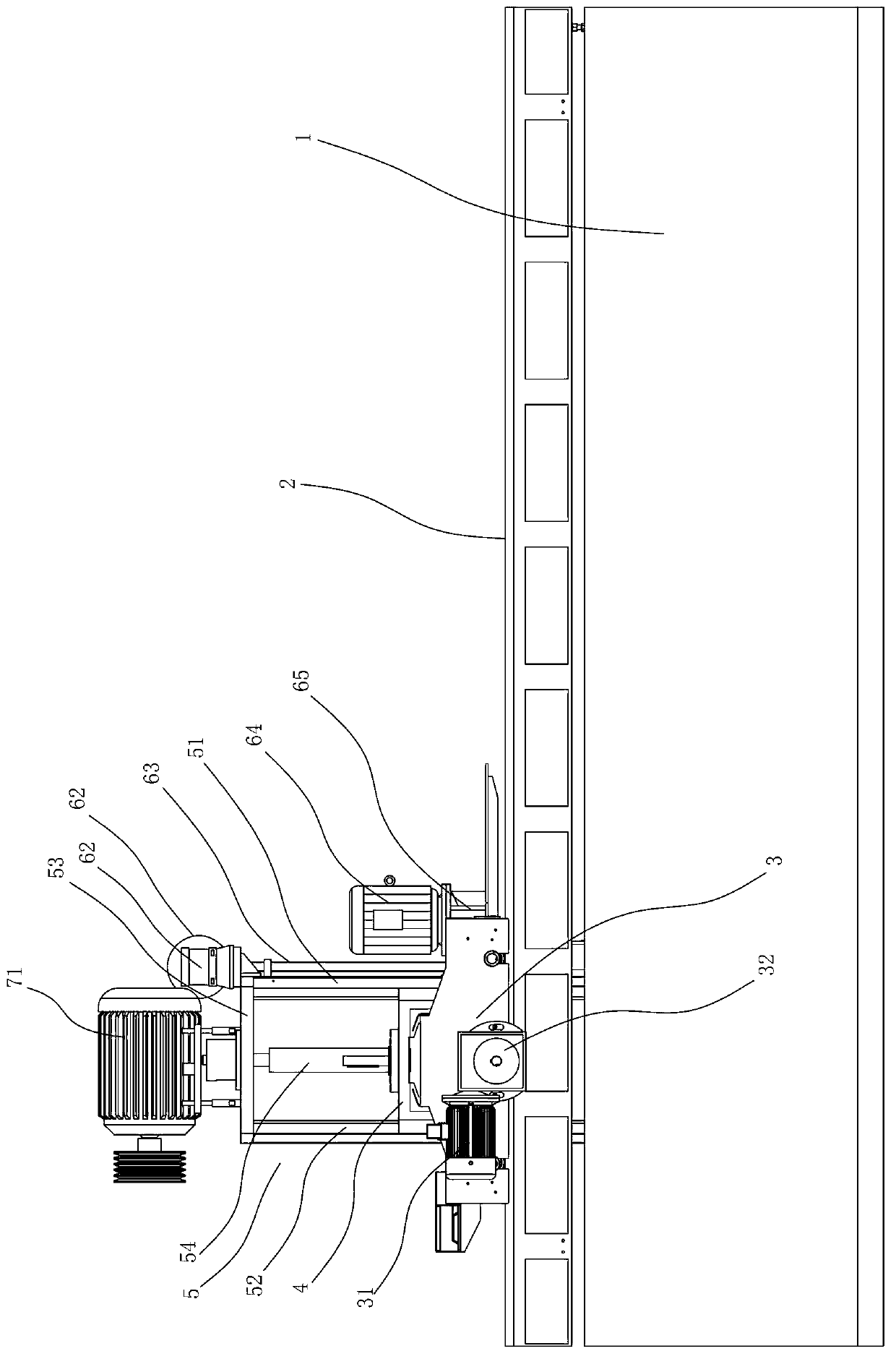

[0016] refer to figure 1 , figure 2 and image 3 As shown, a bridge-type stone cutter with grinding and polishing functions includes a cement foundation 1, two longitudinal beams 2 arranged on the cement foundation 1 at intervals in the transverse direction, a crossbeam 3 erected between the two longitudinal beams 2, and a laterally movable ground The moving base 4 arranged on the beam 3, the elevating frame 5 arranged on the moving base 4 that can be moved up and down, the workbench 8, the cutting device arranged on the elevating frame 5, the The longitudinal movement mechanism, the transverse movement mechanism 41 arranged between the moving base 4 and the crossbeam 3, the lifting movement mechanism arranged between the lifting frame 5 and the moving base 4, the grinding and polishing device arranged on the lifting frame 4 and respectively Control devices connected with various mechanisms and devices.

[0017] The lifting movement mechanism is an oil cylinder 54 vertical...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com