Special cutting tool for transformer oil-resistant sealing ring

An oil-resistant sealing ring and cutting tool technology, which is applied in metal processing and other directions, can solve the problems of inappropriate size of the spare sealing ring, insufficient sealing accuracy, and cumbersome cutting instruments, so as to achieve low manufacturing and use costs, and improve cutting accuracy and efficiency. , the effect of reducing labor intensity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

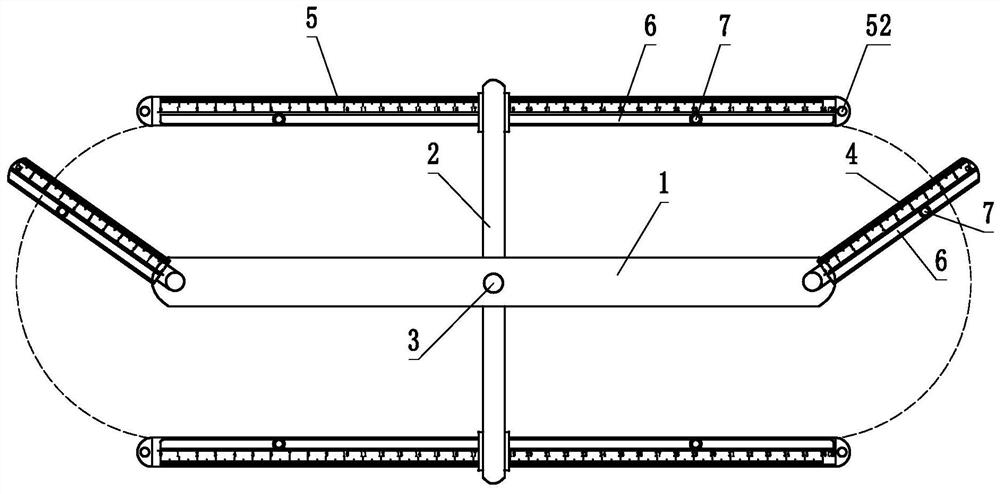

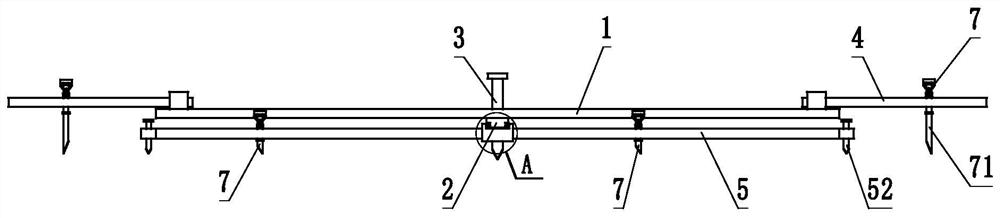

[0030] This embodiment provides a special cutting tool for transformer oil-resistant sealing rings. The tool includes a skeleton, and the skeleton includes a transverse skeleton 1 and a longitudinal skeleton 2 crossed and fixed with the transverse skeleton 1. In this embodiment, the transverse skeleton is preferred. The intersection point of 1 and longitudinal frame 2 is fixed by bolts or pins, and the angle between horizontal frame 1 and longitudinal frame 2 can be adjusted by adjusting the tightness of bolts or pins. And / or the central point of the transverse frame 1 is provided with a positioning pin A3, when the cross fixing point is provided with a positioning pin A3, the positioning pin A3 can be a screw or a pin for fixing the transverse frame 1 and the longitudinal frame 2, see Figure 1-3 ; The two ends of the transverse framework 1 are respectively hinged with a measuring arm A4, and the measuring arm A4 can be rotated relative to the transverse framework 1 with the h...

Embodiment 2

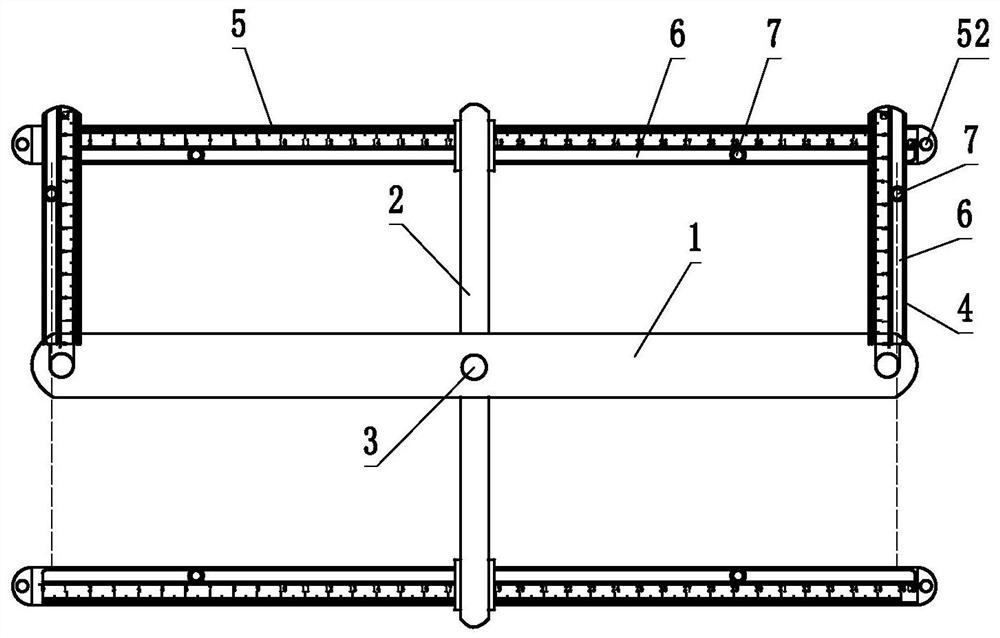

[0036] Compared with Embodiment 1, the difference of this embodiment is that two groups of longitudinal skeletons 2 parallel to each other are arranged on the transverse skeleton 1, and the two groups of longitudinal skeletons 2 parallel to each other and the transverse skeleton 1 are connected by pins or spirals at the intersection points. fixed, see Figure 9-10 , the cutting tool with this structure can make the movement of the measuring arm B5 more stable and synchronous.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com