Multifunctional composite cutter

A composite tool and multi-functional technology, which is applied in the direction of tools for lathes, drilling tool accessories, manufacturing tools, etc., can solve problems such as affecting machining accuracy and reducing work efficiency, and achieves high degree of combination, low cost, and wide availability. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

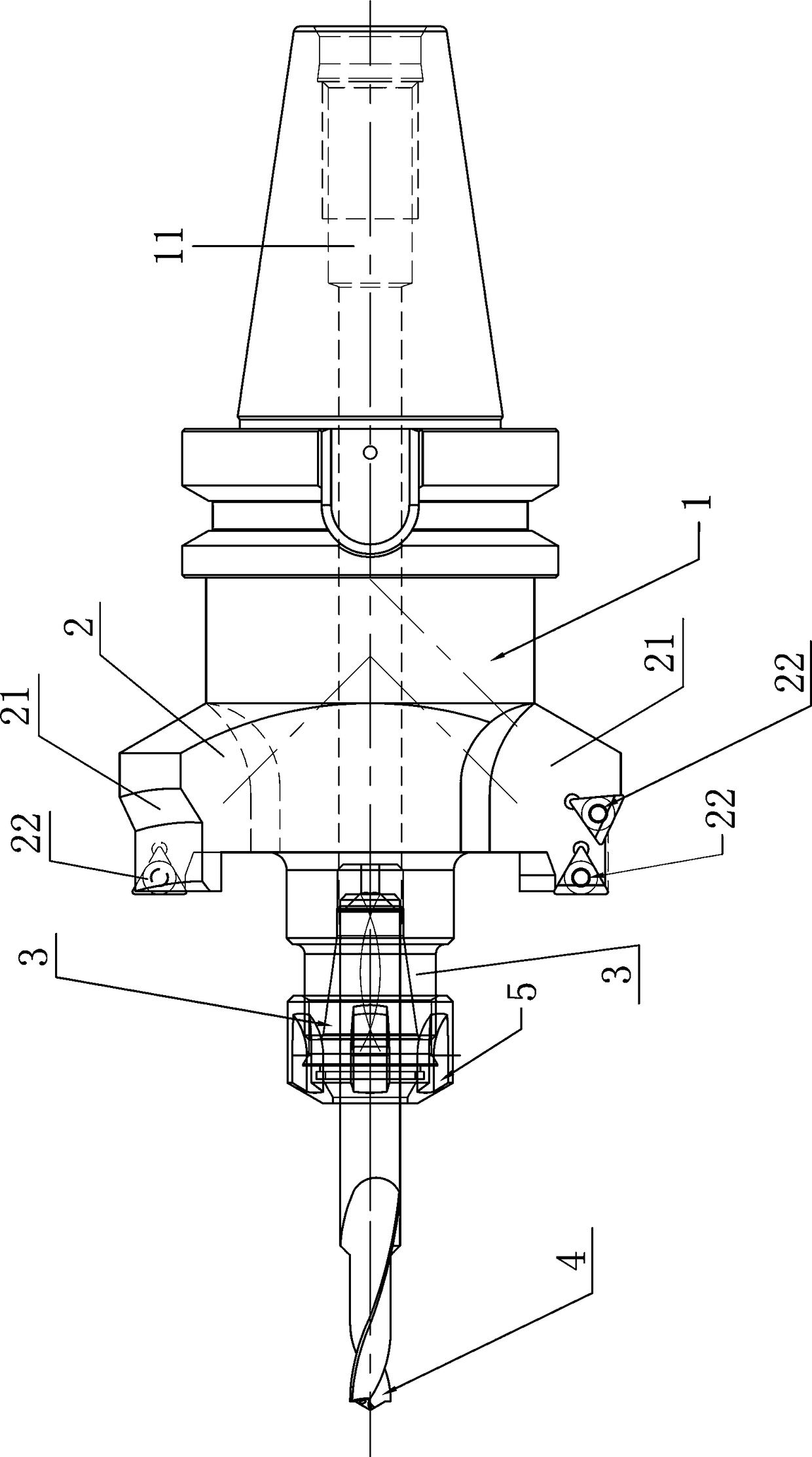

[0016] A multi-functional compound tool, including a tool handle 1, a cutting disc 2, a locking sleeve 3, a drill bit 4 and a fastening nut 5, such as figure 1 As shown, the specific structure is:

[0017] The rear end face of the cutting disc 2 is fixed on the front end face of the handle 1, the central axes of the cutting disc 2 and the handle 1 coincide with each other, and the outer edge of the front end face of the cutting disc 2 is provided with three cutting seats 21, each A cutting blade 22 is respectively fixed on the cutting seat 21;

[0018] There are three locking sleeves 3, the locking sleeves 3 are vertically fixed in the middle of the front end of the cutting disc 2 and the locking sleeves 3 are evenly distributed around the central axis of the cutting disc 2, and the outer surface of the front part of the locking sleeve 3 is tapped with external threads ;

[0019] The rear portion of the drill bit 4 is inserted between the lock sleeves 3, and the tightening n...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com