Patents

Literature

52results about How to "With cutting function" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

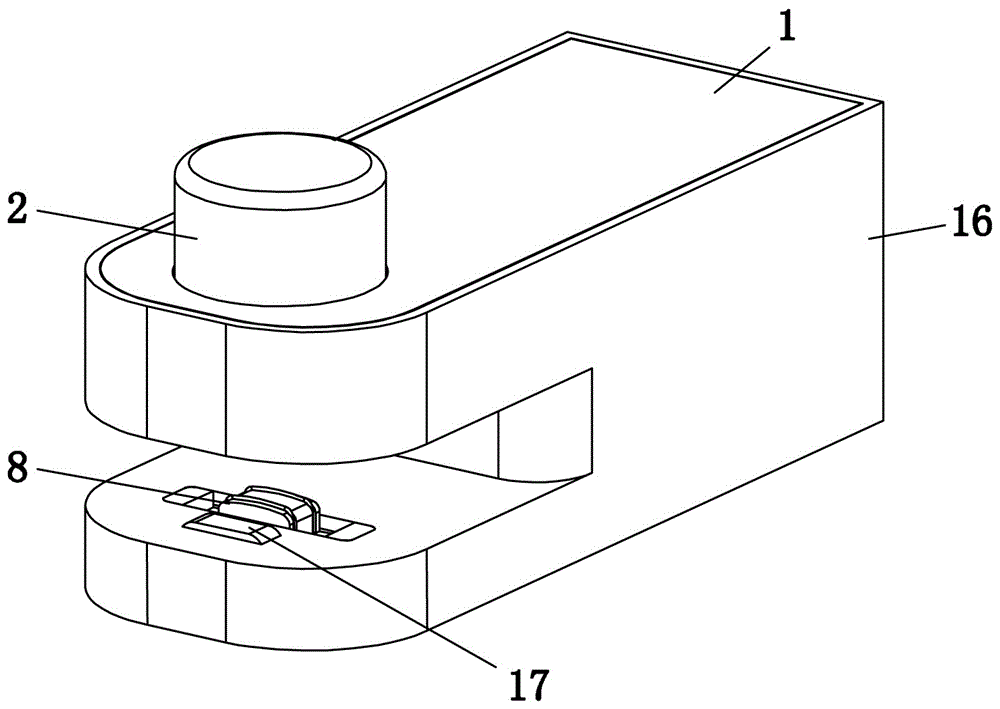

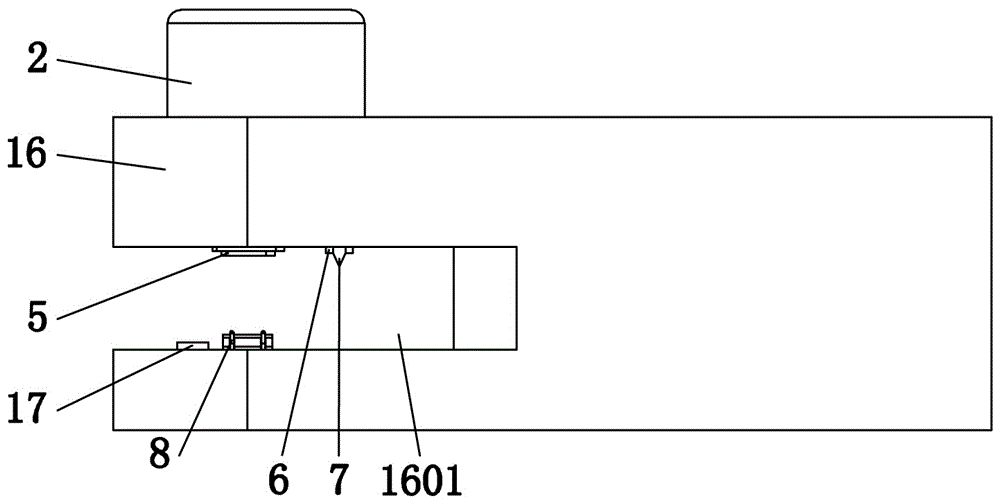

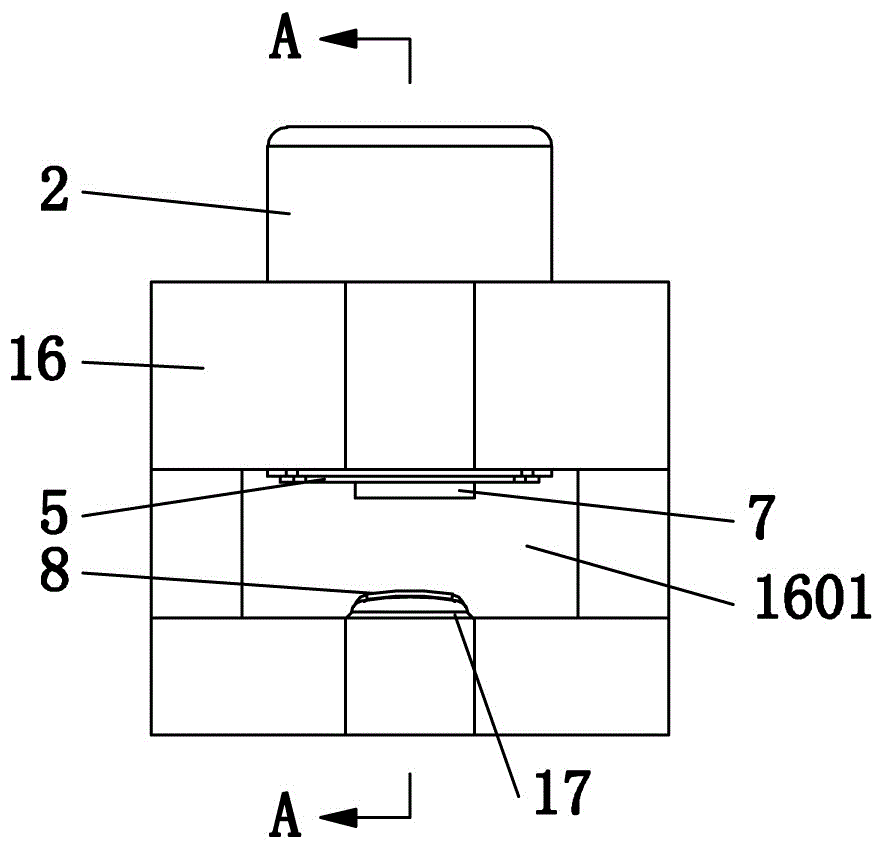

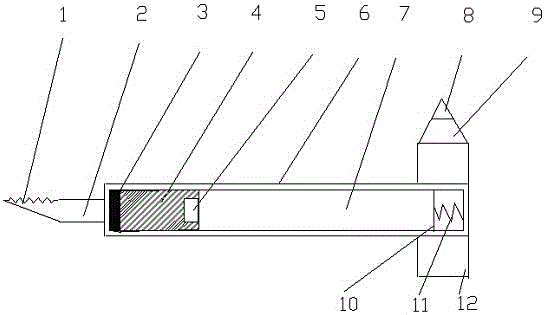

Handheld sealing machine capable of preventing wrong heating

PendingCN106628405ASimple structureImprove assembly efficiencyWrapper twisting/gatheringElectric heatingElectricity

The invention relates to a handheld sealing machine capable of preventing wrong heating. The machine comprises a shell, an electric heating module, a pressure contact module and a power supply module; an opening groove is formed in the shell; the electric heating module and the pressure contact module are respectively arranged on two sides of the opening groove; the power supply module is arranged in the shell, and is electrically connected with the electric heating module through a switch mechanism; the pressure contact module is arranged in an elastic return motion manner corresponding to the direction of the electric heating module; the pressure contact module is provided with a touch head for touching the switch mechanism; the pressure contact module and the shell are movably and adjustably matched; and through adjusting relative positions of the pressure contact module and the shell, the alignment of the touch head to the switch mechanism or the staggering of the touch head from the switch mechanism is realized. As the pressure contact module is movably arranged, the sealing and adjusting functions are finished; through adjusting relative positions of the pressure contact module and the shell, the touch head can be aligned to or staggered from the switch mechanism; during aligning, a normal working state is achieved; and during staggering, a non-working state is achieved, so that the human body injury caused by wrong operation heating is effectively prevented.

Owner:广东顺德可可麦科技产业孵化有限公司

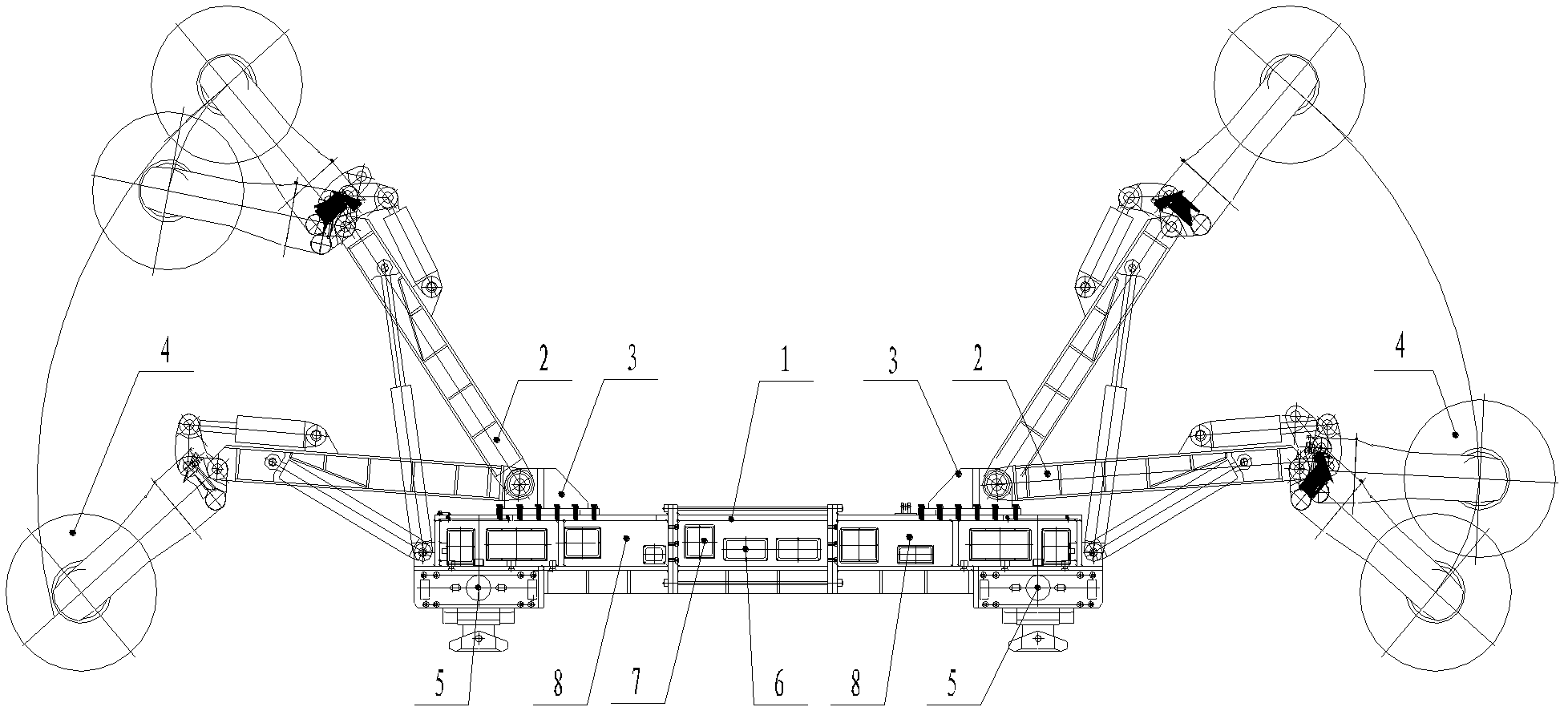

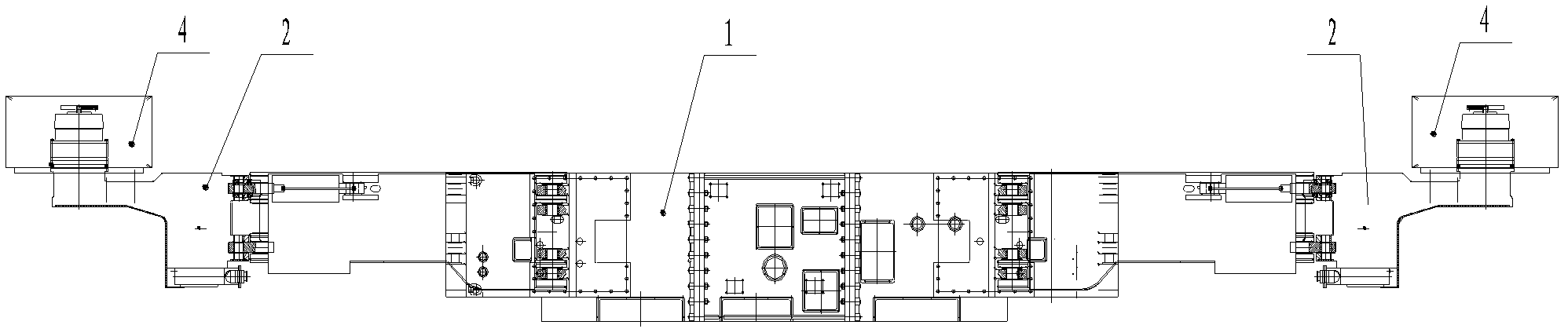

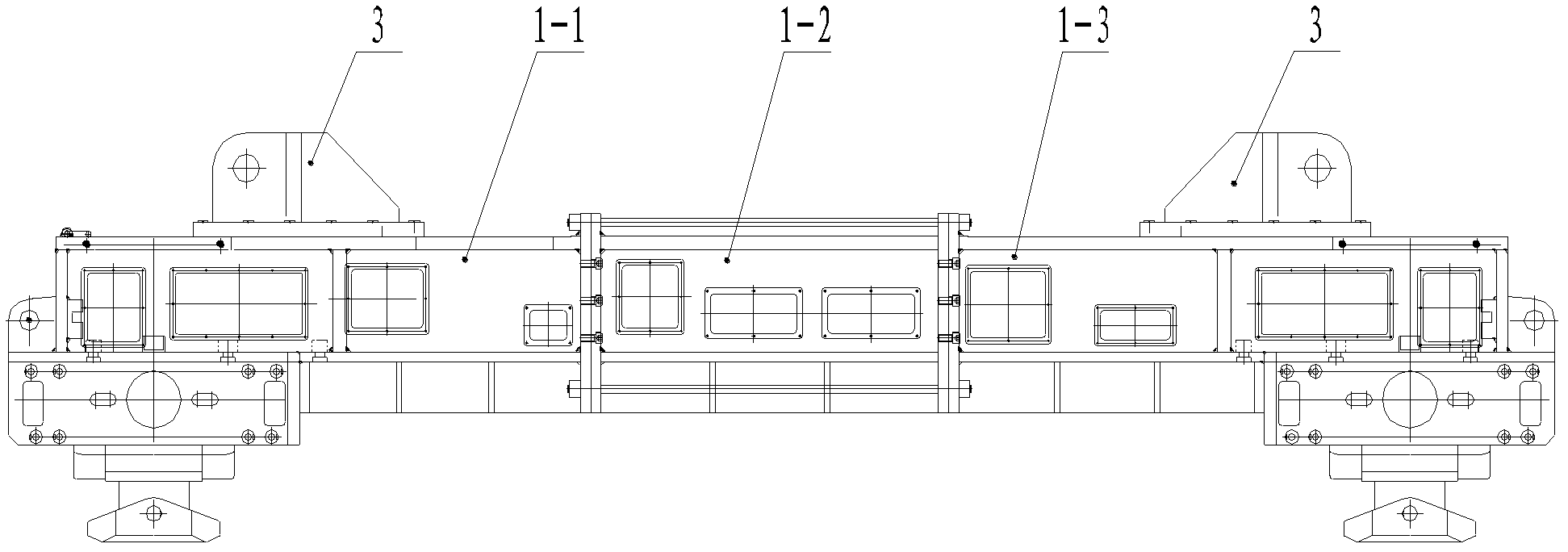

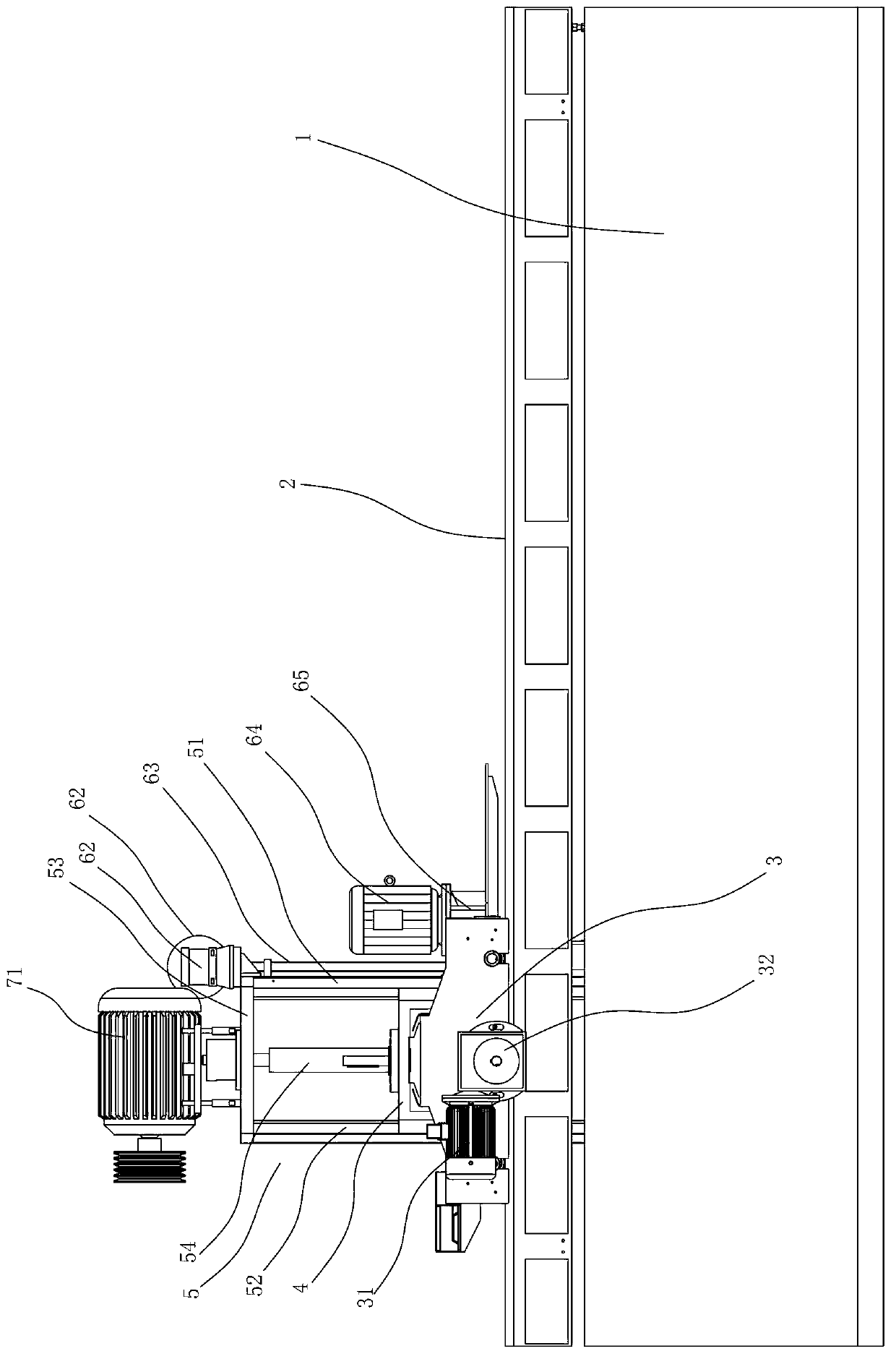

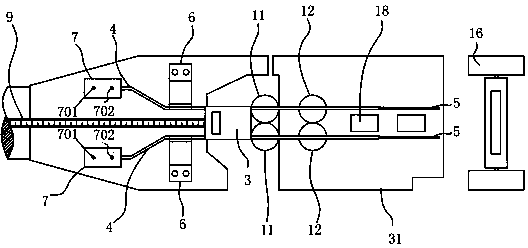

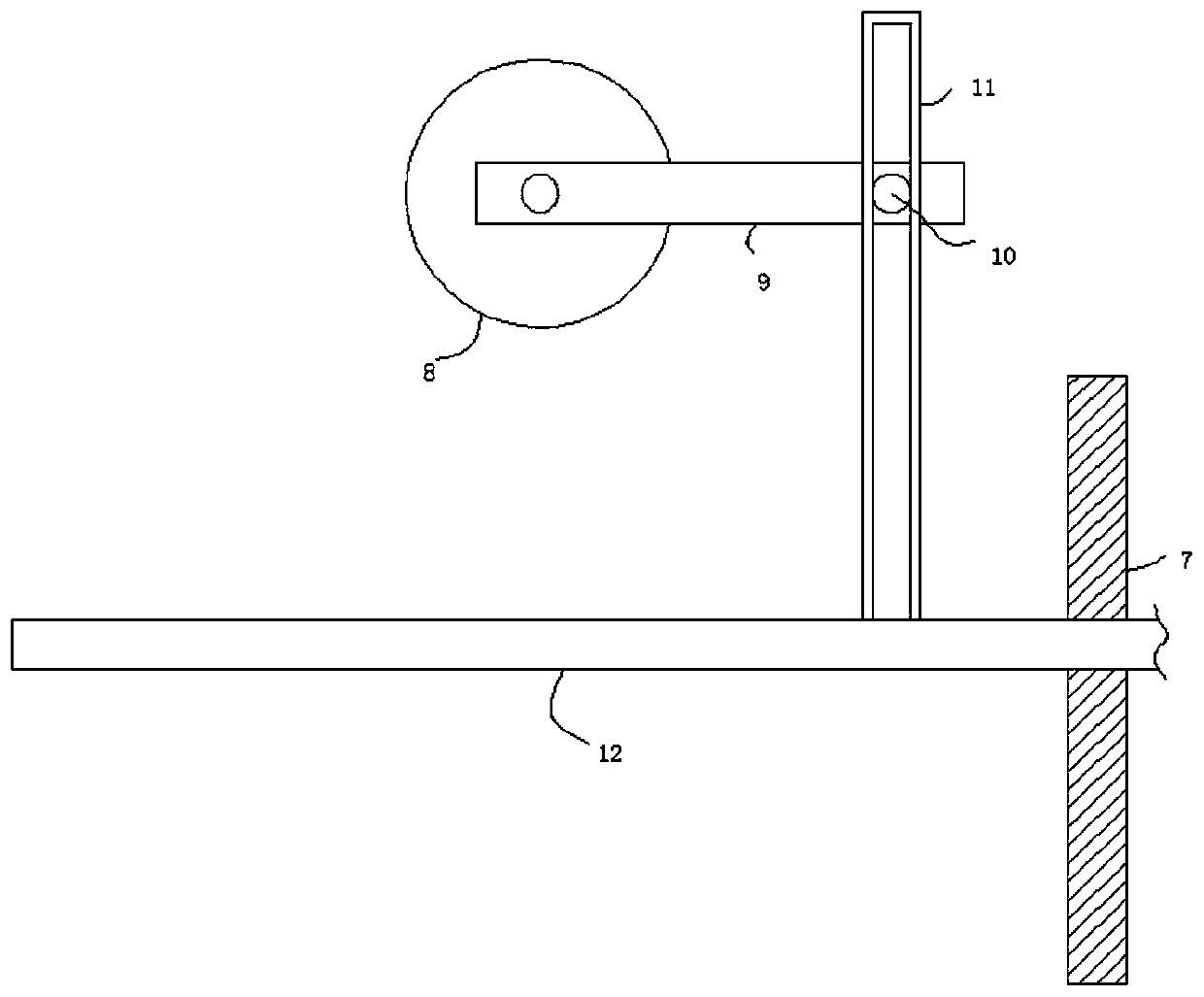

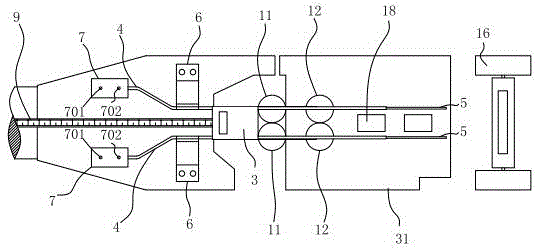

Combined height-adjustable coal cutting machine with small roller and large mining height, as well as coal cutting process of combined height-adjustable coal cutting machine

InactiveCN102536233AReduce energy consumptionReduce cutting resistanceUnderground miningSurface miningElectrical controlCoal

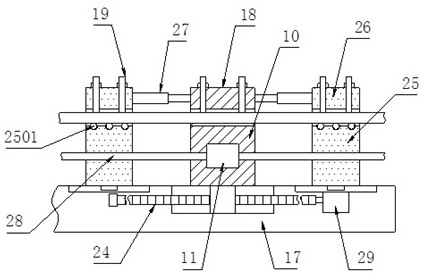

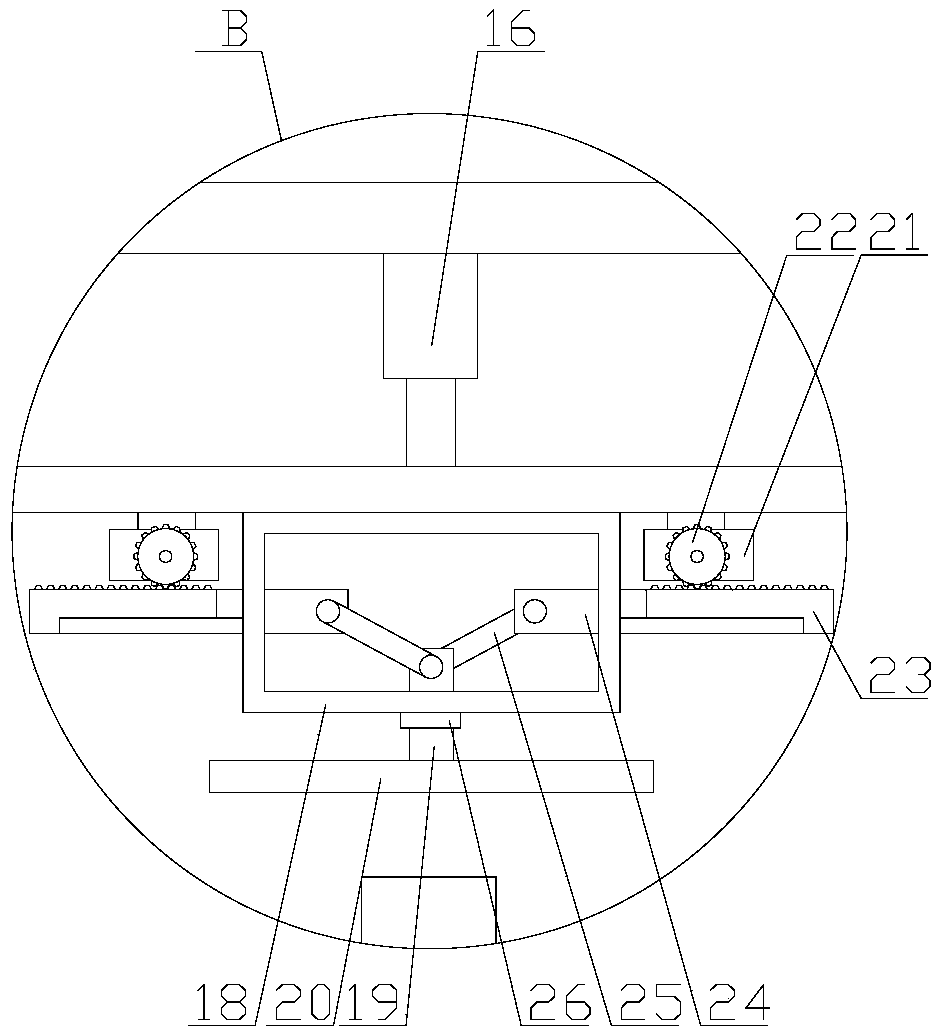

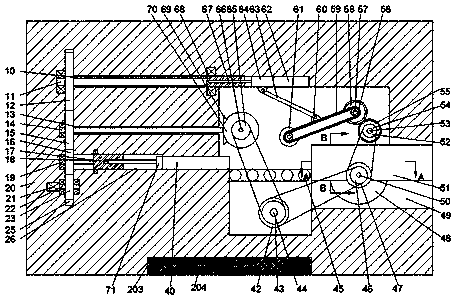

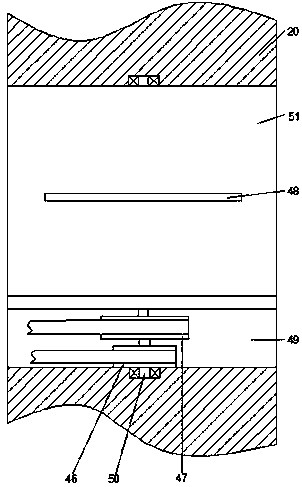

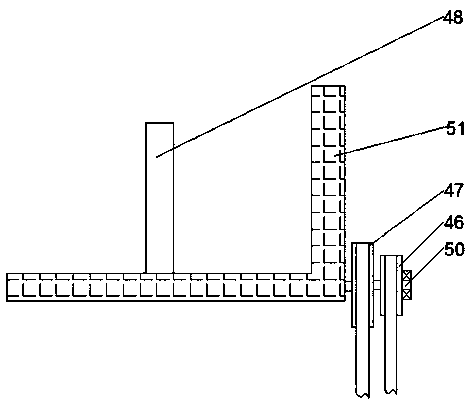

The invention relates to a combined height-adjustable coal cutting machine with a small roller and a large mining height, as well as a coal cutting process of the combined height-adjustable coal cutting machine. The combined height-adjustable coal cutting machine comprises a machine body assembly, coal cutting rollers, a travelling mechanism, an auxiliary device, a hydraulic control system and an electrical control system, and is characterized in that combined height-adjusting devices are symmetrically mounted on two side surfaces of the machine body assembly; and each combined height-adjusting device comprises a main height-adjusting oil cylinder, an auxiliary height-adjusting cutting arm and an auxiliary height-adjusting oil cylinder. The coal cutting process adopts a knife inserting method without notch cutting; the coal cutting roller at the front end of the coal cutting machine cuts residual coal bodies under the action of the oscillation of both the main height-adjusting cutting arm and the auxiliary height-adjusting cutting arm, wherein the moving trace is an arc, and the oscillation angle Alpha is at least 90 DEG; and the coal cutting roller at the rear end of the coal cutting machine cuts coal along a bottom plate, wherein the moving trace is a straight line. The coal cutting machine has the advantages that the structure is compact; the size and the weight are smaller; the suitability is strong; the mounting and the transportation are convenient; and the coal cutting machine is suitable for large, middle or small scale of coal mines with large mining heights.

Owner:闫振东

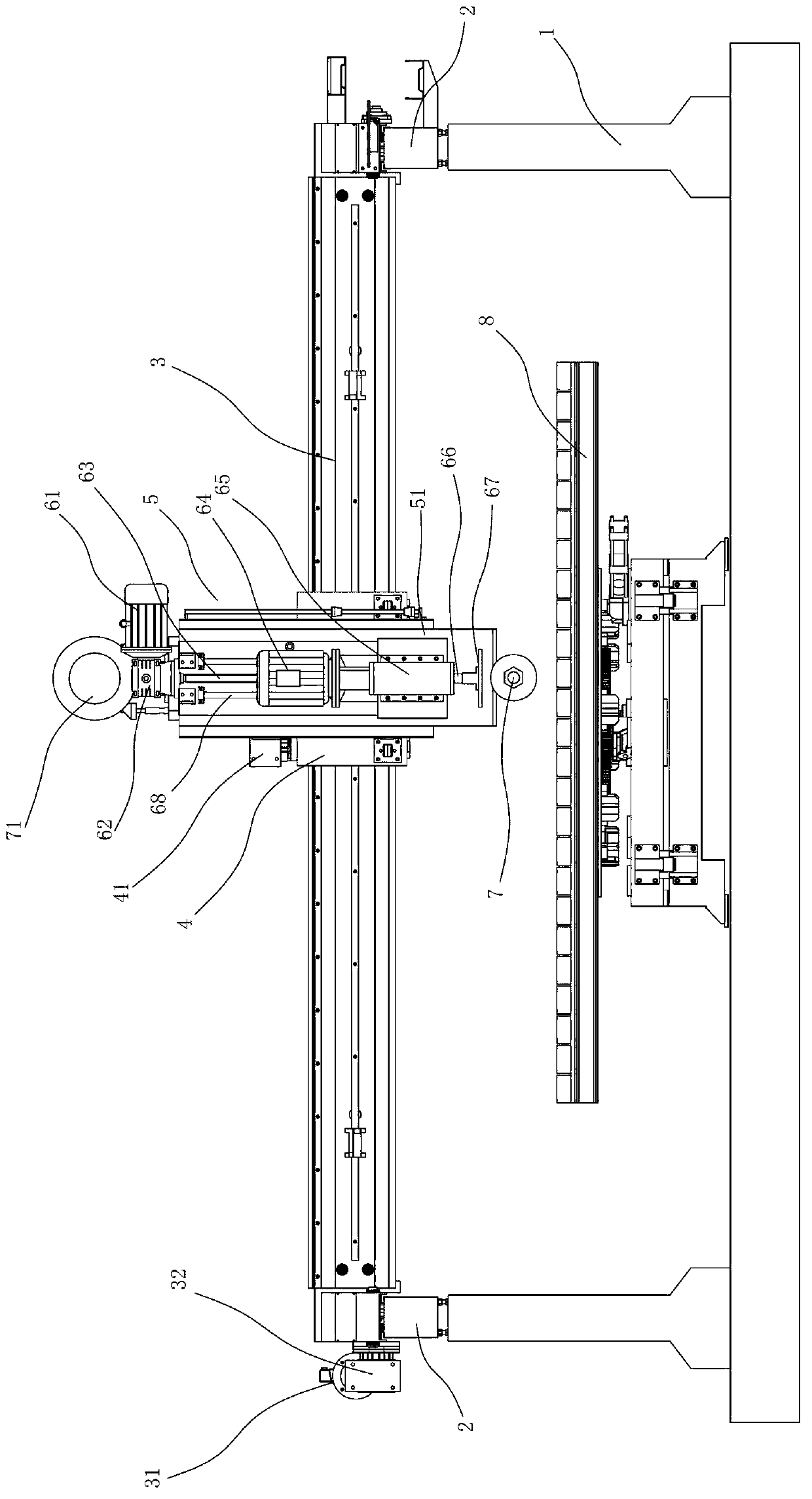

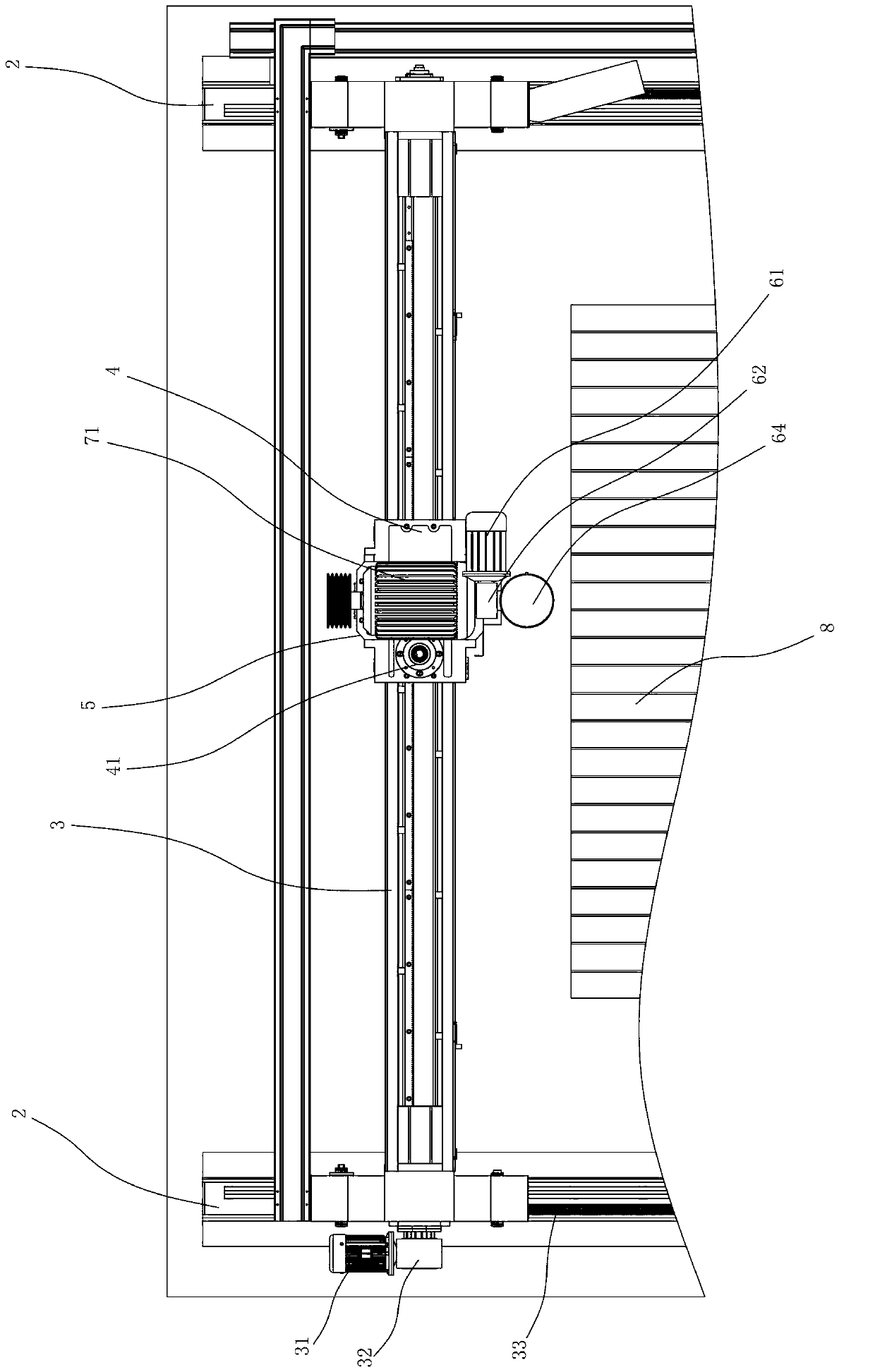

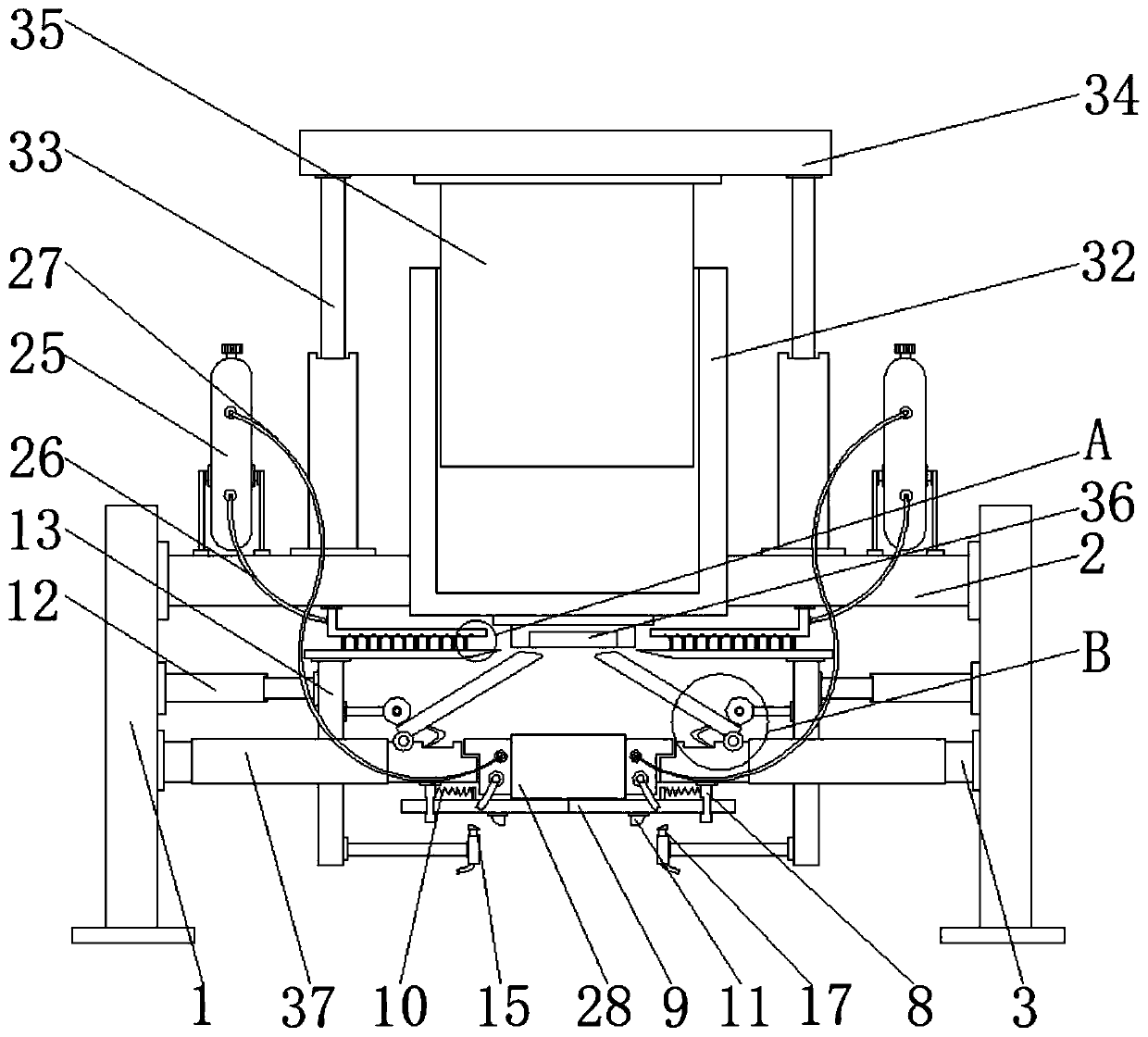

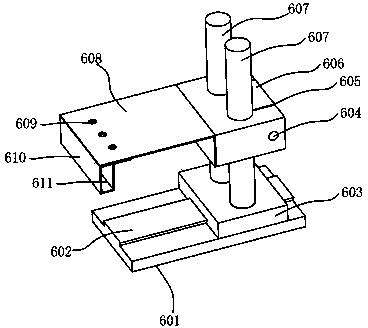

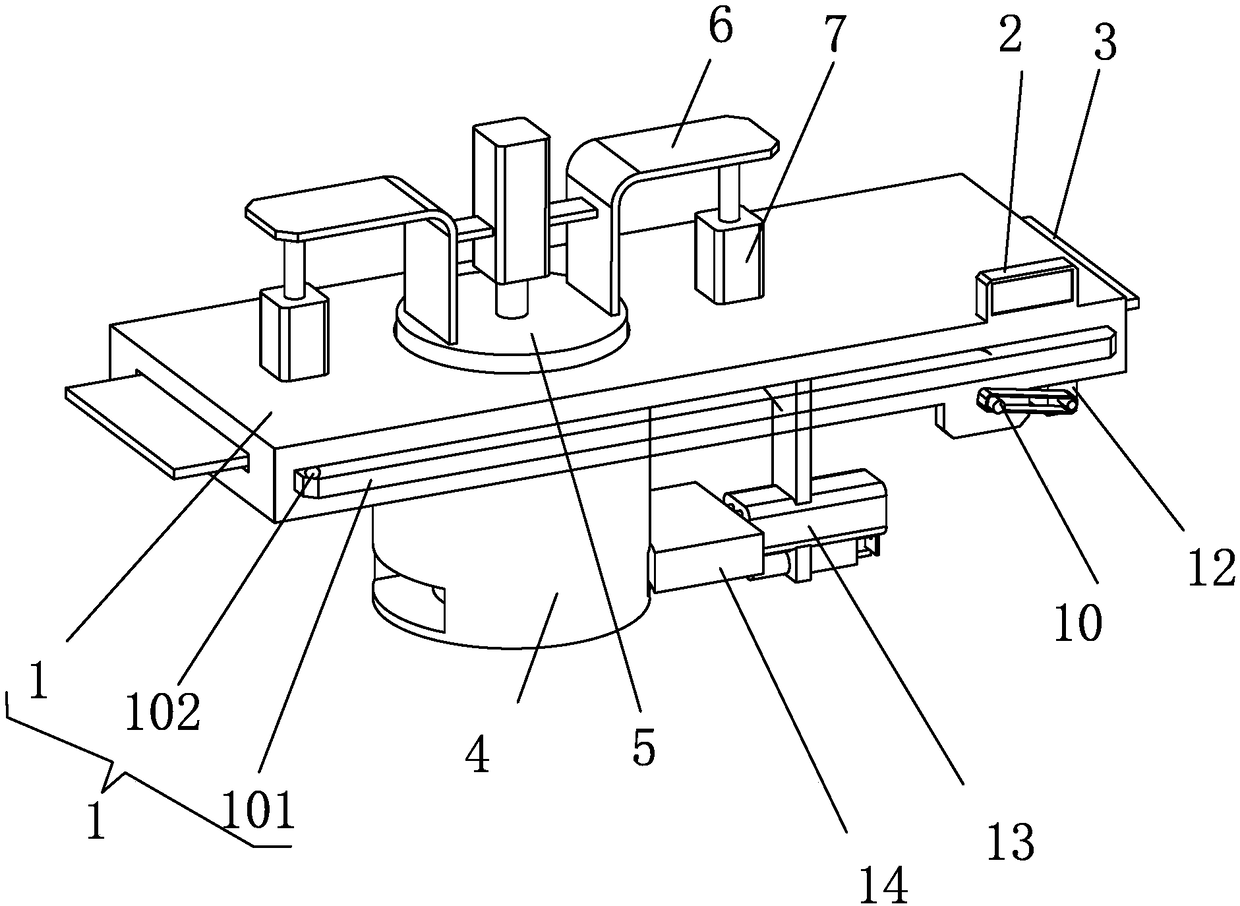

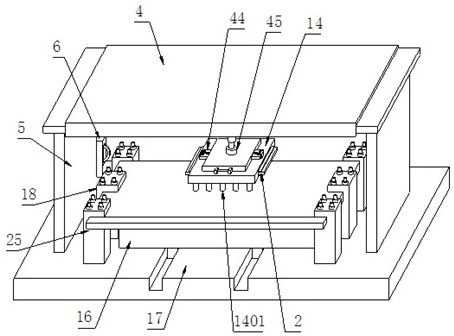

Bridge type stone cutter with polishing function

ActiveCN103128860AWith cutting functionReduce the handling processGrinding machinesStone-like material working toolsSTONE CUTTERBridge type

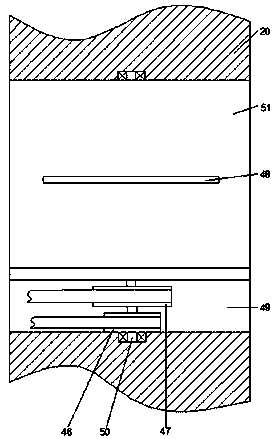

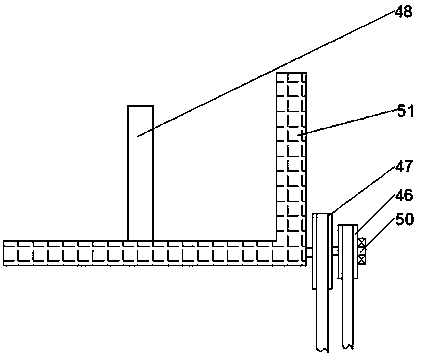

A bridge type stone cutter with a polishing function comprises a crossbeam, two longitudinal beams, a moving seat, a lifting frame, a worktable and a cutting device. The cutting device is arranged on the lifting frame, a longitudinal moving mechanism is arranged among the crossbeam and the longitudinal beams, a transverse moving mechanism is arranged between the moving seat and the crossbeam, and a lifting moving mechanism is arranged between the lifting frame and the moving seat. The bridge type stone cutter is characterized by further comprising a polishing device, the polishing device is arranged on the lifting frame and comprises a spindle box, a spindle, a main motor, an abrasive disc and a vertical moving mechanism, the spindle box is arranged on the lifting frame in such a manner that the spindle box can vertically move up and down on the lifting frame, the spindle is vertically arranged on the spindle box, the main motor is arranged on the spindle box and is connected with the spindle to drive the spindle to rotate, the abrasive disc is arranged at the lower end of the spindle, and the vertical moving mechanism is connected with the spindle box to drive the spindle box to vertically move. The bridge type stone cutter has the advantages that a cutting function is integrated with the polishing function, a procedure for shifting stone between cutting equipment and polishing equipment and a procedure for clamping the stone are omitted, the stone processing efficiency is improved, and the labor cost is saved.

Owner:福建省南安市巨轮机械有限公司

Cake extrusion moulding device with cutting function

InactiveCN109691473AWith cutting functionAvoid stickinessDough shaping and cutting apparatusDough extruding machinesExtrusion mouldingEngineering

The invention discloses a cake extrusion moulding device with a cutting function. The device comprises two support legs. The opposite sides of the support legs are both fixedly connected to a connection block. An extruding mechanism is arranged between two connection blocks. A fixed plate is fixed on the bottoms of the connection blocks and is arranged between the opposite sides of the support legs. The middle of the fixed plate is connected to a die through a card slot. The opposite sides of two support legs are both provided with a power mechanism. The provided device has the advantages thatwhen a cake is mechanically cut, the raw materials will not be stuck on the cutters, demoulding and moulding are easy, splashing of raw materials is avoided, the production environment is very hygiene, and the cake quality the production efficiency are improved.

Owner:安徽品滋味食品股份有限公司

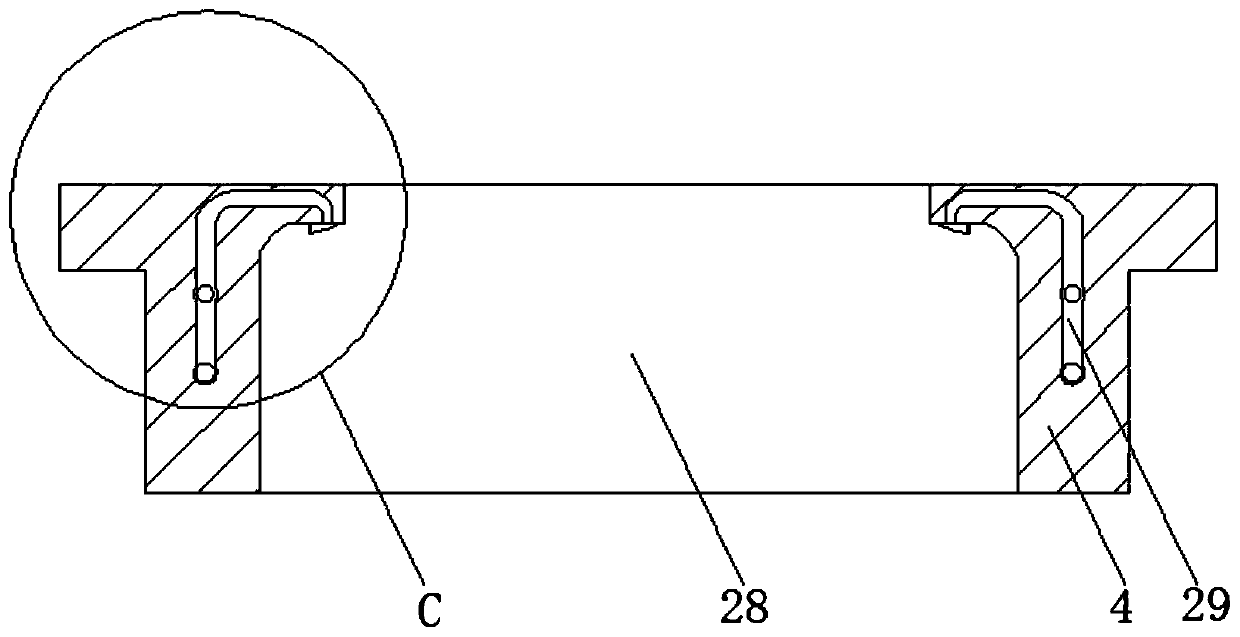

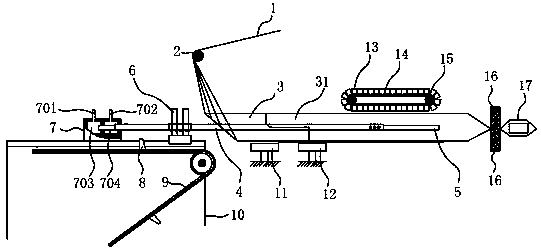

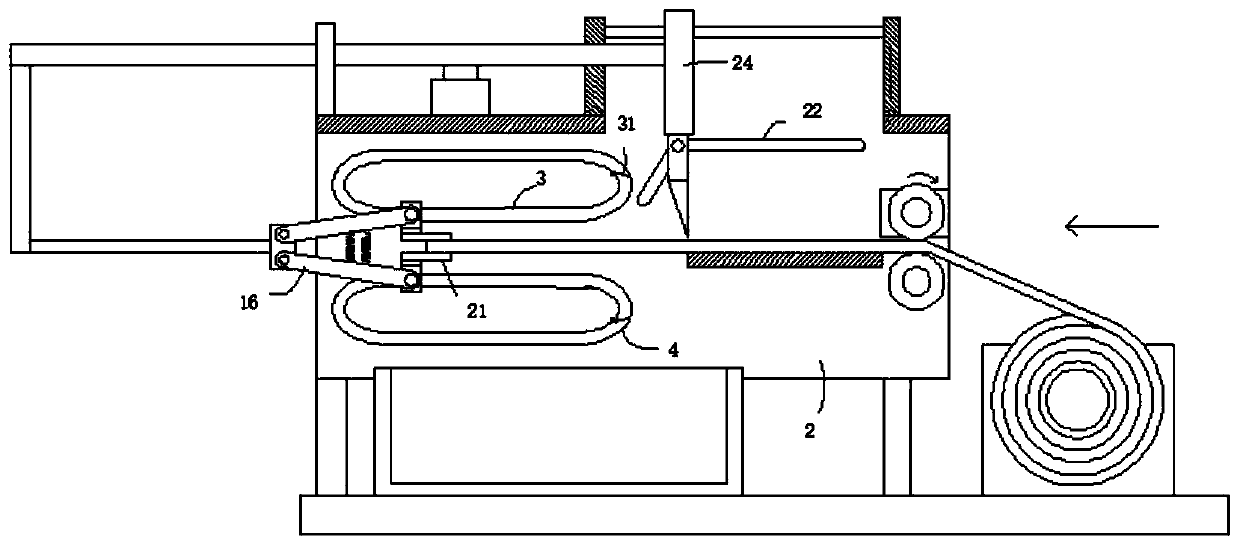

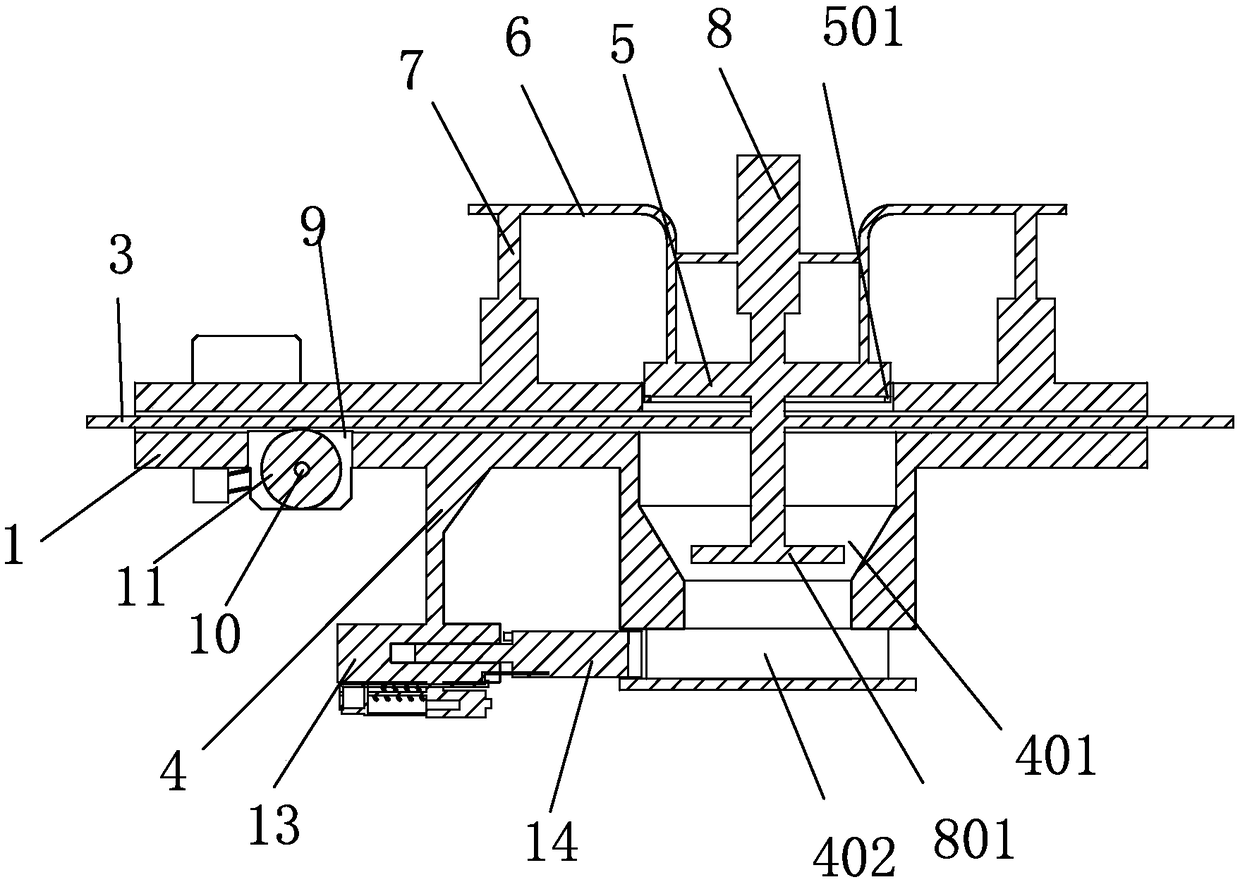

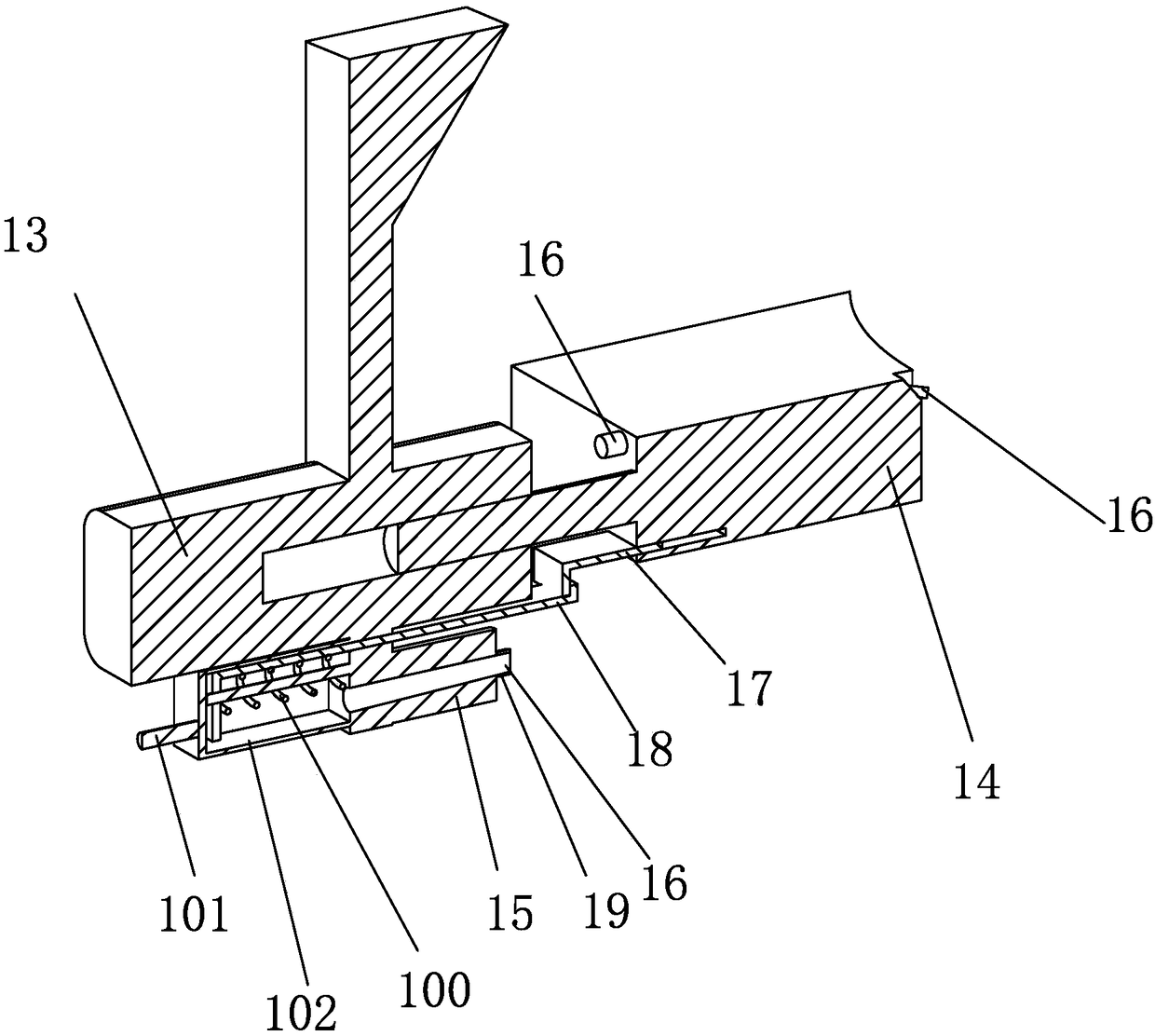

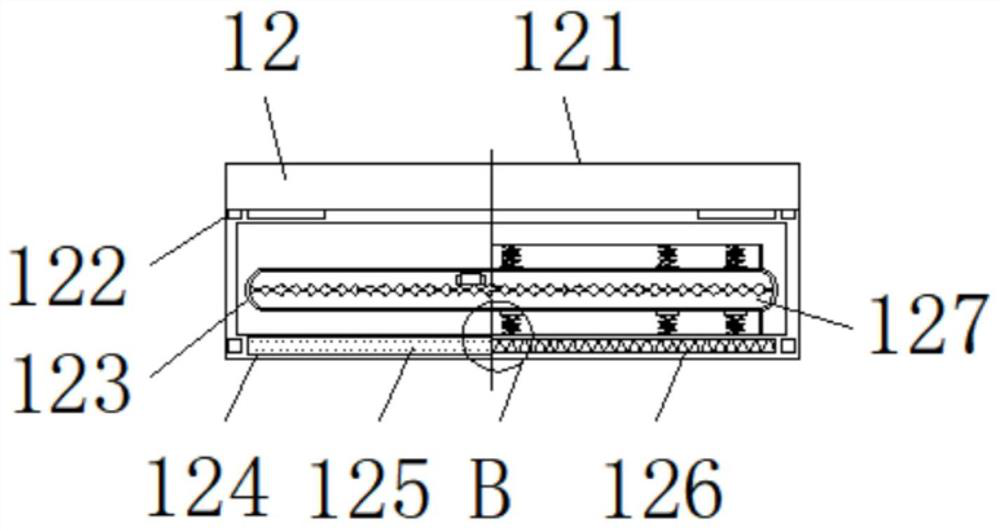

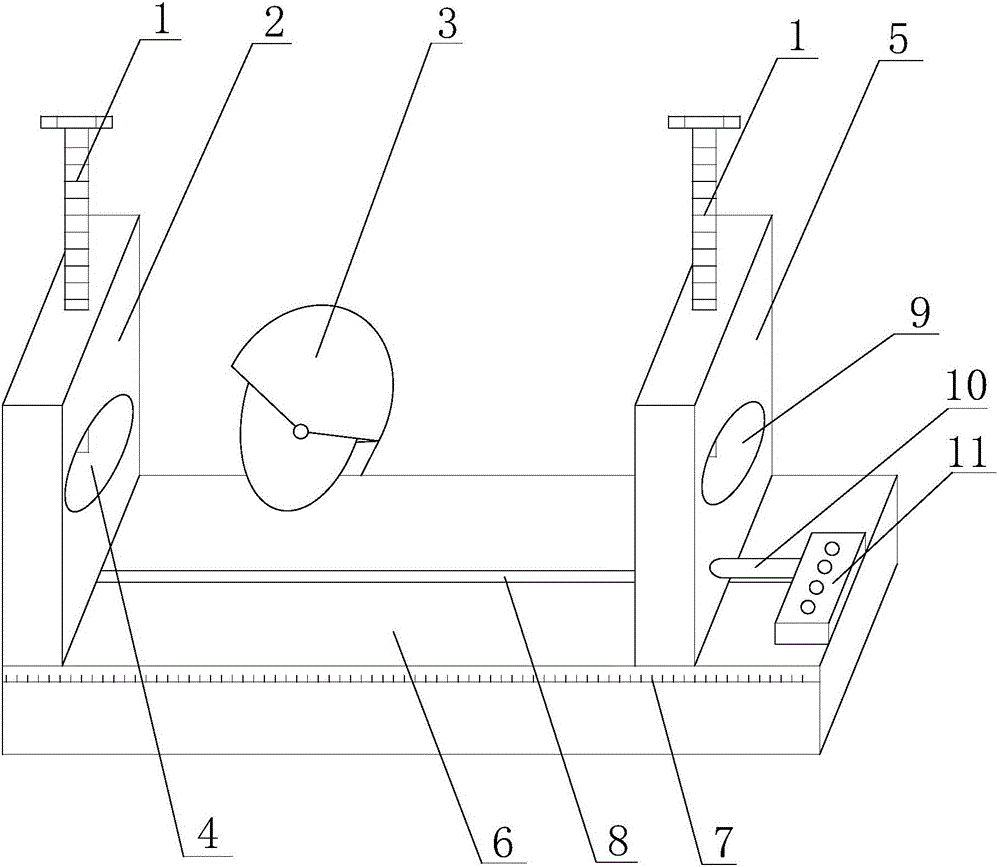

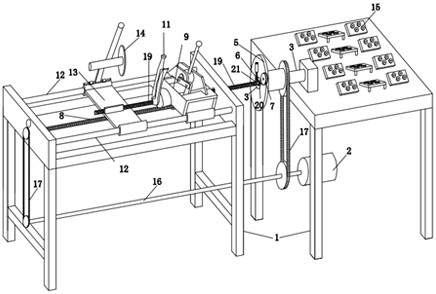

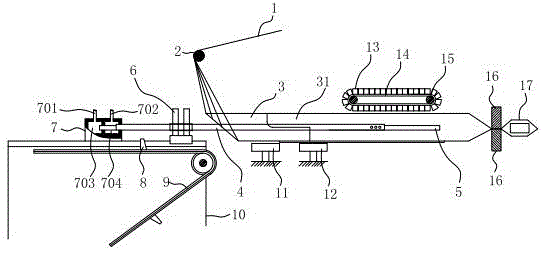

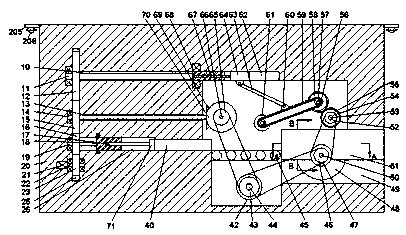

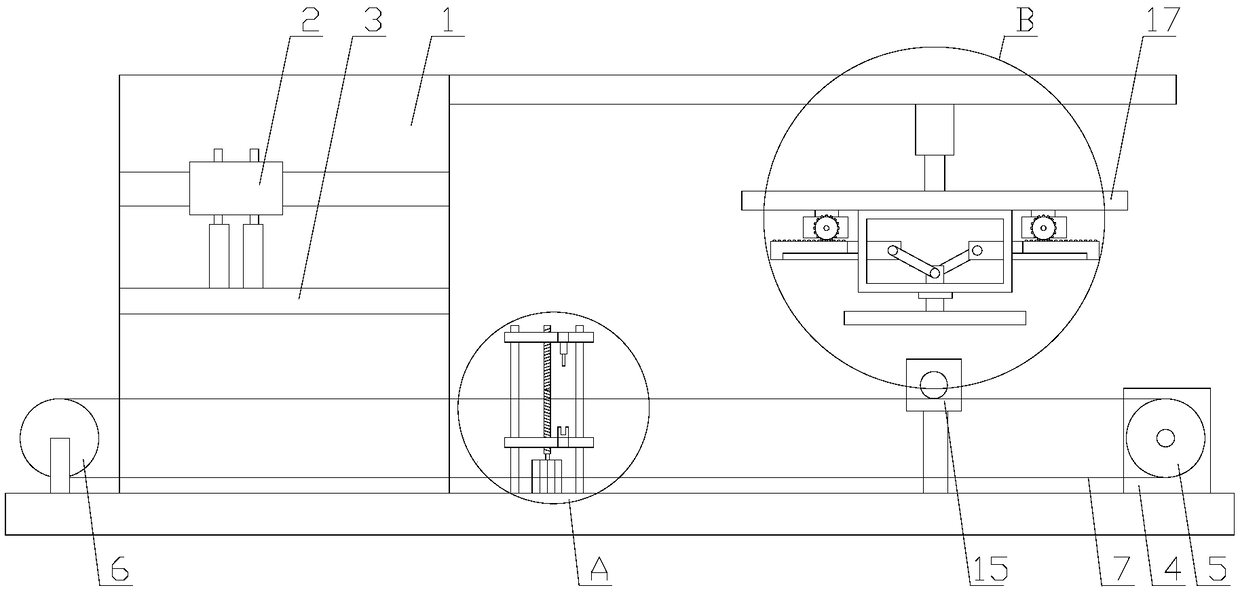

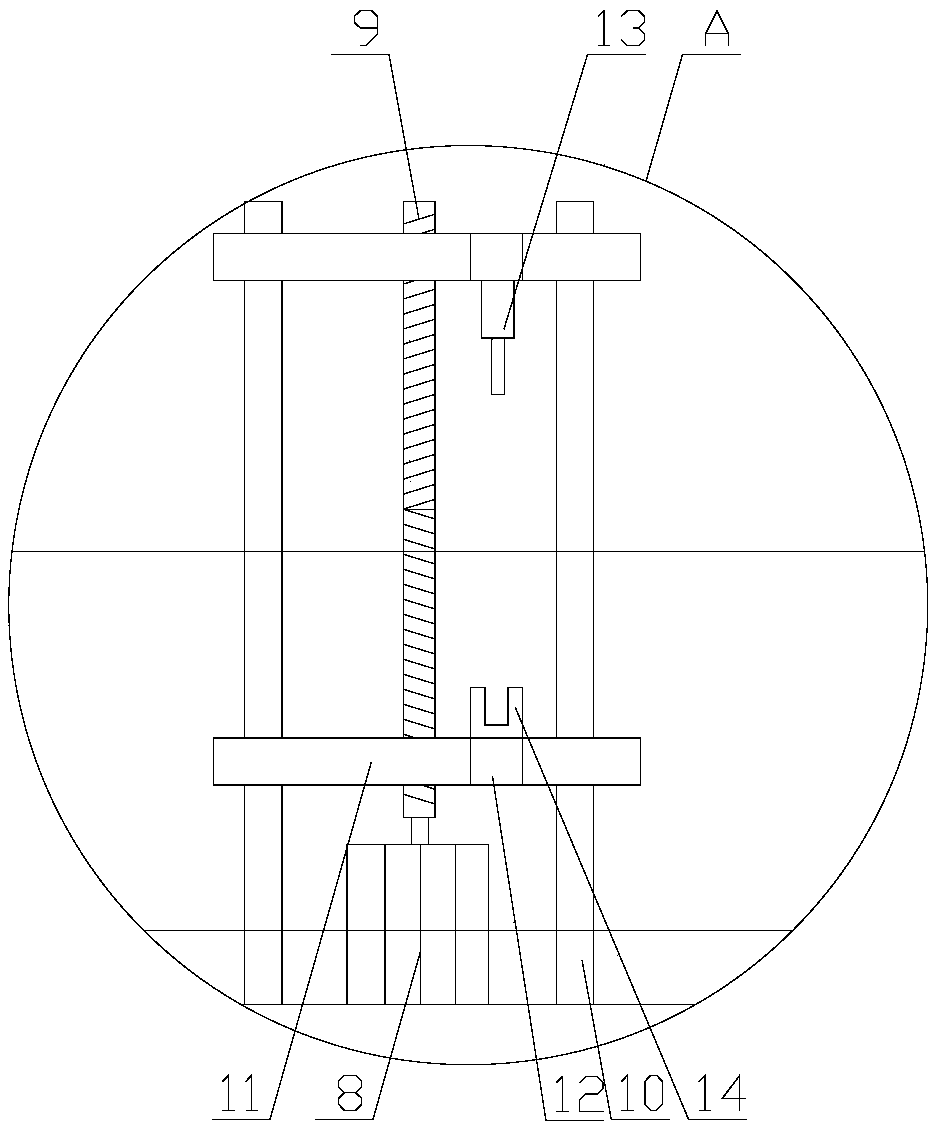

Fully-automatic continuous bag type modified atmosphere packaging machine

ActiveCN104192343AIncrease replacement rateIncrease profitPackaging by pressurising/gasifyingModified atmosphereEngineering

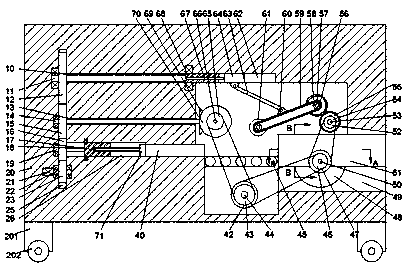

The invention relates to a fully-automatic continuous bag type modified atmosphere packaging machine. The packaging machine comprises a machine frame, wherein a feeding chain is arranged on the machine frame, a set of air pipe connectors and a set of air pipe fixing devices are arranged on the machine frame symmetrical about the feeding chain, gas replacement mechanisms are installed on the air pipe fixing devices respectively, one end of each gas replacement mechanism is communicated with the corresponding air pipe connector, and the other end of each gas replacement mechanism extends into a packaging cavity. The packaging machine is simple in structure and quick and convenient to install, movement of the gas replacement mechanisms in the left-right directions, up-down directions and front-back directions can be effectively achieved due to the arrangement of the air pipe fixing devices, so that modified atmosphere packaging requirements of different products are met, and adjustment is flexible, quick and convenient. Due to the arrangement of the air pipe connectors, inflation of an inflation pipe and exhaust of an exhaust pipe can be achieved at the same time, and in this way, replacement speed of gas in the packaging cavity is high, the replacement rate is high, and gas mixing precision is high.

Owner:JIANGNAN UNIV

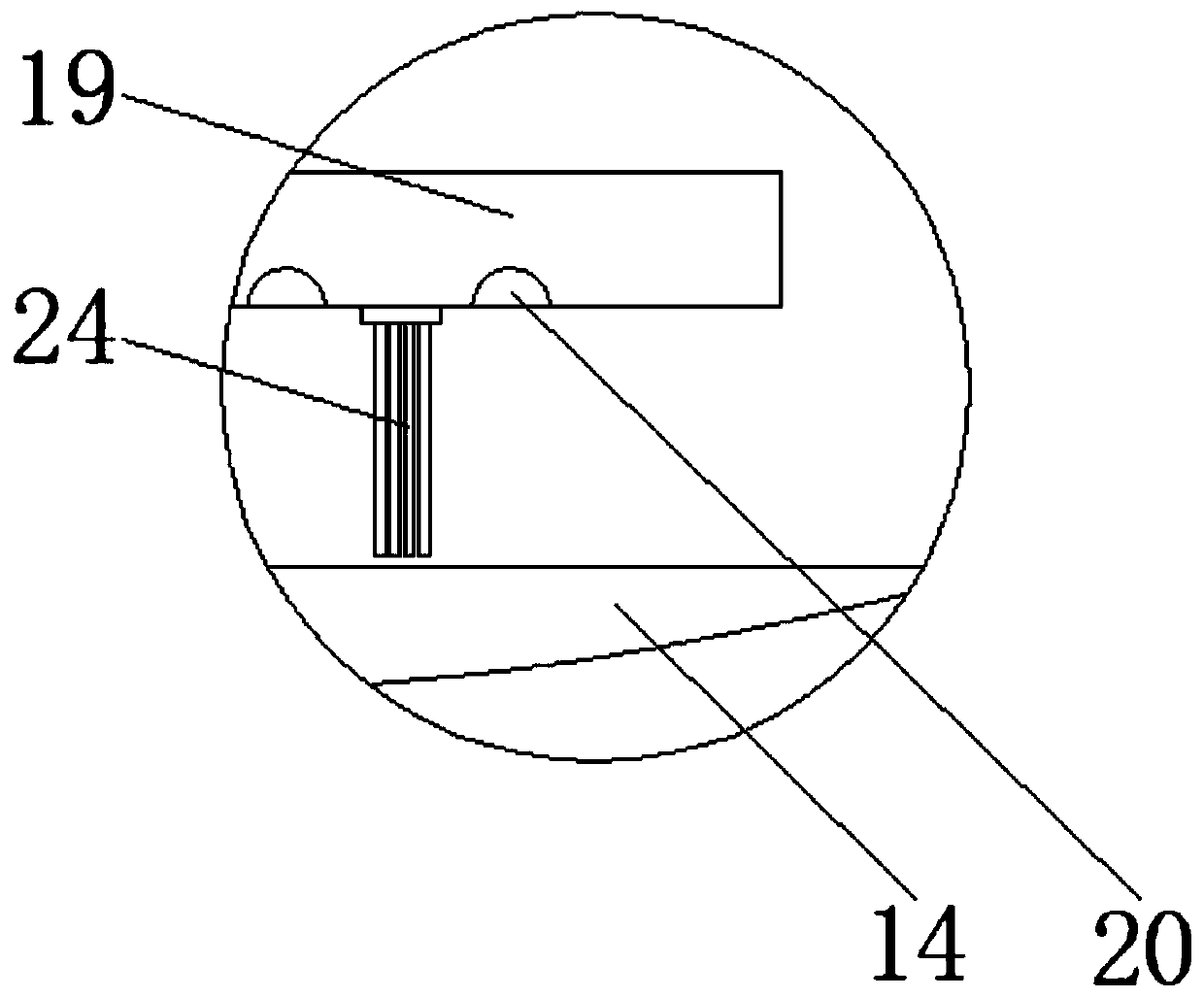

Clamping and feeding device for fireproof coiled material processing

InactiveCN110625655ASimple structureReduce manufacturing costMetal working apparatusEngineeringMaterials processing

The invention discloses a clamping and feeding device for fireproof coiled material processing, relates to the field of fireproof coiled material processing and aims at solving the problems of low manual cutting machining efficiency and large danger coefficient of an existing fireproof coiled material. The following technical scheme is now presented, the clamping and feeding device comprises two mounting plates which are fixed on a base in a front-back manner; a transverse top plate is fixed between the upper ends of the two mounting plates; a rectangular mounting pipe is fixed to the top of each top plate; a rectangular through hole, below the lower side of each rectangular mounting pipe, is formed in the top plate; a clamping and feeding assembly, a cutting assembly and a loading assembly are arranged between the two mounting plates; the clamping and feeding assembly is installed on one side of the cutting assembly; and the cutting assembly is installed above the feeding assembly. The whole device is simple in structure and low in manufacturing cost and has functions of automatic clamping, feeding and cutting, and the whole processing process can be continuously performed, so that the processing efficiency is greatly improved, and the mounting cost is lowered.

Owner:HUZHOU TEACHERS COLLEGE

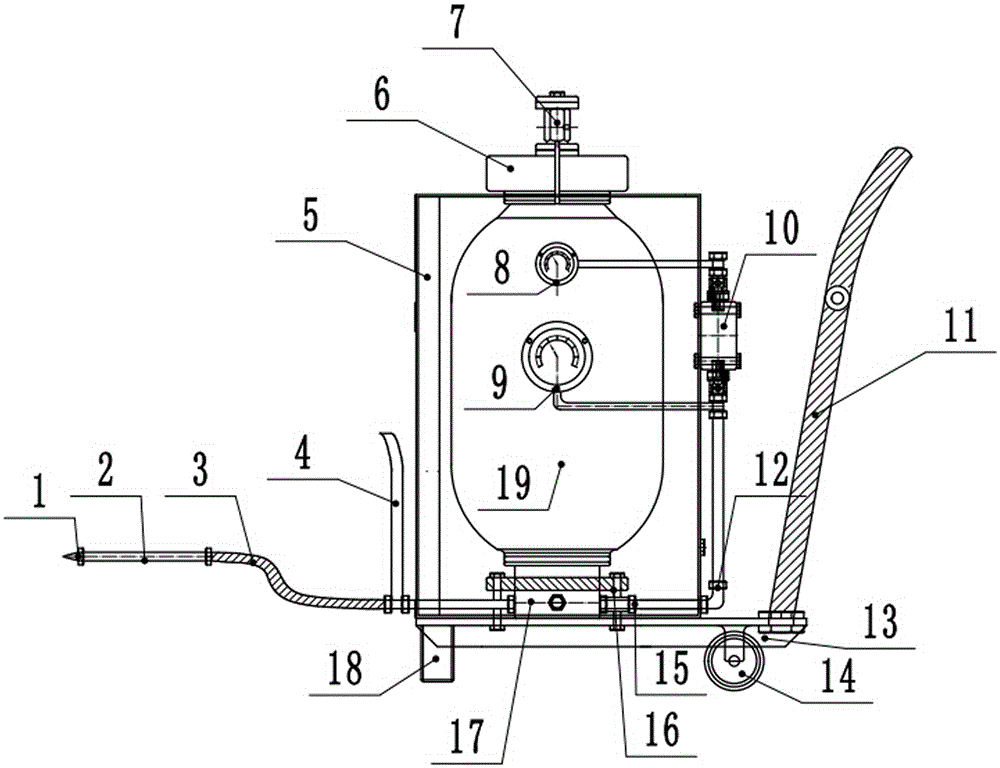

Cleaning, de-rusting and cutting automatic conversion all-in-one machine for offshore oil platform

InactiveCN105081983AReduce trafficRelieve pressureAbrasive feedersAbrasive machine appurtenancesWorking pressureSpray nozzle

The invention discloses a cleaning, de-rusting and cutting automatic conversion all-in-one machine for an offshore oil platform. The cleaning, de-rusting and cutting automatic conversion all-in-one machine for the offshore oil platform comprises a jewel orifice, a spraying gun handle, a high-pressure rubber pipe, a sand amount adjustment handle, a protective shield, an end cover, a pressure relief valve, a liquid inlet pressure gauge, a work pressure gauge, a pressure flow amount control valve, a pushing handle, a high-pressure liquid inlet pipe, a base, a trundle, a one-way valve, a balance water adjustment button, a mixing valve assembly, a supporting leg, an abrasive tank and other parts. After pressure water is subjected to pressure flow amount adjustment through the pressure flow amount control valve, the pressure water enters the mixing valve through the high-pressure liquid inlet pipe. Abrasives in the abrasive tank enter the mixing valve, are mixed with the water and then enter the jewel orifice through the high-pressure rubber pipe. The jewel orifice accelerates the mixed water and sprays the water on an object on the platform. The function of automatic conversion of cleaning, de-rusting and cutting is realized by adjusting the diameter of the jewel orifice.

Owner:天津艾浮瑞特科技有限公司

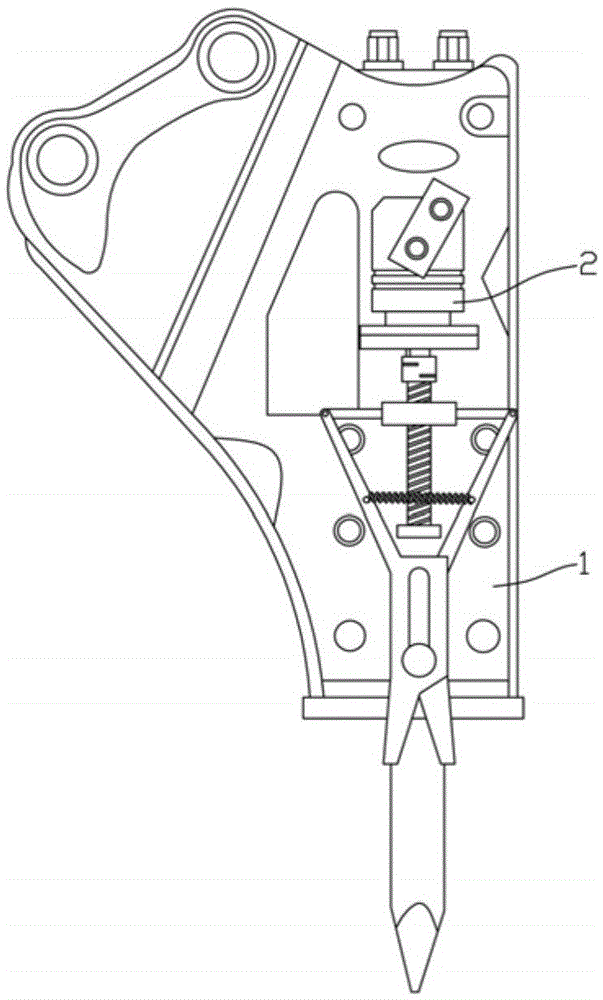

Breaking hammer with shearing device

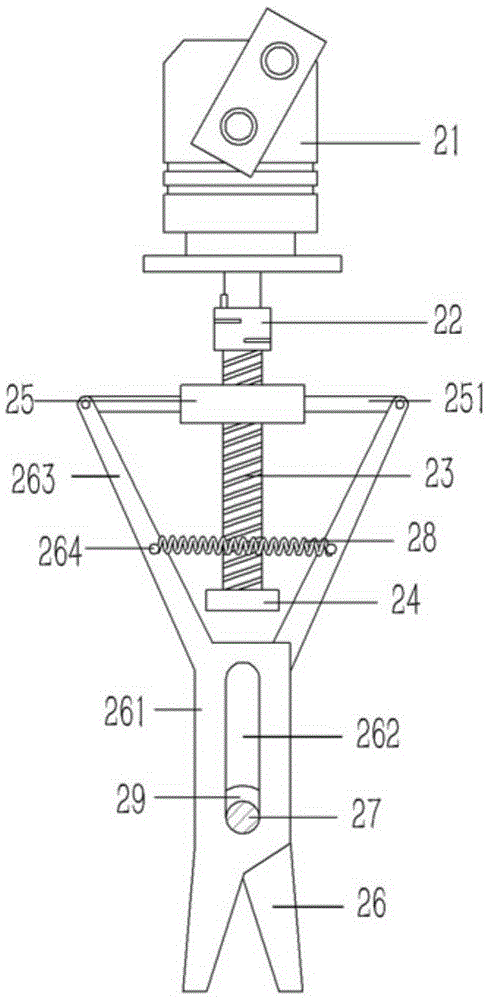

ActiveCN105484309AWith cutting functionBuilding repairsSoil-shifting machines/dredgersHydraulic motorCoupling

Disclosed is a breaking hammer with a shearing device. A shearing mechanism of the breaking hammer comprises a hydraulic motor, wherein the hydraulic motor is fixed to the side wall of a breaking hammer body. A rotating shaft of the hydraulic motor and the upper end of a vertical lead screw are connected together through a coupler, and the lower end of the lead screw is hinged to a base. The base is fixed to the side wall of the breaking hammer body. A shearing knife is arranged on the lower side of the base, and comprises two staggered and symmetrical blades. Rectangular piece bodies which extend upwards are formed on the blades, vertical guide grooves are formed in the rectangular piece bodies, and the guide grooves of the two blades overlap together. A guide column is inserted into the guide grooves in a connected mode, and fixed to the side wall of the breaking hammer body. Inclined connecting rods are formed at the upper ends of the rectangular piece bodies of the blades. A rectangular sliding block is connected to the lead screw in a screwed mode, and abuts against the side wall of the breaking hammer body, supporting rods are formed on the two sides of the sliding block, and the top ends of the connecting rods on the blades are hinged to the supporting rods. The breaking hammer is provided with the shearing mechanism, and the shearing mechanism can be hydraulically driven to shear off rebars in the construction process.

Owner:XUZHOU DONGYA ELECTRICAL APPLIANCE

Hammer

The invention discloses a hammer comprising a handle and an iron head; the handle is provided with a cavity on which a spring is arranged; the handle is provided with a knife on which a tooth edge is arranged; and the iron head is provided with a hammerhead on which a hammer pick is arranged. The hammer is provided with the hammerhead so as to have a powerful hammering function; in addition, the hammerhead is provided with the hammer pick, so that higher power is generated during hammering, and more labors are saved during hammering; the hammer is provided with the knife so as to have a cutting function; the knife of the hammer is provided with the tooth edge so that the cutting function of the knife is more powerful; and the hammer is novel in structure and more convenient to use in production and life, people use the hammer with great facility, and the work efficiency is increased.

Owner:林丽芳

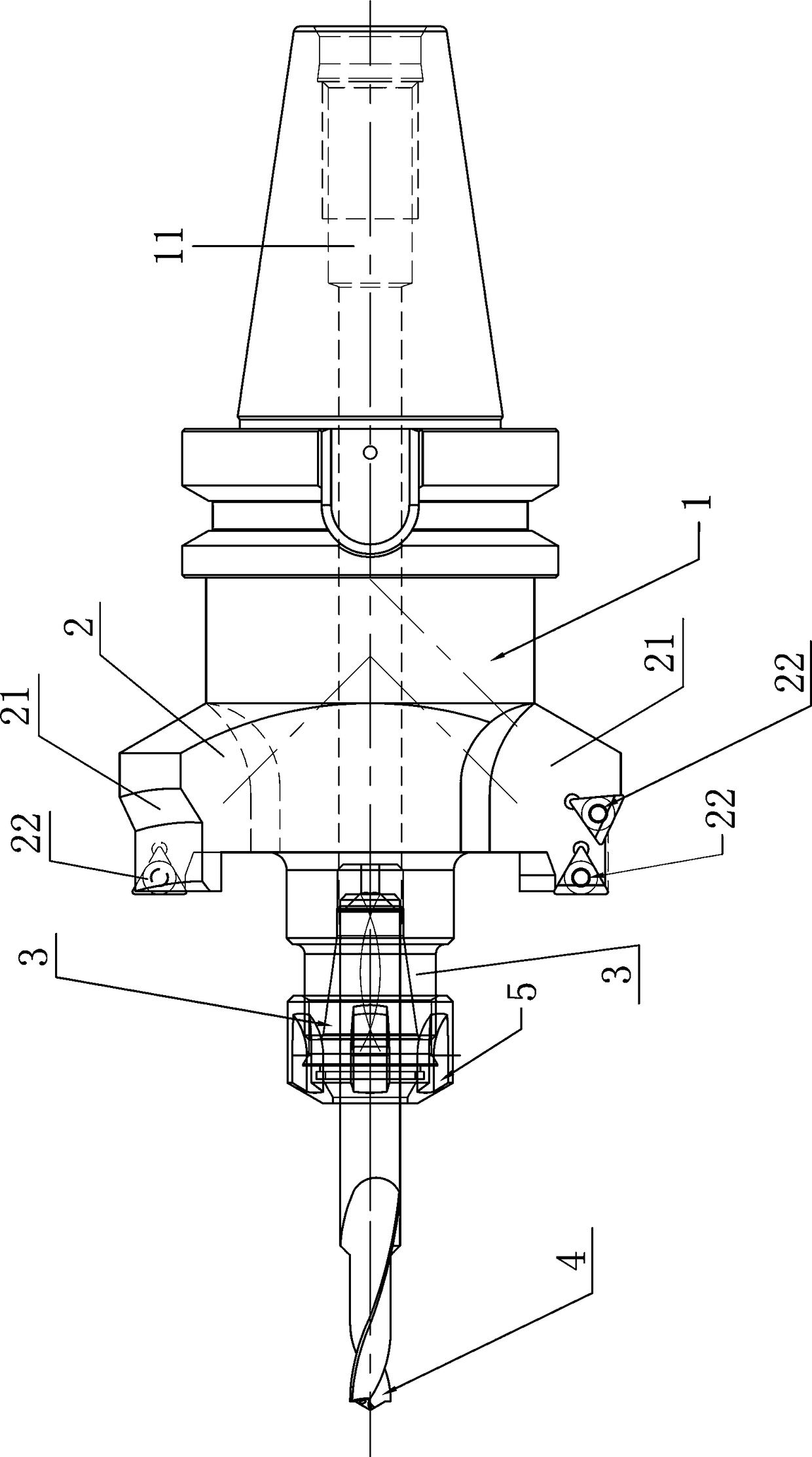

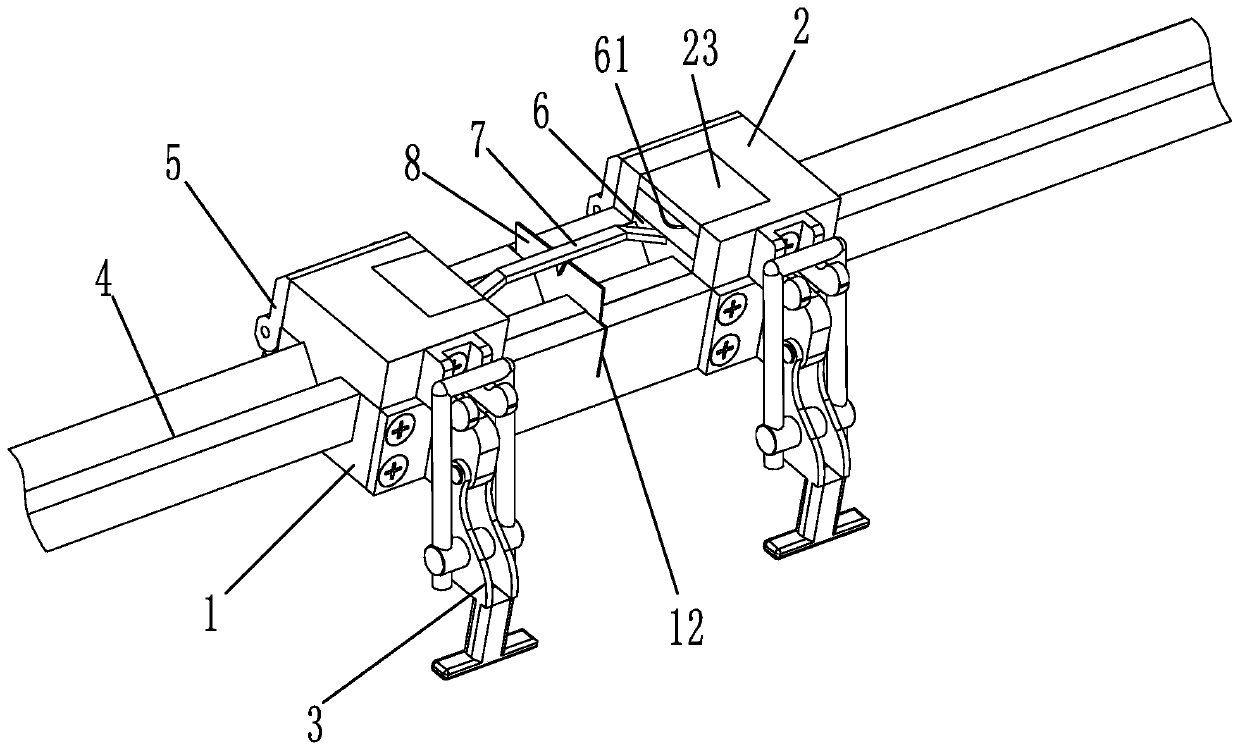

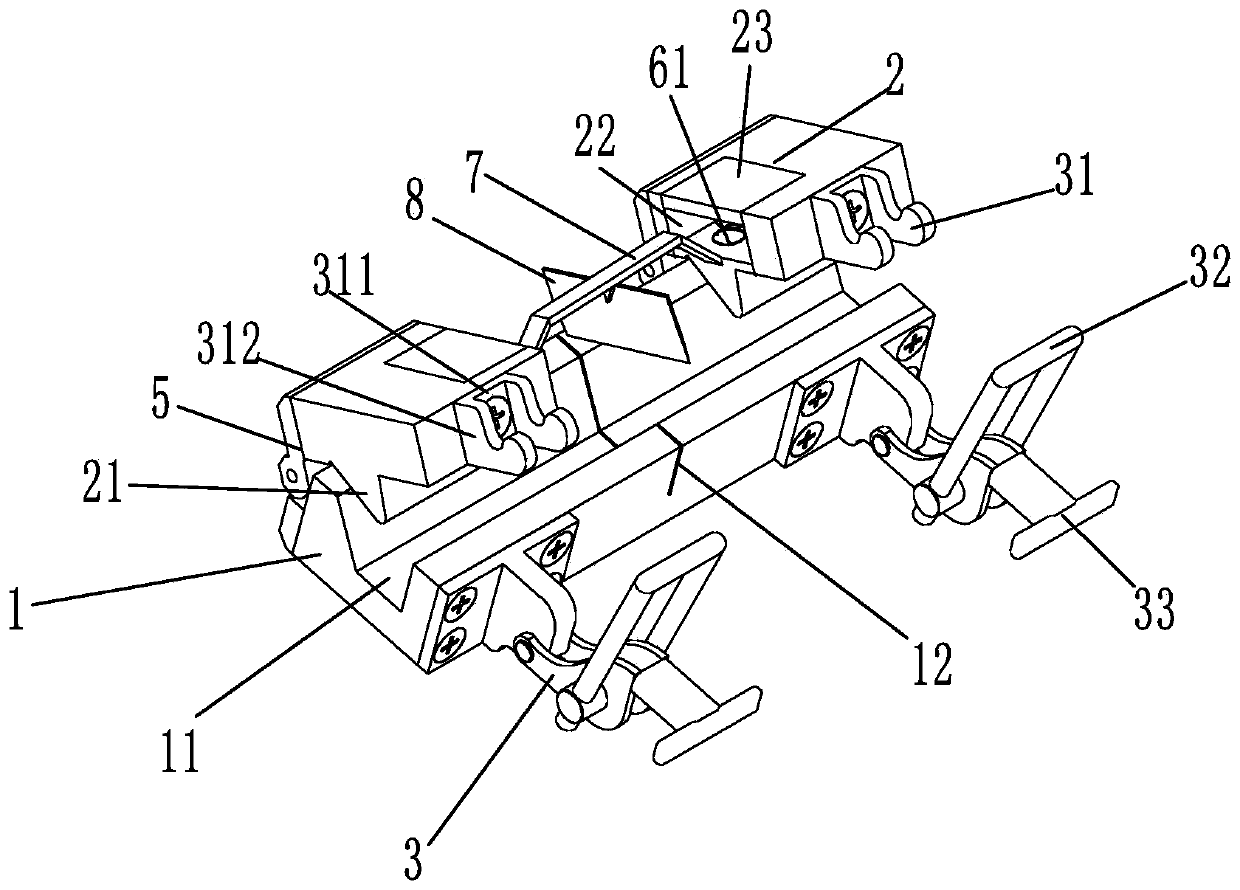

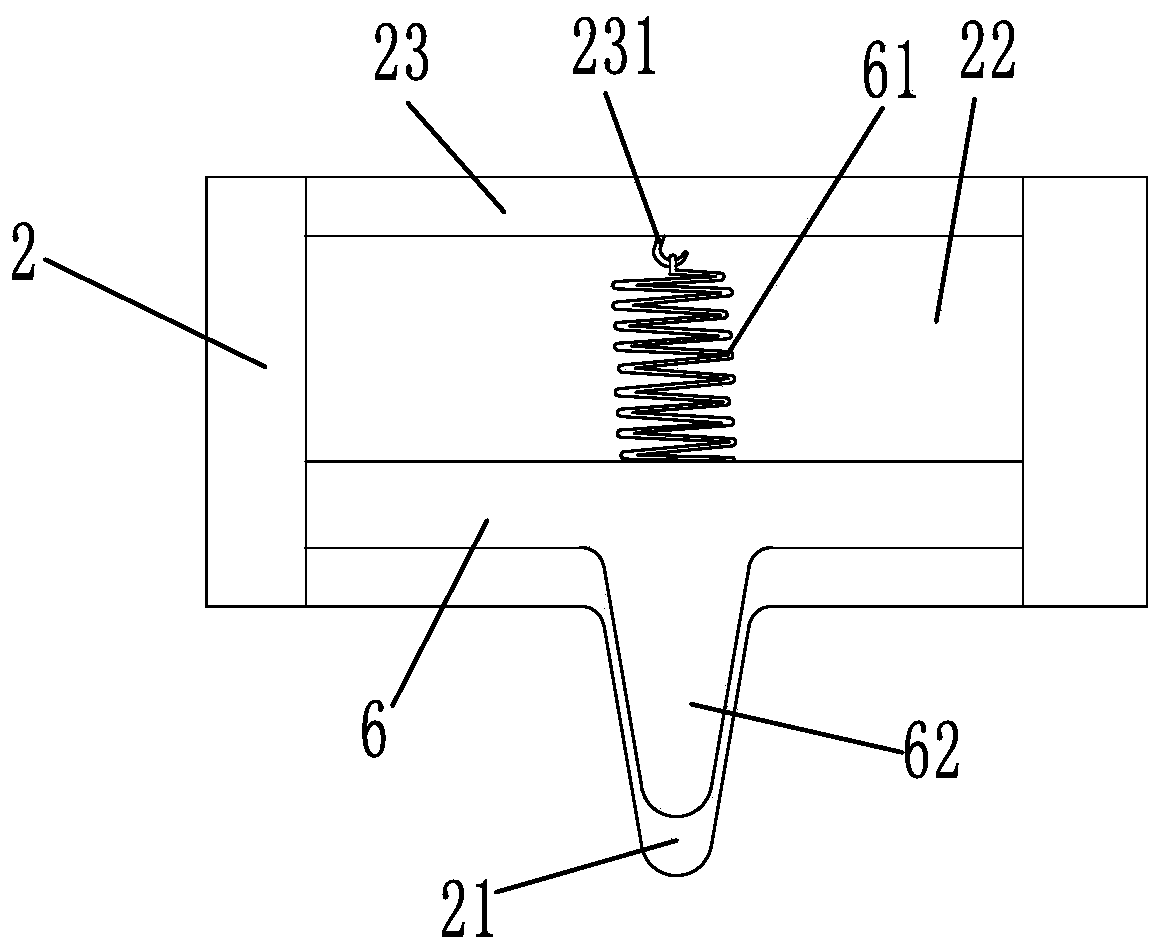

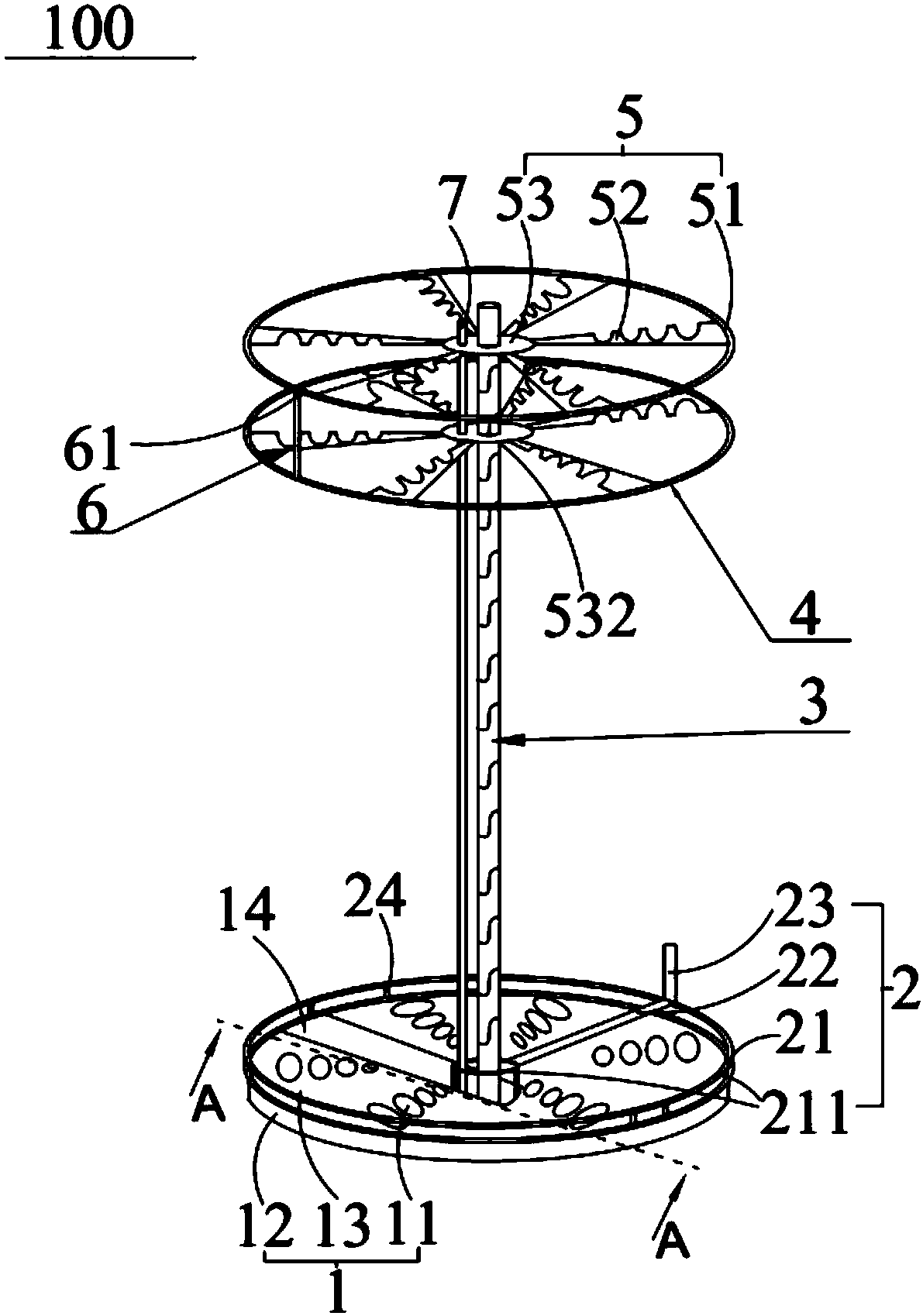

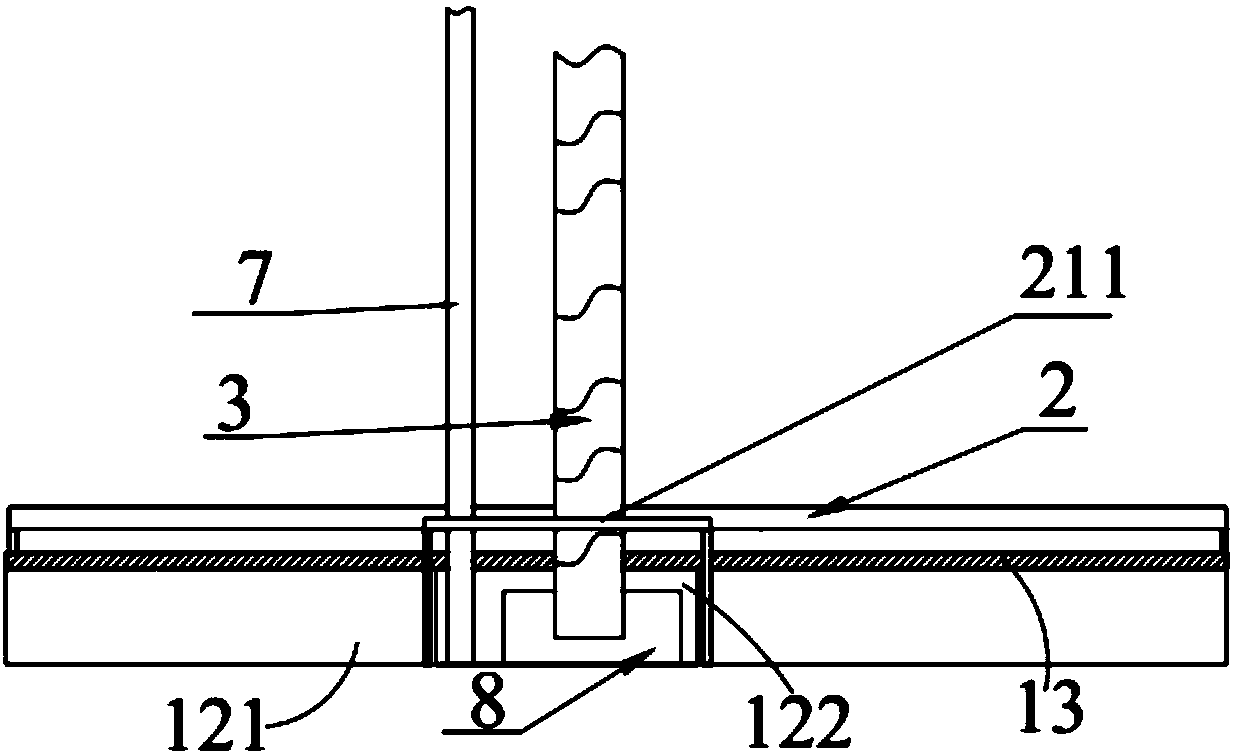

Multifunctional composite cutter

PendingCN108655430AWith cutting functionQuick changeTransportation and packagingTurning toolsEngineeringKnife blades

The invention relates to the field of cutters for metal cutting machining, in particular to a multifunctional composite cutter. The multifunctional composite cutter comprises a knife handle (1), and the multifunctional composite cutter is characterized in that the cutter further comprises a cutting disc (2), tight locking sleeves (3), a drill bit (4) and a fastening nut (5), wherein the rear end face of the cutting disc (2) is fixed on the front end face of the knife handle (1), at least three cutting seats (21) are arranged at the outer edge of the front end face of the cutting disc (2), andeach cutting seat is fixedly provided with a cutting blade (22); the tight locking sleeves (3) are vertically fixed in the middle of the front end face of the cutting disc (2), and the tight locking sleeves (3) are distributed evenly around the central axis of the cutting disc (2), and the outer side faces of the front parts of the tight locking sleeves (3) are tapped with external threads; and the rear part of the drill bit (4) is inserted among the tight locking sleeves (3), and screw the fastening nut (5) to the outer threads of the tight locking sleeves (3). According to the cutter, the structure is small, use is convenient, combination degree is high, and application range is wide.

Owner:上海新山田精密刀具有限公司

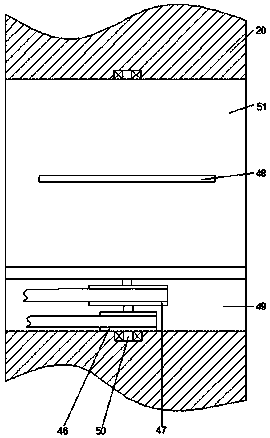

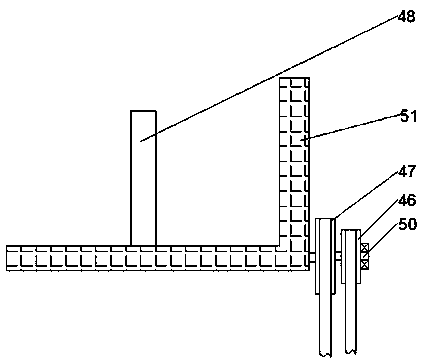

Pneumatic stretching mould

The invention discloses a pneumatic stretching mould. The pneumatic stretching mould comprises a material base, wherein a PLC is mounted on the upper surface of the material base; the input end of thePLC is electrically connected with the output end of an external power supply; a material cavity in the horizontal direction is arranged in the middle part of the material base; an aluminum board isarranged in the material cavity; and the lower surface of the material base is equipped with a mould base. According to the pneumatic stretching mould disclosed by the invention, a first pressure plate and a second pressure plate stamp and process the aluminum board into an aluminum cover, the first pressure plate has a material cutting function, and continuous stretching operation of the aluminumcover is realized in a mode of matching with horizontal feeding of rollers; the second pressure plate is matched with a shrinkage cavity of the mould base for realizing stretching and forming of thealuminum cover, and the processed aluminum cover is pushed out from the side surface of the mould base through a pushing plate, and is stretched and formed once; a device for automatically clearing scrap iron is arranged at the lower side of a third air cylinder, so that action of clearing up scrap iron can be completed automatically during working, and therefore, a plurality of problems caused byscrap iron residues are reduced, aluminum cover processing efficiency is improved, labor intensity of a worker is reduced, and use is more convenient.

Owner:嘉兴恒益安全服务股份有限公司

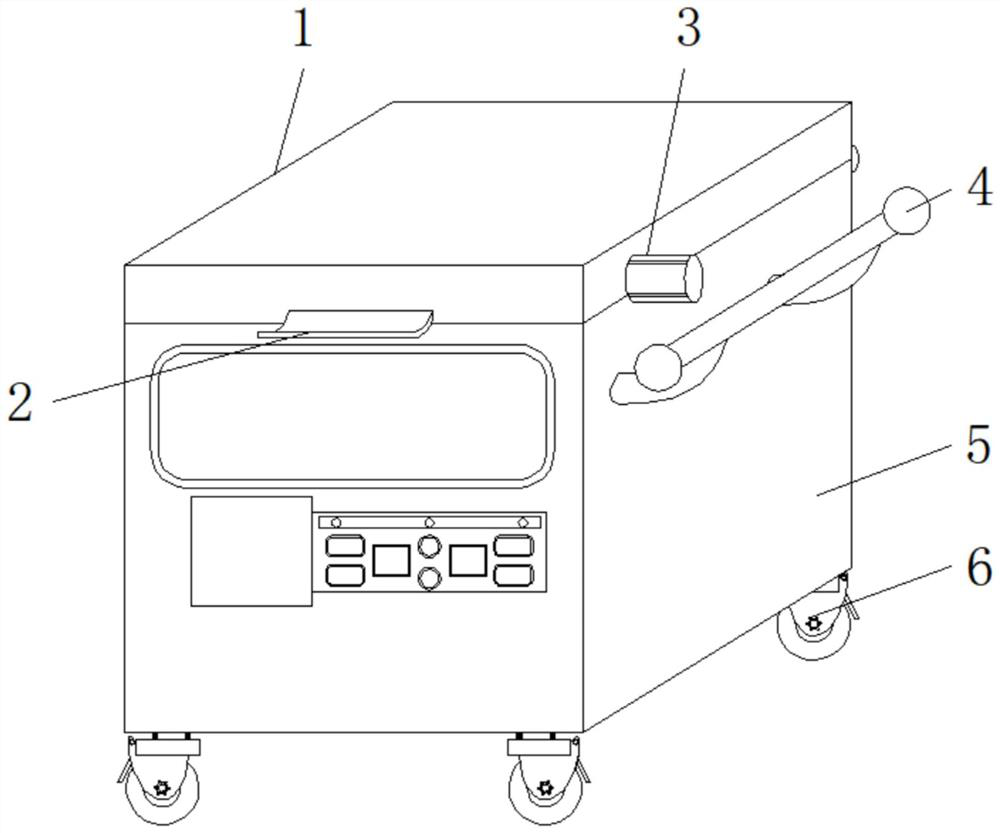

High-safety vacuum packaging equipment for food

InactiveCN111846367AImprove vacuuming effectQuick sealPackaging by pressurising/gasifyingCleaning using toolsEngineeringFood packaging

Owner:马鞍山金瓦格机械科技有限公司

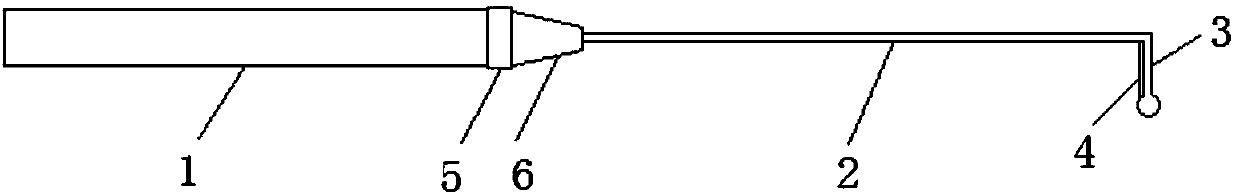

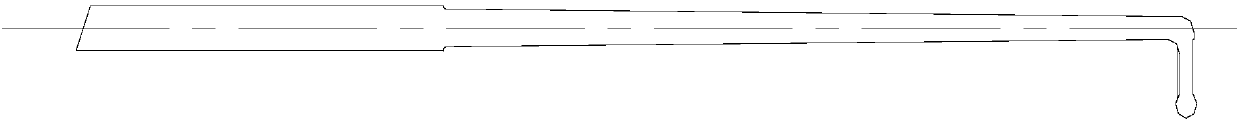

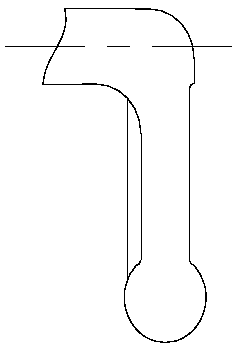

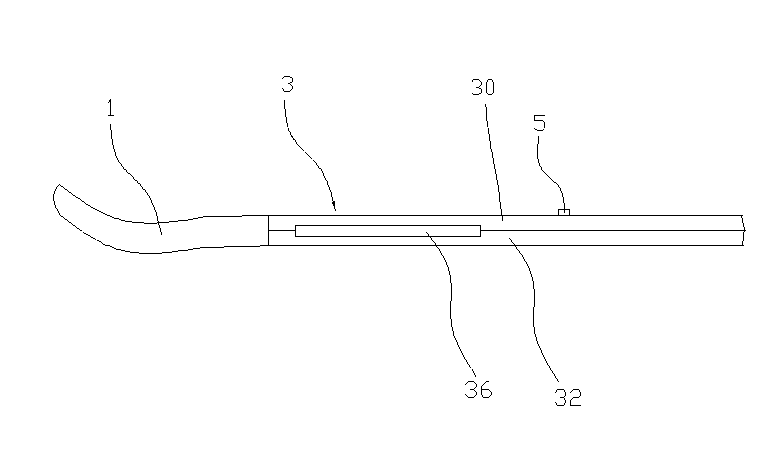

Elevator

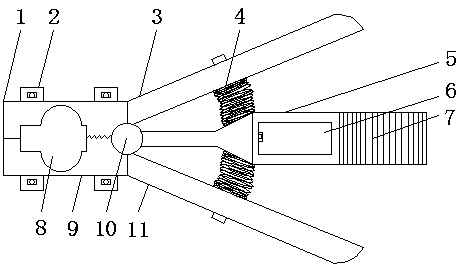

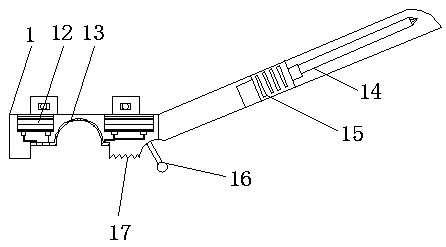

PendingCN107595364AWith cutting functionWith separation functionSurgeryEngineeringSkull base surgery

The invention relates to an elevator. The elevator comprises an operation portion (2) and a hand-held portion (1) which are coaxially connected successively from front to back. The front end of the operation portion (2) is laterally bended to form a hook-shaped head (3). An included angle formed by the hook-shaped head (3) and the operation portion (2) is 90 DEG. A cutter knife (4) is formed at aninner side of the included angle formed by the hook-shaped head (3) and the operation portion (2). A blade of the cutter knife (4) is parallel to an extension direction of the hook-shaped head (3). The elevator has cutting and separating functions and can be used for separation of important blood vessels and nerves and sharp incision of superficial tissues, and the number of operating apparatusesin a narrow surgical space is reduced. The cutting blade is formed at the inner side of the hook-shaped head of the elevator, the cutting edge is positioned below the hook-shaped head, and the cutting direction is consistent with the axial direction of the operation portion, thereby facilitating operation in a narrow and long space. Requirements of a deep skull base surgery can be satisfied.

Owner:BEIJING NEUROSURGICAL INST

Household noodle machine

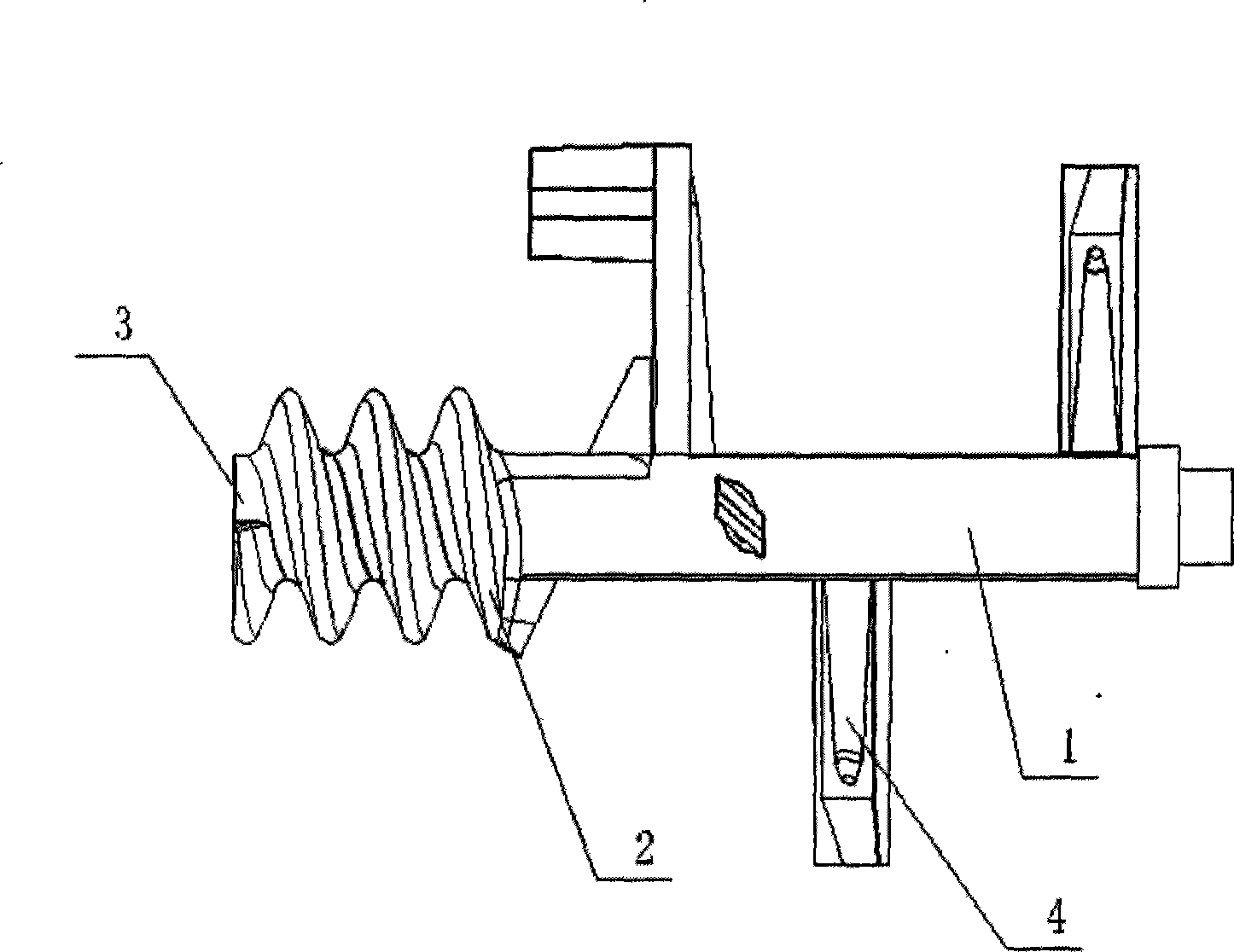

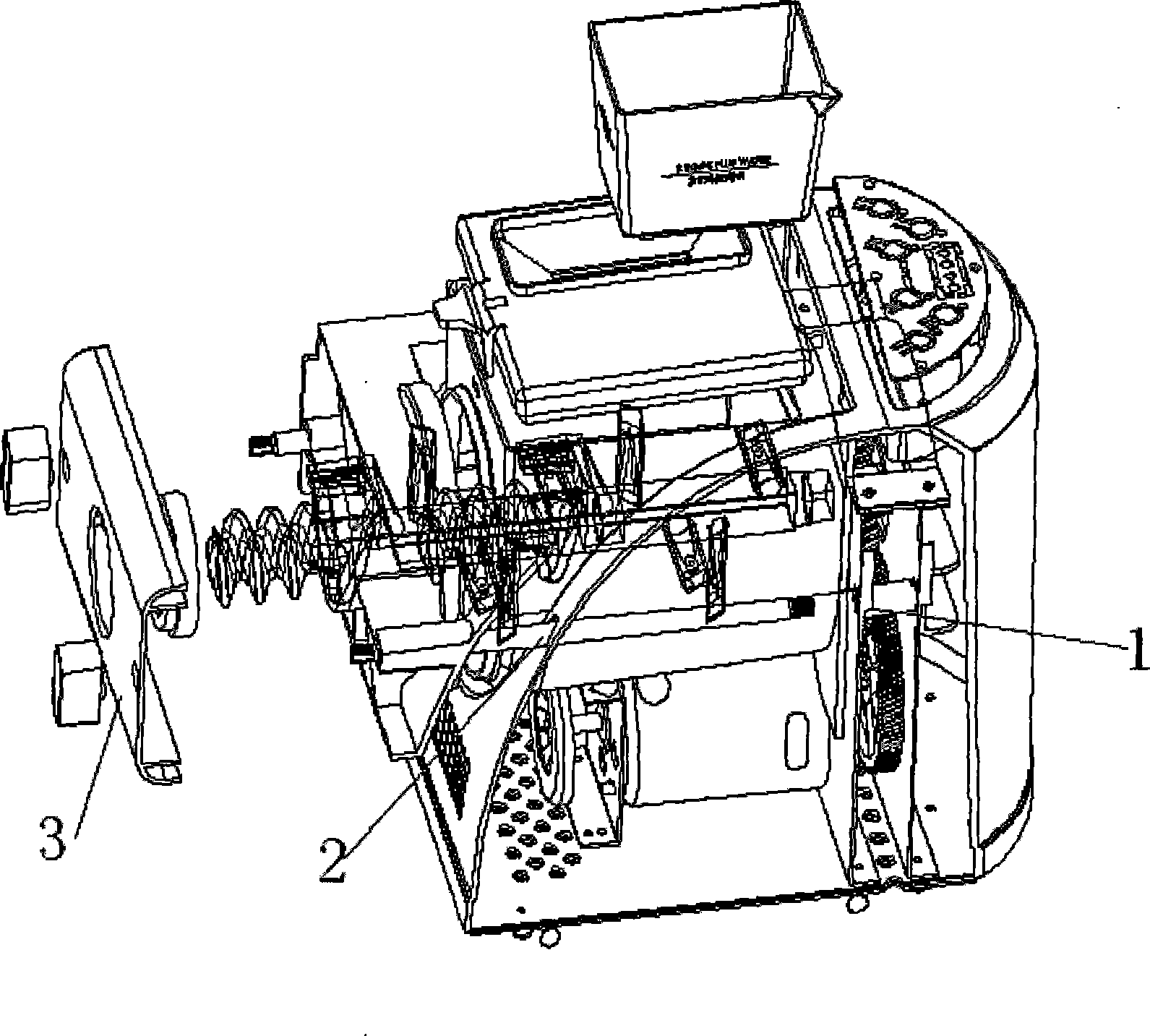

InactiveCN102934953AEven by forceThe noodles are chewy and deliciousKitchen equipmentFood preparationEngineeringMechanical engineering

The invention discloses discloses a stirring, conveying and dough kneading shaft for a noodle machine. The stirring, conveying and dough kneading shaft is characterized by comprising a shaft body, wherein a section of the shaft body is a screw, a squeezing shaft is arranged at the front end of the screw, a stirring fingers are arranged on the other section, the stirring fingers are distributed on the shaft body in a staggering mode, and the stirring fingers are cylinders. According to the noodle machine, when water is added in flour (noodles), the finger-shaped stirring fingers is used for stirring, and the flour can be stirred into pasty or cotton-shaped small blocks. During forward rotation, by the aid of the scientific angle design, stirring is facilitated, and during reversal, all the flour can be conveyed into a flour pressing head properly and evenly. The noodle machine is decent and practical.

Owner:王玉霞

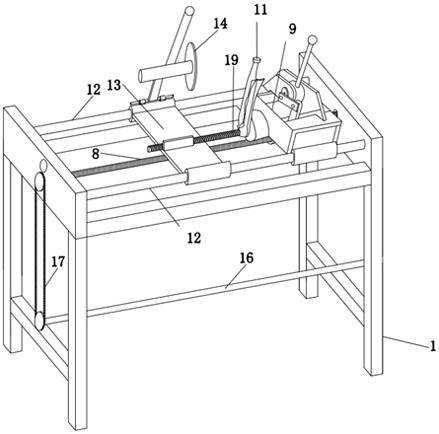

Multifunctional motorcycle part maintenance clamp

The invention discloses a multifunctional motorcycle part maintenance clamp which comprises an upper clamping head, a first clamping plate, a handle, a lower clamping head and a storage battery. The first clamping plate is installed on the outer wall of one side of the upper clamping head. A second clamping plate is installed on the outer wall of one side of the lower clamping head. The upper clamping head and the lower clamping head are installed on a movable piece through connecting pieces respectively. The outer wall of one side of the upper clamping head and the outer wall of one side of the lower clamping head are each provided with an illumination lamp. The handle is installed on the outer wall of the movable piece through a connecting rod. The upper clamping head and the lower clamping head are connected with the handle through springs respectively. The storage battery is installed on the inner wall of the upper clamping head. An electromagnet is installed on the inner wall of one side of the upper clamping head. An electric push rod is installed in the first clamping plate. By arranging cutting sawteeth, the clamp has a function of clamping and also has a function of shearing, and functions are powerful.

Owner:ANXI XIANCAI TEA MACHINERY CO LTD

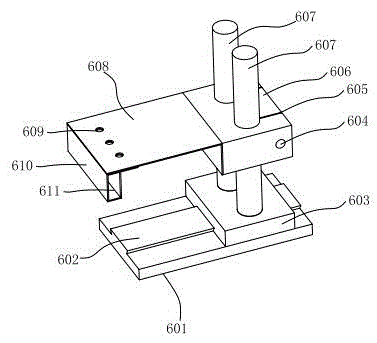

Mechanical part clamping equipment with cutting function

The invention discloses mechanical part clamping equipment with a cutting function. The mechanical part clamping equipment comprises a base and a cutting device. The cutting device is located on the side face of the base, and the top of the base is provided with a first supporting table, a second supporting table and a driving mechanism. The first supporting table is provided with a blind hole and a threaded rod, and the threaded rod penetrates in the blind hole. The second supporting table is provided with a through hole and a threaded rod, and the threaded rod penetrates in the through hole. A driving shaft of the driving mechanism is connected with the second supporting table. The top of the base is further provided with a sliding groove. A connection block is arranged in the sliding groove and connected with the second supporting table. The side face of the base is further provided with a dividing rule. The mechanical part clamping equipment not only can clamp hook-face cylindrical workpieces, but also can clamp plane type workpieces, and meets the clamping and cutting requirements of cylindrical workpieces with different diameters and different lengths. An operator can accurately determine a cutting point through the dividing rule arranged on the base, and cutting precision for the workpieces can be improved.

Owner:LUZHOU YUANCHENG ENG MACHINERY CO LTD

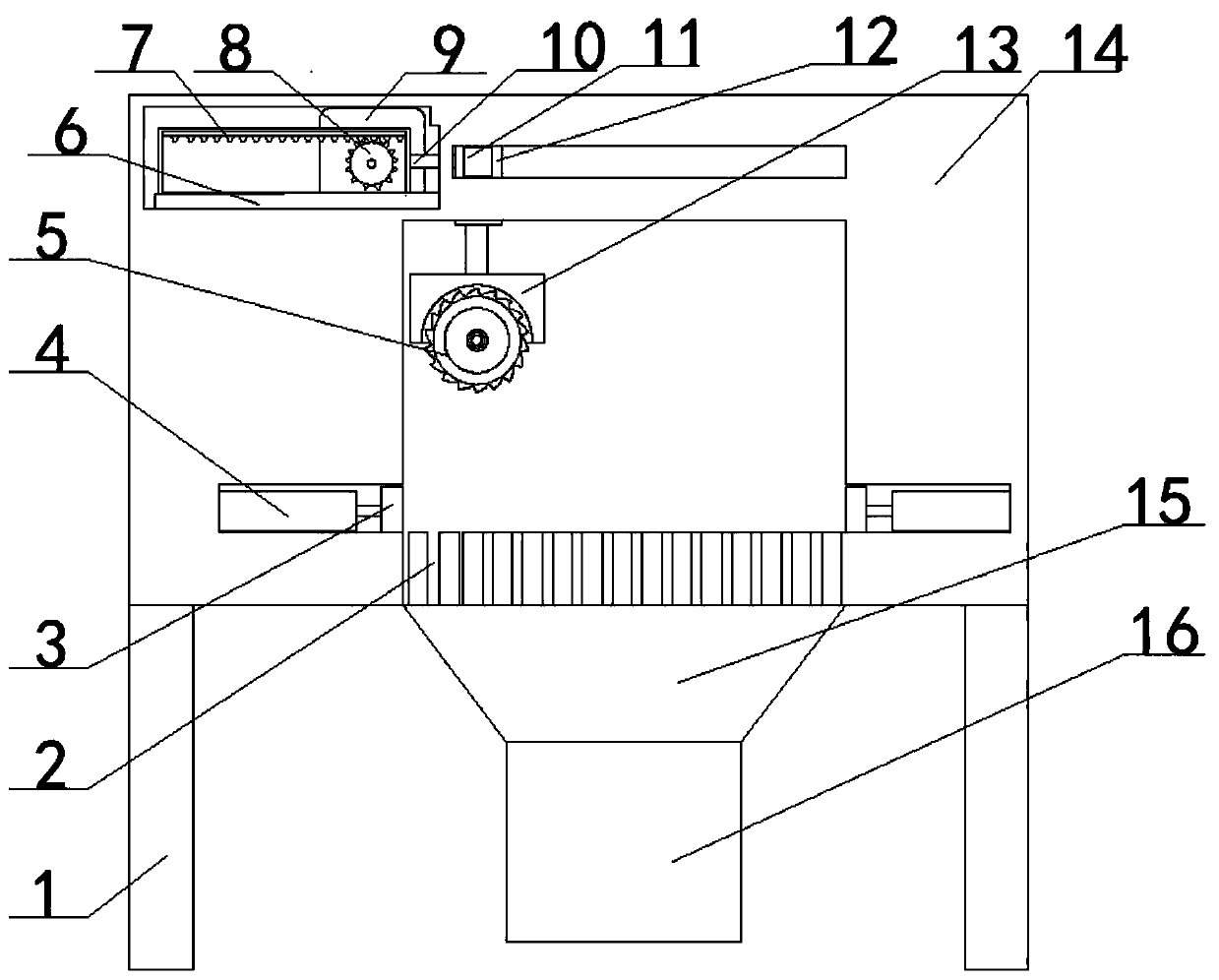

Metal processing device with cutting and recycling functions

InactiveCN110814809AWith cutting functionWith recycling functionMetal sawing devicesMetal sawing accessoriesNonferrous metalGear wheel

The invention relates to the technical field of nonferrous metal processing, and discloses a metal processing device with cutting and recycling functions. The metal processing device comprises a supporting column, wherein a box body is fixedly connected to the top of the supporting column; a cutting table is fixedly connected to the inner wall of the box body; a dust suction cover is fixedly connected to the bottom of the cutting table; and a recycling box is fixedly connected to the bottom of the dust suction cover. According to the metal processing device with the cutting and recycling functions, metal is placed on the cutting table, then a first electric telescopic rod pushes a fixing block to fix the metal, a second electric telescopic rod pushes a cutting disc to be in contact with the metal, then the cutting disc rotates, a motor rotates to drive a gear to rotate, the gear rotates to drive a support to move rightwards, the support moves rightwards to drive a connecting rod to move rightwards, the connecting rod moves rightwards to push the second electric telescopic rod to move rightwards, the second electric telescopic rod moves rightwards to drive the cutting disc to move rightwards, and therefore the metal with different sizes can be cut, and the waste of factory funds is reduced.

Owner:湖南华耀环保科技有限公司

Punching equipment suitable for storage battery grid

ActiveCN114042803AWith cutting functionImprove punching effectPerforating toolsMetal-working feeding devicesPunchingElectric machinery

The invention discloses punching equipment suitable for a storage battery grid. The punching equipment comprises an operation table, a punching assembly and a limiting assembly. Supporting plates are fixedly connected to the top of the operation table, a transverse plate is fixedly connected to the tops of the two supporting plates, a punching assembly is installed at the bottom of the transverse plate and comprises a built-in plate, a stamping die and a hydraulic air cylinder, the built-in plate is connected to a first lead screw in a sleeving mode, and the first lead screw is connected into the transverse plate in a sleeving mode and rotatably connected with the transverse plate. A first motor is installed at the right end of the first lead screw, the built-in plate is in sliding connection with the transverse plate, a hydraulic air cylinder is fixedly connected to the bottom of the built-in plate, a stamping die is installed on the hydraulic air cylinder through a connecting plate, a recycling box is installed at the bottom of the stamping die, and the bottom of the recycling box is clamped to the operation table. The limiting assembly is installed on the top of the operation table. According to the punching equipment, the limiting range can be adjusted, the cutting function is achieved, and the punching effect is good.

Owner:小洋电源股份有限公司

Novel high-corrosion-resistance lid maker die material equipment

InactiveCN109226884ASimple structureEasy to useMetal sawing devicesFeeding apparatusControl engineeringCorrosion

The invention provides novel high-corrosion-resistance lid maker die material equipment. The equipment comprises a machine body, wherein the inner portion of the machine body is provided with a motor,the right side of the motor is provided with a first installation groove located in the machine body, the first installation groove is provided with a first steering shaft rotationally cooperating with the bottoms of the left and right end walls of the first installation groove, the stretching portion of the left end of the first steering shaft is in power connection with the motor, the left endof the first steering shaft is fixedly and cooperatively connected with a first tooth wheel, the right side of the first installation groove is provided with a communicated first communication cavity,a second steering shaft is rotationally and cooperatively connected between the first communication cavity and the first installation groove, and the second steering shaft of the first installation groove is fixedly and cooperatively connected with a second tooth wheel cooperatively connected with the first tooth wheel.

Owner:佛山腾谱工业设计有限公司

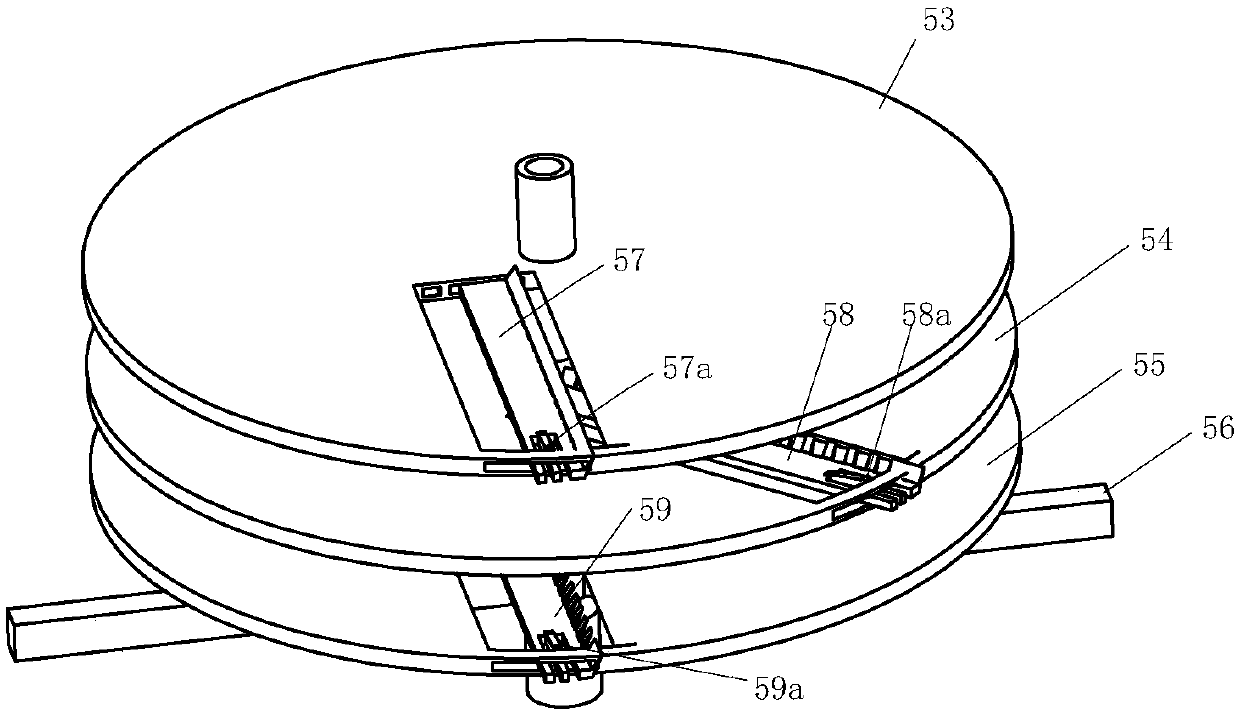

Field online replacing tool and method for wind power main shaft sealing ring

The invention discloses a field online replacing tool and method for a wind power main shaft sealing ring. The field online replacing tool comprises a positioning block and a plurality of pressing blocks, wherein the positioning block is used for positioning the sealing ring; the pressing blocks are opposite to the positioning block and are used for pressing the sealing ring; the pressing blocks are detachably fixed to the positioning block, and the sealing ring is positioned between the pressing blocks and the positioning block. The field online replacing tool has the beneficial effects thatclamping of the sealing ring can be quickly accomplished through the tool, field cut-off and field connecting and fixing of the sealing ring can be realized, cutting convenience of the sealing ring can be guaranteed, field connecting and fixing of the sealing ring is convenient, cut aligning during viscose connecting after the cut sealing ring sleeves the main shaft can be guaranteed, a cutting surface lip is precisely in butt joint, bonding strength, sealing performance and service life of the sealing ring are effectively guaranteed, and labor intensity and operation difficulty of a worker are relieved.

Owner:ZHEJIANG WINDEY

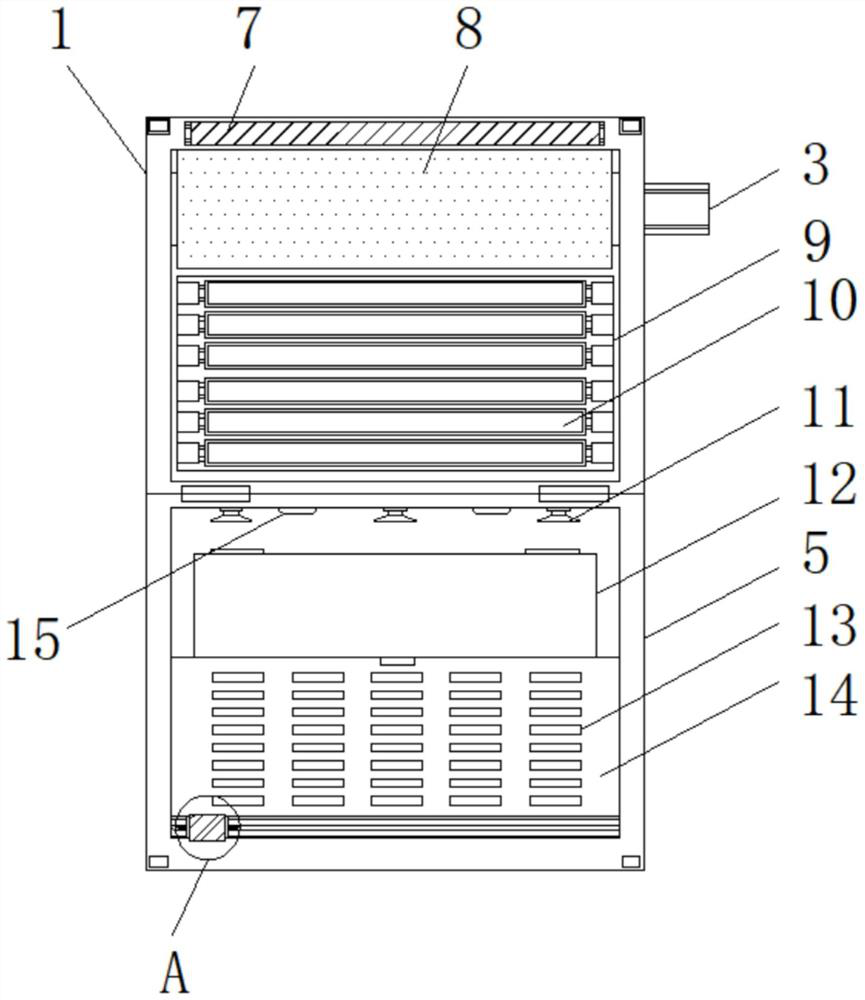

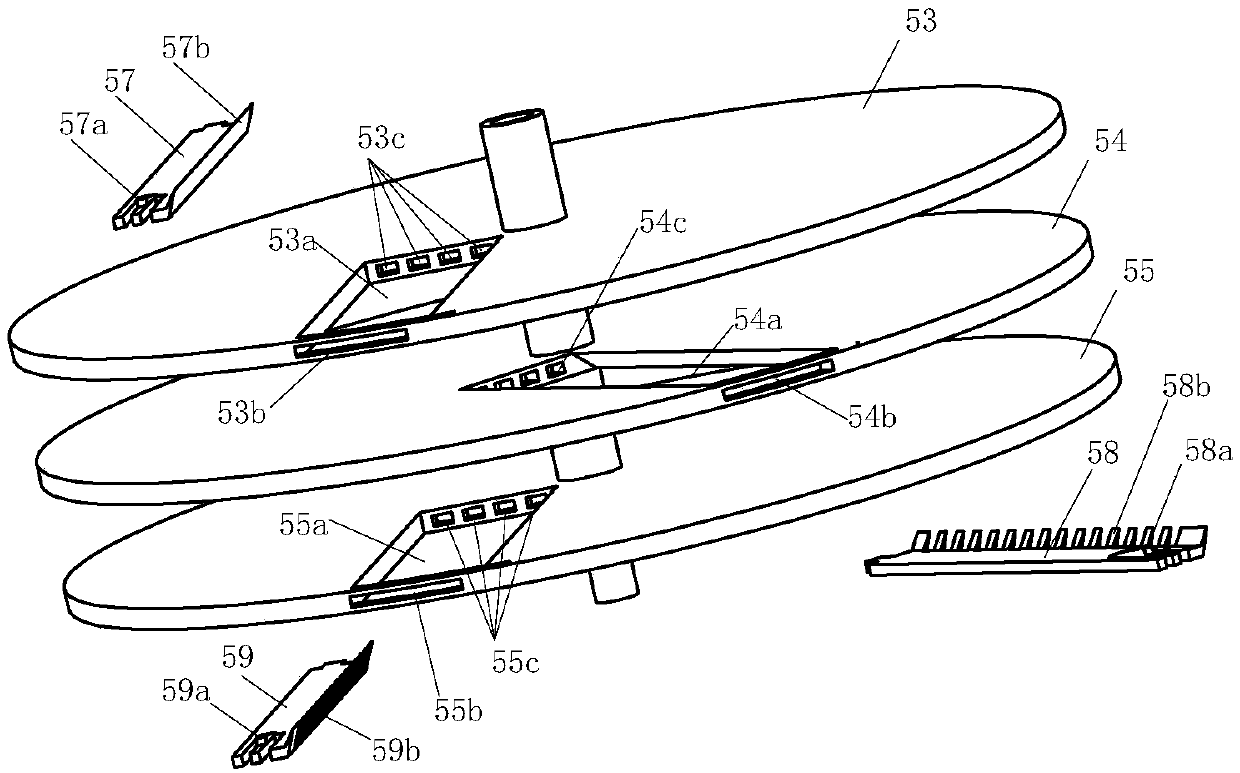

Filter element skeleton welding machine

PendingCN111805240AImprove roundnessSimple structureOther manufacturing equipments/toolsElectric machineryEngineering

The invention belongs to the technical field of filter element skeleton welding, and particularly relates to a filter element skeleton welding machine. The filter element skeleton welding machine comprises a rack, a driving motor and a supporting bar wire-feeding shaft, wherein the supporting bar wire-feeding shaft is provided with a plurality of supporting bar wire-feeding through holes in an array way at equal intervals according to the same center of a circle; a rotary disk is installed to the supporting bar wire-feeding shaft in a sleeving mode and can rotate relative to the supporting barwire-feeding shaft; the rotary disk is driven through the driving motor to rotate by taking the supporting bar wire-feeding shaft as the center of the circle; the rotary disk is fixedly provided witha seam welder and a wire winding material disk; the rack is provided with a regulation lead screw; the regulation lead screw is in driving connection with the driving motor; the regulation lead screwis cooperatively connected with a sliding seat; the sliding seat is provided with a skeleton perforation; the skeleton perforation is used for a filter element skeleton to penetrate; one end of the skeleton perforation is provided with locking pliers; and the locking pliers are used for clamping the filter element skeleton. The filter element skeleton welding machine has a simple structure and has a low production cost, and in addition, the roundness of the filter element skeleton can be improved. In addition, the filter element skeleton welding machine has a cutting function and can cut thefilter element skeleton of a required length according to requirements.

Owner:安平县燕赵矿筛网业有限公司

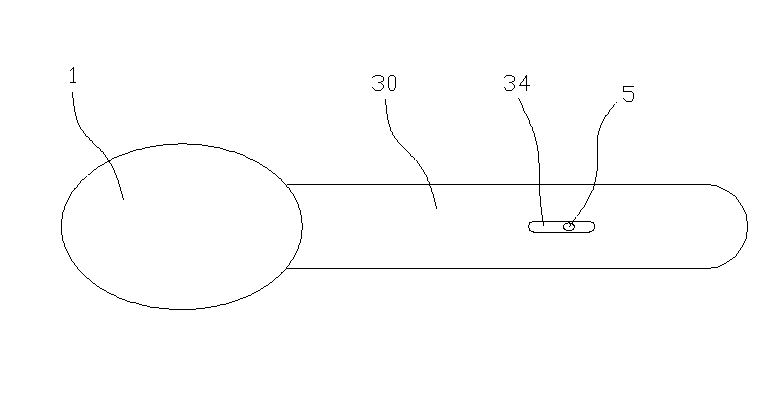

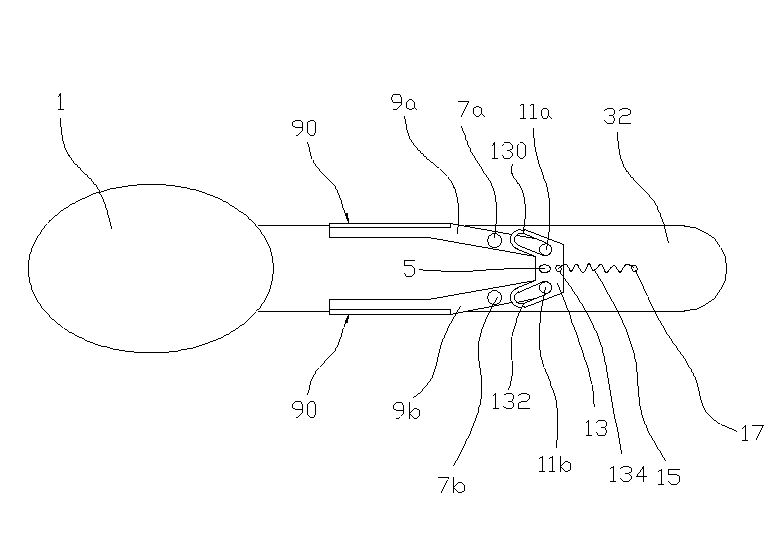

Spoon with cutting function

InactiveCN102302310BNot easy to touchWith cutting functionKitchen equipmentTablewaresEngineeringMechanical engineering

The invention discloses a spoon with a cutting function, which comprises a spoon body and a spoon handle, wherein the spoon handle is connected with the spoon body; the spoon handle is formed by splicing an upper cover and a lower cover, the lower cover is provided with a left pivot shaft and a right pivot shaft, a left rotating arm and a right rotating arm are respectively sleeved on the left pivot shaft and the right pivot shaft by through holes respectively formed on the left rotating arm and the right rotating arm, and the ends of the left rotating arm and the right rotating arm are respectively provided with a left pin shaft and a right pin shaft; the lower cover is also movably provided with a slide block, and the slide block is provided with a left through slot and a right through slot; the slide block is also provided with an elastic assembly; the left rotating arm and the right rotating arm are respectively provided with a sharp cutting edge; the upper cover is provided with a first through slot; a pulling block is arranged above the slide block; and the pulling block is arranged in the first through slot, and part of the pulling block is exposed above the first through slot. The spoon disclosed by the invention has a cutting function, and can be used for cutting fruits, tearing preservative films, and the like; and when the sharp cutting edge of the spoon is not operated, the sharp cutting edge can not be touched easily by a hand, therefore, the spoon is safe in use.

Owner:陈浩

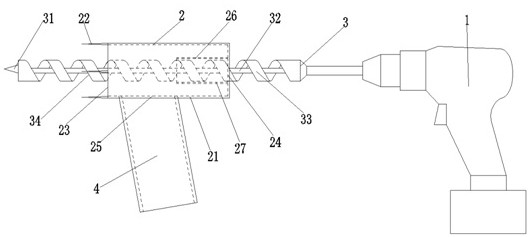

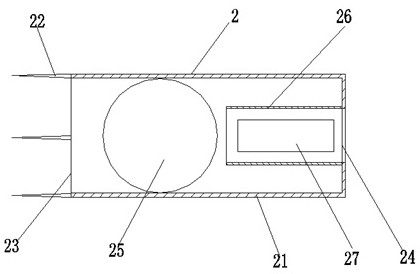

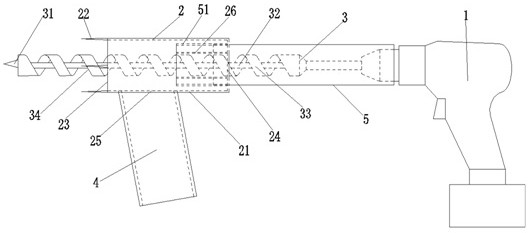

Hay sampling device

The invention discloses a hay sampling device which comprises an electric drill, a sampling barrel and a drill rod, the drill rod is detachably arranged on the electric drill, and the electric drill can drive the drill rod to rotate; the drill rod comprises a tip part, a shaft rod and a spiral conveying part, the tip part is arranged at one end of the shaft rod, the spiral conveying part spirally extends in the axial direction of the shaft rod, the sampling barrel comprises a barrel body and a plurality of fixing sharp feet, a first opening, a second opening and a discharging port are formed in the barrel body, and the fixing sharp feet are arranged on the first opening side of the barrel body; the drill rod tip part, the shaft rod and the spiral conveying part can penetrate through the barrel and the first opening through the second opening, the second opening is connected with the guide sleeve, and the guide sleeve is arranged in the barrel. The hay sampling device is high in sampling speed and large in single sampling amount, hay samples are easy to collect and not prone to leaking and scattering, and operation is easy and convenient.

Owner:河北省畜牧兽医研究所

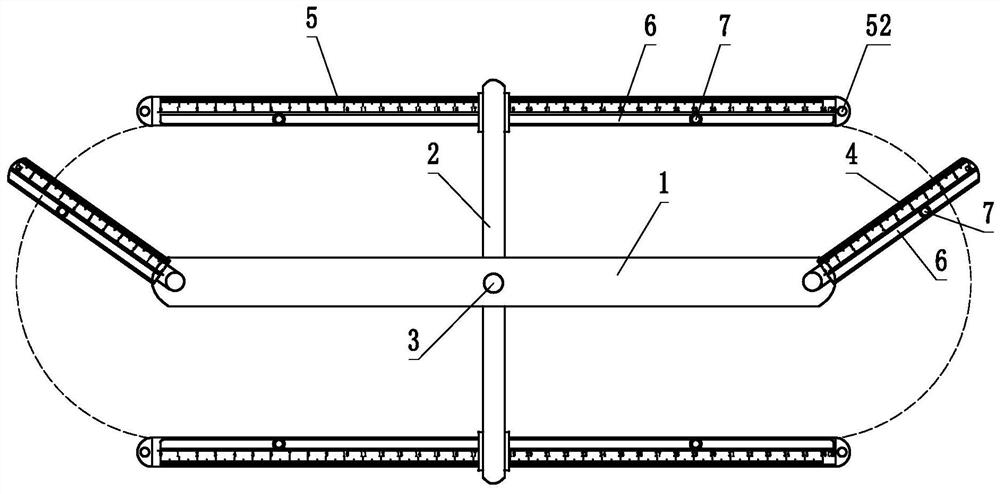

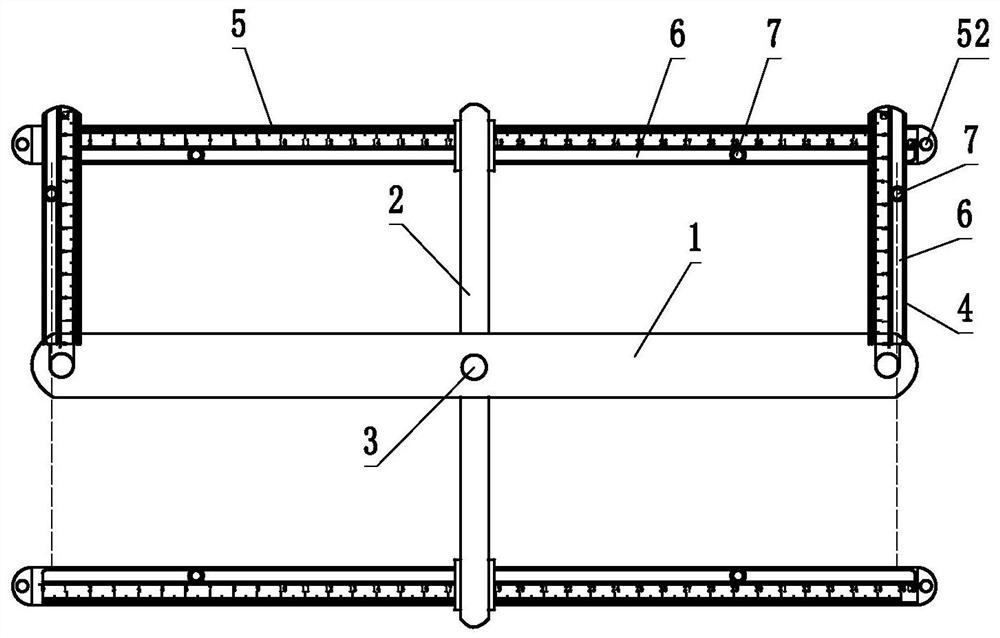

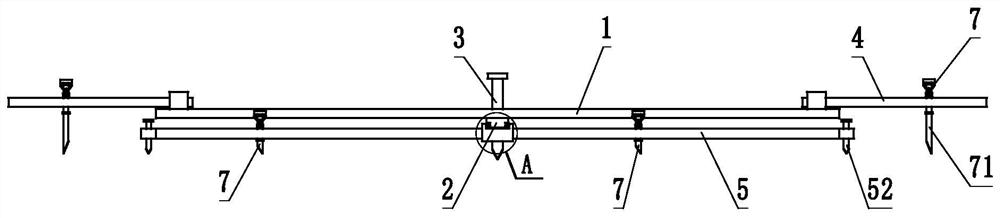

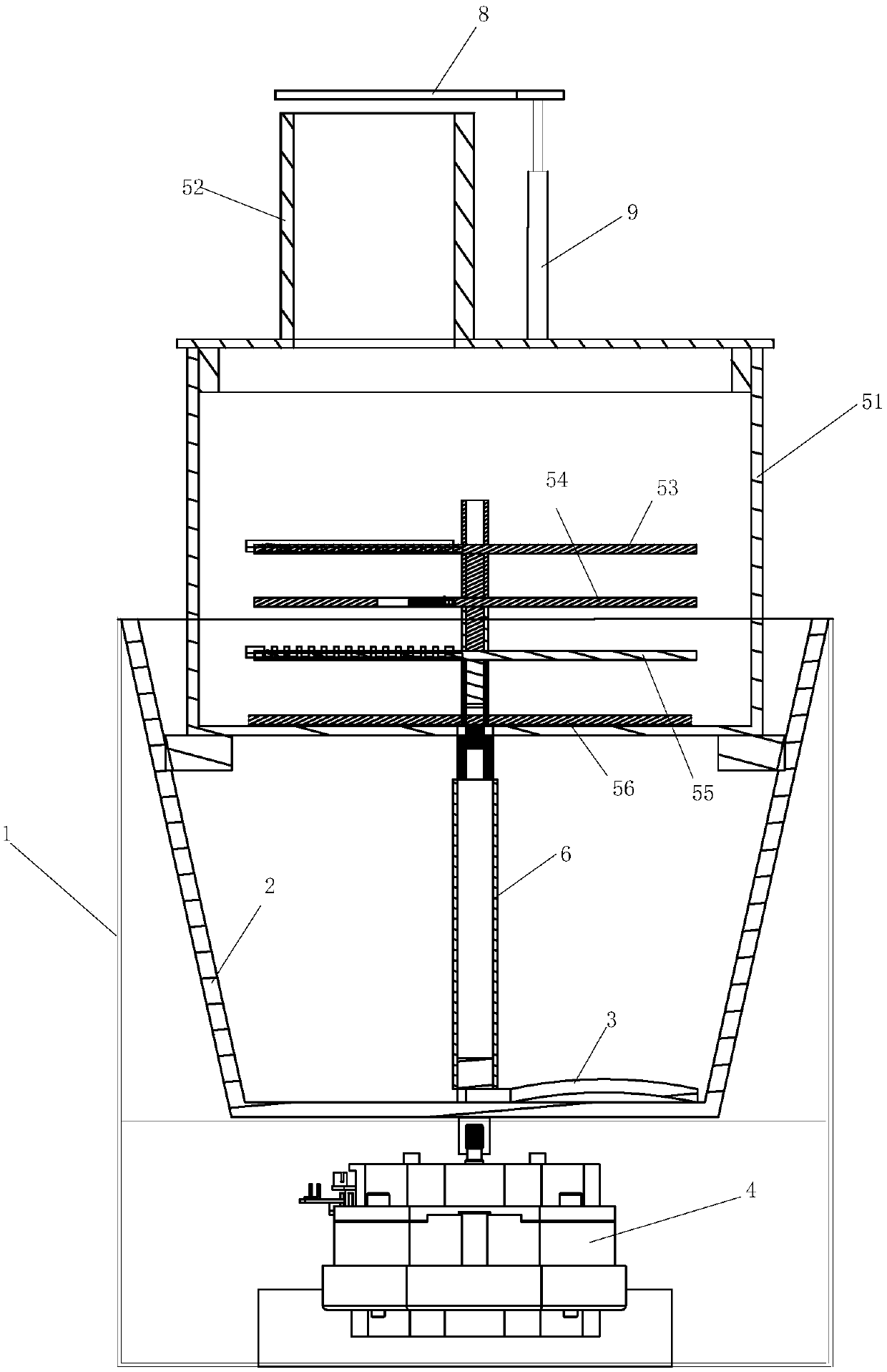

Special cutting tool for transformer oil-resistant sealing ring

The invention discloses a special cutting tool for a transformer oil-resistant sealing ring. The special cutting tool comprises a framework, the framework comprises a transverse framework and at leastone longitudinal framework fixed with the transverse framework in a crossed manner; a positioning needle A is arranged at a crossed fixing point of the transverse framework and the longitudinal framework and / or the central point of the transverse framework; measuring arms A are hinged to the two ends of the transverse framework respectively and can rotate relative to the transverse framework witha hinge point as the circle center; the two ends of the longitudinal framework are each provided with at least one group of measuring arms B, and the measuring arms B can reciprocate in the length direction of the longitudinal framework; the measuring arms A and the measuring arms B are provided with scales and rails in the length direction of the measuring arms A and the measuring arms B respectively; and the rails penetrate through the measuring arms, at least one group of cutting knife assemblies are arranged in the rails, each cutting knife assembly comprises a cutting knife and a lockingpiece, and the locking pieces can fix the cutting knives to the rails. The cutting efficiency and precision of the transformer oil-resistant sealing ring can be improved through the cutting tool.

Owner:KUYTUN POWER SUPPLYING CO STATE GRID XINJIANG ELECTRIC POWER CO

Food processer with cutting and matching function

The invention relates to a food processer with a cutting and matching function. The food processer includes a machine body, an opening pot body which is arranged at the top in the machine body, a stirring assembly which is arranged in the pot body, a driving motor which is arranged in the machine body, connected with the stirring assembly and used for driving the stirring assembly to rotate, a cutting and matching assembly can be arranged in the pot body and above the stirring assembly, and a cutting and matching driving mechanism which is communicated with the cutting and matching assembly and drives the cutting and matching assembly to rotate, wherein the cutting and matching assembly comprises a cutting and matching shell, a first cutter head, a second cutter head and a third cutter head which are sequentially arranged in the cutting and matching shell up and down at intervals, and a first blade, a second blade and a third blade which are respectively arranged on the first cutter head, the second cutter head and the third cutter head. Compared with the prior art, the food processer with a cutting and matching function has the advantages that three different cutting and matchingprocedures can be completed in sequence by arranging the three layers of cutter heads and the paired blades.

Owner:NINGBO FOTILE KITCHEN WARE CO LTD

Automatic Continuous Bag Type Modified Atmosphere Packaging Machine

ActiveCN104192343BIncrease replacement rateIncrease profitPackaging by pressurising/gasifyingModified atmosphereAir conditioning

The invention relates to a fully-automatic continuous bag type modified atmosphere packaging machine. The packaging machine comprises a machine frame, wherein a feeding chain is arranged on the machine frame, a set of air pipe connectors and a set of air pipe fixing devices are arranged on the machine frame symmetrical about the feeding chain, gas replacement mechanisms are installed on the air pipe fixing devices respectively, one end of each gas replacement mechanism is communicated with the corresponding air pipe connector, and the other end of each gas replacement mechanism extends into a packaging cavity. The packaging machine is simple in structure and quick and convenient to install, movement of the gas replacement mechanisms in the left-right directions, up-down directions and front-back directions can be effectively achieved due to the arrangement of the air pipe fixing devices, so that modified atmosphere packaging requirements of different products are met, and adjustment is flexible, quick and convenient. Due to the arrangement of the air pipe connectors, inflation of an inflation pipe and exhaust of an exhaust pipe can be achieved at the same time, and in this way, replacement speed of gas in the packaging cavity is high, the replacement rate is high, and gas mixing precision is high.

Owner:JIANGNAN UNIV

Screw-rod-driven sugarcane harvesting planter

InactiveCN108094108AWith plantingWith defoliationSugarcane cultivationHarvestersHome usePulp and paper industry

Disclosed is a screw-rod-driven sugarcane harvesting planter. The planter comprises a planting piece, a guide rod, a supporting screw rod, a leaf removing mechanism and a cutting piece, the guide rodis installed on the planting piece, and the support screw rod is rotatably installed on the planting piece; the leaf removing mechanism comprises a first leaf removing piece, a second leaf removing piece and an adjustment rod connecting two leaf removing pieces, the second leaf removing piece is located between the first leaf removing piece and the planting piece, the first leaf removing piece andthe second leaf removing piece both comprise driving nuts, outer-side fixing rings and a plurality of leaf removing blades, the driving nuts sleeve the support screw rod, the outer-side fixing ringssleeve the driving nuts, the two ends of each leaf removing blade are connected with the corresponding driving nut and the corresponding outer-side fixing ring respectively, and an operation adjustingrod can make the second leaf removing piece rotate relative to the first leaf removing piece; the cutting piece comprises a mounting frame and a cutter, the mounting frame is installed on the planting piece, and the cutter is movably installed on the mounting frame. The screw-rod-driven sugarcane harvesting planter is suitable for home use and has the functions of sugarcane planting, leave removing and cutting at the same time.

Owner:柳州吉辉机械设计有限公司

Device for cutting coils

The invention relates to a device for cutting coils. The device comprises a box shell, a motor is arranged inside the box shell, a first containing groove located in the box shell is formed in the right side of the motor and provided with a first rotating pin shaft rotatably matched with the bottoms of the left and right end walls, the extending part of the left end of the first rotating pin shaftis in power connection with the motor, a first tooth-shaped wheel is fixedly and cooperatively connected to the left end of the first rotating pin shaft of the first containing groove, a first through cavity is communicated with the right side of the first containing groove, a second rotating pin shaft is rotatably and cooperatively connected between the first through cavity and the first containing groove, and the second rotating pin shaft of the first containing groove is fixedly and cooperatively connected with a second tooth-shaped wheel cooperatively connected with the first tooth-shapedwheel.

Owner:广州俊天科技有限公司

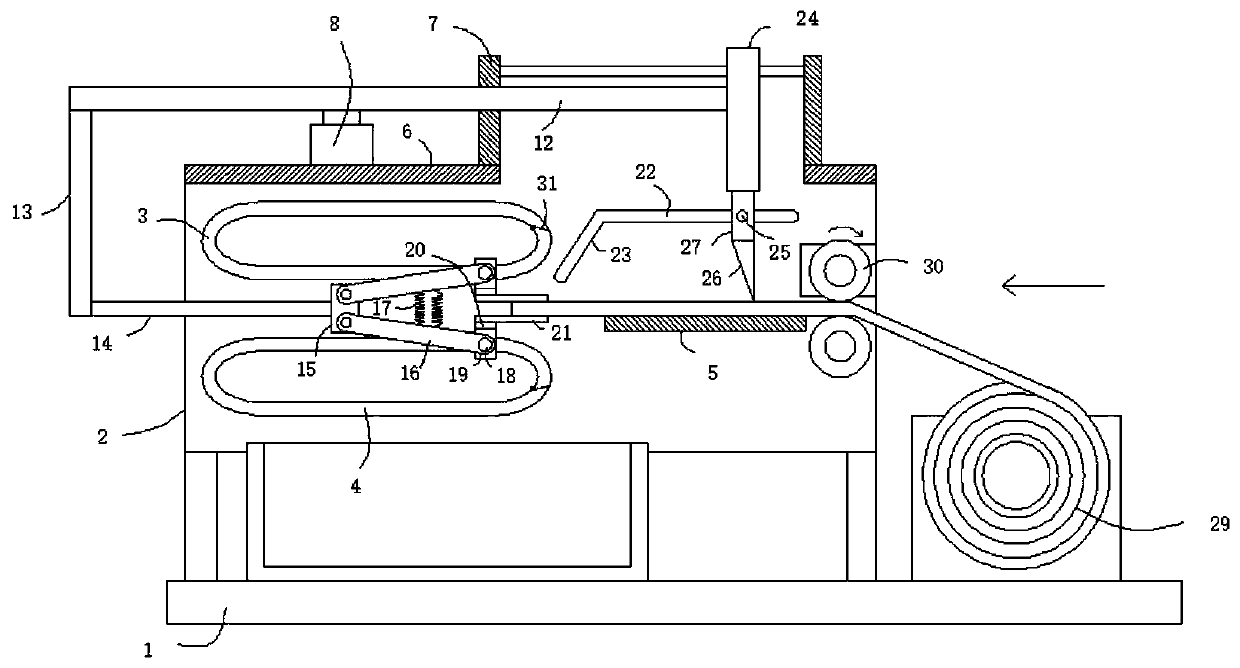

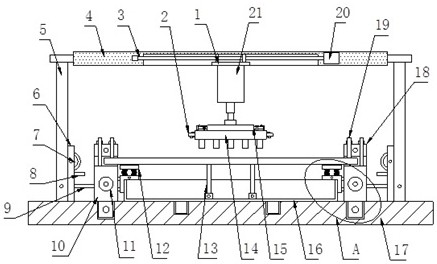

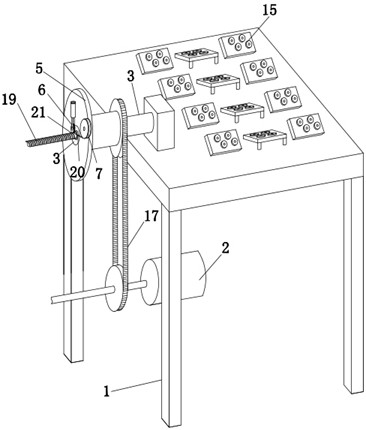

An intelligent screen printing machine with cutting function

ActiveCN107175892BWith cutting functionReduce demandScreen printersMetal working apparatusScreen printingDrive wheel

The invention relates to an intelligent silk printing machine with a good cutting effect. The intelligent silk printing machine comprises a main body, a printing device, a printing forme device and a printing bearing device. The main body further comprises a cutting device and a storage device. The printing bearing device comprises a first motor, a drive wheel, a driven wheel and a belt. The cutting device comprises a second motor, a lead screw, a sliding rod, a sliding block, a fulcrum bar, a cutter and a limiting groove. The storage device comprises a first air cylinder and a compaction mechanism. According to the intelligent silk printing machine with the good cutting effect, the cutting device further comprises a limiting function, when the cutter cuts a carton, the cutting device can limit the carton at the same time, the part making contact with the cutter is prevented from sinking downwards, the carton is cut completely, the cutting effect is improved, and the production efficiency is improved; and in addition, the storage device further comprises a compaction mechanism, when cartons are put into a storage box, the compaction mechanism can compact cartons one by one, the space of the storage box is utilized to the maximum extent, the demand number of storage boxes is reduced, and the production cost is reduced for an enterprise.

Owner:GUANGZHOU FENGSHANG ELECTRIC APPLIANCE

Safe garbage crushing primary selection mechanism

The invention provides a safe garbage crushing primary selection mechanism. The safe garbage crushing primary selection mechanism comprises a box body, wherein a driving machine is arranged in the boxbody, a first mounting groove located in the box body is arranged on the right side of the driving machine, the first mounting groove is provided with a first rotating shaft being in rotating fit with the bottoms of the left end wall and the right end wall, and the left end extension of the first rotating shaft is in power connection with the driving machine; the left end of the first rotating shaft of the first mounting groove is connected with a first toothed wheel in a fixed fit manner; a communicating first through cavity is arranged on the right side of the first mounting groove; a second rotating shaft is connected between the first through cavity and the first mounting groove in a rotating fit manner; and the second rotating shaft of the first mounting groove is in fixed cooperation connection with a second toothed gear which is matched and connected with the first toothed wheel.

Owner:广州国创科技有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com