Pneumatic stretching mould

A technology of drawing dies and cylinders, which is applied in the field of stamping machines, can solve problems such as high working intensity, inconvenient disassembly and installation, and inability to continue processing, and achieve the effects of improving processing efficiency, convenient installation and disassembly, and reducing labor intensity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] The present invention will be further described below in conjunction with accompanying drawing description and specific embodiment:

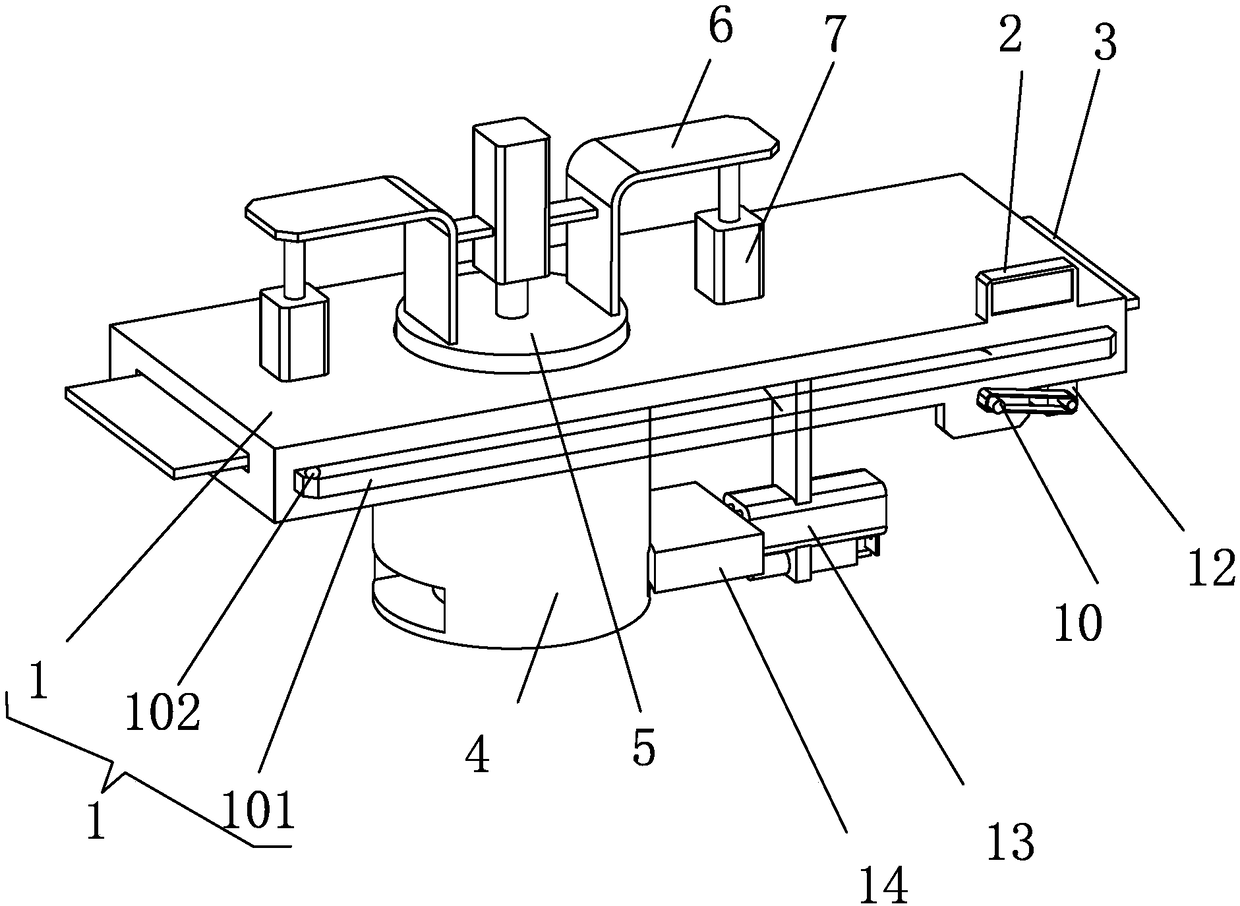

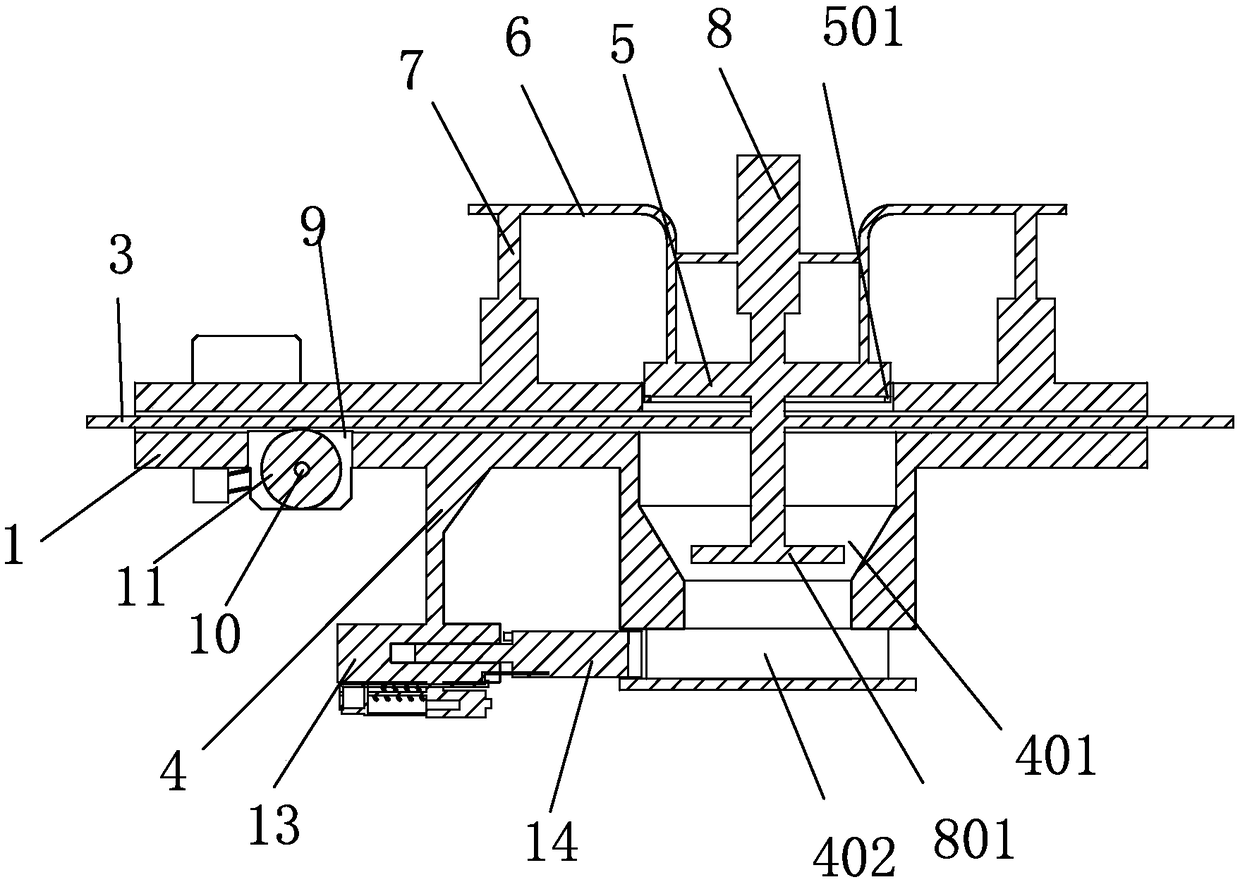

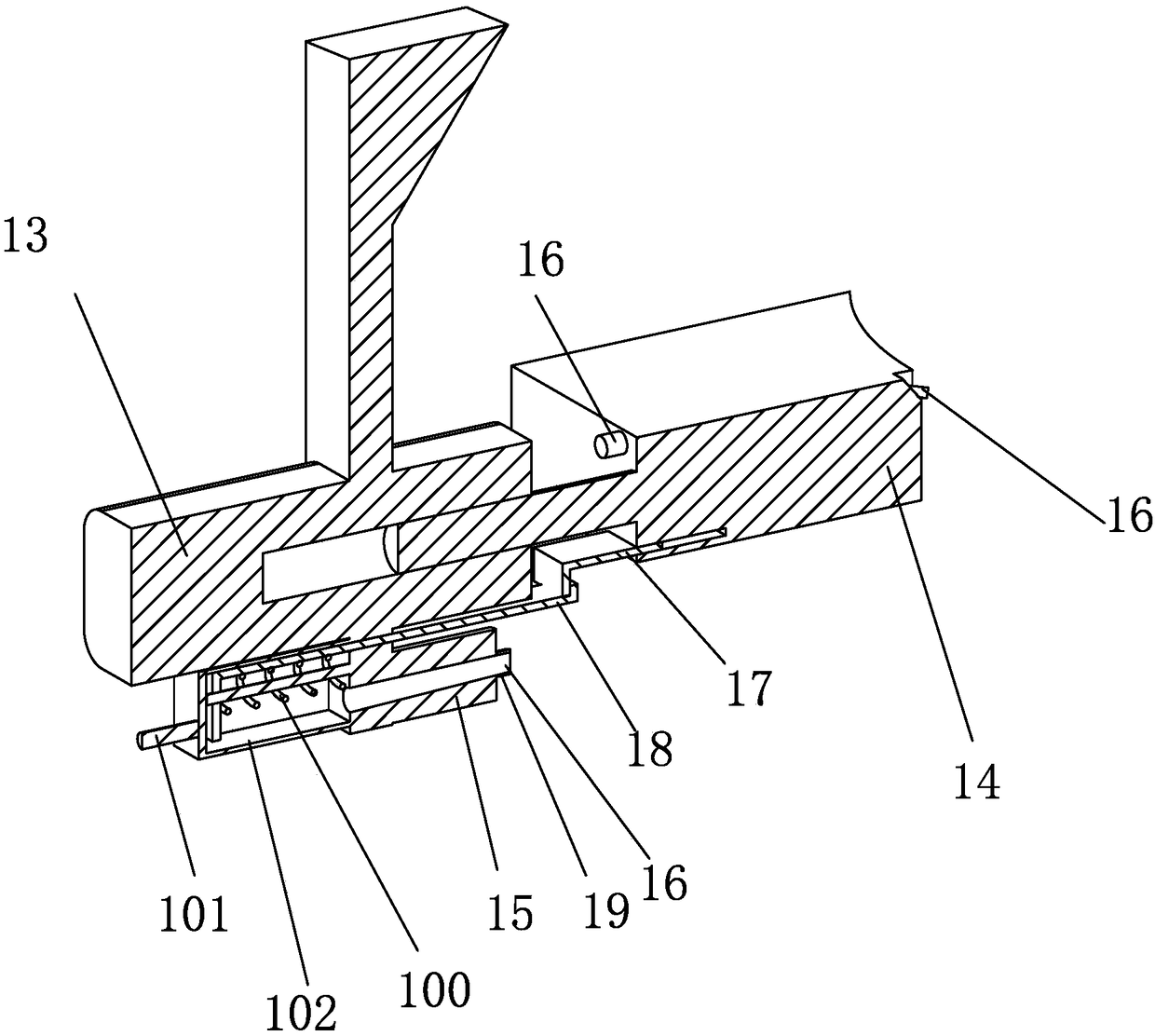

[0018] Such as Figures 1 to 3 A kind of pneumatic drawing die shown, comprises material base 1, is characterized in that the upper surface of described material base 1 is equipped with PLC controller 2, and the input end of described PLC controller 2 is electrically connected with the output end of external power supply , the middle part of the material base 1 is provided with a material cavity in the horizontal direction, the aluminum plate 3 is arranged in the material cavity, the lower surface of the material base 1 is provided with a mold base 4, and the upper surface of the material base 1 and the mold base 4. A pressure opening is provided at the corresponding position, and a first pressure plate 5 is arranged inside the pressure opening. An annular pressure knife 501 is fixed on the edge of the lower surface of the first pressure ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com