Filter element skeleton welding machine

A welding machine and frame technology, applied in the field of filter frame welding machines, can solve the problems of high purchase cost, large equipment volume, and low roundness of filter frame

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

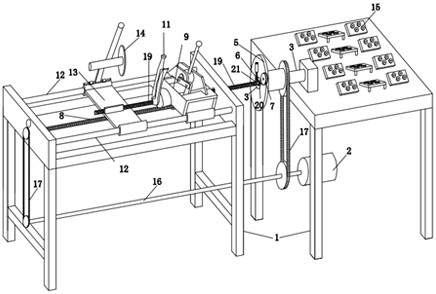

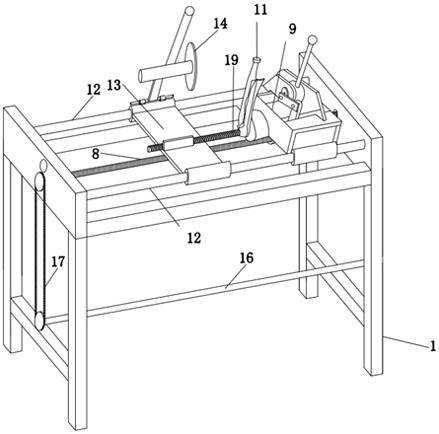

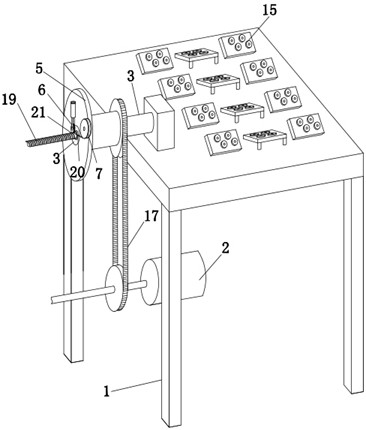

[0019] A specific embodiment of the present invention will be described in detail below in conjunction with the accompanying drawings, but it should be understood that the protection scope of the present invention is not limited by the specific embodiment.

[0020] Such as Figure 1-7 As shown, a filter frame welding machine provided by the embodiment of the present invention includes a frame (1), a driving motor (2), a support bar inlet shaft (3), and the support bar inlet shaft (3) is concentric with the center of the circle, etc. There are several support bar inlet through-holes (4) away from the array, and each support bar wire-entry through hole (4) corresponds to a support bar 21, and the rotating disc (5) is sleeved on the support bar inlet shaft (3) through a rotating bearing And it can rotate relative to the support bar incoming shaft (3). The rotating disc (5) is driven to rotate by the drive motor (2) with the support bar incoming shaft (3) as the center of a circle...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com