Field online replacing tool and method for wind power main shaft sealing ring

A wind power main shaft and sealing ring technology, which is applied in the field of on-site on-site replacement tooling for wind power main shaft sealing rings, can solve the problems of low replacement efficiency of sealing rings, difficulty in matching and bonding cutting surfaces of sealing rings, etc., to ensure sealing performance, reduce labor intensity and Difficult to operate and highly consistent effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

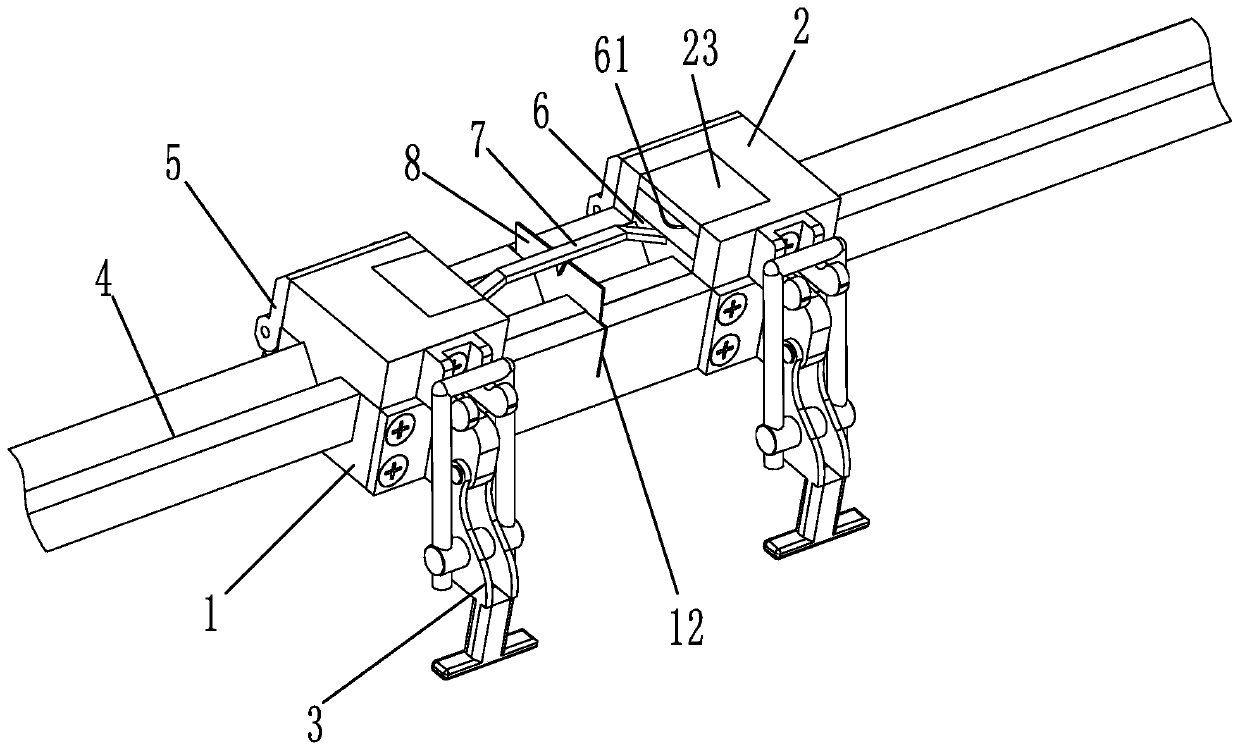

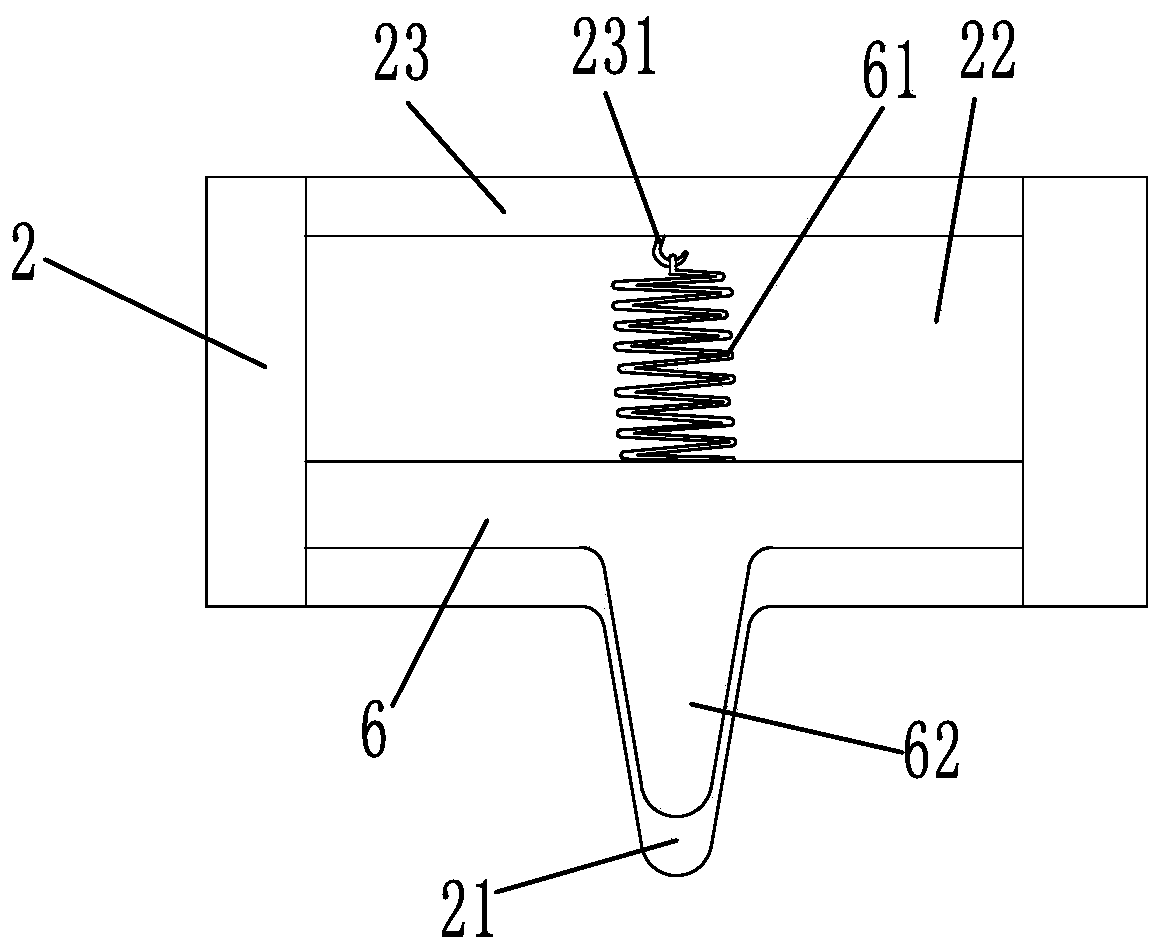

[0033] refer to Figure 1 to Figure 3As shown, a wind power main shaft seal ring on-site replacement tooling includes a positioning block 1 for installing the seal ring and two pressing blocks 2 that cooperate with the positioning block 1. The positioning block 1 is provided with a positioning groove 11 for positioning The cross-sectional shape of the groove 11 is the same as the outer cross-sectional shape of the sealing ring. The cross-sectional shape of the compression strip 21 is the same as the inner cross-sectional shape of the sealing ring. The positioning groove 11 and the positioning bar can both be linear or concentric circular arcs. The pressing block 2 is arranged opposite to the positioning block 1 , and the sealing ring is located between the pressing block 2 and the positioning block 1 . The side of the compression block 2 facing the positioning block 1 is provided with a compression strip 21, the compression block 2 and the positioning block 1 are fixed by th...

Embodiment 2

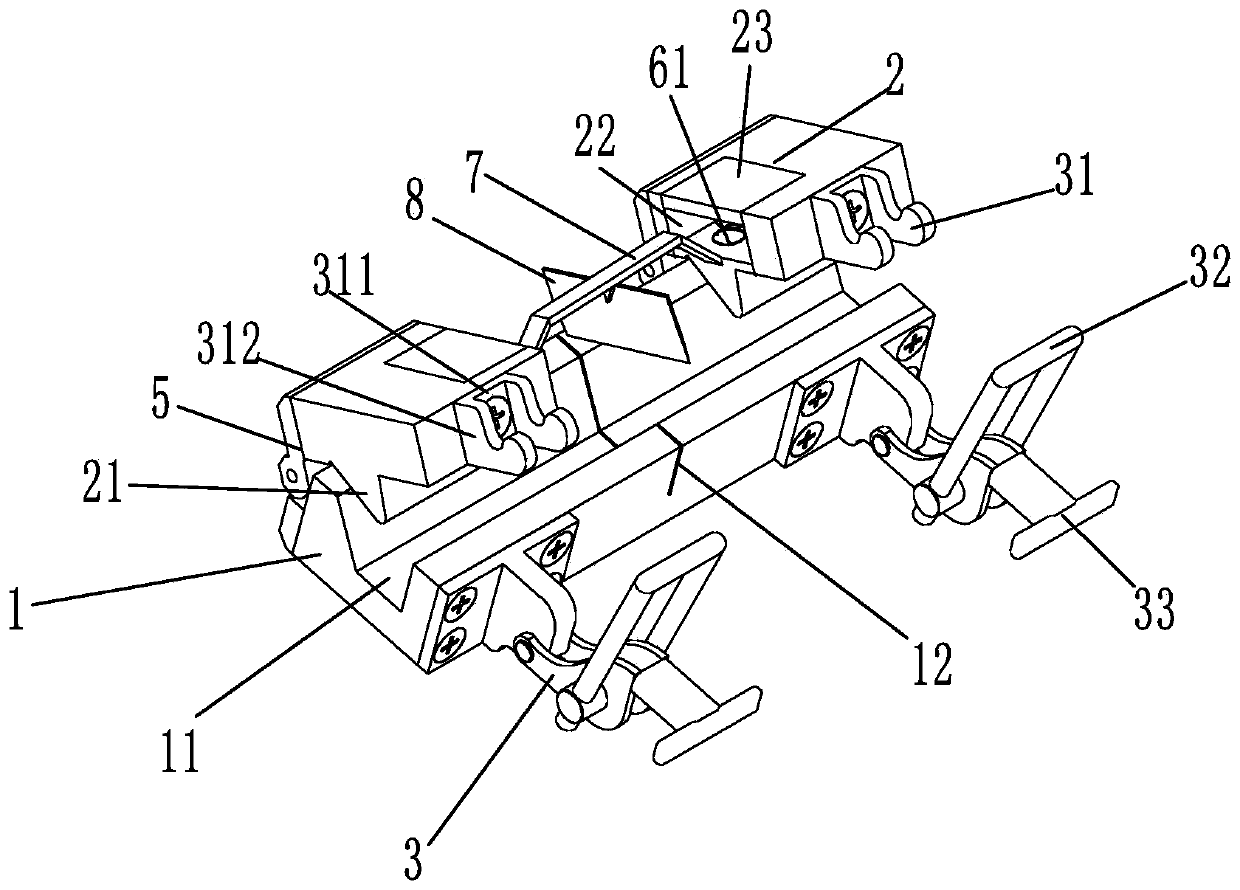

[0036] Figure 4 Among them, a wind power spindle sealing ring on-site replacement tooling, including a positioning block 1 for installing the sealing ring and two pressing blocks 2 that cooperate with the positioning block 1, the positioning block 1 is provided with a positioning groove 11, and the positioning groove The cross-sectional shape of the groove 11 is the same as the outer cross-sectional shape of the sealing ring. The cross-sectional shape of the compression strip 21 is the same as the inner cross-sectional shape of the sealing ring. The positioning groove 11 and the positioning bar can both be linear or concentric circular arcs. The pressing block 2 is arranged opposite to the positioning block 1 , and the sealing ring is located between the pressing block 2 and the positioning block 1 . The side of the compression block 2 facing the positioning block 1 is provided with a compression strip 21, the compression block 2 and the positioning block 1 are fixed by the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com