High-safety vacuum packaging equipment for food

A vacuum packaging, high-safety technology, used in packaging, packaging machines, transportation and packaging, etc., can solve the problems of no fast cutting structure installed, inability to quickly cut packaging bags, and unsafe packaging of food hygiene.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

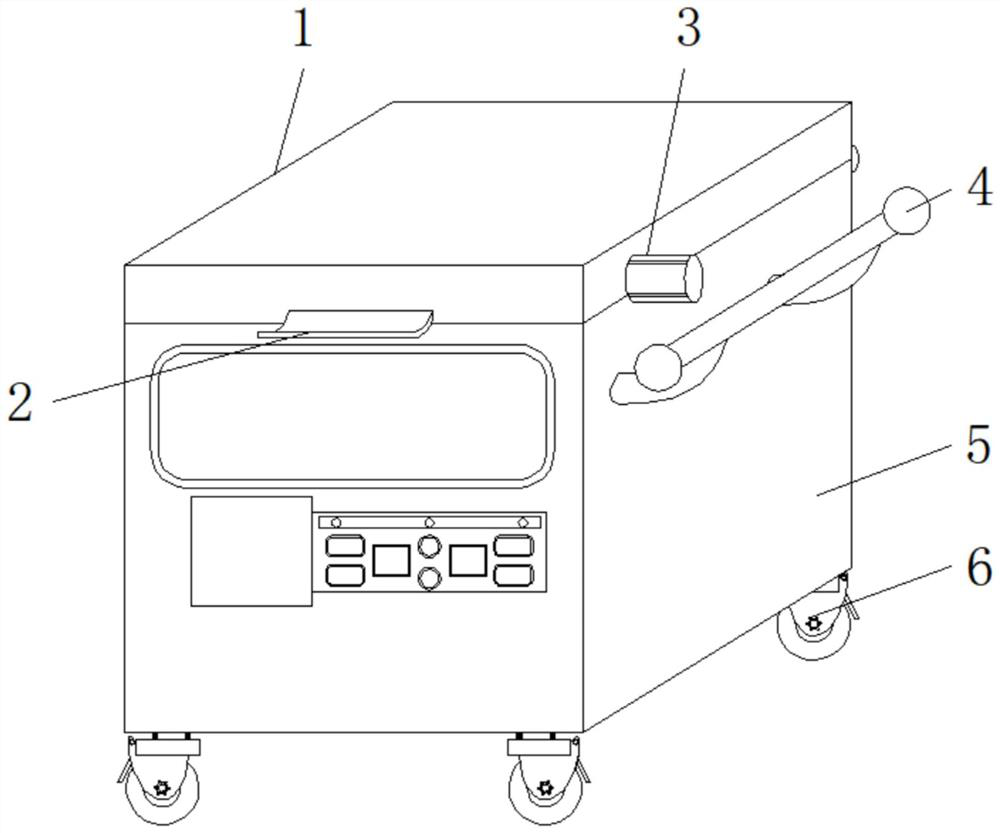

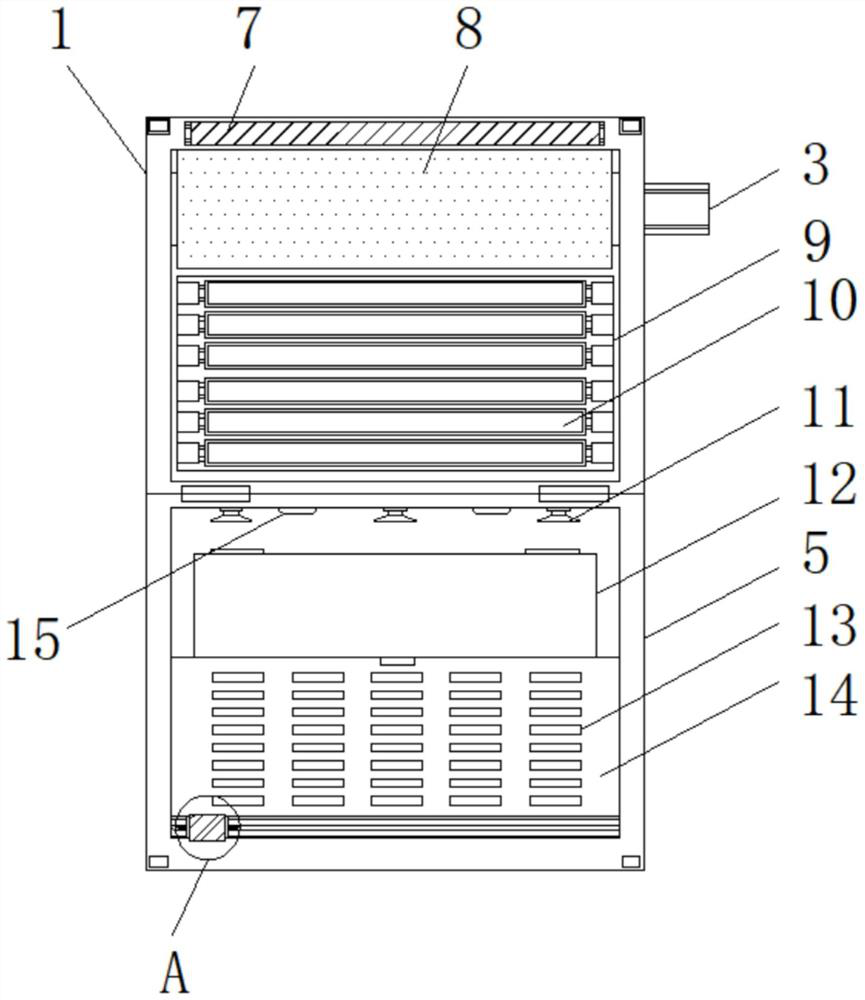

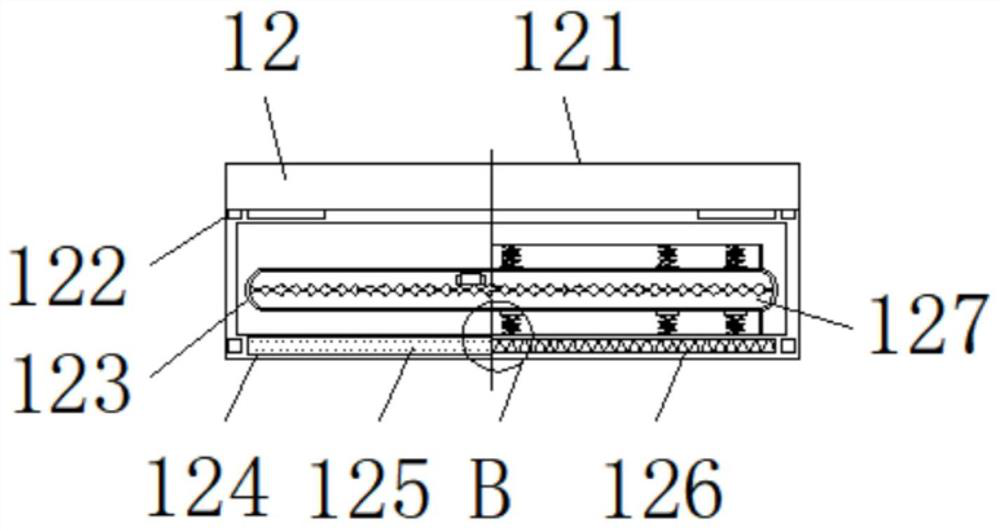

[0029] The technical solutions of the present invention will be further described below in conjunction with the accompanying drawings and through specific implementation methods.

[0030] Such as Figure 1-7As shown, the embodiment provides a high-safety vacuum packaging equipment for food, including a casing 5, a vacuum packaging mechanism 12 and an electric air pump 22, and the inside of the casing 5 is fixedly equipped with a vacuum packaging mechanism 12 , the vacuum packaging mechanism 12 is composed of a top cover 121, an installation shell 122, a heat conducting sheet 125 and a packaging bag corrugated splint 127. The top cover 121 is installed on the top of the installation shell 122 through a hinge, and the inside of the installation shell 122 A packaging bag protection groove 123 is opened, and a packaging bag corrugated splint 127 is installed movable inside the packaging bag protection groove 123, and a connecting spring 128 is fixedly installed at a position close...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com