Patents

Literature

42results about How to "Reduce the handling process" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

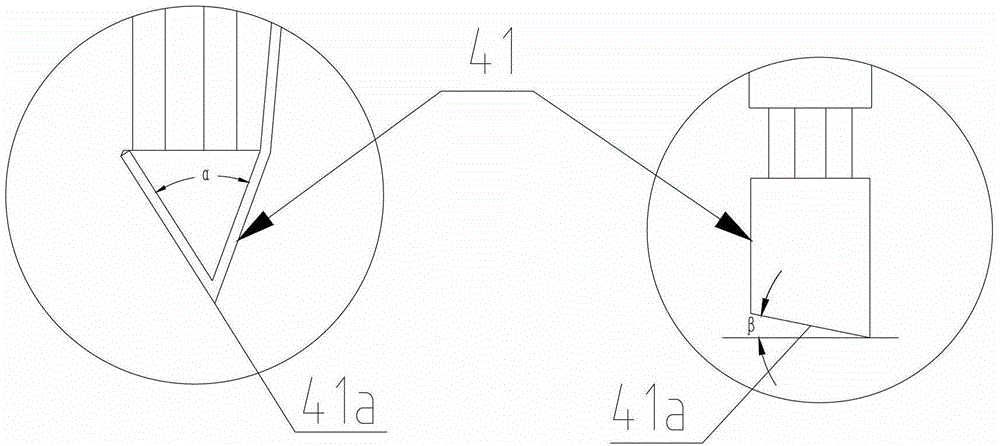

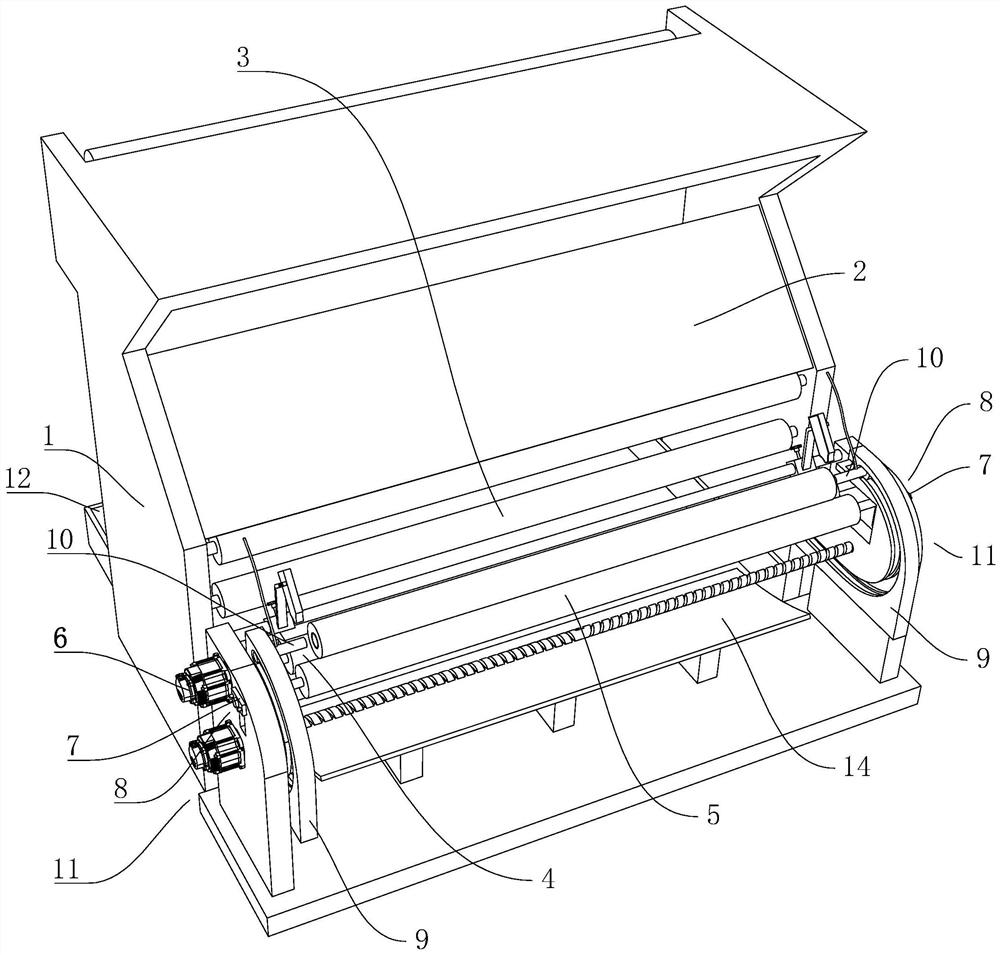

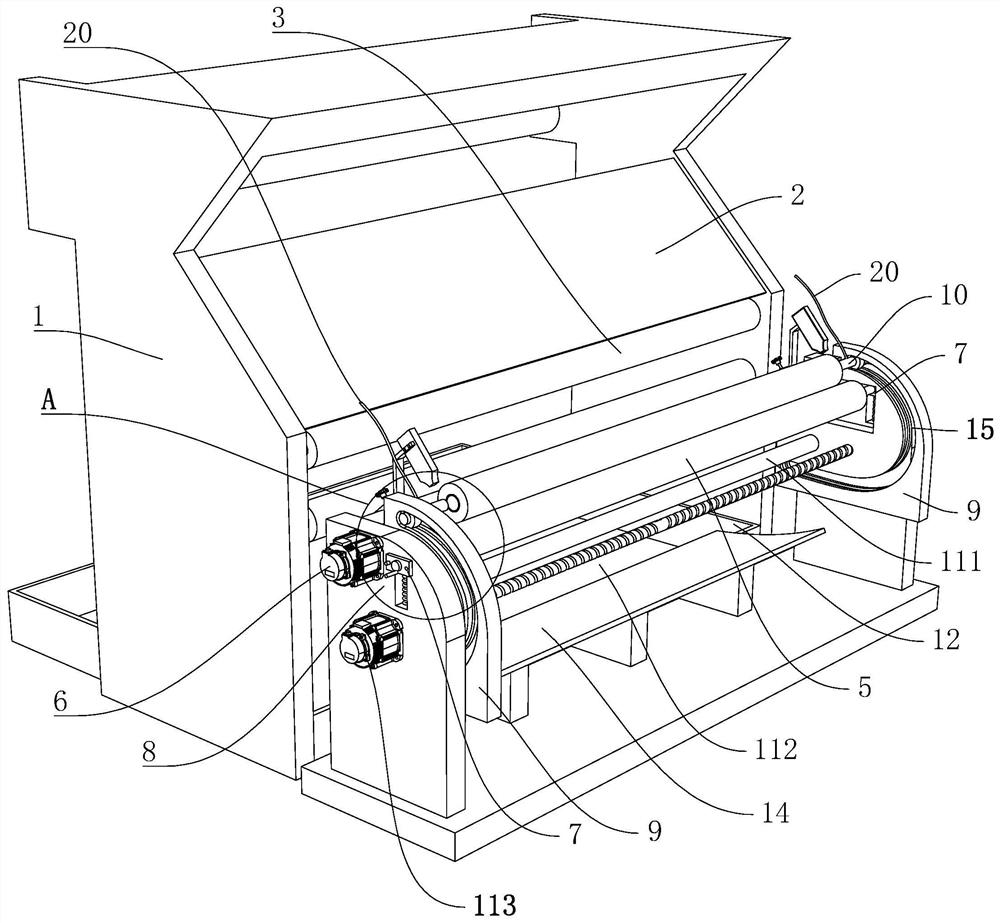

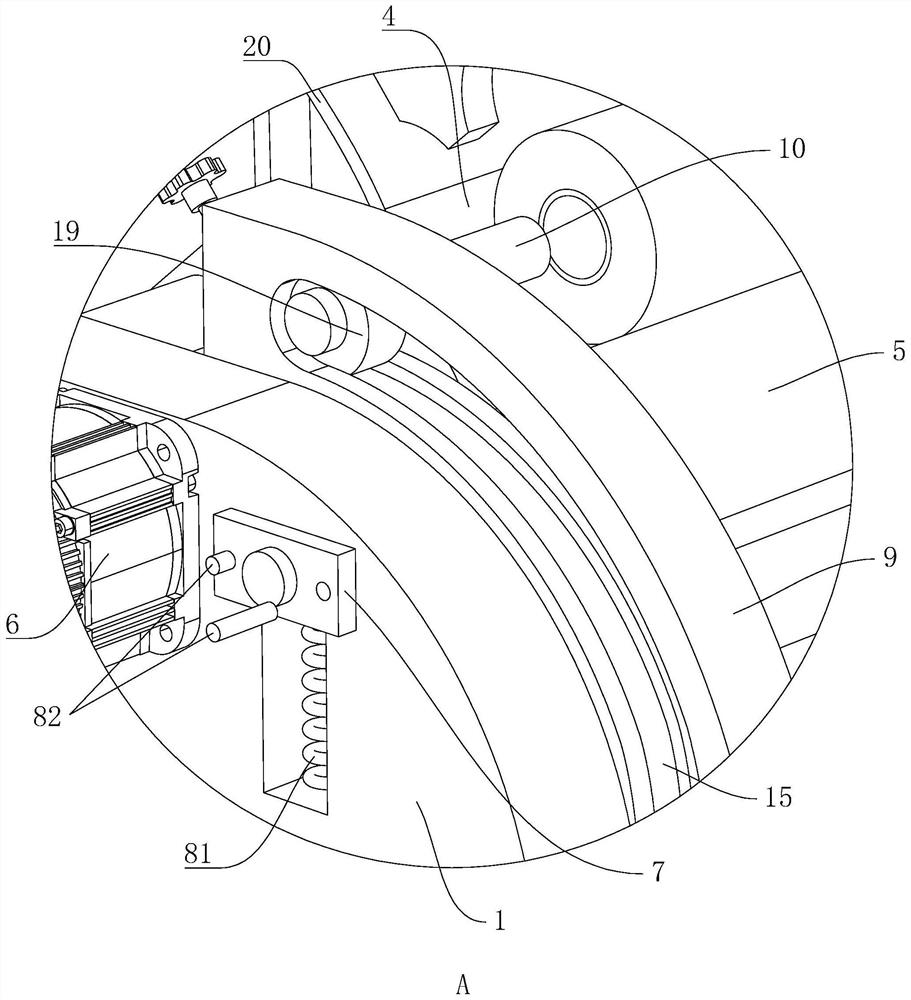

Flat device for pipe and rod materials

ActiveCN104308260AReduce the handling processReduce labor intensityMetal sawing devicesReduction driveEngineering

The invention discloses a flat device for pipe and rod materials. The flat device for pipe and rod materials comprises a rack, wherein a fixed baffle, a clamping roller mechanism, a transmission mechanism, a material discharging mechanism and a saw cutting mechanism are arranged on the rack; the material discharging mechanism comprises a plurality of first stop levers and second stop levers which are arranged on the front and rear sides of an operating floor longitudinally; the operating floor is an inclined surface convenient for material discharging; the upper end of the operating floor is connected with a discharging part of a joint drawing machine; the transmission mechanism is arranged below the material discharging mechanism and comprises a plurality of idler wheels, a belt pulley, a belt pulley transmission motor and a speed reducer; the clamping roller mechanism is located on the left side of the transmission mechanism and comprises a clamping roller, a chain wheel and a clamping roller transmission motor; the saw cutting mechanism is located on the right side of the transmission mechanism and comprises a saw cutting machine stand, a pressing piece and a sew web. The flat device is arranged at the material discharging part of the drawing machine so as to decrease the carrying process and reduce the labor intensity, is reasonable in structure, convenient to operate, adjustable in saw cutting specification and high in work efficiency, and is capable of precisely determining fixed-length flat saw cutting and realizing batched saw cutting.

Owner:JINTIAN COPPER GROUP CORP NINGBO

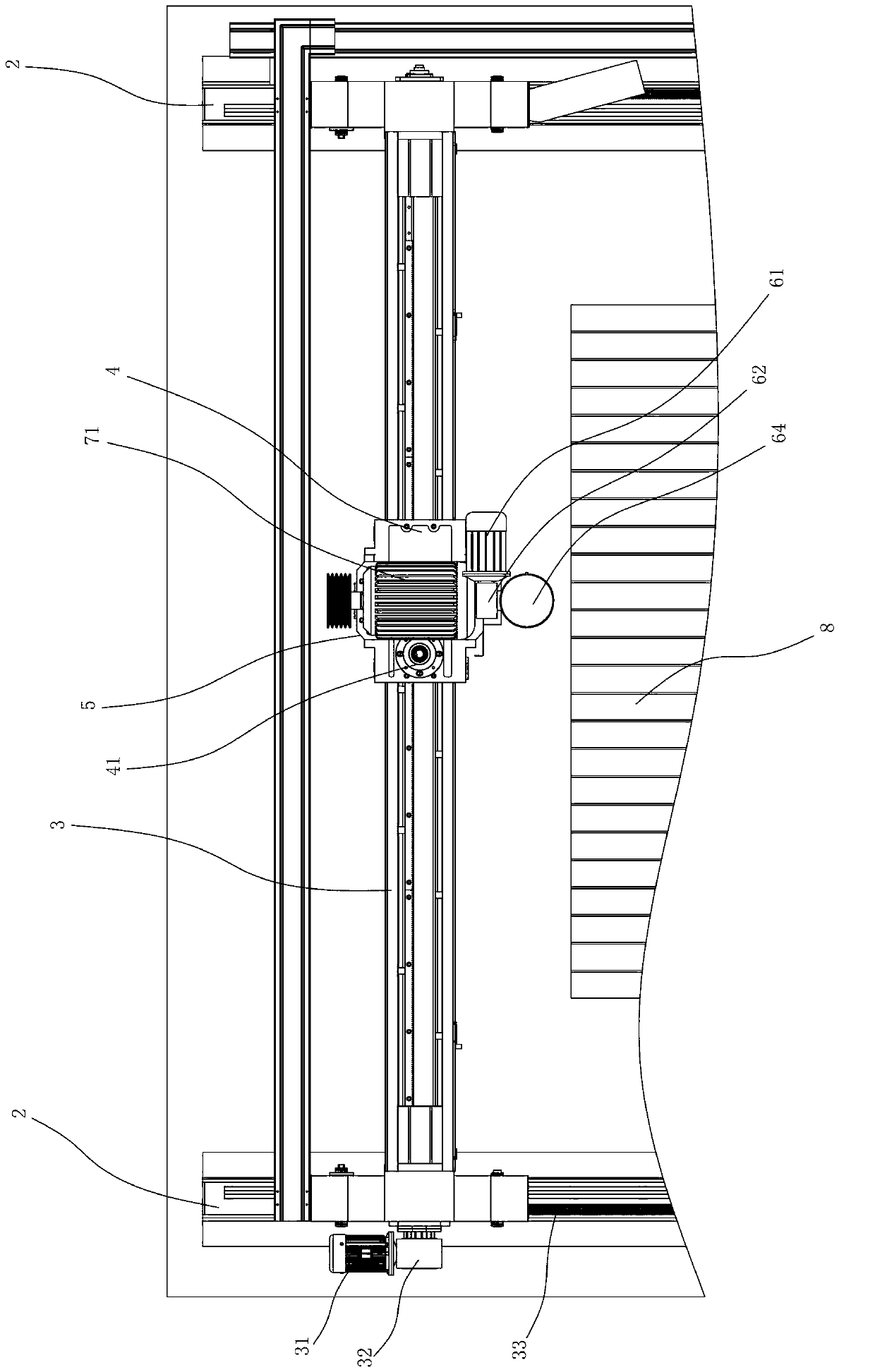

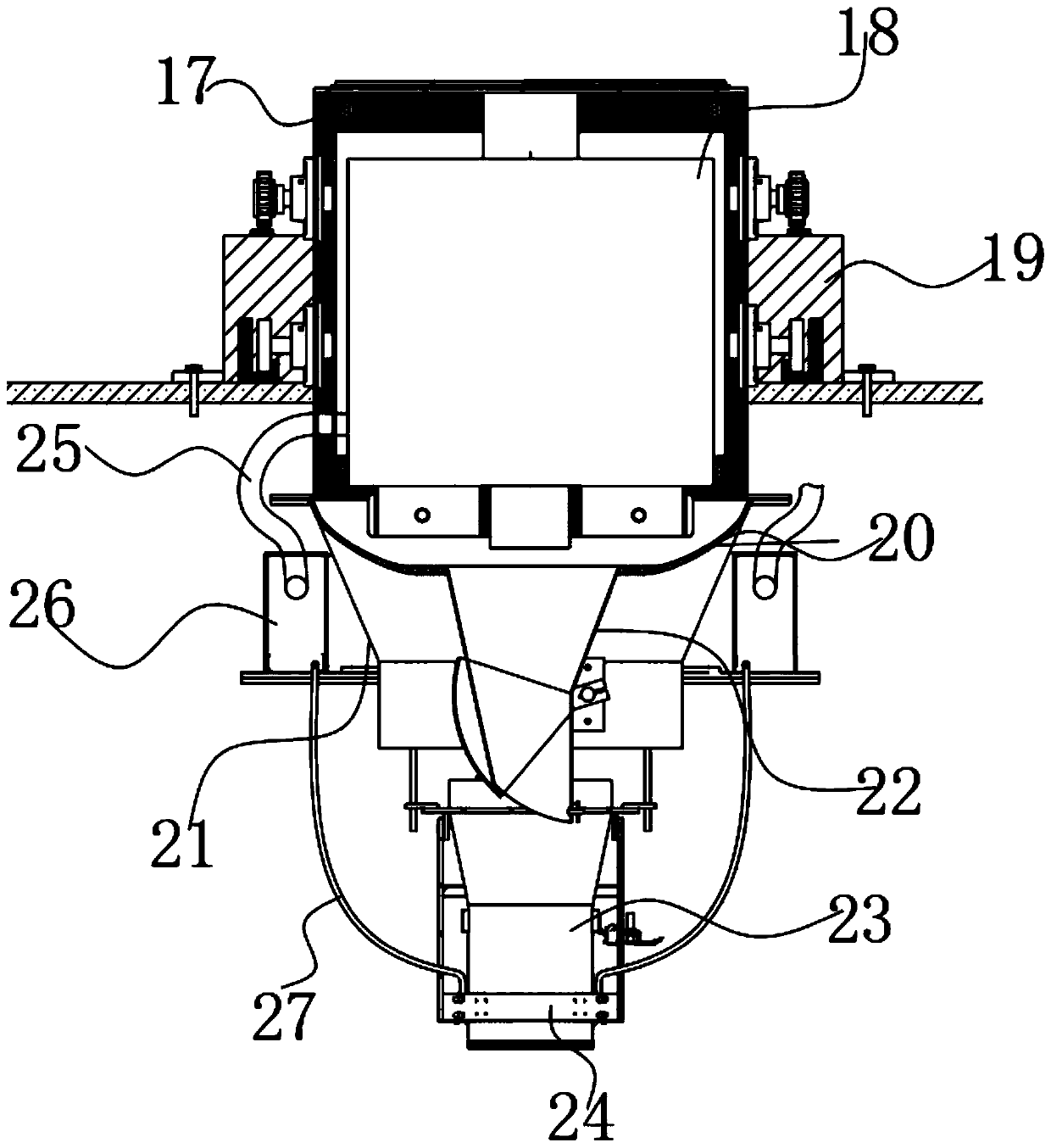

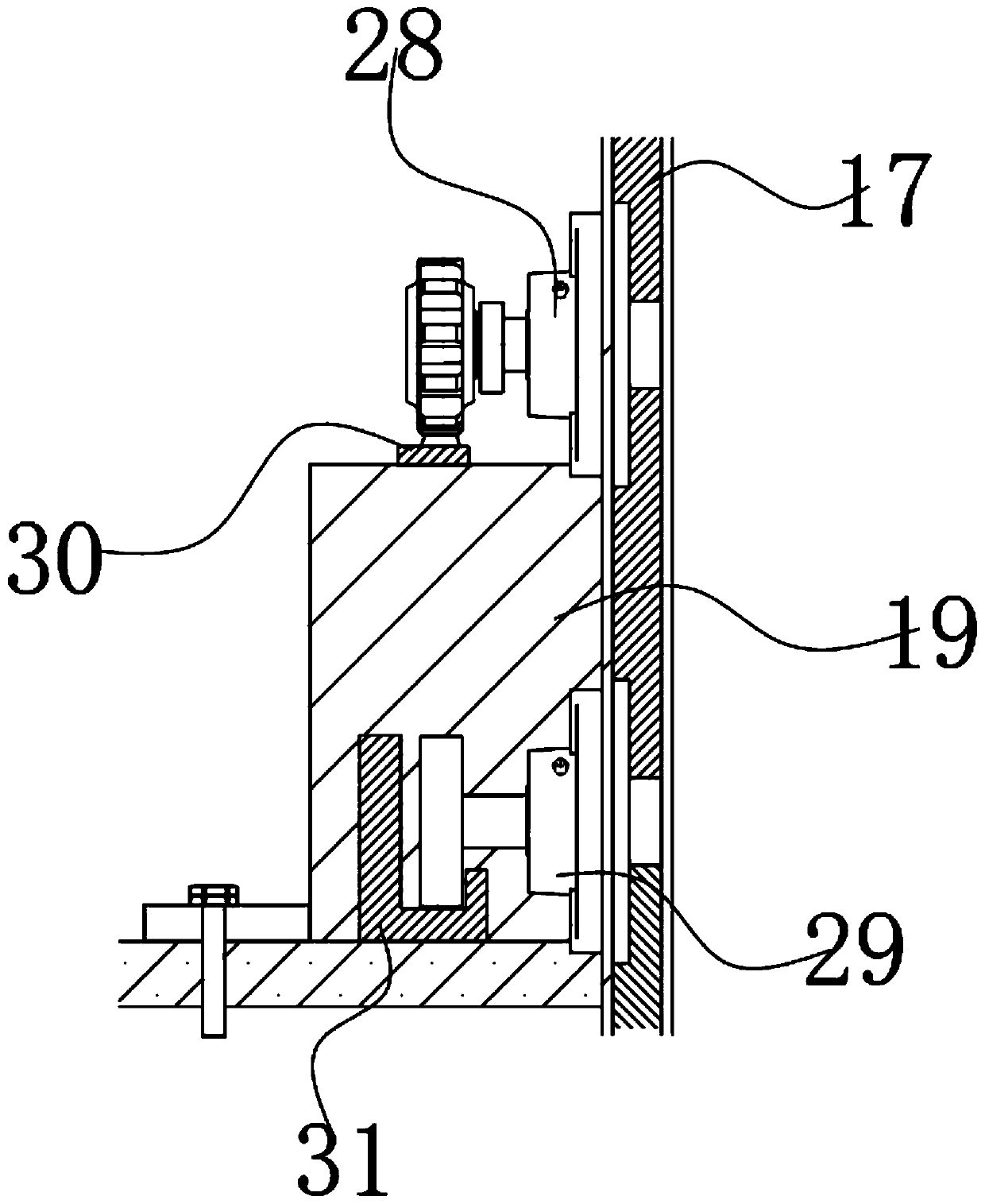

Bridge type stone cutter with polishing function

ActiveCN103128860AWith cutting functionReduce the handling processGrinding machinesStone-like material working toolsSTONE CUTTERBridge type

A bridge type stone cutter with a polishing function comprises a crossbeam, two longitudinal beams, a moving seat, a lifting frame, a worktable and a cutting device. The cutting device is arranged on the lifting frame, a longitudinal moving mechanism is arranged among the crossbeam and the longitudinal beams, a transverse moving mechanism is arranged between the moving seat and the crossbeam, and a lifting moving mechanism is arranged between the lifting frame and the moving seat. The bridge type stone cutter is characterized by further comprising a polishing device, the polishing device is arranged on the lifting frame and comprises a spindle box, a spindle, a main motor, an abrasive disc and a vertical moving mechanism, the spindle box is arranged on the lifting frame in such a manner that the spindle box can vertically move up and down on the lifting frame, the spindle is vertically arranged on the spindle box, the main motor is arranged on the spindle box and is connected with the spindle to drive the spindle to rotate, the abrasive disc is arranged at the lower end of the spindle, and the vertical moving mechanism is connected with the spindle box to drive the spindle box to vertically move. The bridge type stone cutter has the advantages that a cutting function is integrated with the polishing function, a procedure for shifting stone between cutting equipment and polishing equipment and a procedure for clamping the stone are omitted, the stone processing efficiency is improved, and the labor cost is saved.

Owner:福建省南安市巨轮机械有限公司

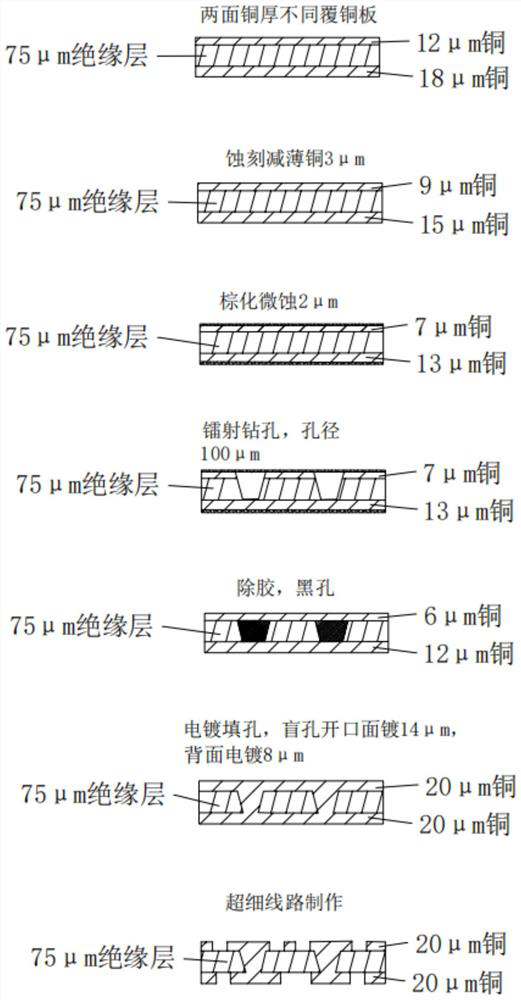

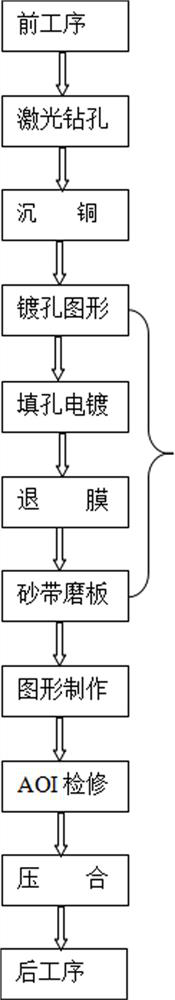

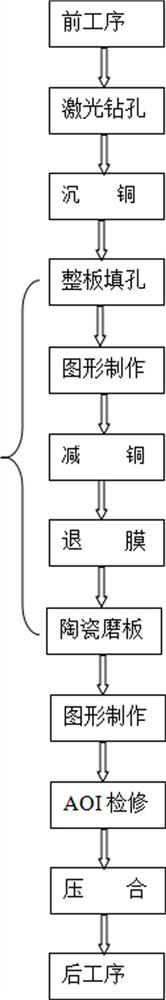

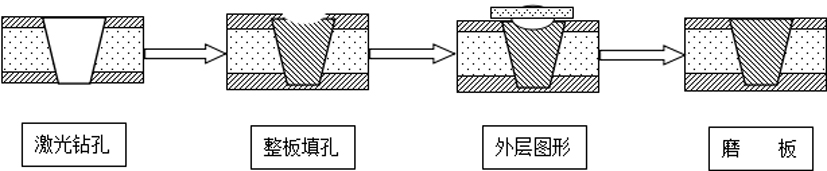

Method for processing core layer of arbitrary-layer interconnected high-density circuit board

ActiveCN112739070AReduce manufacturing costSave resourcesPrinted element electric connection formationComposite materialCopper foil

The invention discloses a method for processing a core layer of an arbitrary-layer interconnected high-density circuit board, relates to the technical field of circuit boards, and aims to solve the problems that when a blind hole is processed in a copper-clad plate with 12-micron copper foil on both sides, the copper foil at the bottom is thin and can be penetrated by liquid medicine; and after blind hole filling electroplating is completed, surface copper is too thick, and copper needs to be etched and thinned to manufacture a thin circuit. The method is characterized in that: the copper-clad plate with copper foil having different thicknesses (the thickness of the upper copper foil is 12 microns, and the thickness of the lower copper foil is 18 microns) on two sides are customized, after copper reduction and browning, the thicknesses of surface copper are 7 microns and 13 microns respectively, and carbon dioxide laser drilling is performed on the 7-micron copper foil surface; and the copper-clad plate with the copper thickness of 20 microns on both sides is prepared through degumming, hole blackening, hole filling and electroplating, and can be directly used for manufacturing an inner-layer circuit.

Owner:麦德美科技(苏州)有限公司

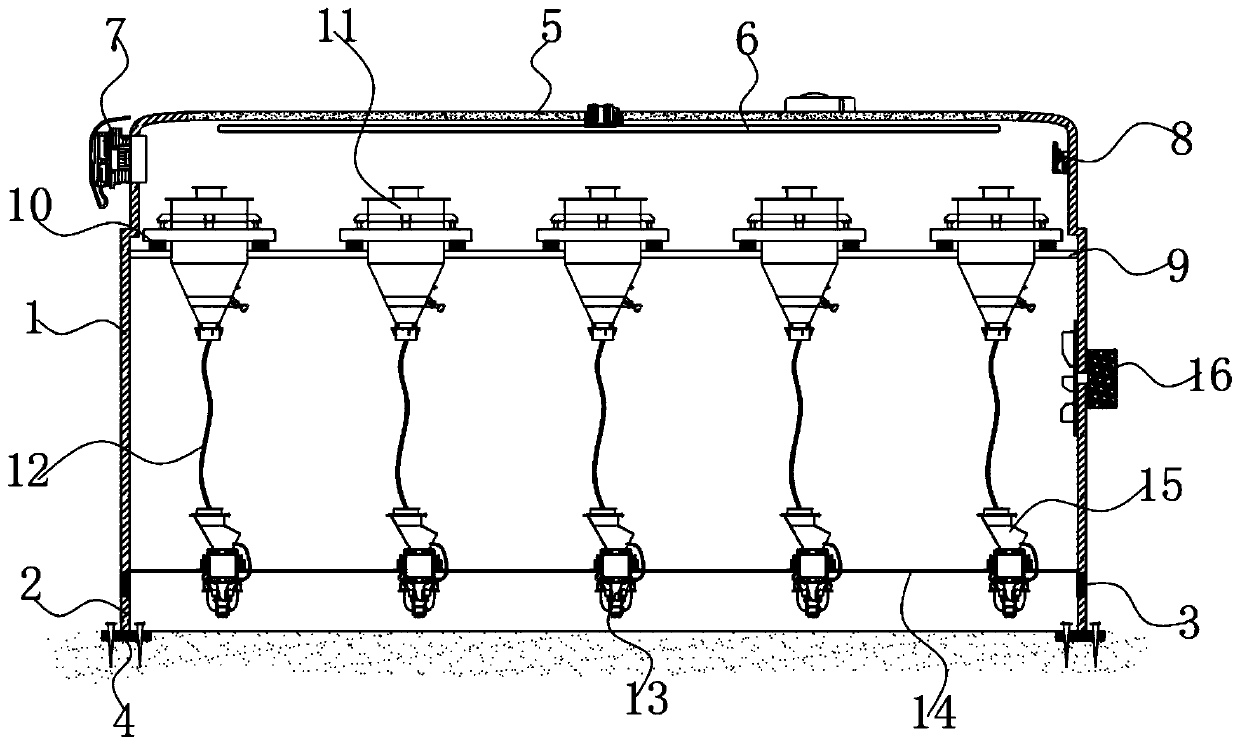

Dedicated multi-functional incubator for morchella artificial cultivation

ActiveCN111527999AReduce the handling processThe handling process is suitable forPressurised distribution of liquid fertiliserCultivating equipmentsAgricultural scienceAgricultural engineering

The invention discloses a dedicated multi-functional incubator for morchella artificial cultivation. The incubator comprises a box body, a base, liquid storage tanks and drip irrigation assemblies, wherein the plurality of liquid storage tanks are fixed in a horizontal array at the middle of the box body, a liquid outlet end of each liquid storage tank is connected to each drip assembly by a flexible bellows, the bottom of the box body is opened, the bottom of the box body is disposed on the base by a plurality of lifting rods, and the bottom of the base is anchored in a cultivation field by aplurality of anchoring bases; a box door is also disposed on the front side face of the box body for access of a cultivation worker; and each drip irrigation assembly can be moved slightly along a horizontal direction so as to get adapted to a moving direction of morchella in the cultivation field, liquid storage tanks are kept still during drip irrigation, and the drip irrigation assemblies canbe moved back and forth along a longitudinal moving direction of the morchella so as to realize drip irrigation.

Owner:安徽农农乐农业科技有限公司

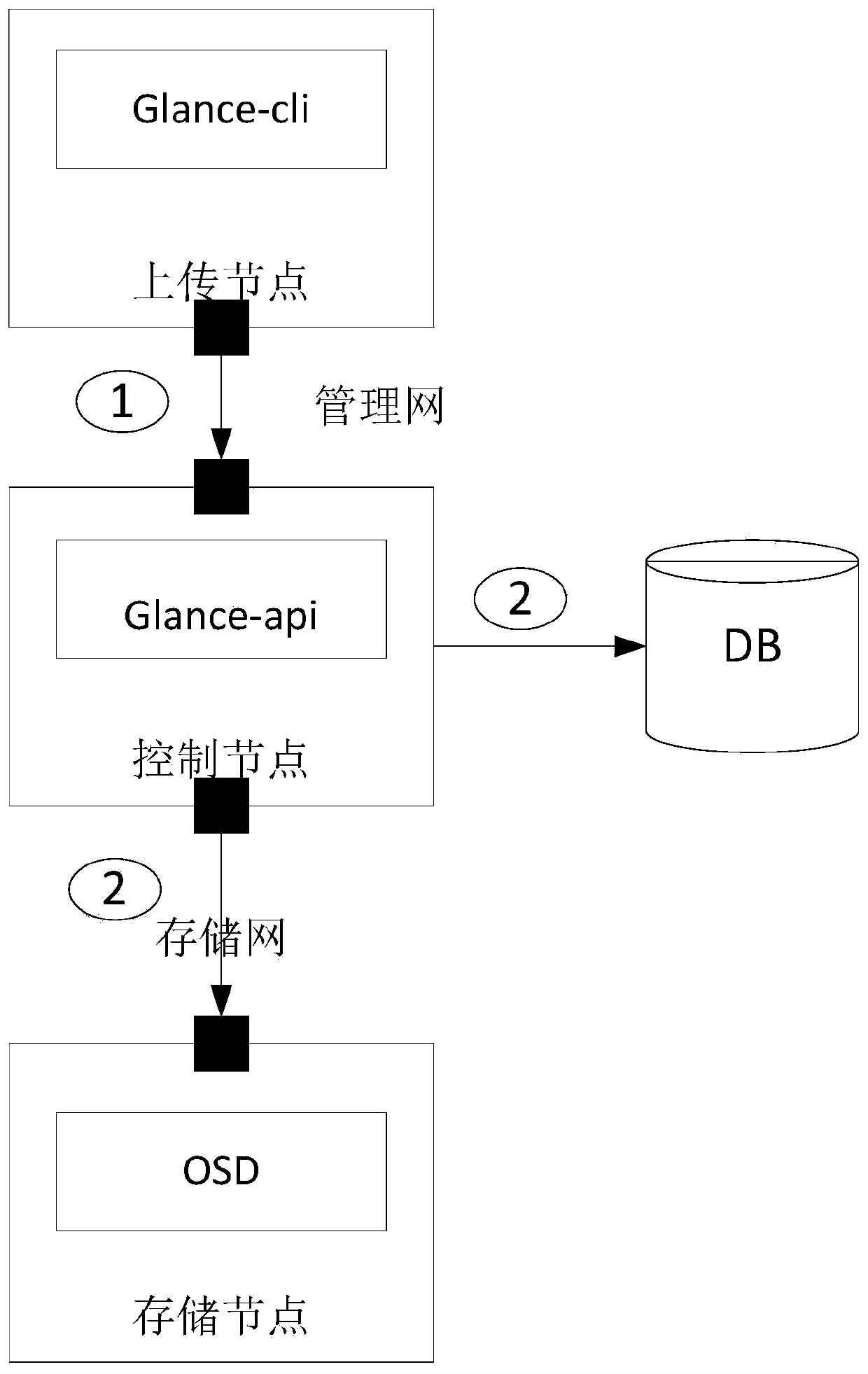

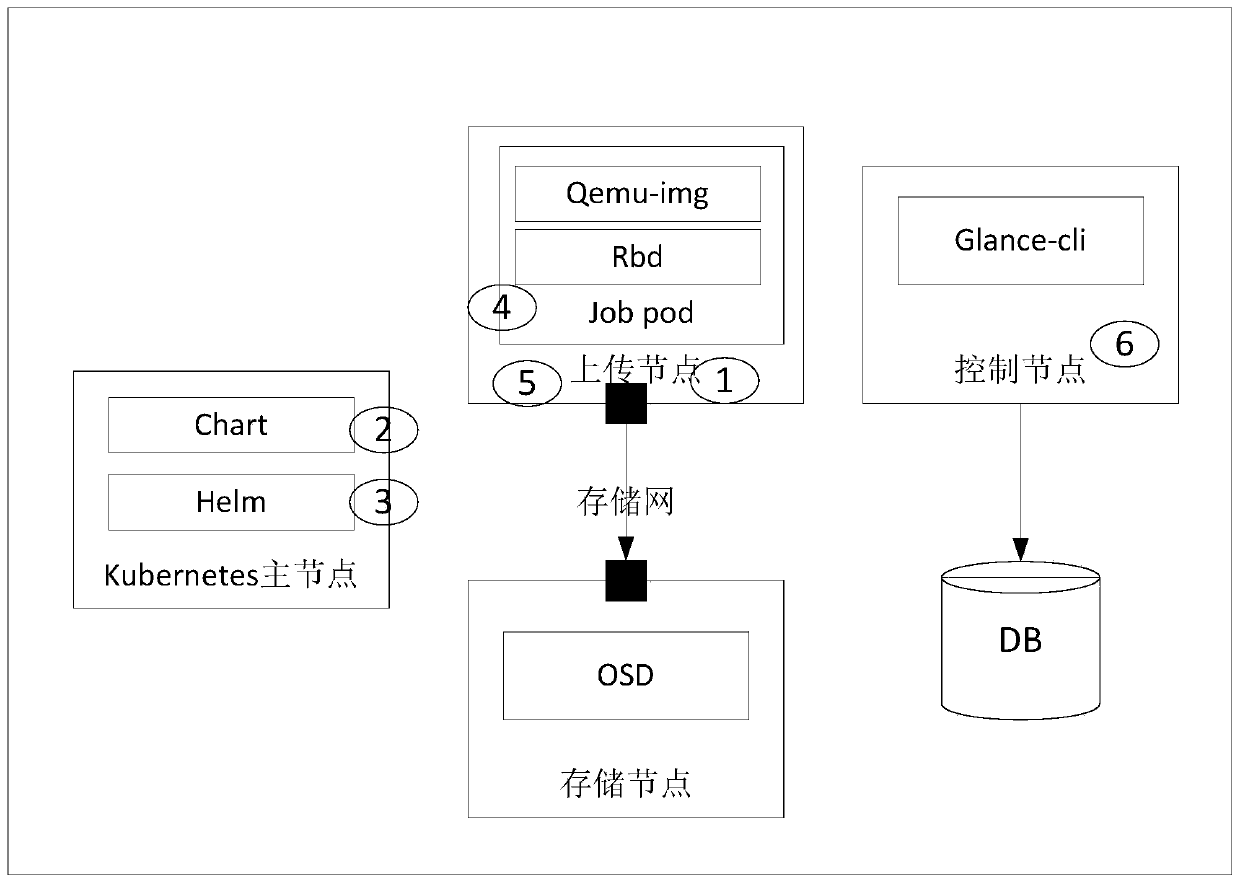

Method and system for quickly importing virtual machine mirror image in OpenStack environment

ActiveCN111427666AShorten the timeReduce storage footprintFile system administrationSoftware simulation/interpretation/emulationInternet trafficEngineering

The invention discloses a method and a system for quickly importing a mirror image of a virtual machine in an OpenStack environment. The invention belongs to the technical field of cloud computing, the technical problem to be solved by the invention is how to reduce mirror image content transmission links, reduce upload time, improve success rate of mirror image import at the same time without occupying the management network flow.. According to the technical scheme, the method comprises the steps that an rbd client side of a ceph cluster is used for importing a virtual machine mirror image into a ceph mirror image pool; a grance client side is used for supplementing metadata of the virtual machine mirror image to a database; whether the mirror image state is normal or not is checked, andmirror image service can be provided for the outside normally. The system comprises an uploading node unit, a storage node unit, a kubernetes main node unit and a control node unit.

Owner:SHANDONG LANGCHAO YUNTOU INFORMATION TECH CO LTD

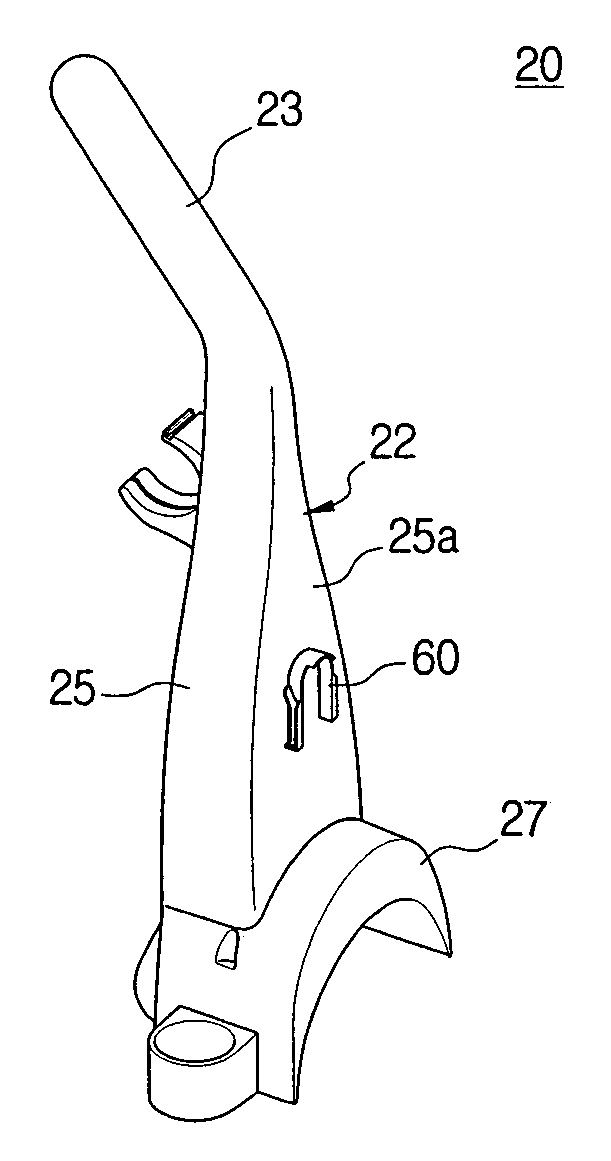

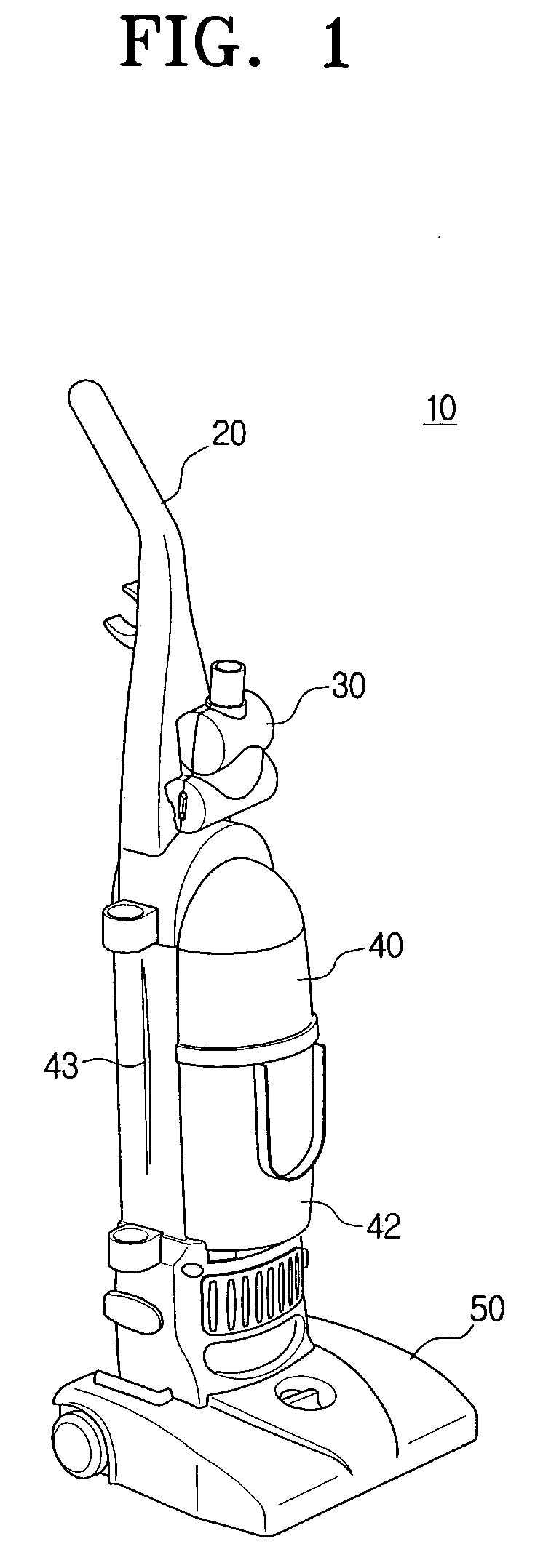

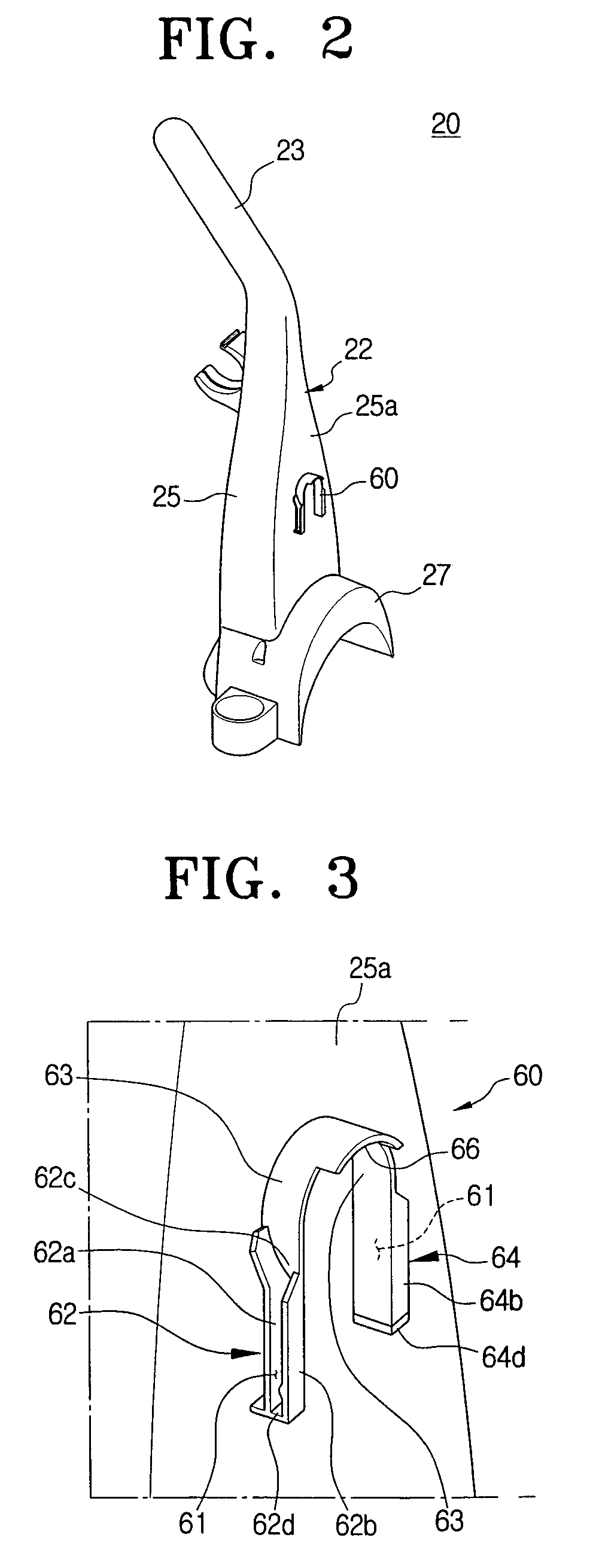

Handle unit for vacuum cleaner

InactiveUS7406743B2Easy to storeEasy to useSuction cleaner storing devicesCable arrangements between relatively-moving partsEngineeringInjection molding process

The present disclosure relates to a handle unit for a vacuum cleaner. The handle unit for the vacuum cleaner for controlling a cleaner body of the vacuum cleaner includes a handle body of the vacuum cleaner; and a supporting unit projected from one side of the handle body, the supporting unit holding an accessory brush, wherein the supporting unit and the handle body is molded in a single piece by the injection molding process.

Owner:SAMSUNG GWANGJU ELECTRONICS CO LTD

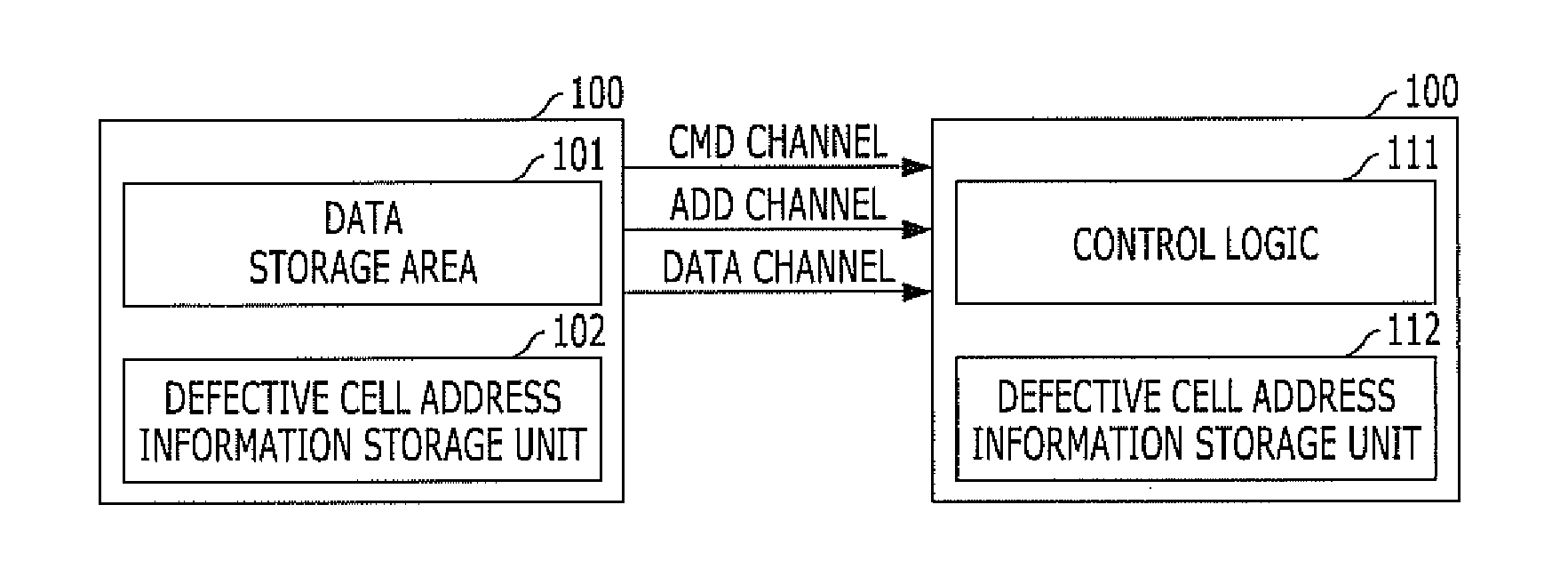

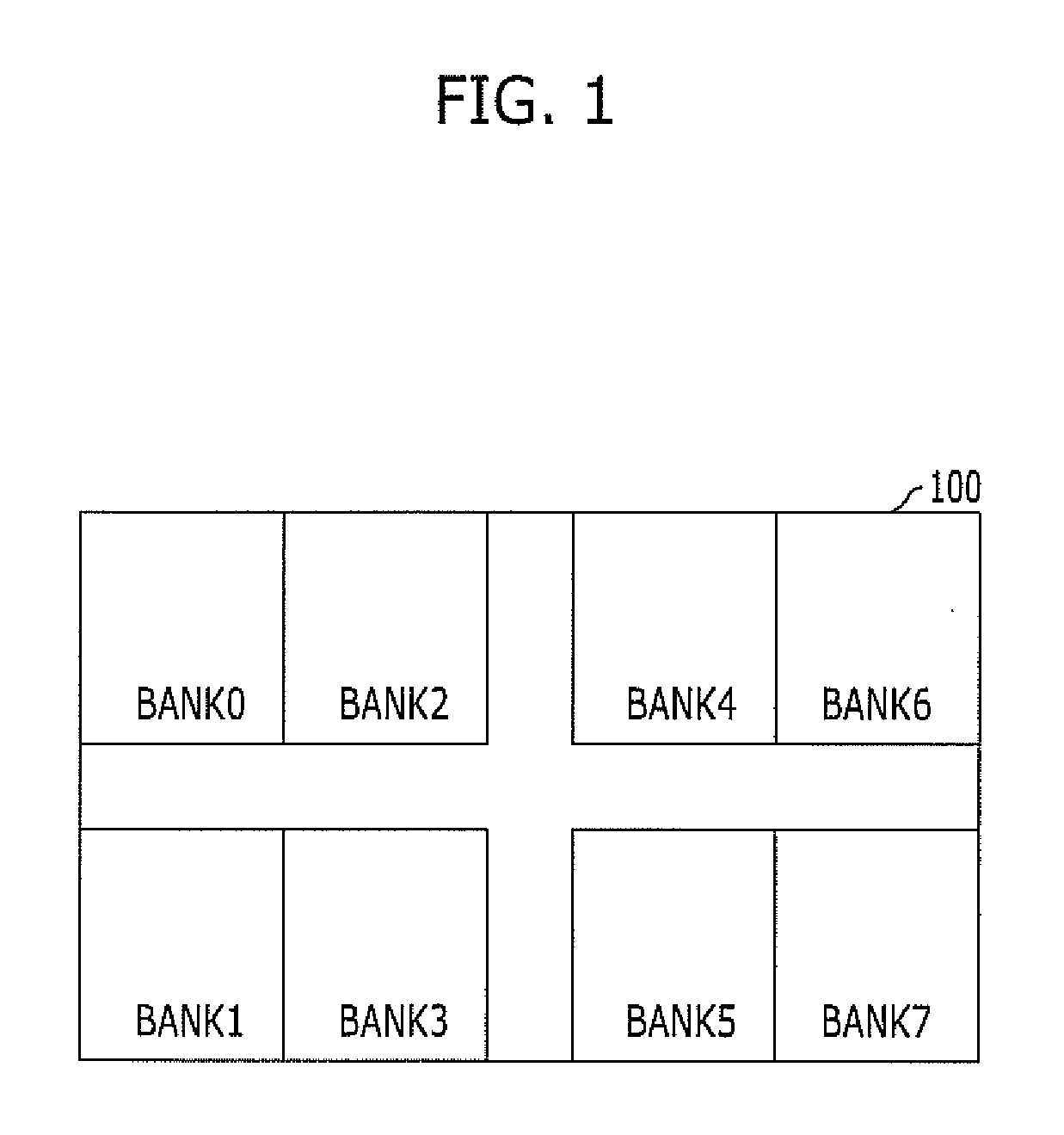

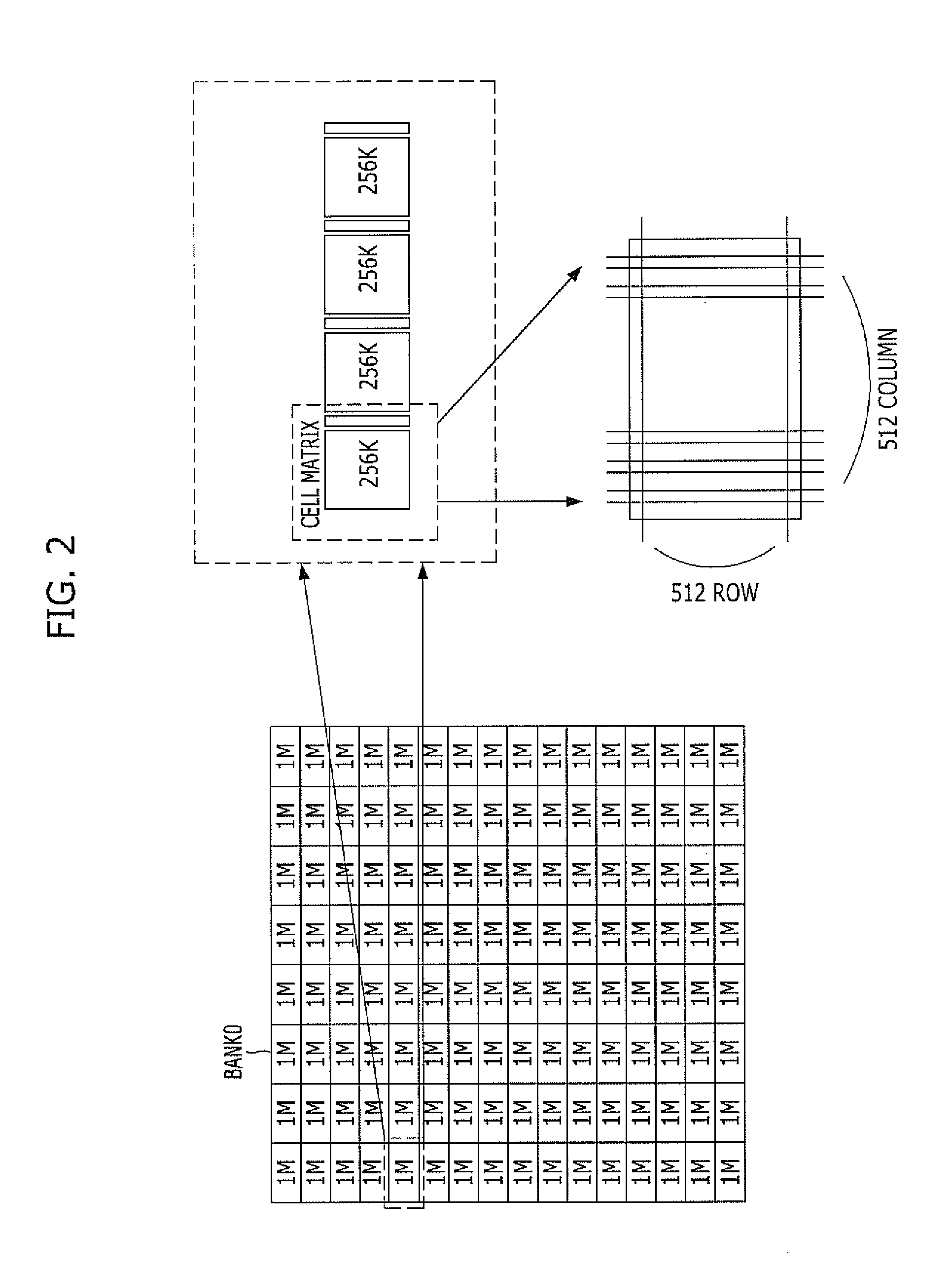

Memory system having memory and memory controller and operation method thereof

InactiveUS20120269018A1Low costReduce the handling processDigital storageMemory systemsComputer hardwareMemory controller

An operation method of a memory system including a memory and a memory controller includes transmitting defective-cell address information to the memory controller from the memory at an initial operation of the memory, wherein the defective-cell address information includes an address of a defective cell of the memory, and accessing, by the memory controller, an area of the memory excluding an area indicated by the defective-cell address information inside the memory.

Owner:SK HYNIX INC

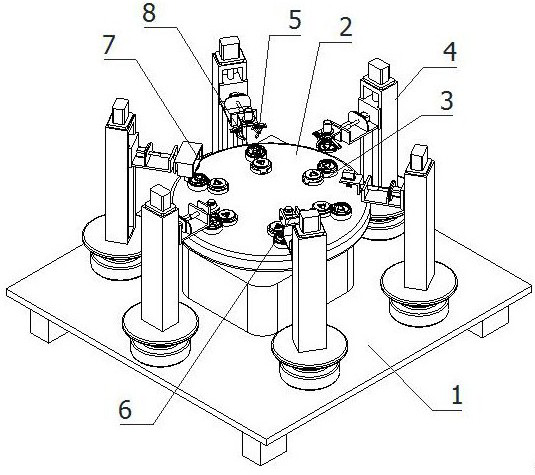

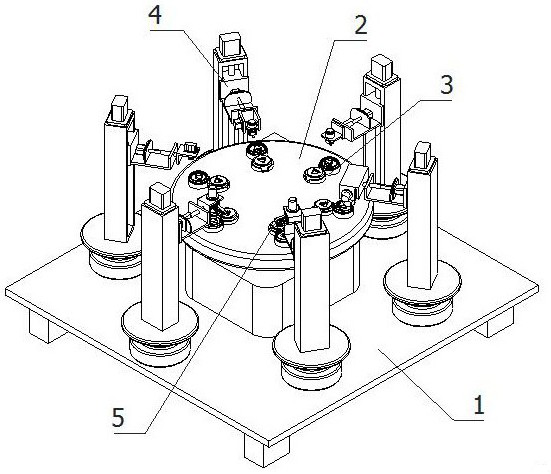

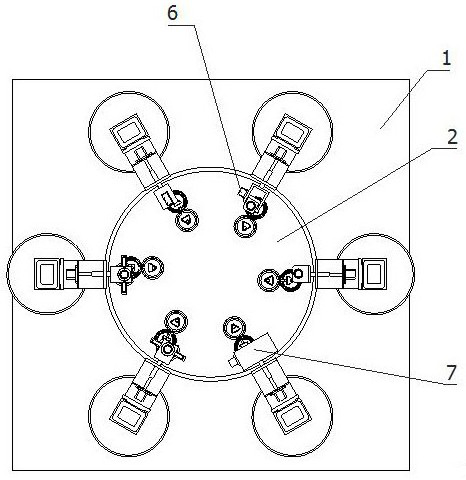

Multi-station efficient assembling equipment for vacuum cup cover

InactiveCN112296670AAvoid handlingAvoid installationAssembly machinesStructural engineeringSilica gel

The invention relates to the technical field of vacuum cup assembly, in particular to multi-station efficient assembling equipment for a vacuum cup cover. The equipment comprises a rack, a six-stationmachining turntable arranged on the rack, positioning the mounting assemblies, raw material clamping assemblies arranged at the output ends of carrying assemblies, a steering assembly arranged at theoutput end of one of the carrying assemblies, an extrusion combining hinging assembly arranged at the output end of one of the carrying assemblies, and the vacuum cup cover. The vacuum cup cover comprises a cup cover base, a cup cover cap, a silica gel strip, a plastic buckle, a rubber seal cover, and a hinging metal rod. Each raw material clamping assembly comprises a cover body clamping mechanism, a rubber strip clamping mechanism, a triangular clamping mechanism, and a cylinder clamping mechanism. According to the multi-station efficient assembly equipment for the vacuum cup cover, all parts of the vacuum cup cover can be accurately installed step by step, the working efficiency is improved, and the installation precision is improved.

Owner:余祖广

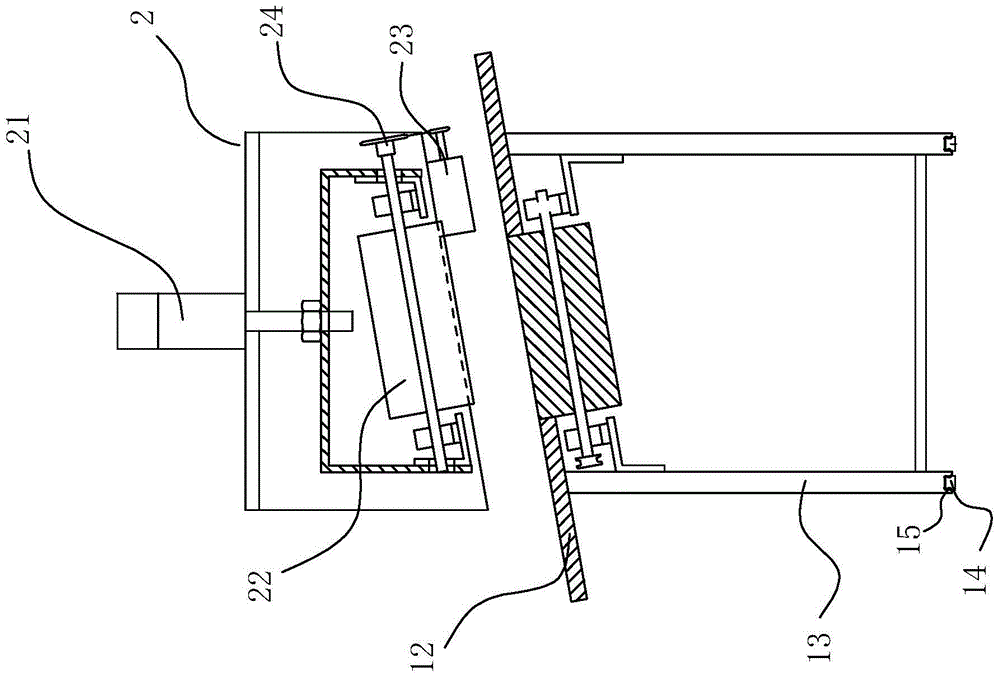

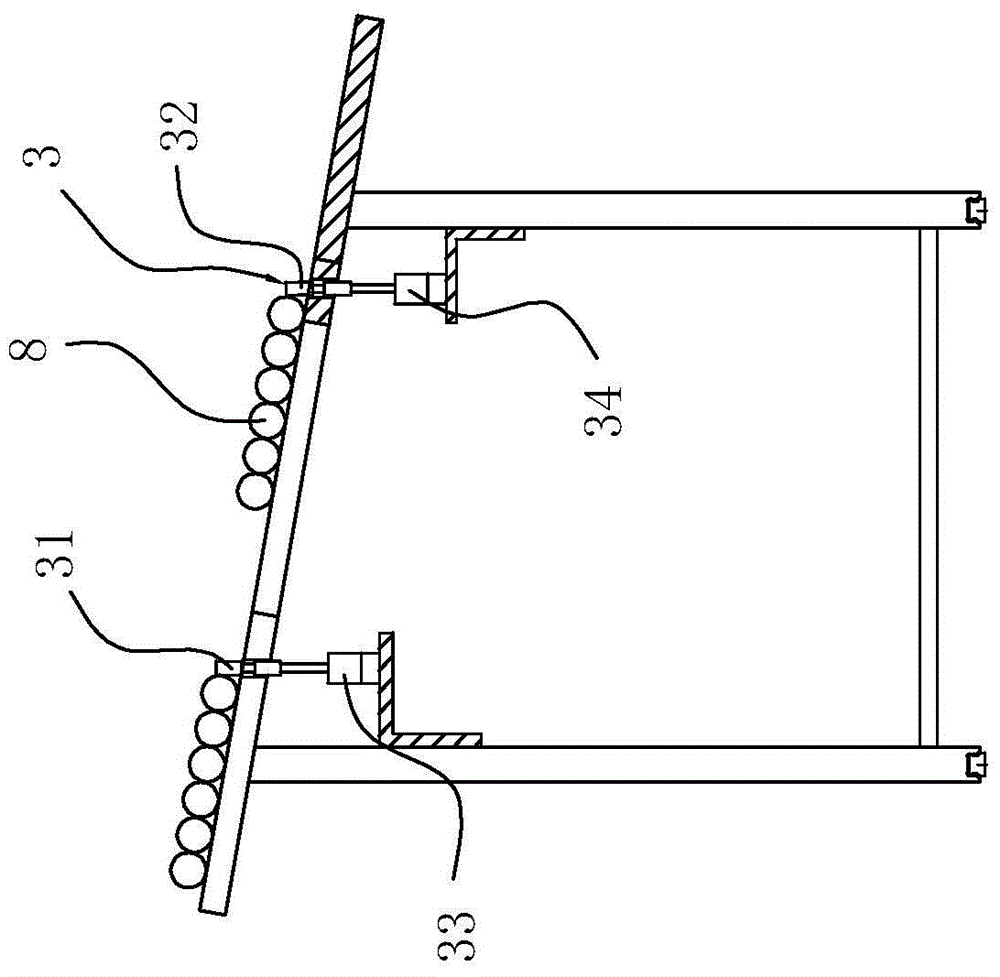

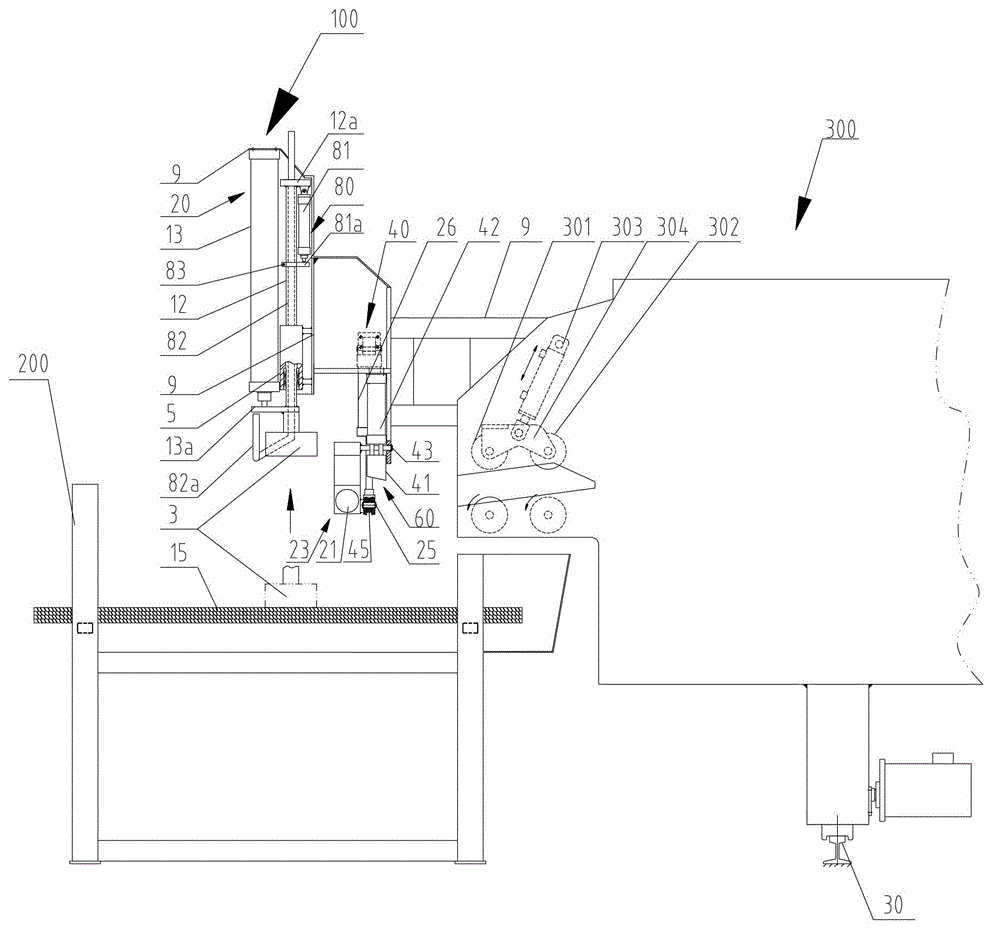

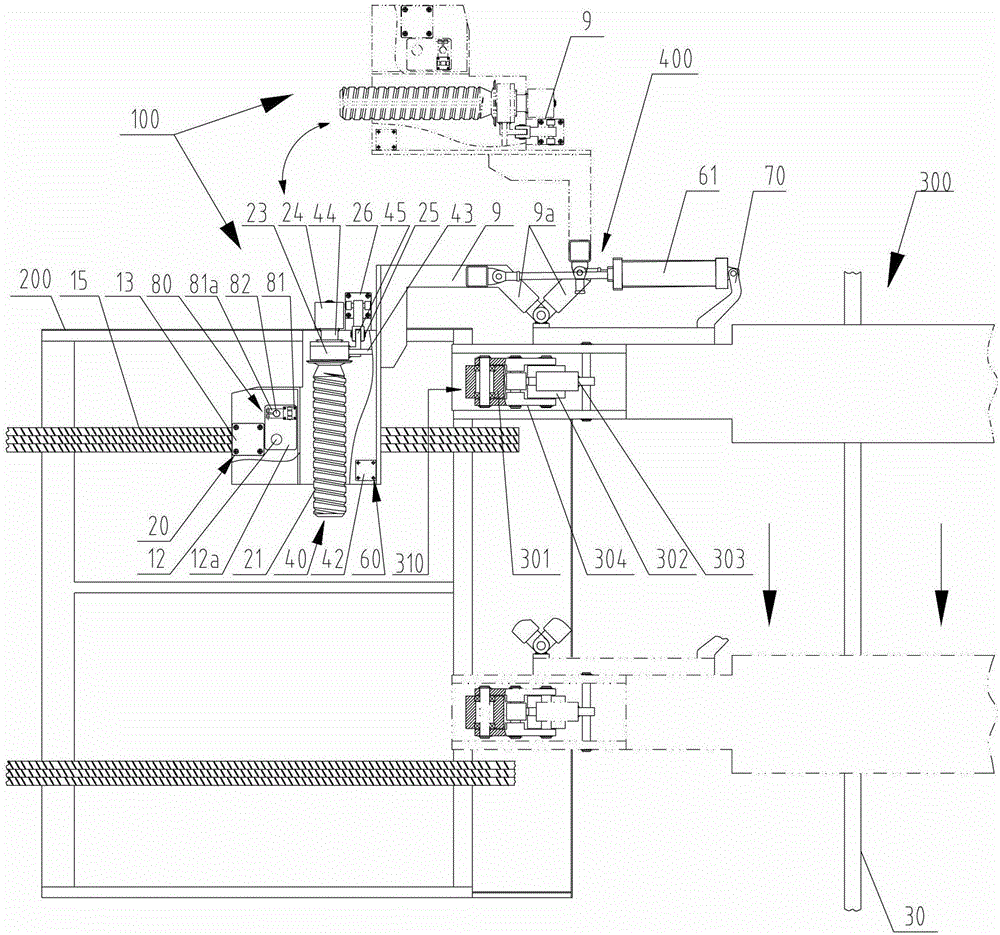

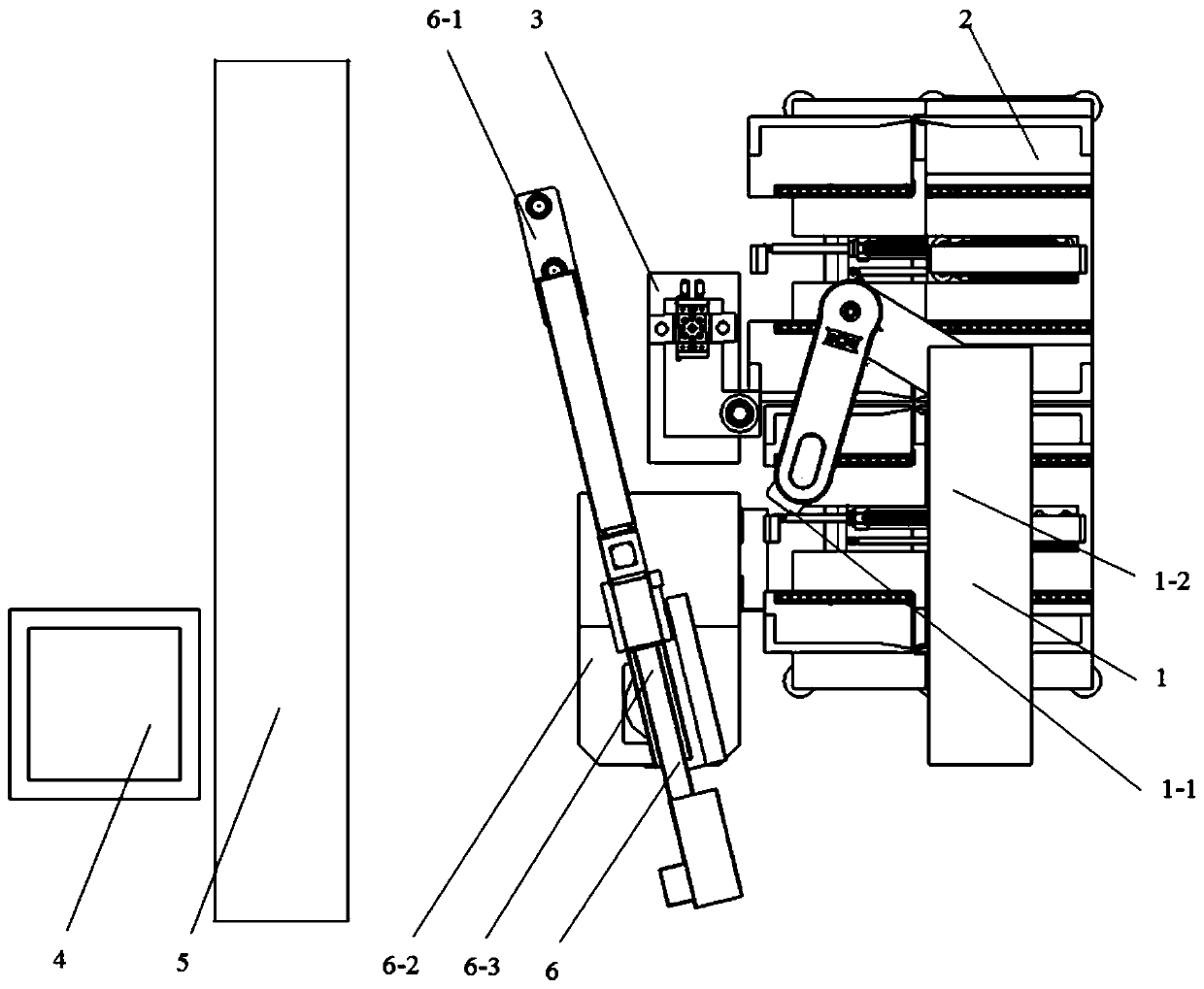

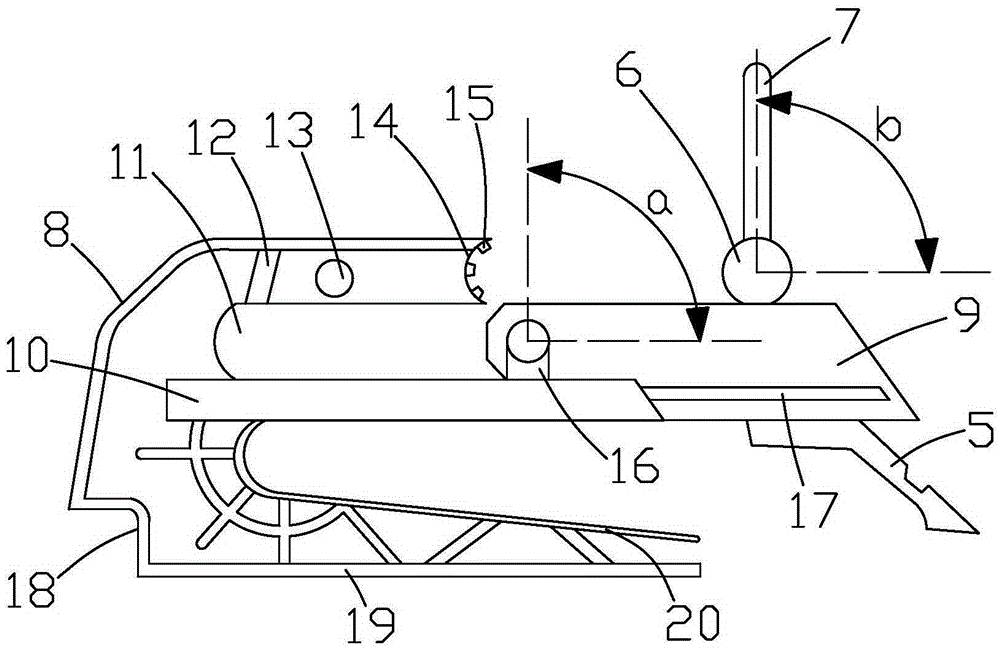

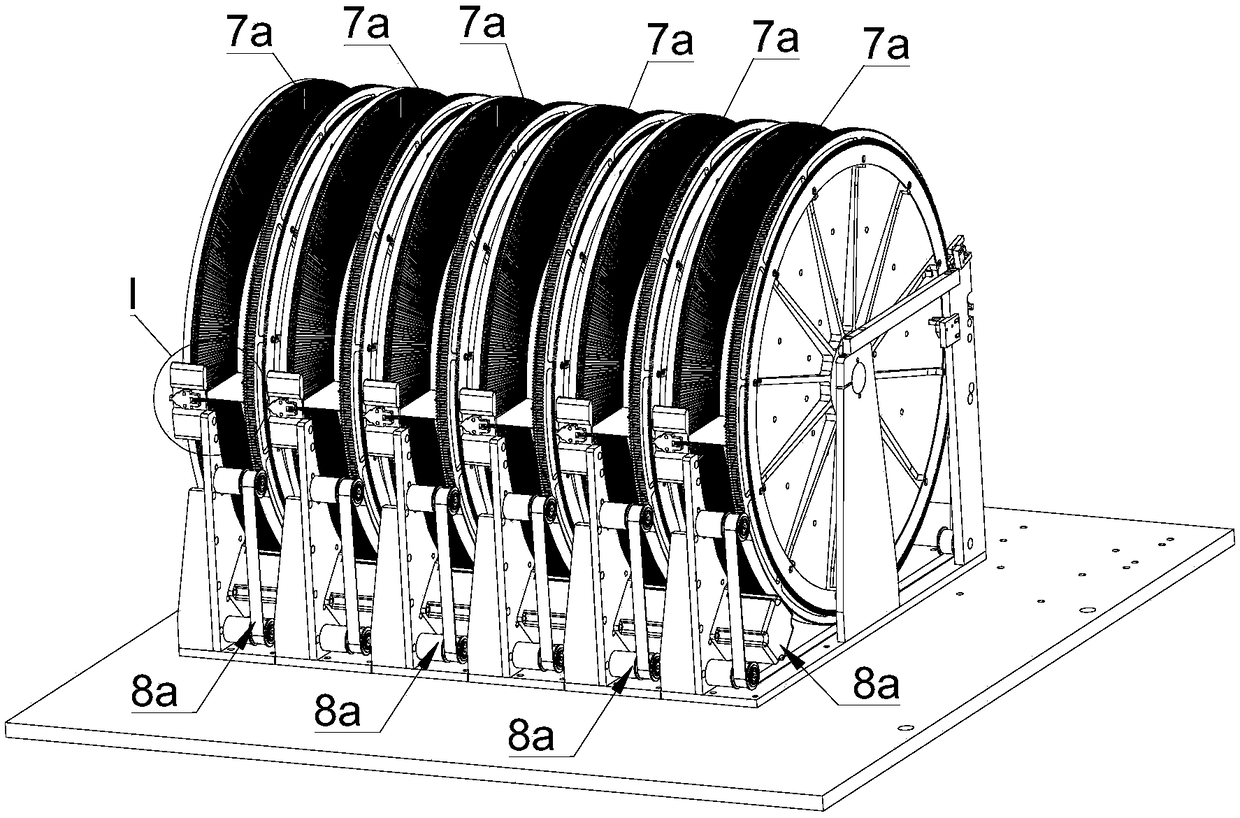

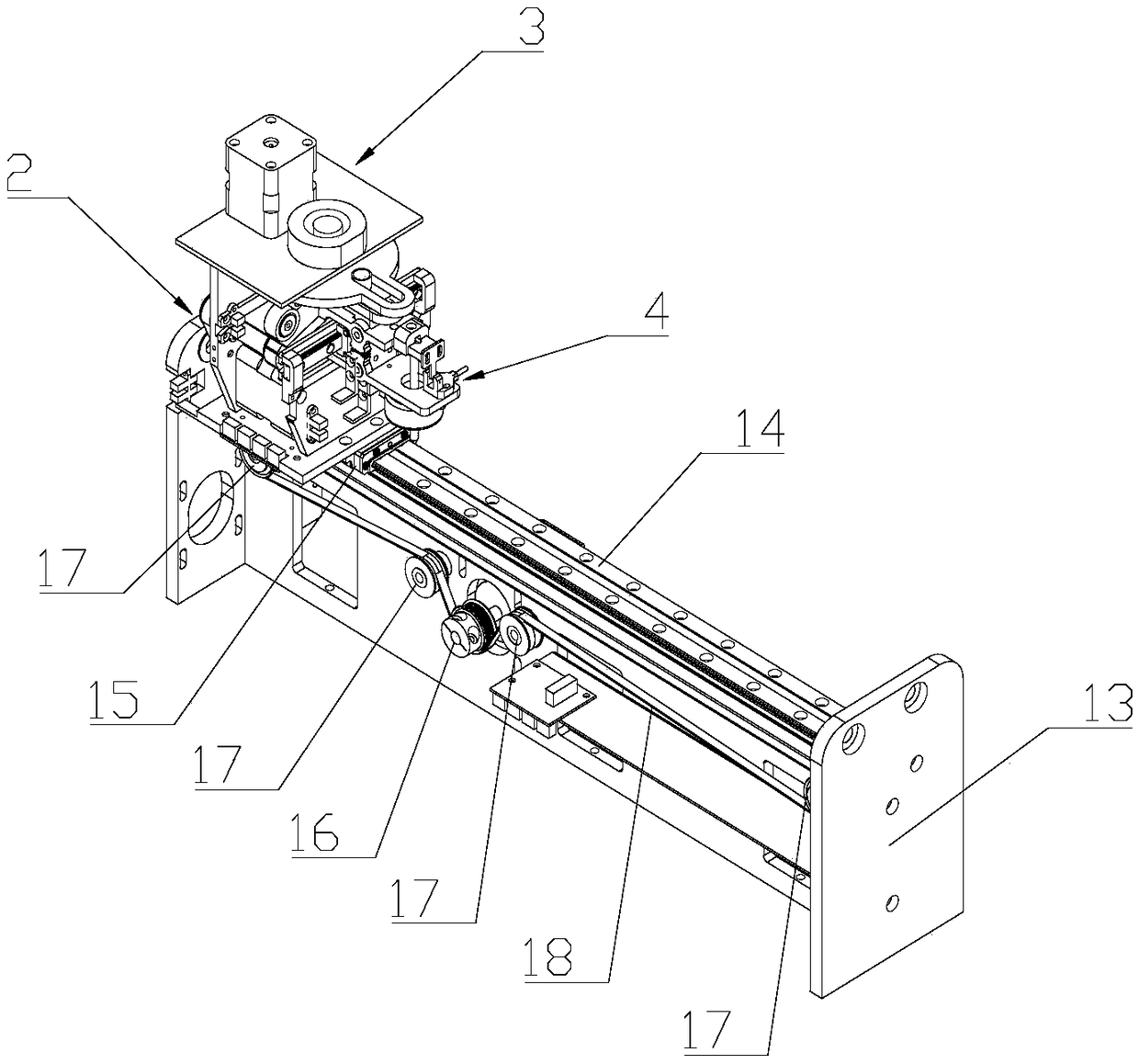

Automatic lifting steel bar feeding device in steel bar processing production line and its technology

ActiveCN102989933BSimple structureCompact structureMetal rolling arrangementsProduction lineEngineering

The invention discloses an automatic lifting type rebar feeder and automatic lifting type rebar feeding process in a rebar machining assembly line. The rebar feeder comprises a rack, a material absorbing mechanism, a discharging mechanism, a material guide mechanism and a control device; the material absorbing mechanism, the discharging mechanism, the material guide mechanism and the control device are arranged on the rack; the material absorbing mechanism comprises a material absorbing air cylinder and a magnetic absorbing device; the discharging mechanism comprises a discharging air cylinder and a stainless steel discharging rod; and the material guide mechanism comprises a material guide roller, a material guide roller supporting frame and a material guide air cylinder. The process is carried out by the following steps in sequence: 1) setting an original state; 2) absorbing and lifting a material; 3) discharging and supporting the material; 4) dividing and feeding the material; 5) discharging the material; and 6) drawing a rebar to move. The rebar feeder provided by the invention has the beneficial effects of simple structure, high working efficiency, labor saving, cost reduction and convenience in maintenance. The rebar feeder provided by the invention is hinged on the lateral face of rebar machining equipment, and moves along with the rebar machining equipment, so that a transportation procedure can be eliminated, the space occupied by the former procedure can be saved, and the application range is wider.

Owner:TJK MACHINERY TIANJIN

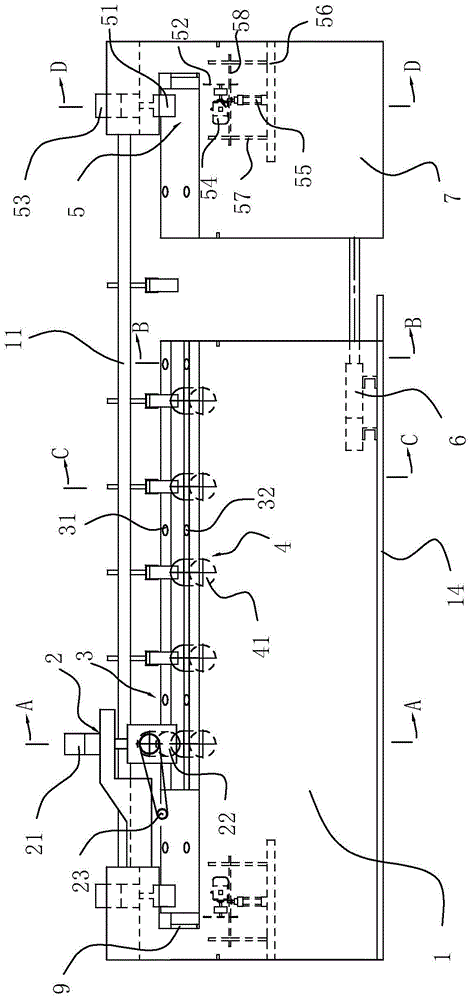

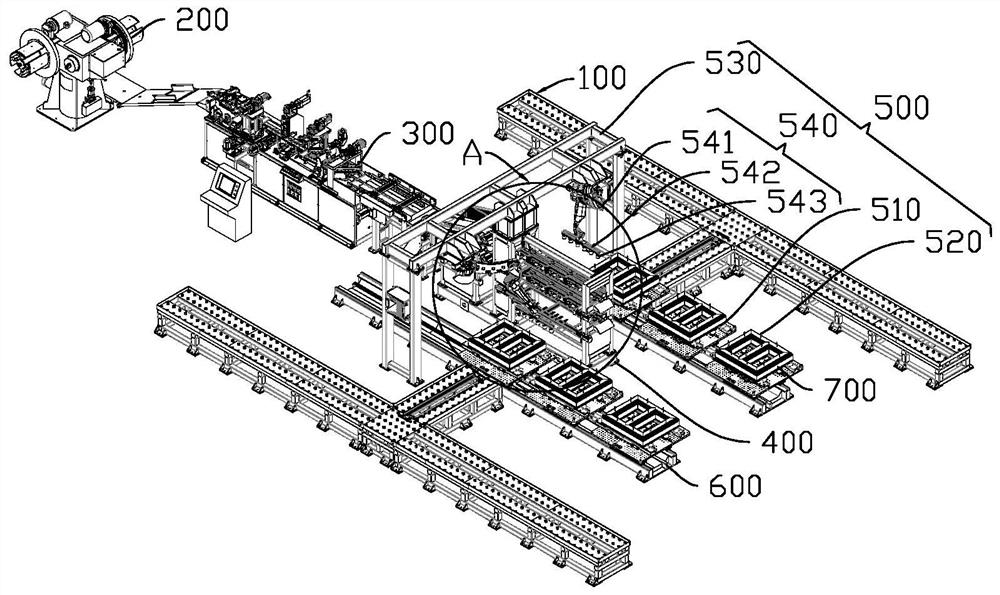

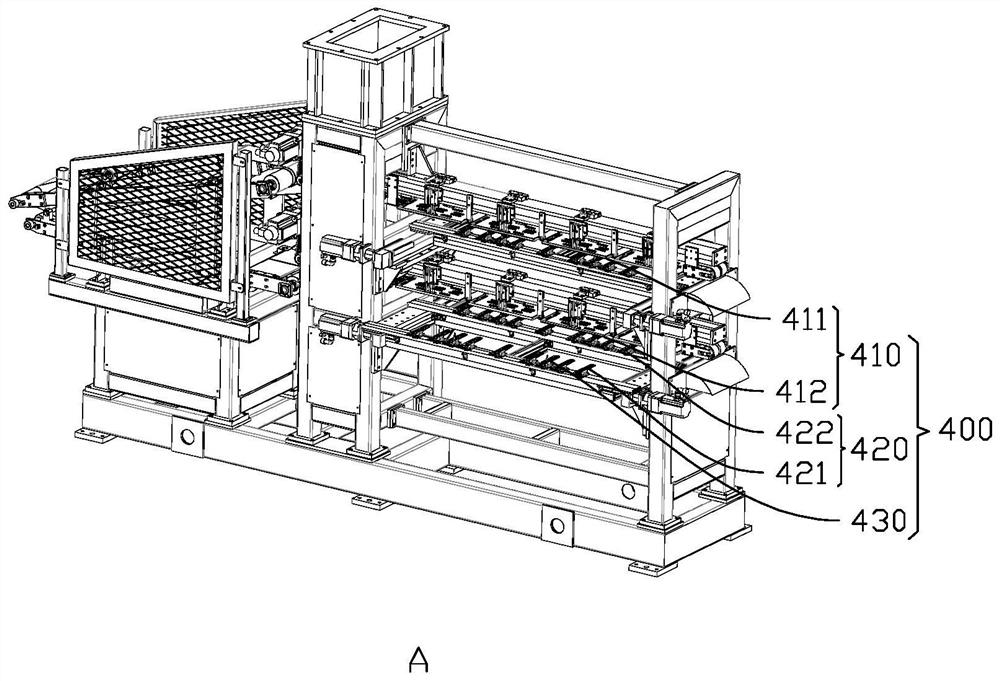

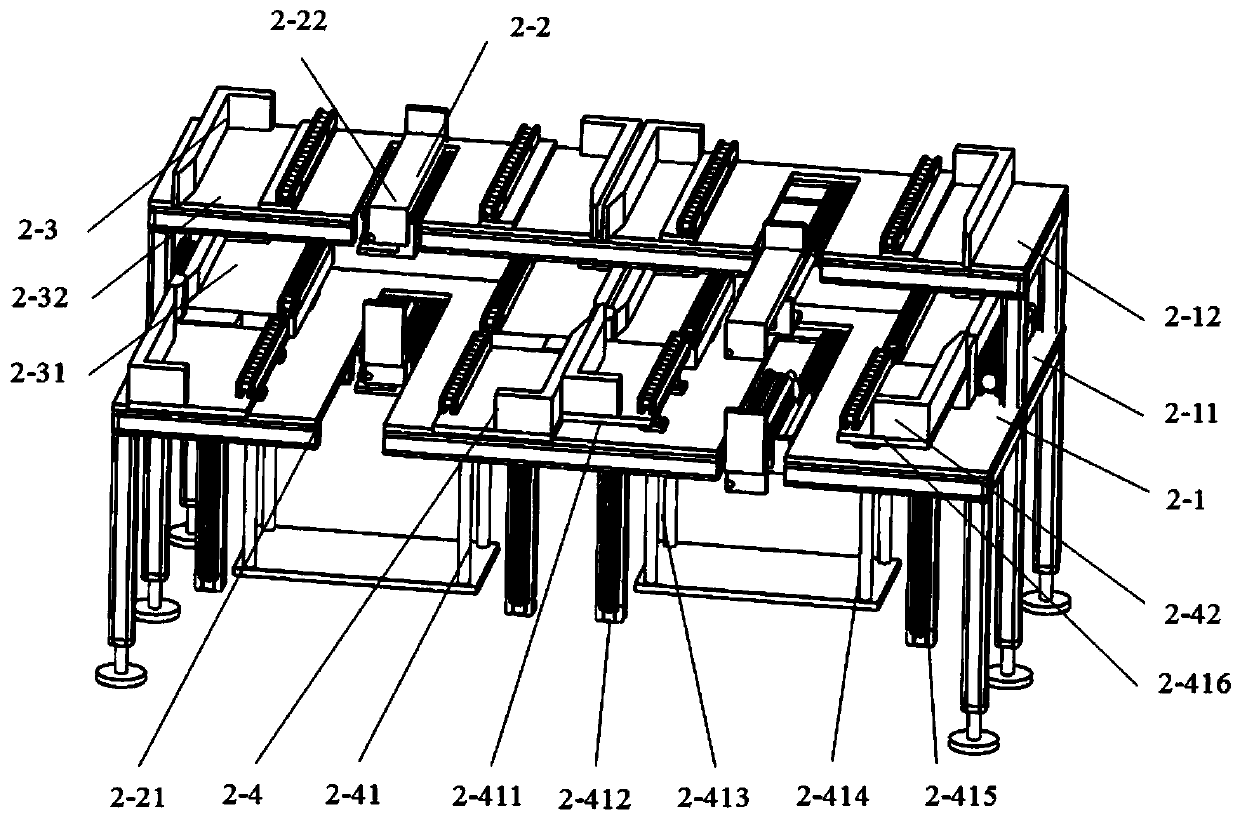

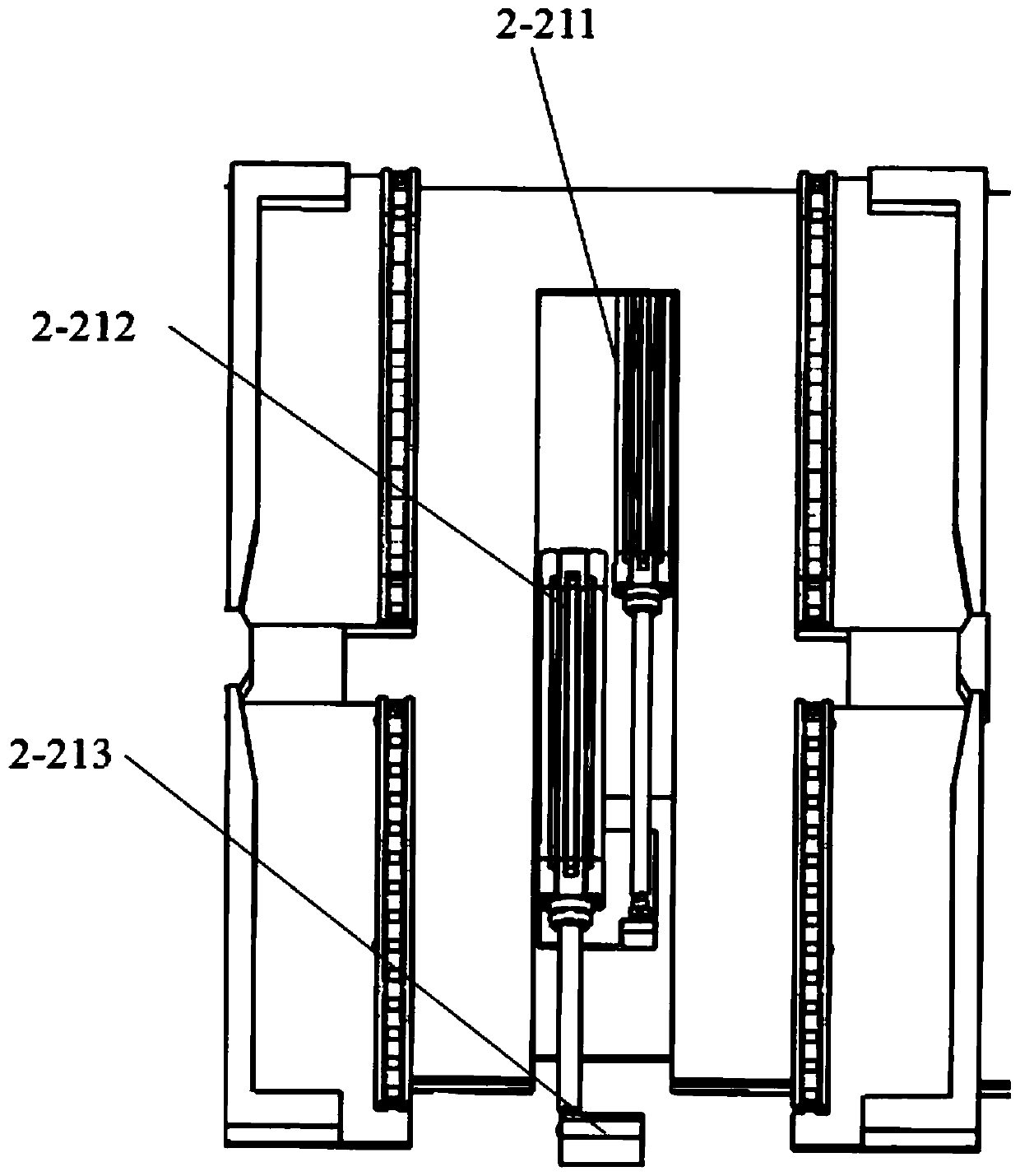

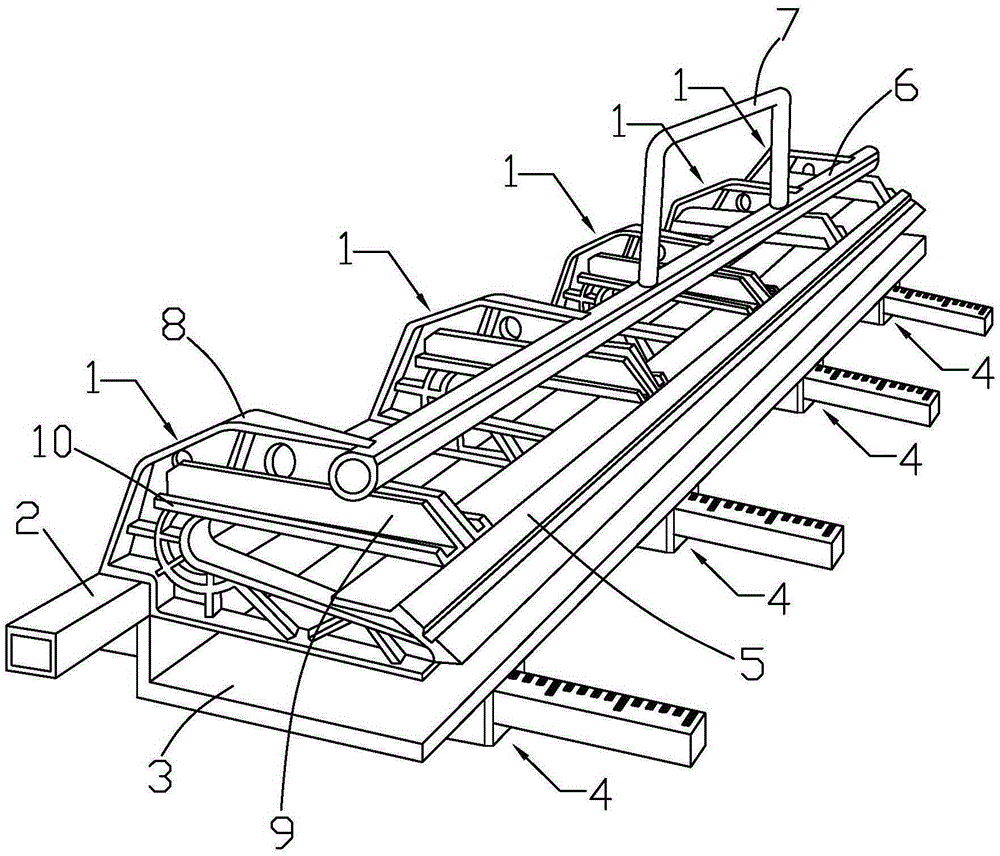

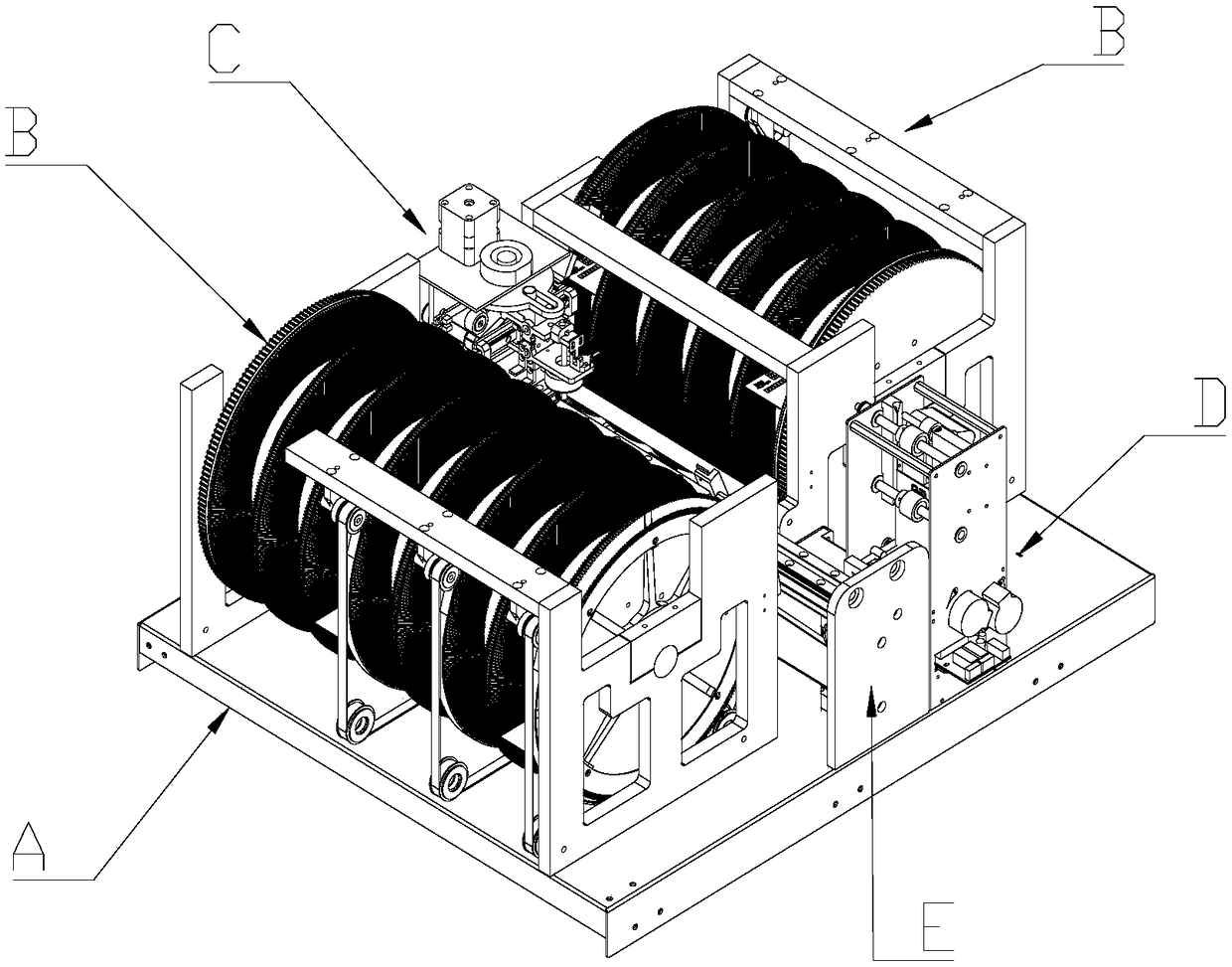

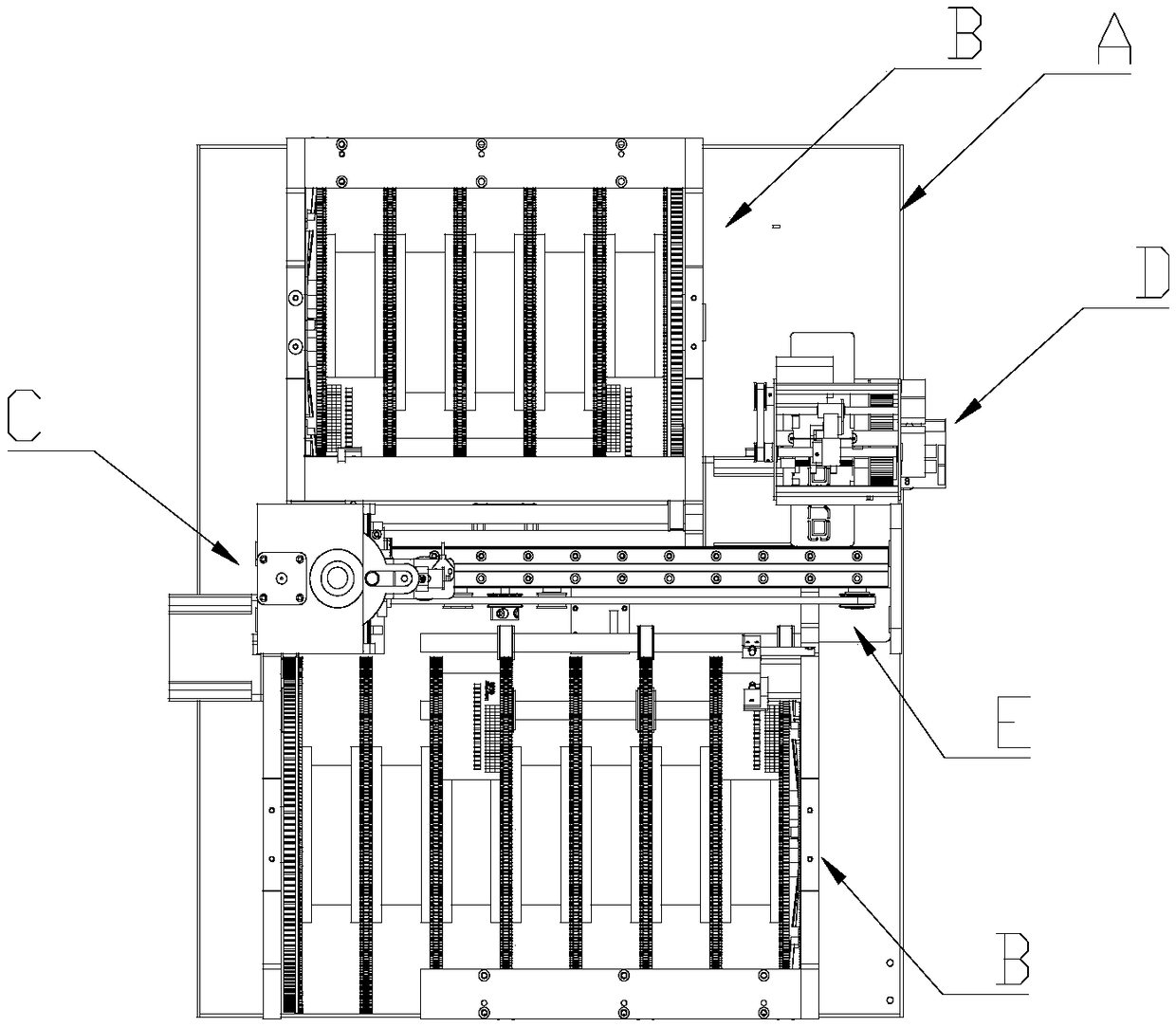

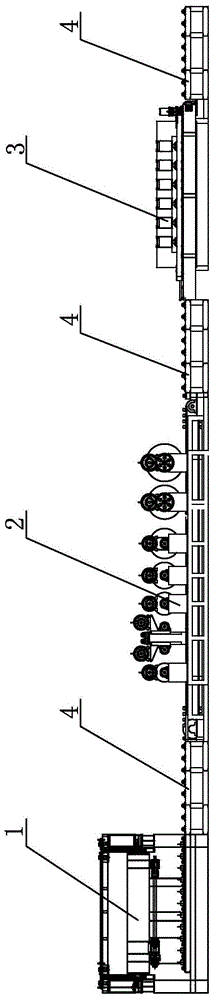

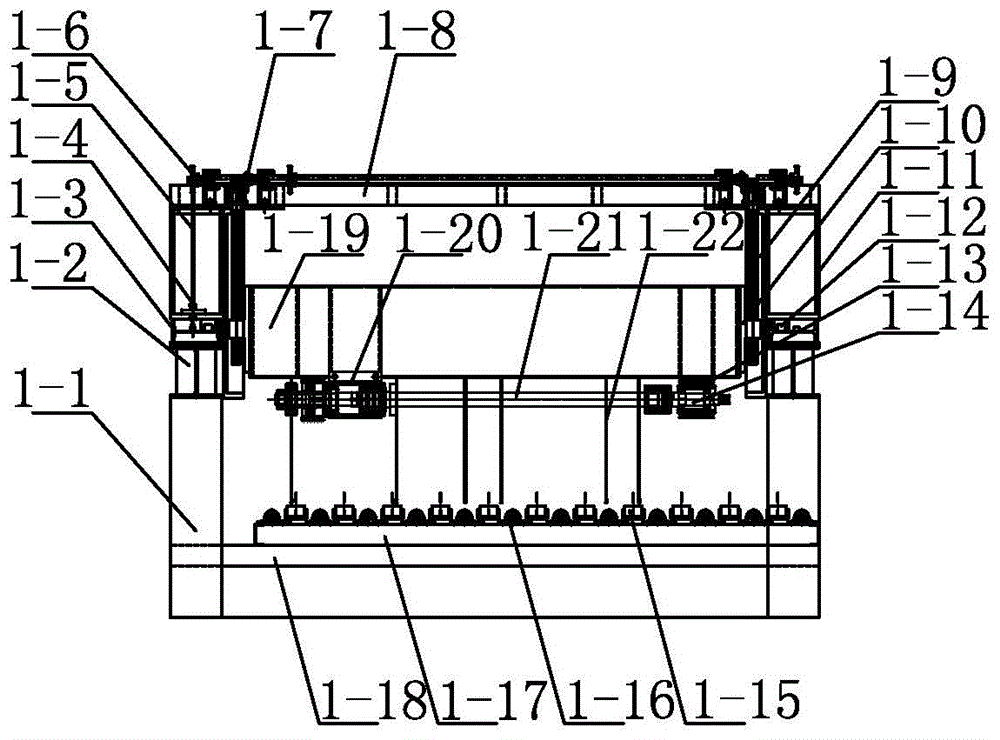

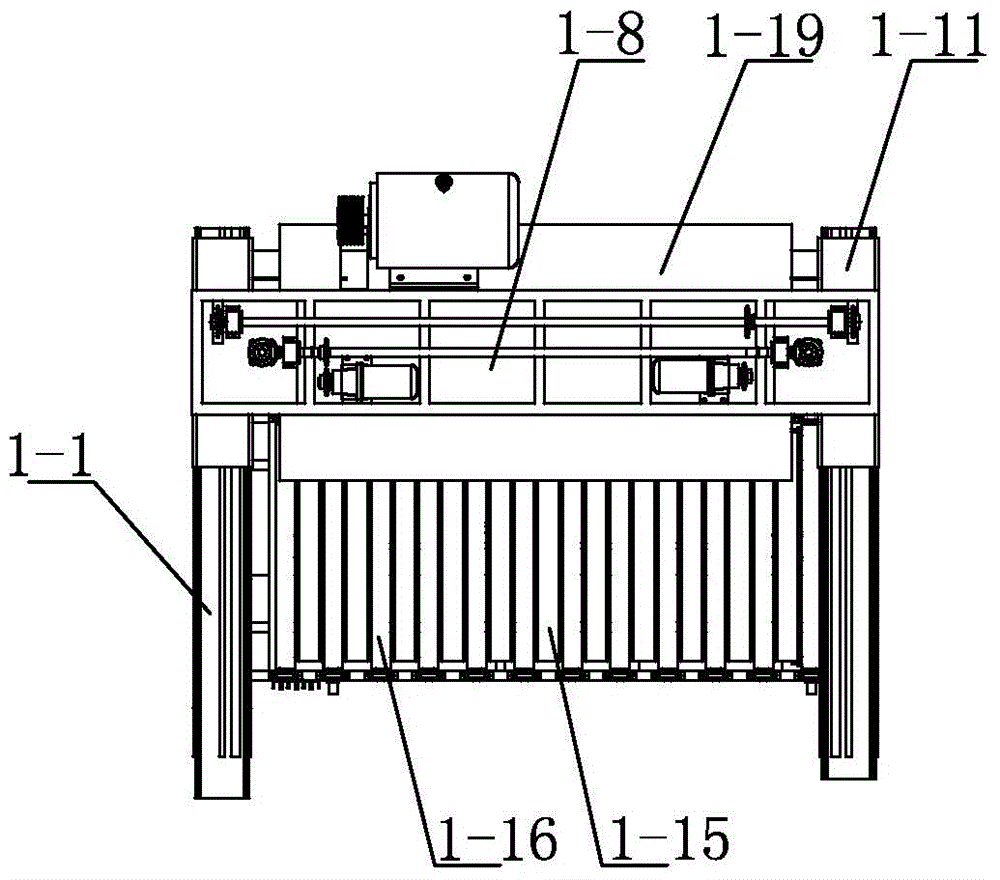

Silicon steel sheet iron core production line

PendingCN112670074ARealize automated productionIncrease flexibilityInductances/transformers/magnets manufactureProduction lineCantilever

The invention discloses a silicon steel sheet iron core production line comprising an unwinding mechanism, a shearing mechanism, a feeding mechanism, a laminating mechanism and a discharging mechanism; the feeding mechanism comprises a magnetic conveying belt, a feeding piece and a first positioning rod; the magnetic conveying belt comprises an upper conveying belt body and a lower conveying belt body, and the feeding piece can extend out in parallel in the orthogonal direction of the magnetic conveying belt; a first feeding sub-table and a second feeding sub-table are mounted below the upper conveying belt and move oppositely; a third feeding sub-table and a fourth feeding sub-table are mounted below the lower conveying belt and move oppositely; the first positioning rod is used for positioning silicon steel sheets, and the lamination mechanism comprises a lamination table, a cantilever beam and two six-degree-of-freedom manipulators; the six-degree-of-freedom mechanical arm is hoisted on the cantilever beam and comprises an electric permanent magnet used for attracting the silicon steel sheets; and the discharging mechanism comprises a sliding plate, and the stacking table is placed on a sliding plate. According to the silicon steel sheet iron core production line, the equipment automation degree can be improved, the lamination speed is increased, and thus the production efficiency of the production line is improved.

Owner:CANWIN AUTOMATIC EQUIP CO LTD

Automatic feeding and discharging device for perforating bullet assembling

The invention discloses an automatic feeding and discharging device for perforating bullet assembling. An assembling transferring mechanism is used for assembling materials and storing the materials temporarily; a four-shaft industrial robot is arranged between a material supplying and storing mechanism and the assembling transferring mechanism, and used for carrying the materials between the material supplying and storing mechanism and the assembling transferring mechanism; a punching robot is arranged between the assembling transferring mechanism and a hydraulic machine, and used for carrying the materials between the assembling transferring mechanism and the hydraulic machine; and a wall is arranged between the punching robot and the hydraulic machine. The feeding and discharging devicereduces the frequency of manual feeding and discharging, and is high in efficiency, wide in movement range, simple in structure and easy to control.

Owner:SICHUAN PETROLEUM PERFORATING EQUIP

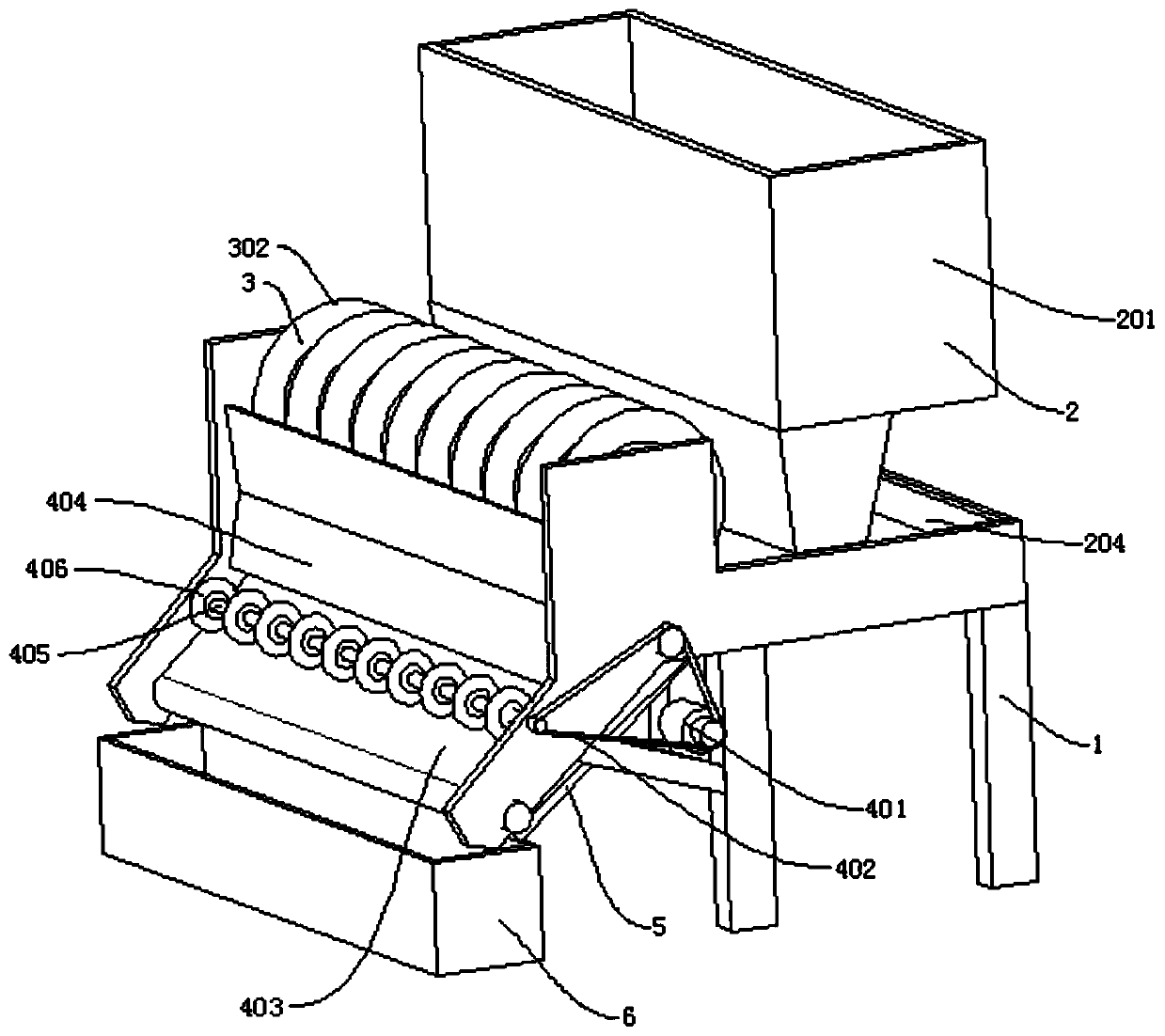

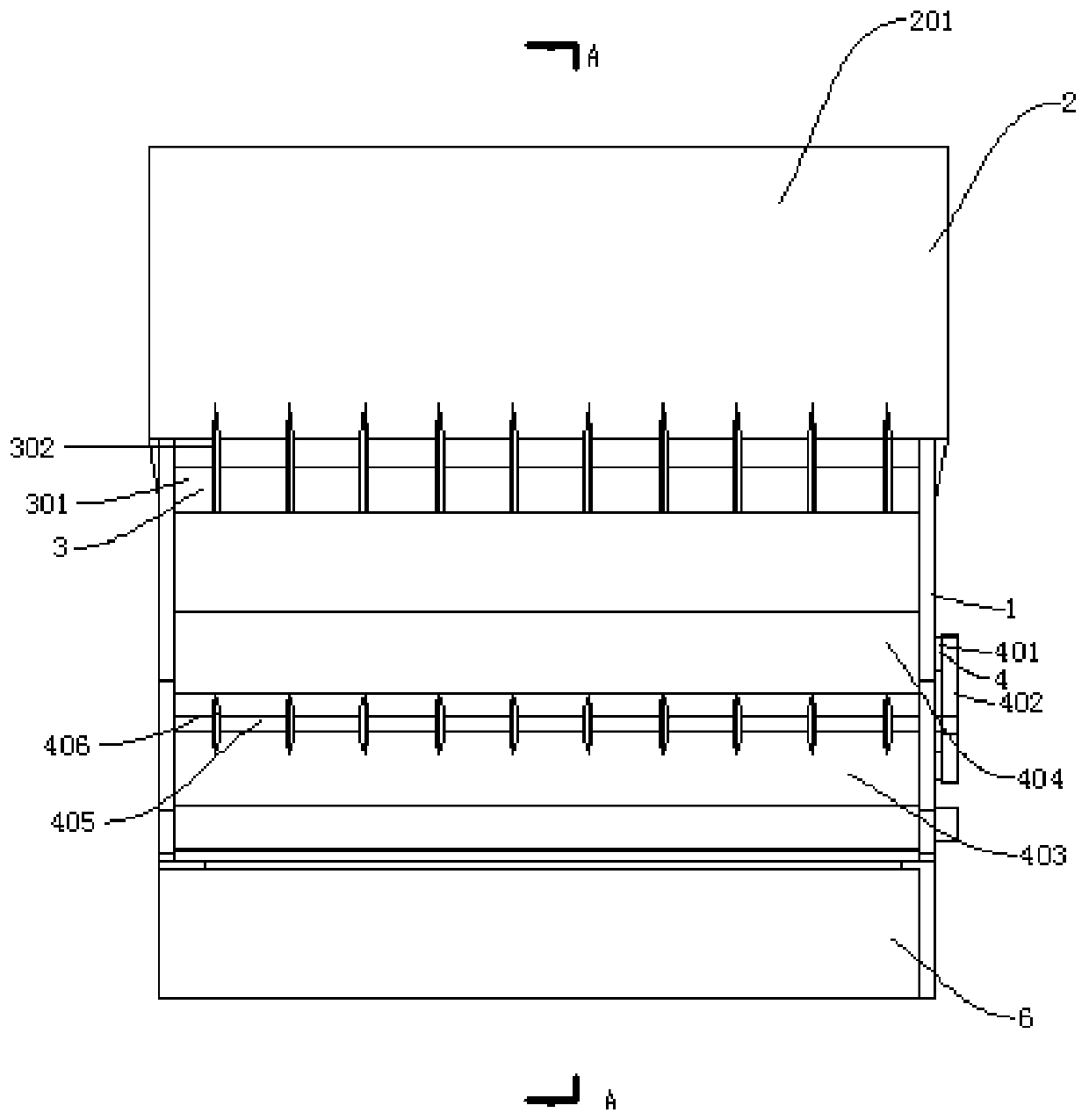

Vegetable cutting device

PendingCN110561542AGuaranteed to passReduce the handling processMetal working apparatusEngineeringVegetable Juices

The invention discloses a vegetable cutting device. The vegetable cutting device comprises a frame, a feeding mechanism and a collecting box, and further comprises a first cutting mechanism, a secondcutting mechanism and a juice baffle, wherein the feeding mechanism is arranged above the frame; the first cutting mechanism is arranged on one side of the feeding mechanism; the second cutting mechanism is arranged obliquely below the first cutting mechanism; the juice baffle is arranged below the second cutting mechanism; and the collecting box is arranged below the juice baffle and the second cutting mechanism. The vegetable cutting device is provided with two groups of cutting mechanisms at the front and rear parts, is convenient for accomplishing the cutting of block-shaped vegetables into stripe vegetables at one step, reduces a process of conveying after the vegetables are cut into stripes, is beneficial to collection of vegetable juice formed by cutting through the arrangement of the juice baffle, is beneficial to environmental protection, prevents stripped vegetables from flying out through a limiting plate during stripe cutting, horizontally lays the stripped vegetables on aconveying belt, and is beneficial to ensuring that the stripped vegetables pass through second blades.

Owner:HEZHOU UNIV

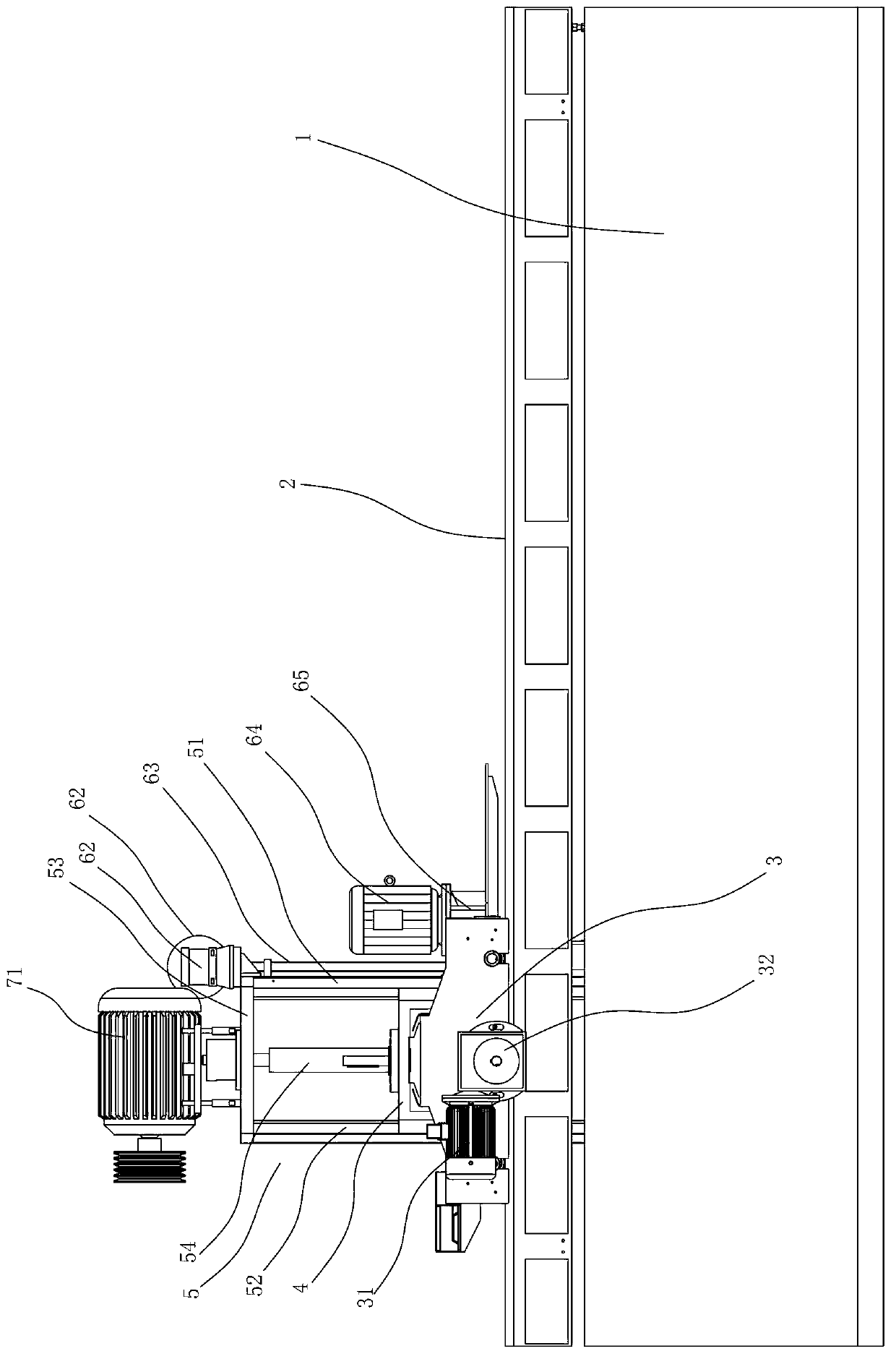

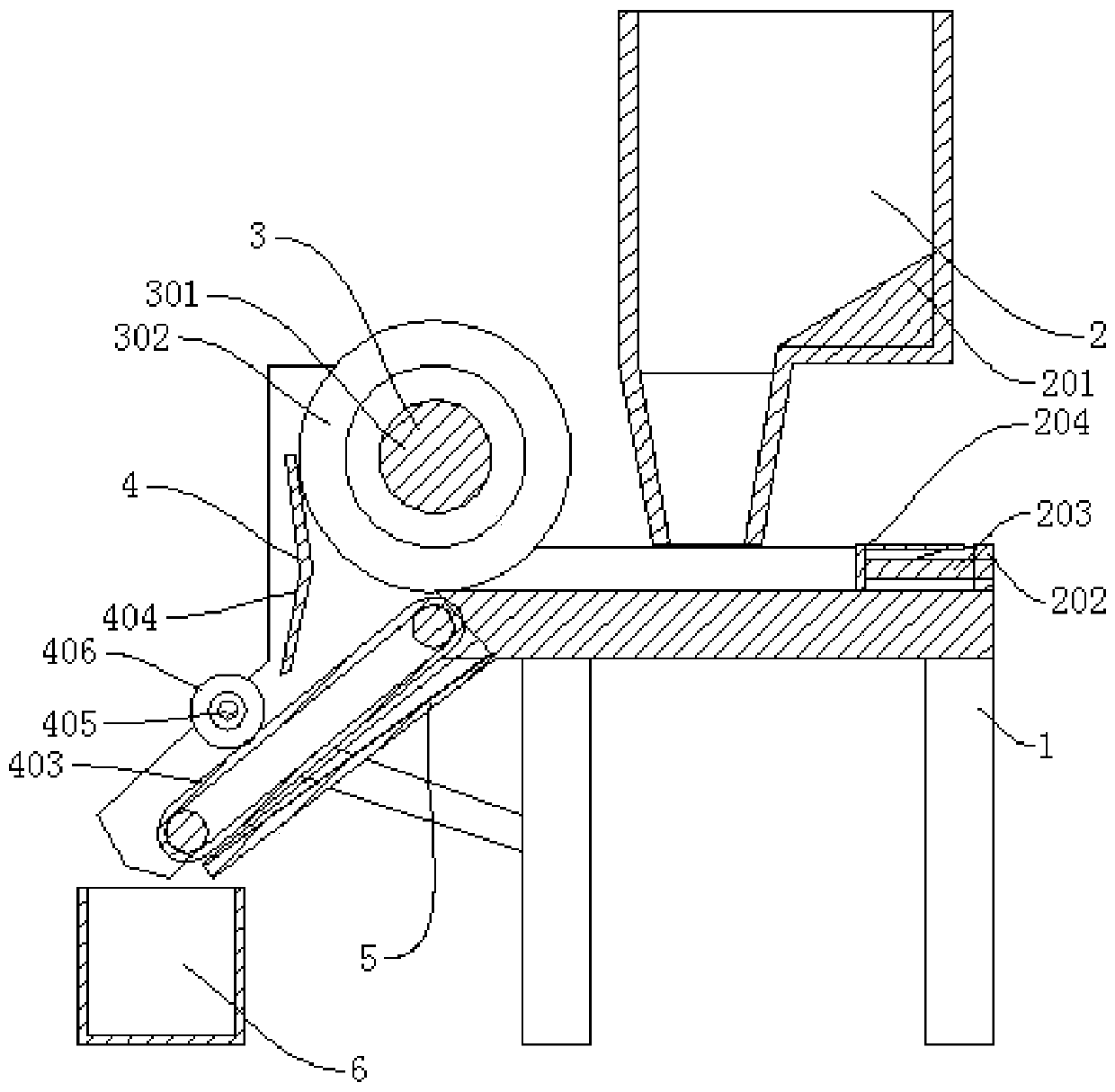

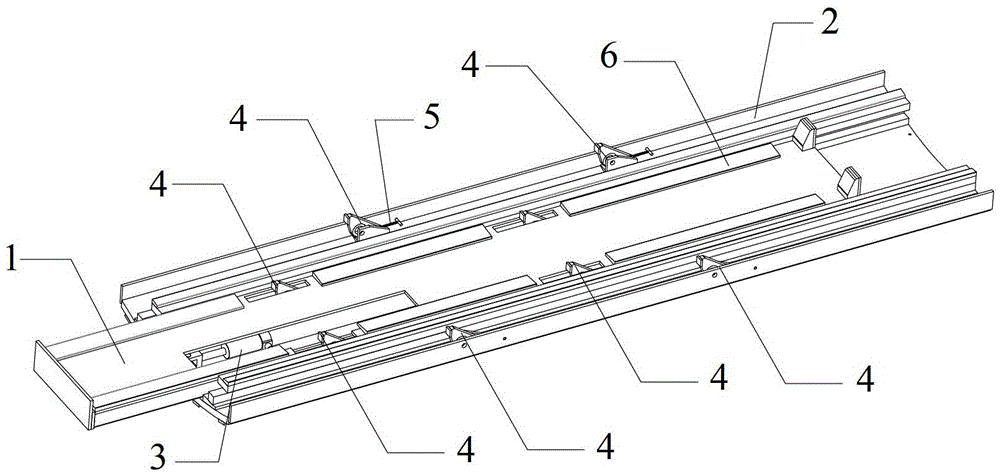

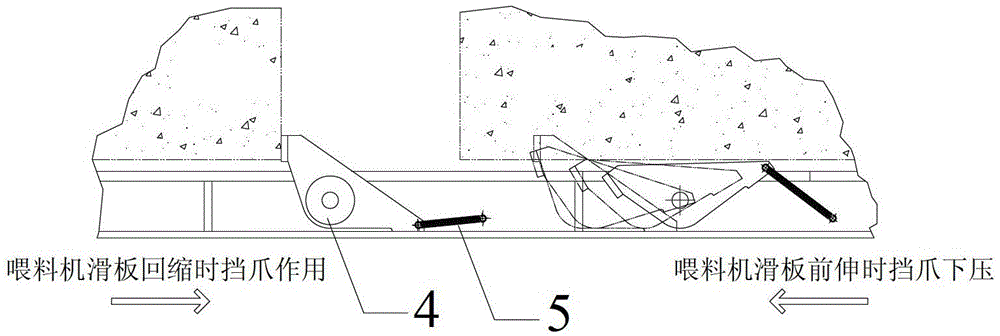

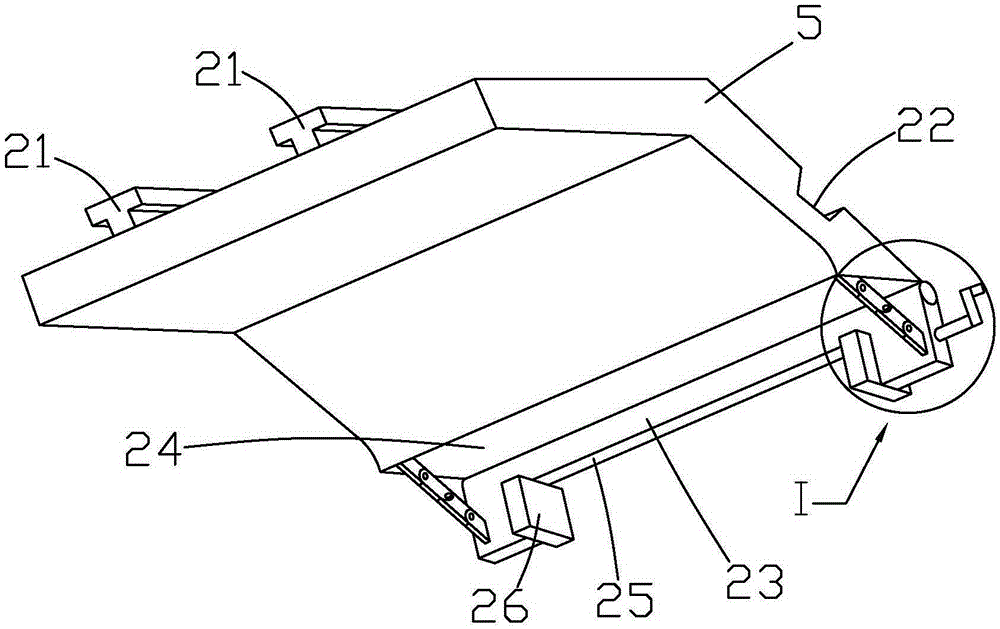

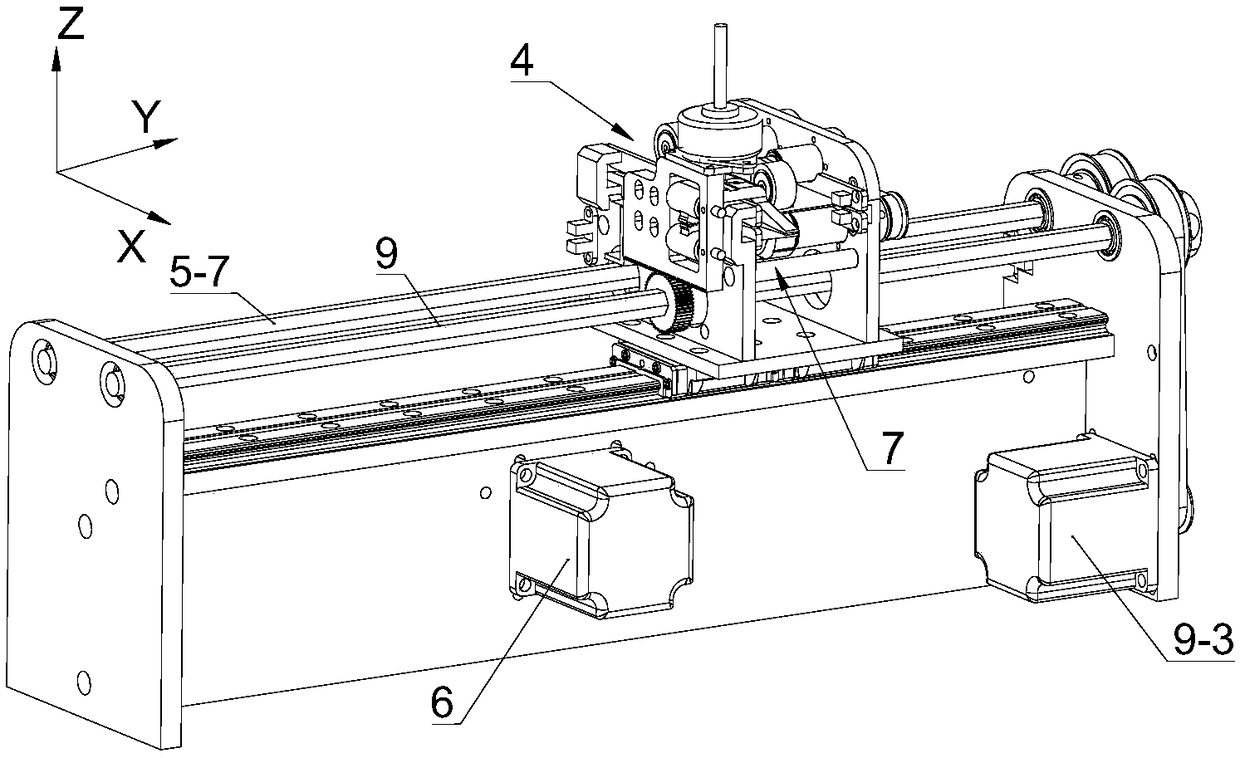

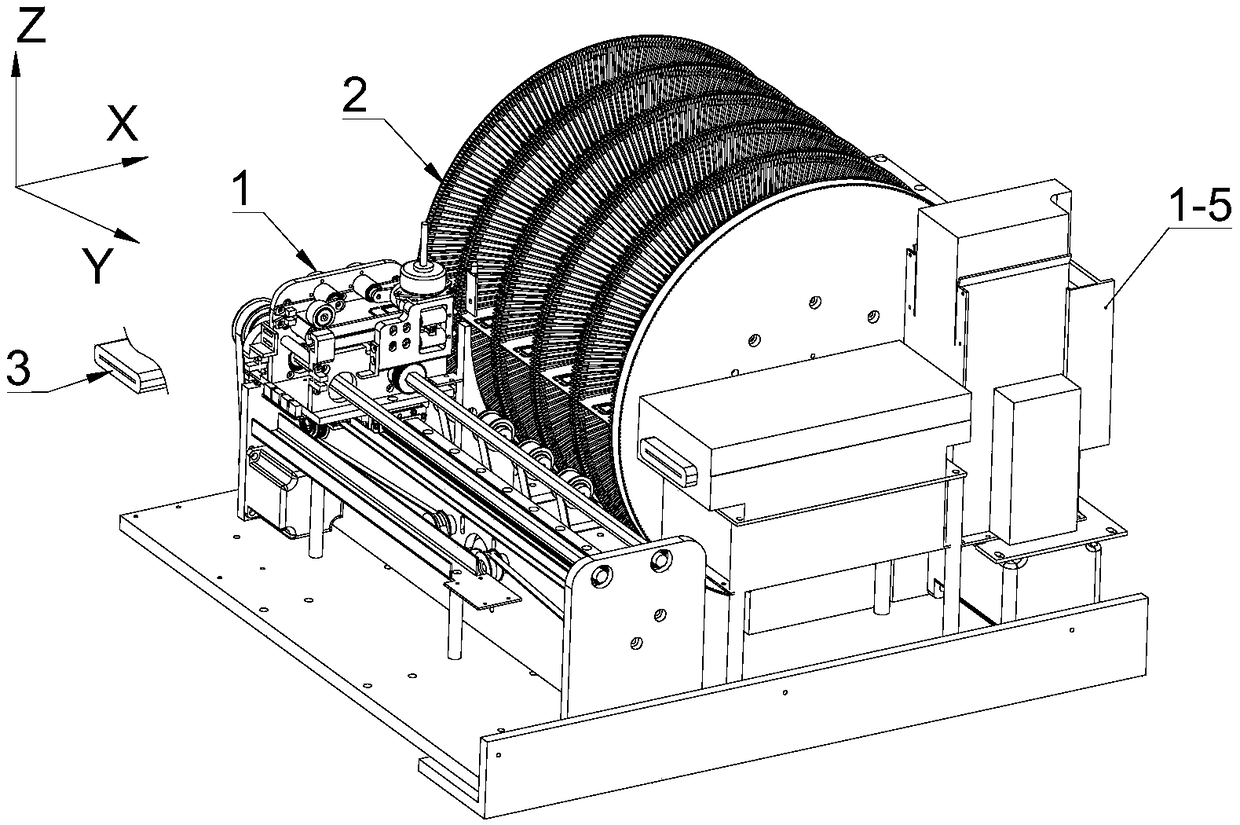

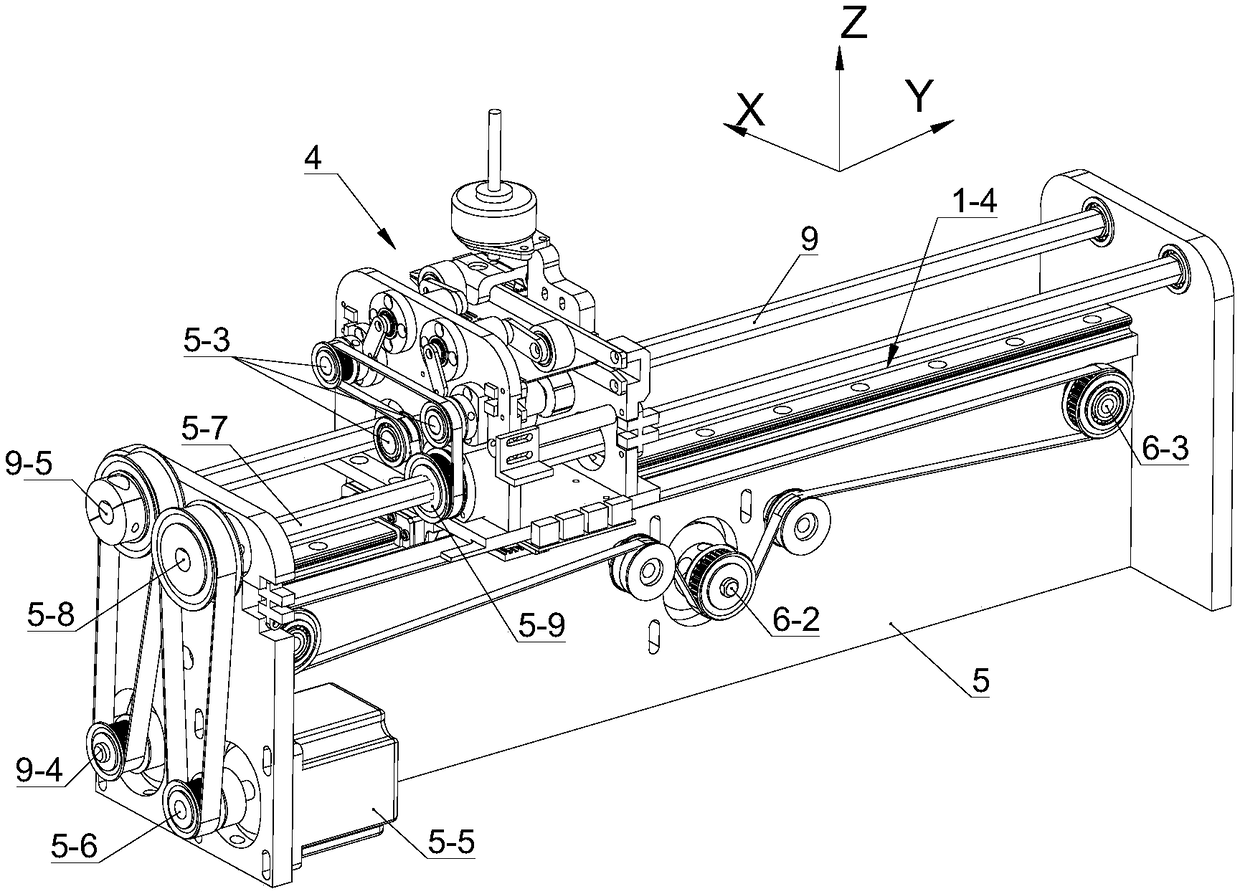

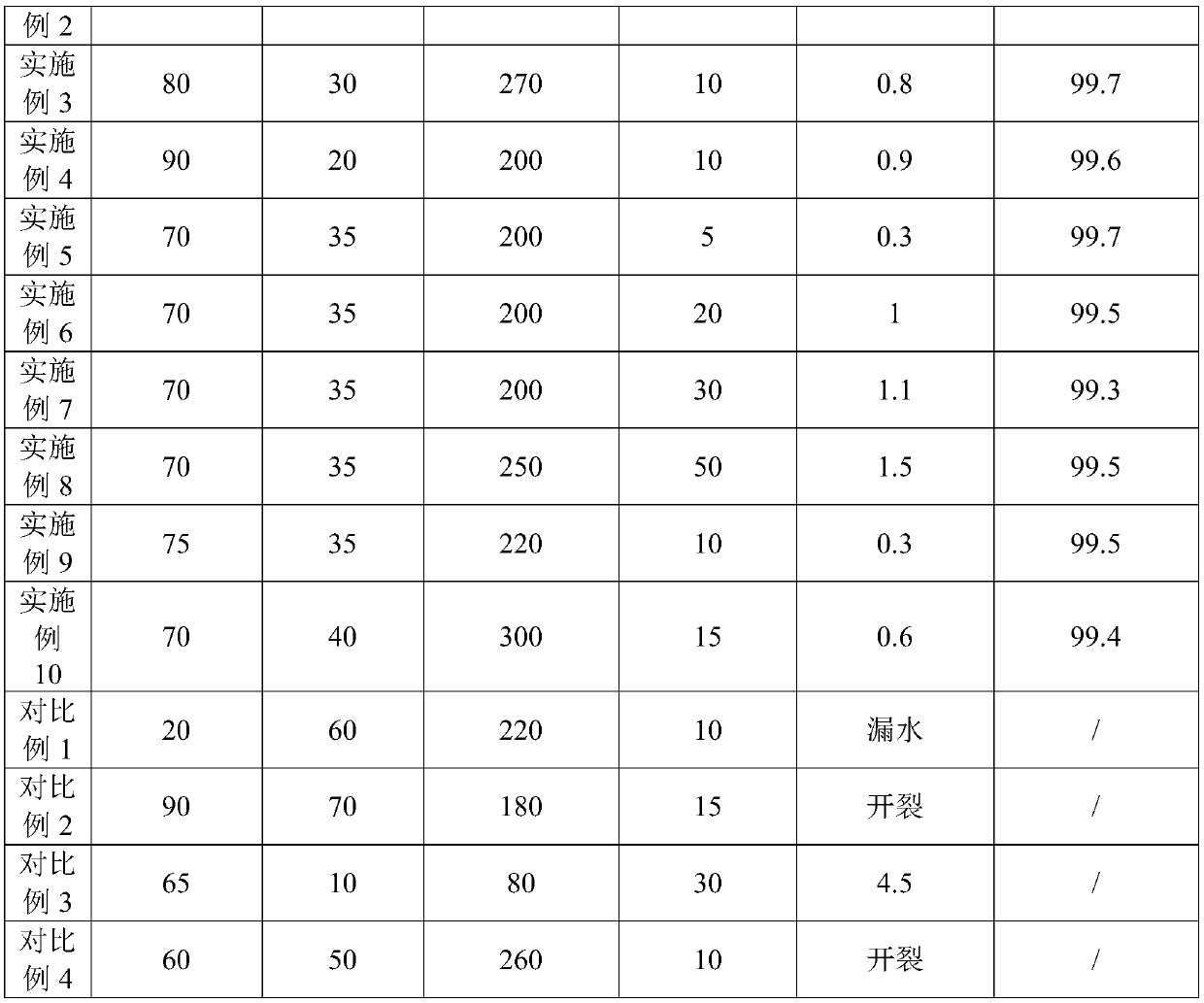

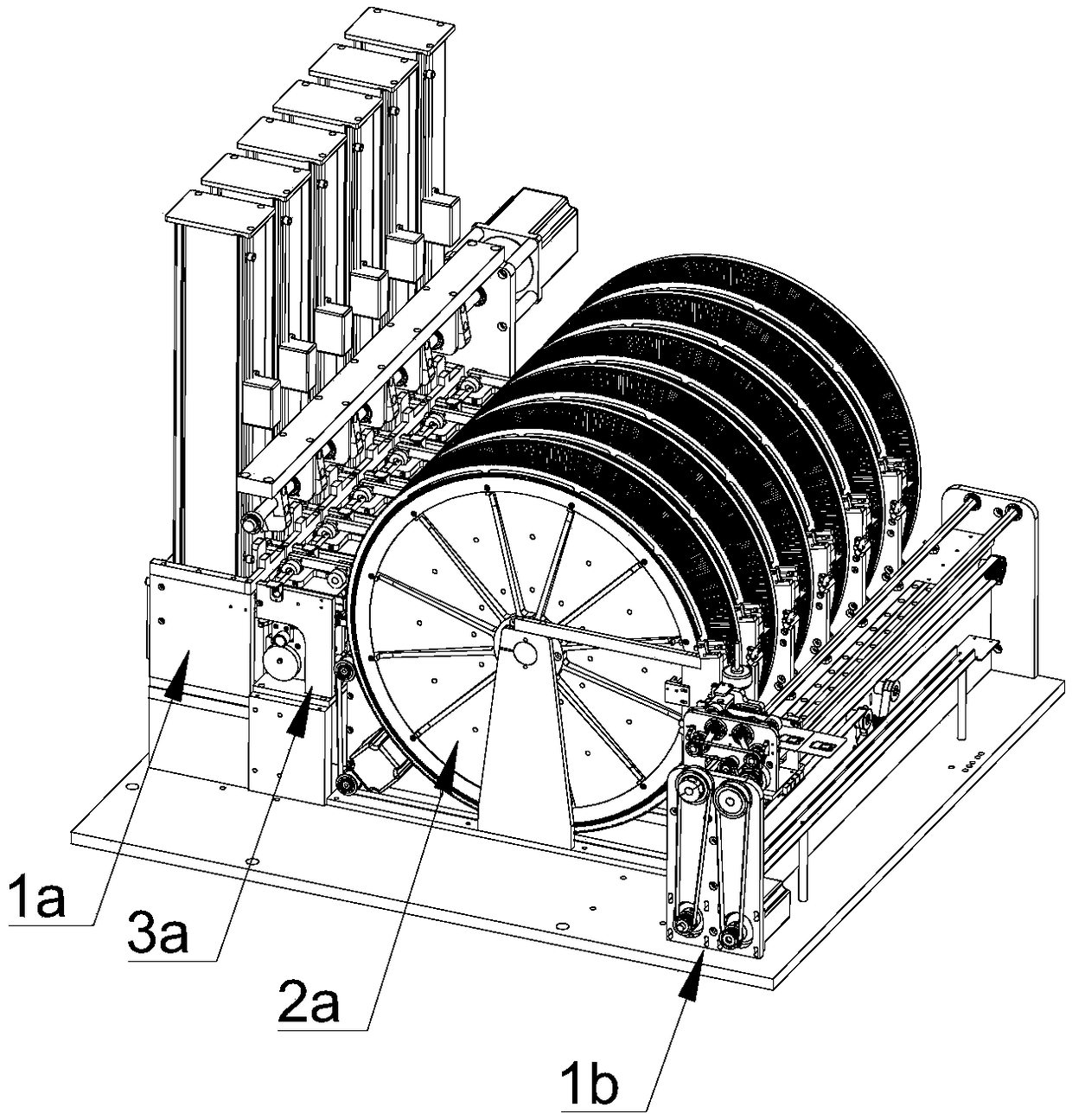

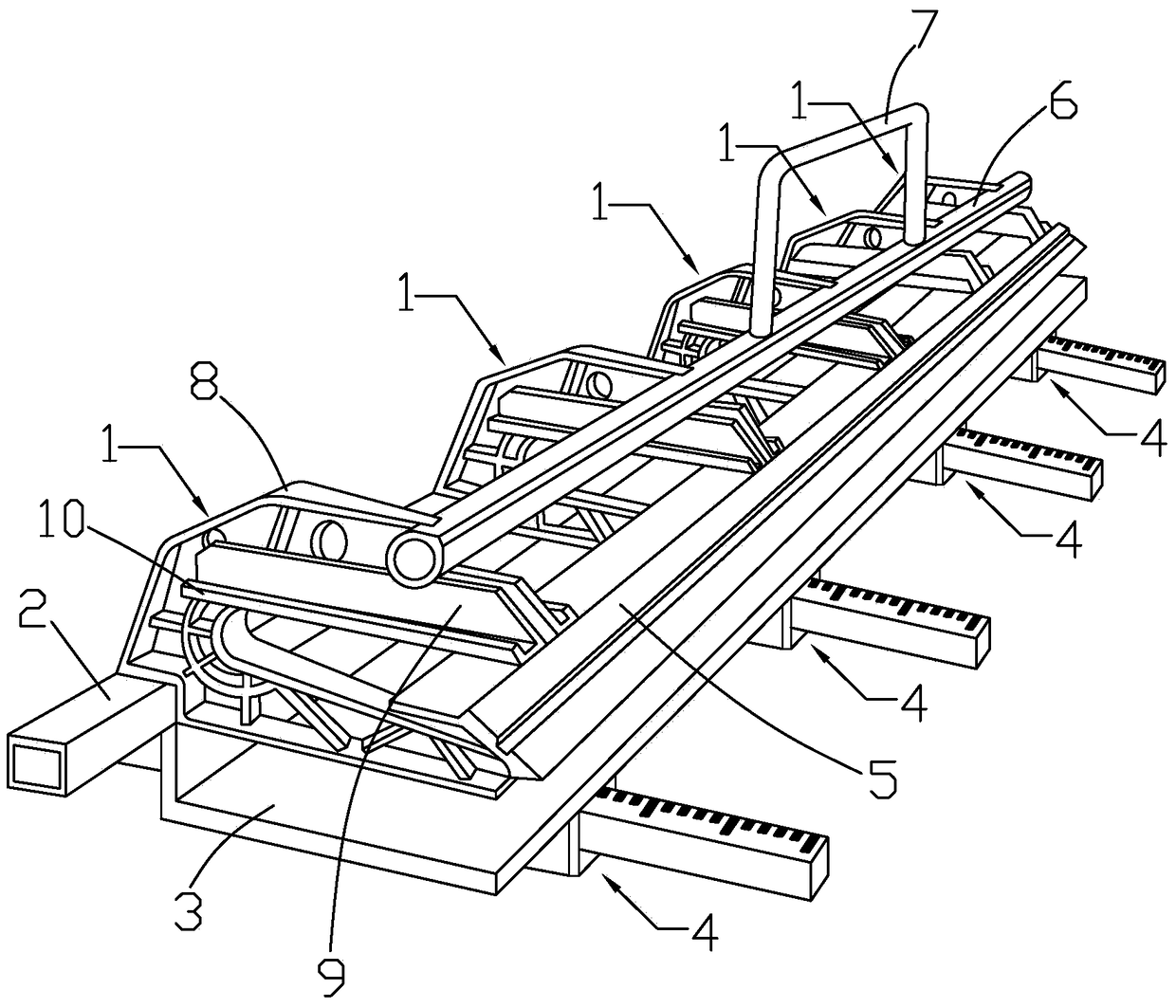

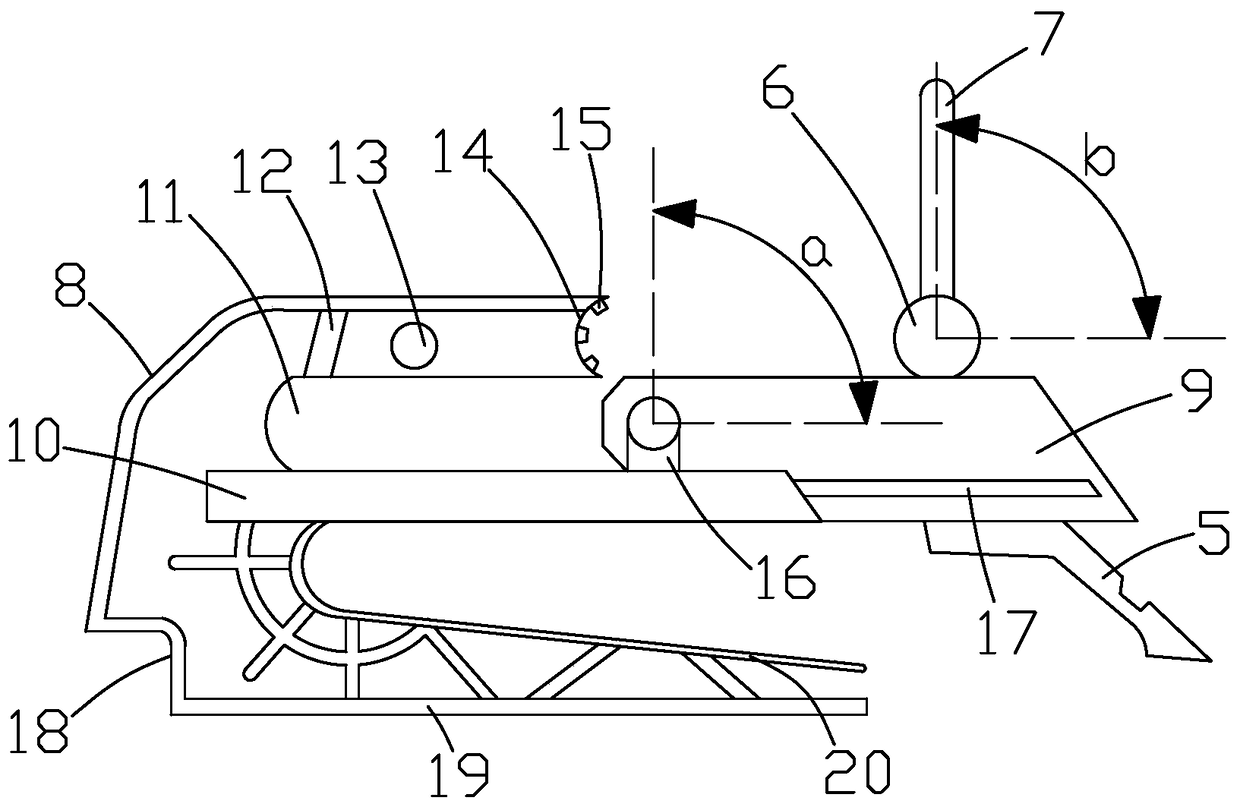

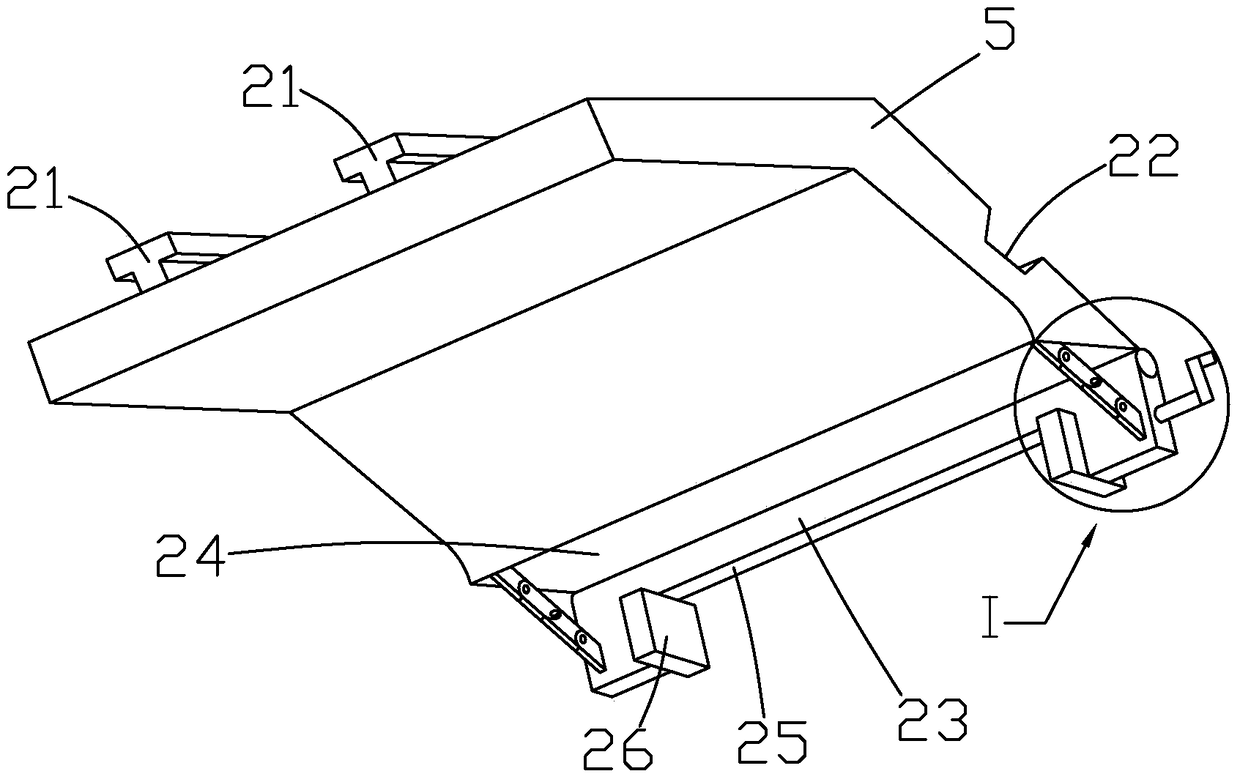

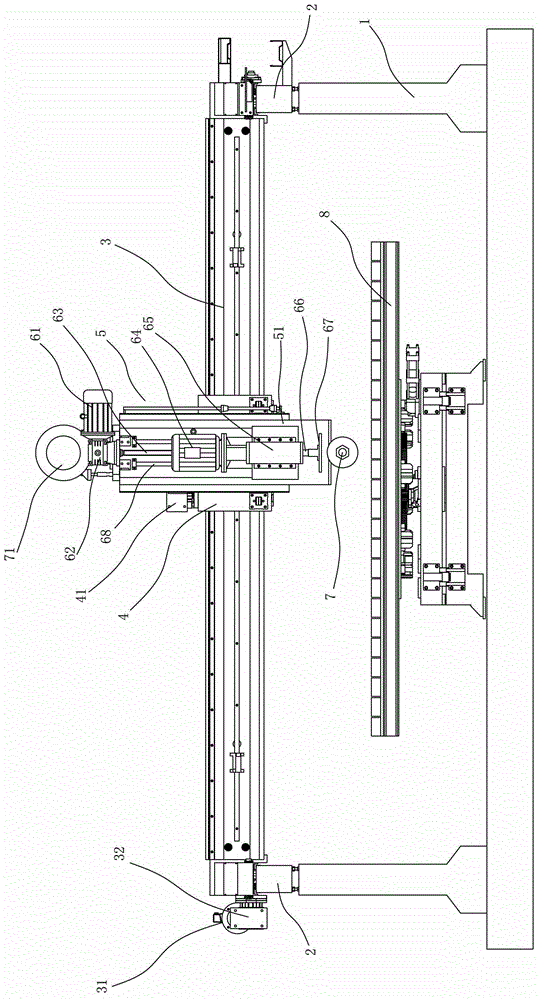

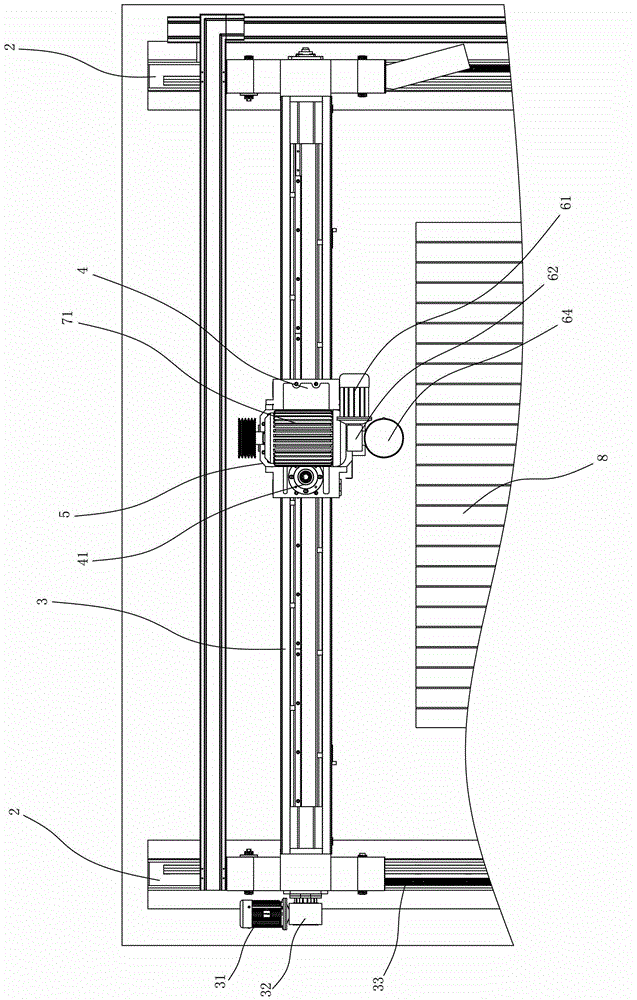

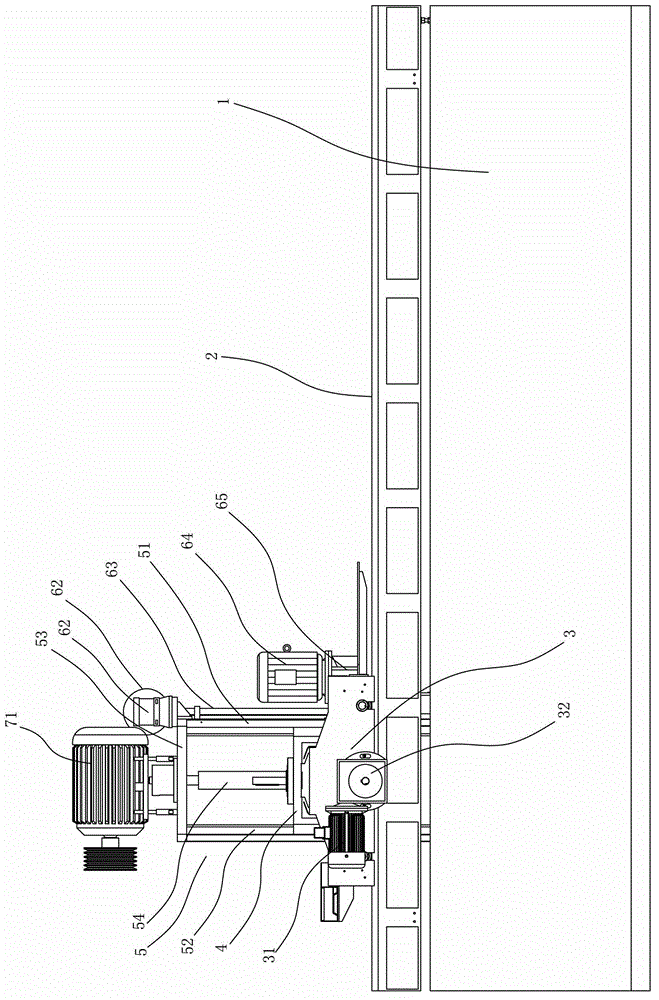

A kind of automatic sheet feeding machine equipment in shield tunneling machine

ActiveCN103867217BReduce the handling processReduce workloadUnderground chambersTunnel liningEngineeringShield tunneling

The invention relates to internal automatic segment feeder equipment of a shield tunneling machine. The internal automatic segment feeder equipment consists of an external conveying platform and an internal conveying platform which is embedded inside the external conveying platform, wherein backstop retaining pawls are respectively arranged at the two sides of each of the external and internal conveying platforms, and tube segments are conveyed to move forwards. Compared with the prior art, the internal automatic segment feeder equipment has the advantages that the structure is simpler, firmer and more reliable, the space utilization ratio is higher, the procedure of ordinary electric hoist transporting is avoided, more construction time is saved, on-site control and automated tube segment assembly can be realized, and the workload of workers is reduced.

Owner:SHANGHAI LIXING ENG TECH DEV

Measurement tool for aluminum strip bender

ActiveCN105403118AAccurate measurementReliable measurementMechanical measuring arrangementsMeasurement deviceAluminum can

The invention discloses a measurement tool for an aluminum strip bender. The measurement tool comprises brake devices, an object carrying plate, a clamping device and measurement devices, wherein the end portions of the brake devices and the object carrying plate are connected with a slide rail, each brake device comprises a fixation support frame, each fixation support frame is successively provided with a limiting clamping groove, a second cantilever, an over beam and a base plate from top to bottom, each second cantilever is symmetrically distributed at the two sides of each fixation support frame, each limiting clamping groove is internally provided with a first cantilever, the two sides of each first cantilever are each provided with a limiting protruding strip, each limiting protruding strip is movably connected with each second cantilever, each first cantilever is rotationally connected with the corresponding limiting protruding strips through a fixation rod, the bottom of the front end of each first cantilever is provided with the clamping device, and the measurement devices are fixedly connected with the bottom of the object carrying plate. The structure is simple, the practicality is high, an aluminum strip can be clamped and positioned, the aluminum can also be loaded and carried, the labor intensity is reduced, the operation is simple and convenient, the safety is high, and the steps for measuring the aluminum strip are simplified.

Owner:嵊州博远铝业有限公司

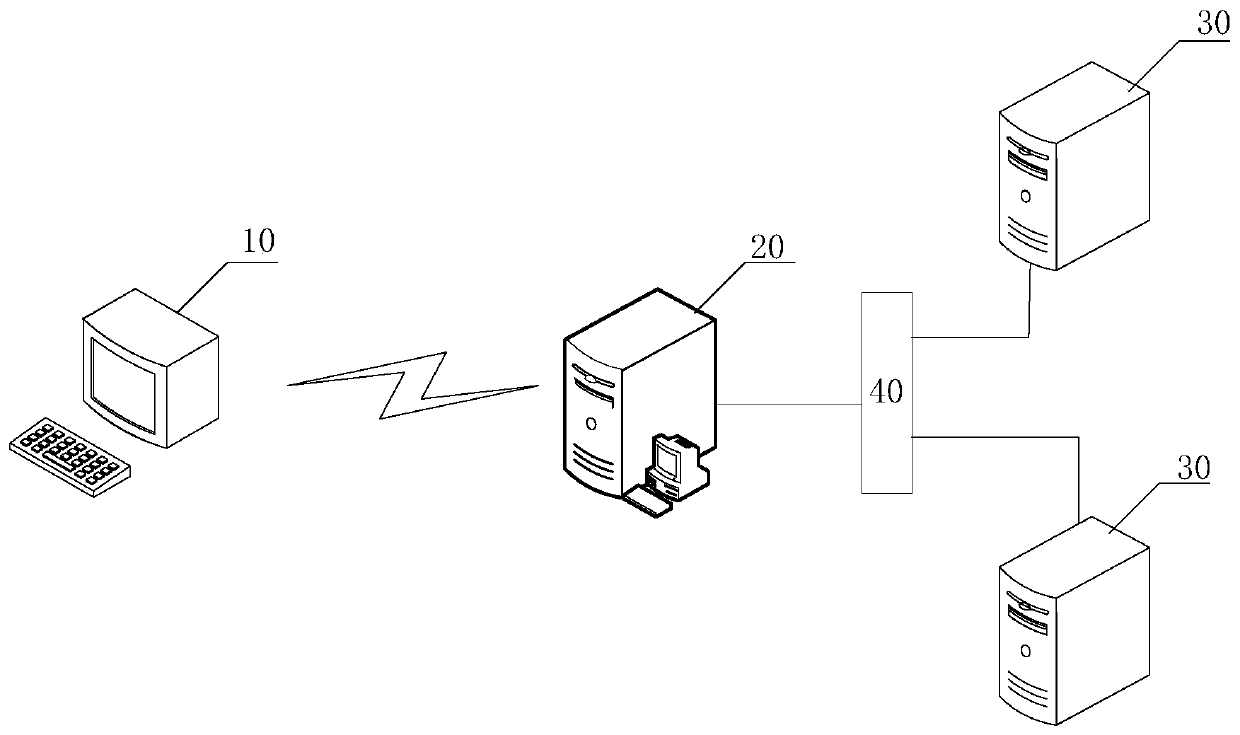

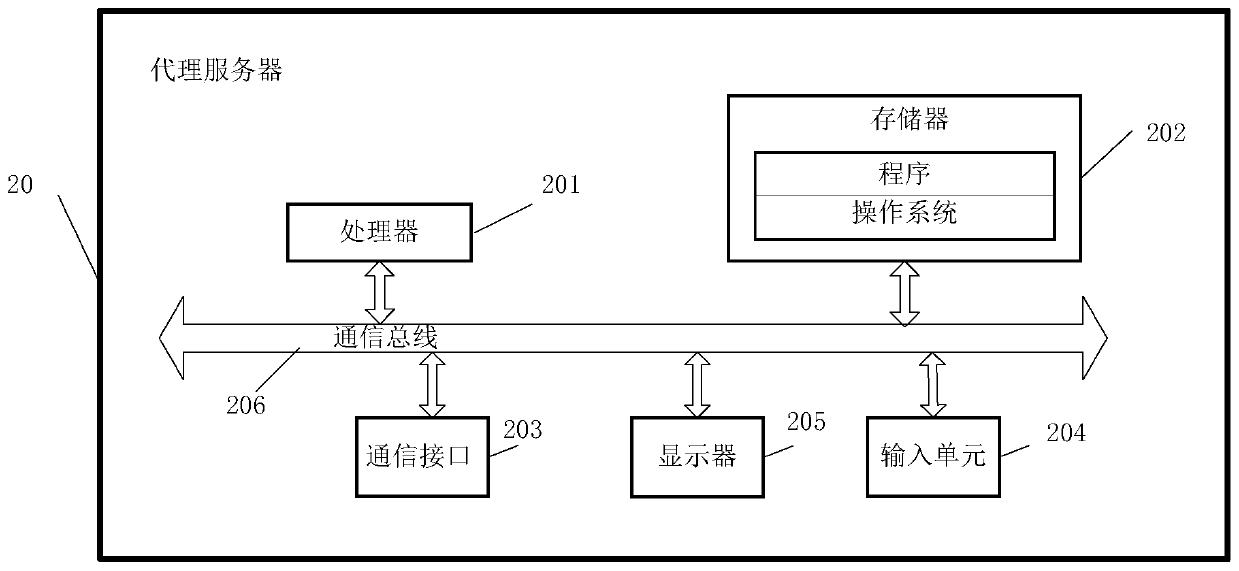

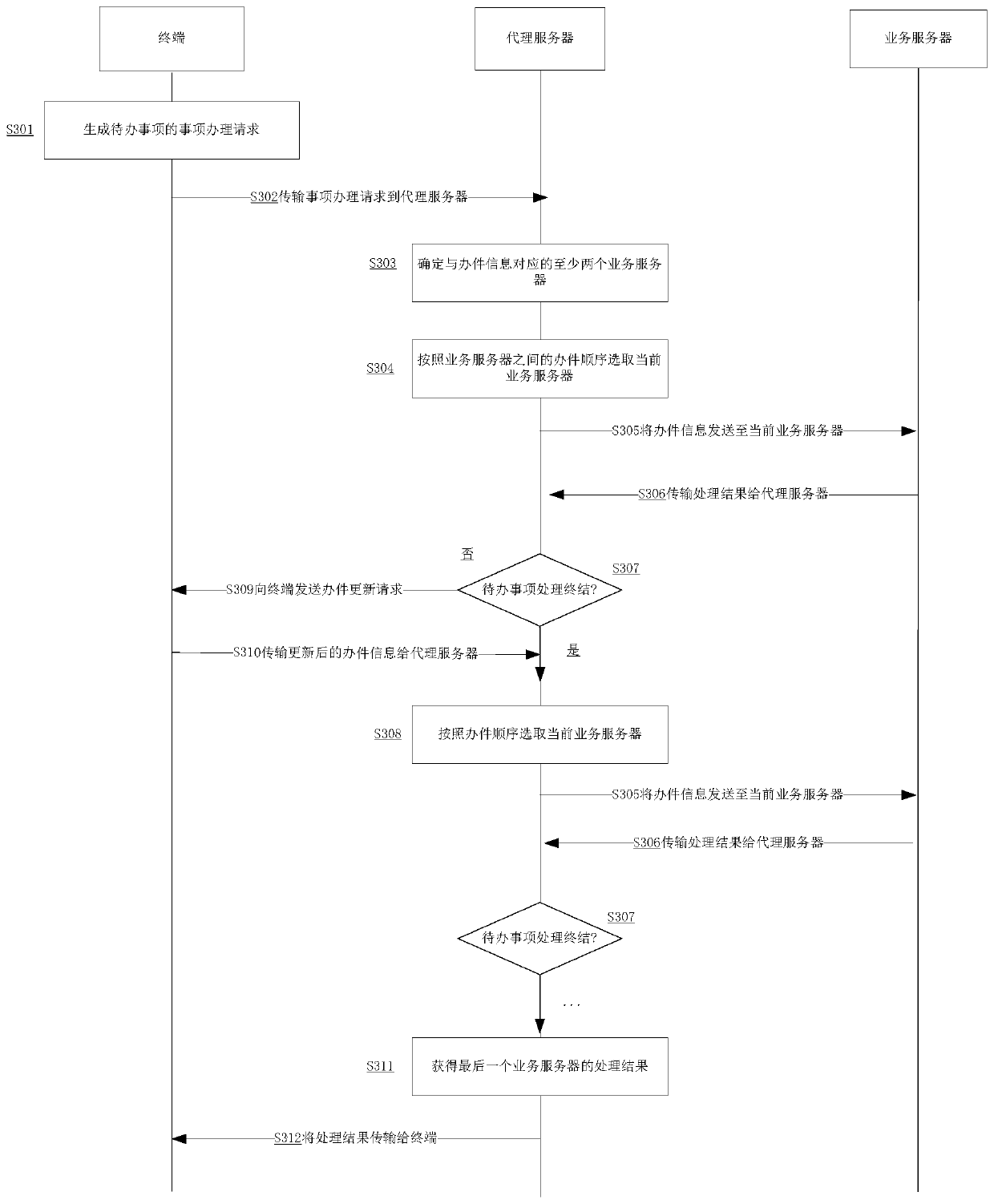

Control method and device, proxy server and storage medium

PendingCN111049916AReduce the handling processReduce time-consumingTransmissionDocument handlingEngineering

The invention discloses a control method and device, a proxy server and a storage medium. The method comprises the steps: receiving an item handling request transmitted by a terminal, and enabling theitem handling request to at least comprise the to-do information of a to-do item of an applicant; determining at least two service servers corresponding to the document handling information; sequentially sending the file handling information to a service server in the at least two service servers by utilizing a gateway between the proxy server and the service server, so that the service server sequentially executes service processing operations corresponding to the file handling information; obtaining a processing result of the last service server in the at least two service servers; and transmitting the processing result to the terminal.

Owner:TENCENT CLOUD COMPUTING BEIJING CO LTD

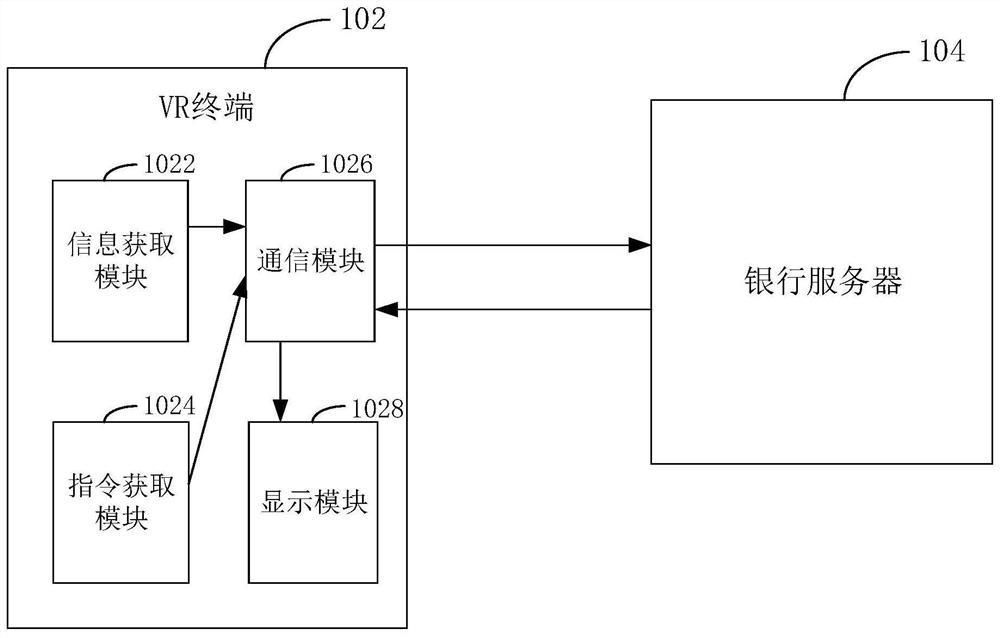

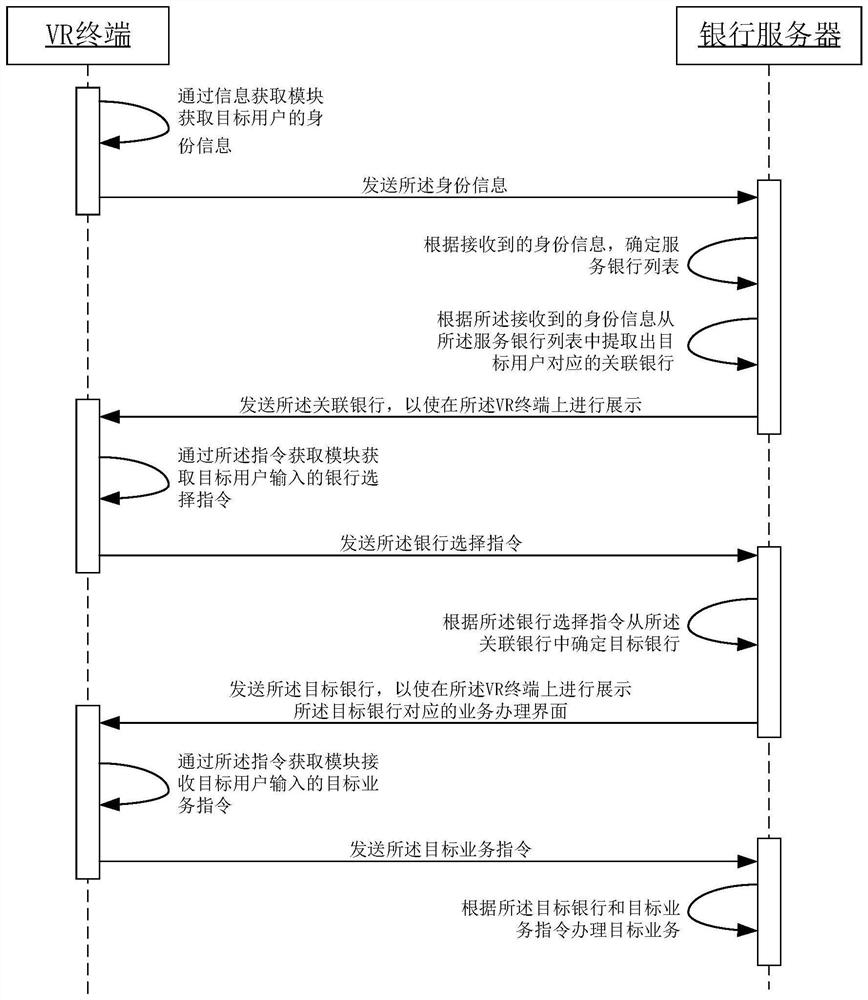

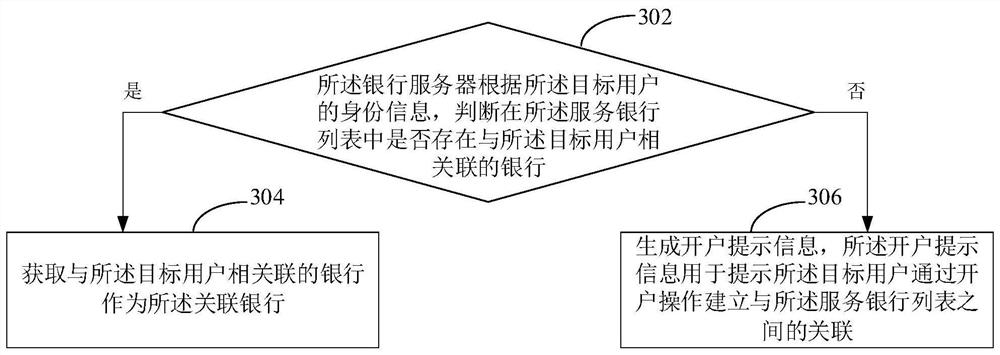

Banking business handling method and system, computer equipment and storage medium

PendingCN113256234AImprove experienceImprove reliabilityFinanceOffice automationBanking industryServer

The invention relates to a banking business handling method, which is based on a banking business processing system comprising a VR terminal and a bank server, and comprises the following steps: the VR terminal sends acquired identity information of a target user to the bank server; the bank server determines a service bank list according to the received identity information; the bank server extracts an associated bank corresponding to the target user from a service bank list according to the received identity information, and sends the associated bank to the VR terminal; the VR terminal sends the acquired bank selection instruction to a bank server; the bank server determines a target bank from the associated banks according to the bank selection instruction and sends the target bank to the VR terminal; the VR terminal sends a received target business instruction input by a user to the bank server; and the bank server handles the target business according to the target bank and the target business instruction, so that the user experience can be enhanced, and the complicated handling process is reduced. In addition, the invention further provides a bank business handling system, computer equipment and a storage medium.

Owner:SHENZHEN YIHUA TIME TECH +2

Card handling device

Owner:GUANGZHOU MINGSEN TECH CO LTD

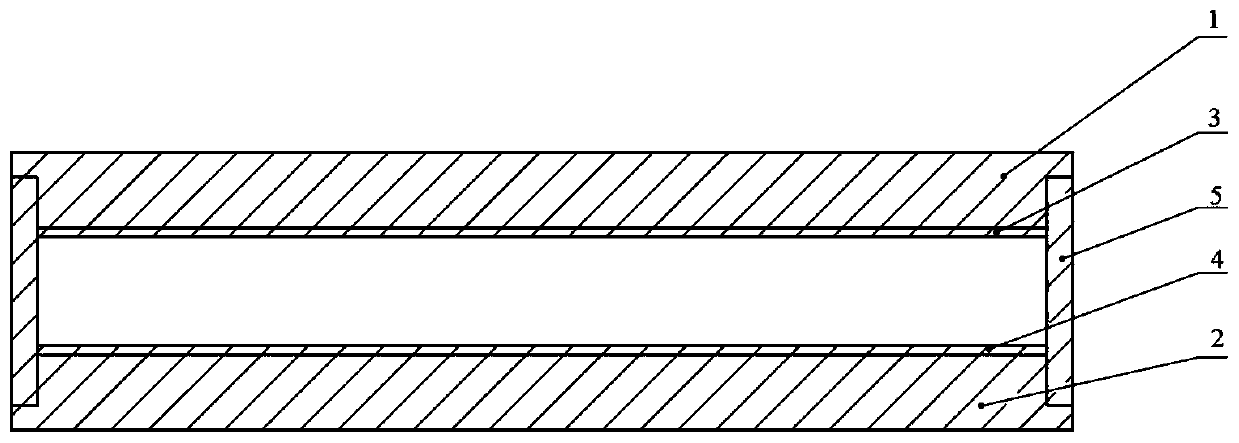

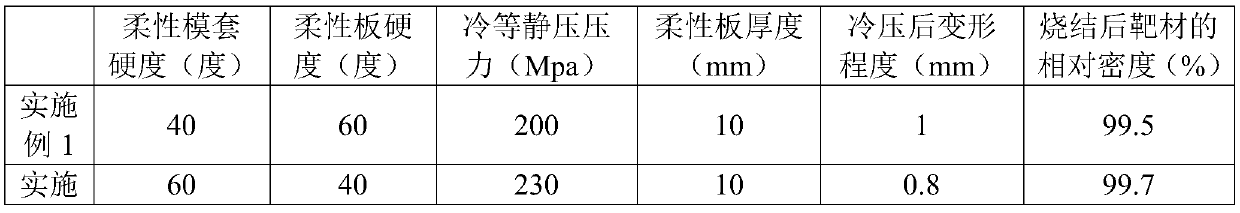

Forming mold and method of planar ceramic target material

The invention discloses a forming mold and method of a planar ceramic target material. The forming mold comprises a steel mold, flexible mold sleeves and a flexible plate. The steel mold comprises anupper steel cover and a lower steel cover. The upper steel cover and the lower steel cover are installed and combined to form an empty cavity. The flexible mold sleeves are mounted at the two ends ofthe steel mold and is in sealing fit with the steel mold. The flexible plate is formed by combining an upper rubber plate and a lower rubber plate and is arranged in the empty cavity of the steel mold. A cavity formed between the upper rubber plate, the lower rubber plate and the flexible mold sleeves serves as a powder filling cavity. The shore hardness of the flexible mold sleeves is 40-90, andthe shore hardness of the flexible plate is 20-60. The forming mold conducts cold isostatic pressing molding on granulation powder, a smooth ceramic target material green body with the regular size can be obtained, and the high-compactness target material can be obtained through sintering. The procedure of oil press molding is omitted in the ceramic material production process, input of equipmentand an oil press mold is reduced, and the risk that the ceramic target material green body cracks during transportation is also reduced.

Owner:广州市尤特新材料有限公司

Self-service card taking terminal

PendingCN108764380AShort tripCard storage is easy to operateConveying record carriersComputer terminalSelf-service

Owner:GUANGZHOU MINGSEN TECH CO LTD

Cloth inspection machine

InactiveCN111674992BAchieve positioningRealize automatic separationInspecting textilesWebs handlingElectric machineryStructural engineering

The invention discloses a cloth inspecting machine, which comprises a frame, a cloth inspecting platform and a plurality of transmission rollers, a driving roller and a driven roller are arranged on the frame, a drive motor is arranged on the frame to drive the driving roller to rotate, and the frame There are two sliding blocks that slide back and forth along the vertical direction, the two ends of the driven roller are respectively connected to the two sliding blocks, the first drive assembly is provided between the frame and the sliding blocks, and two Two fixed plates, both fixed plates are provided with connecting shafts, and the frame is equipped with a second drive assembly that drives the two fixed plates to move toward each other or in the opposite direction along the axial direction of the driven roller. A collection box is placed under the frame to collect One side of the box is provided with a guide plate, and the fixed plate is provided with a guide groove for the sliding of the connecting shaft to guide the cloth roll on the connecting shaft from above the driven roller to above the guide plate. The present invention has the following advantages and effects: the present invention replaces manual transportation of the cloth rolls into the cloth roll collection box in a mechanical manner, shortens the handling process of the cloth rolls, and improves the working efficiency of the cloth inspection machine.

Owner:JIAXING VOCATIONAL TECHN COLLEGE

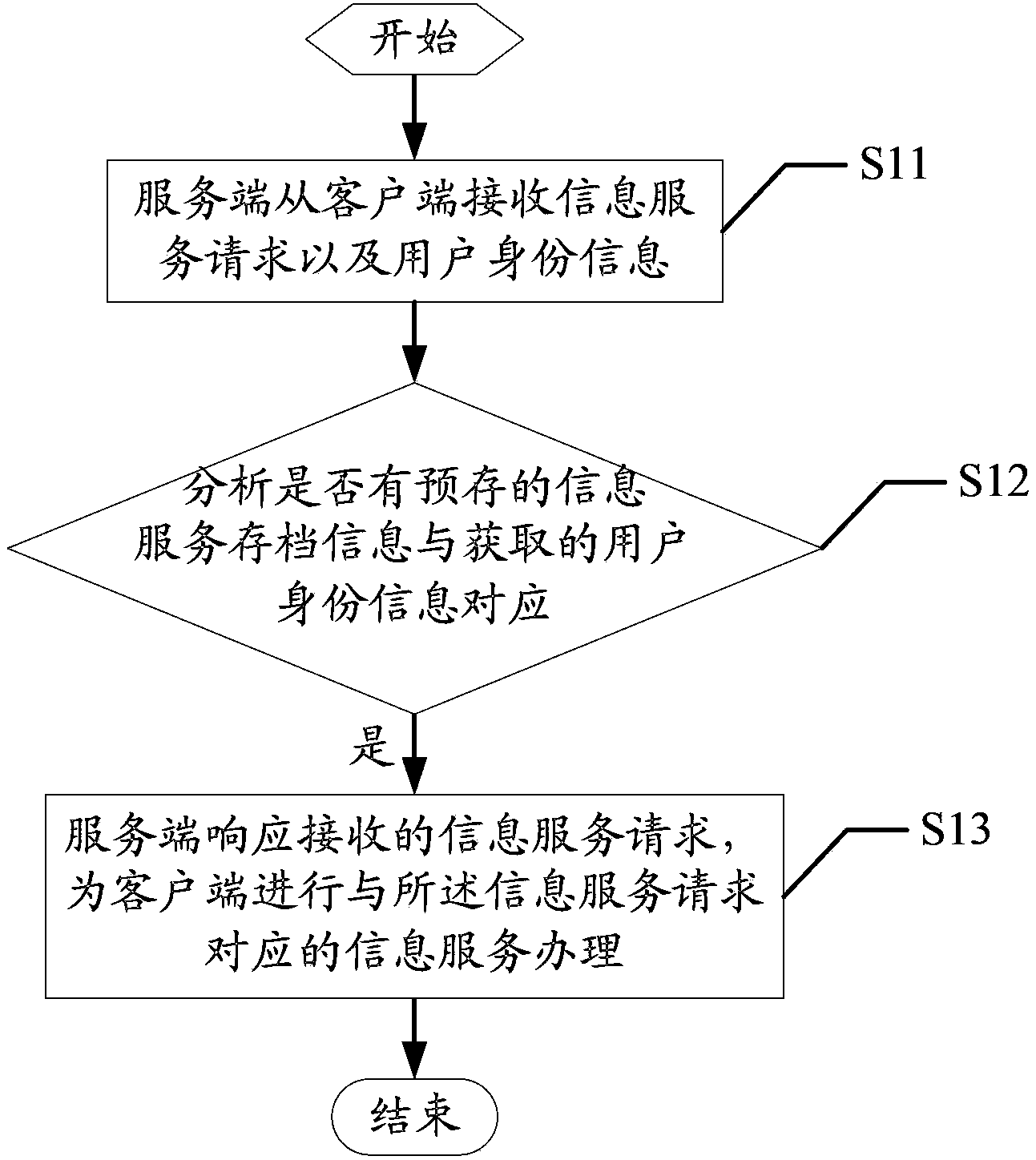

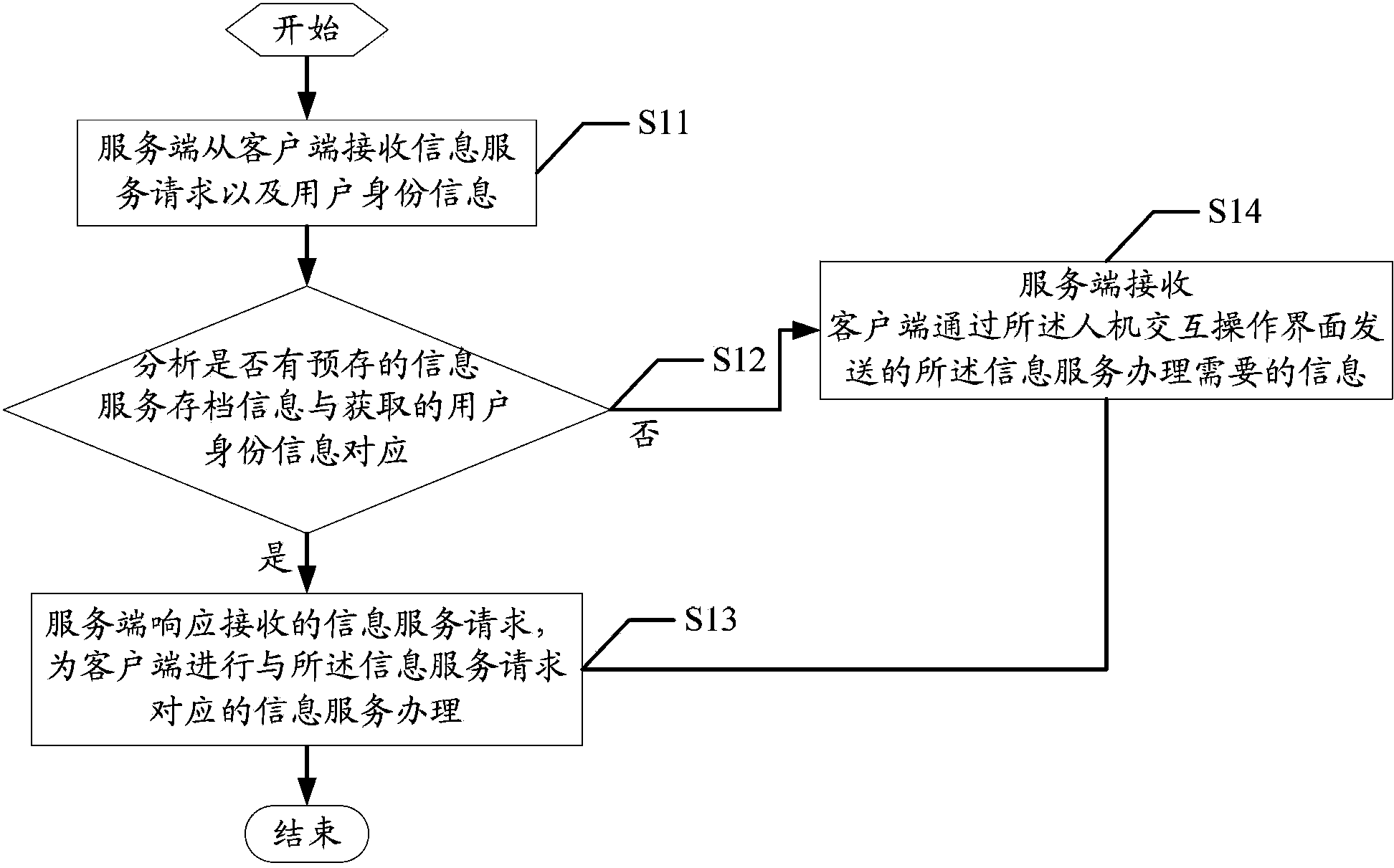

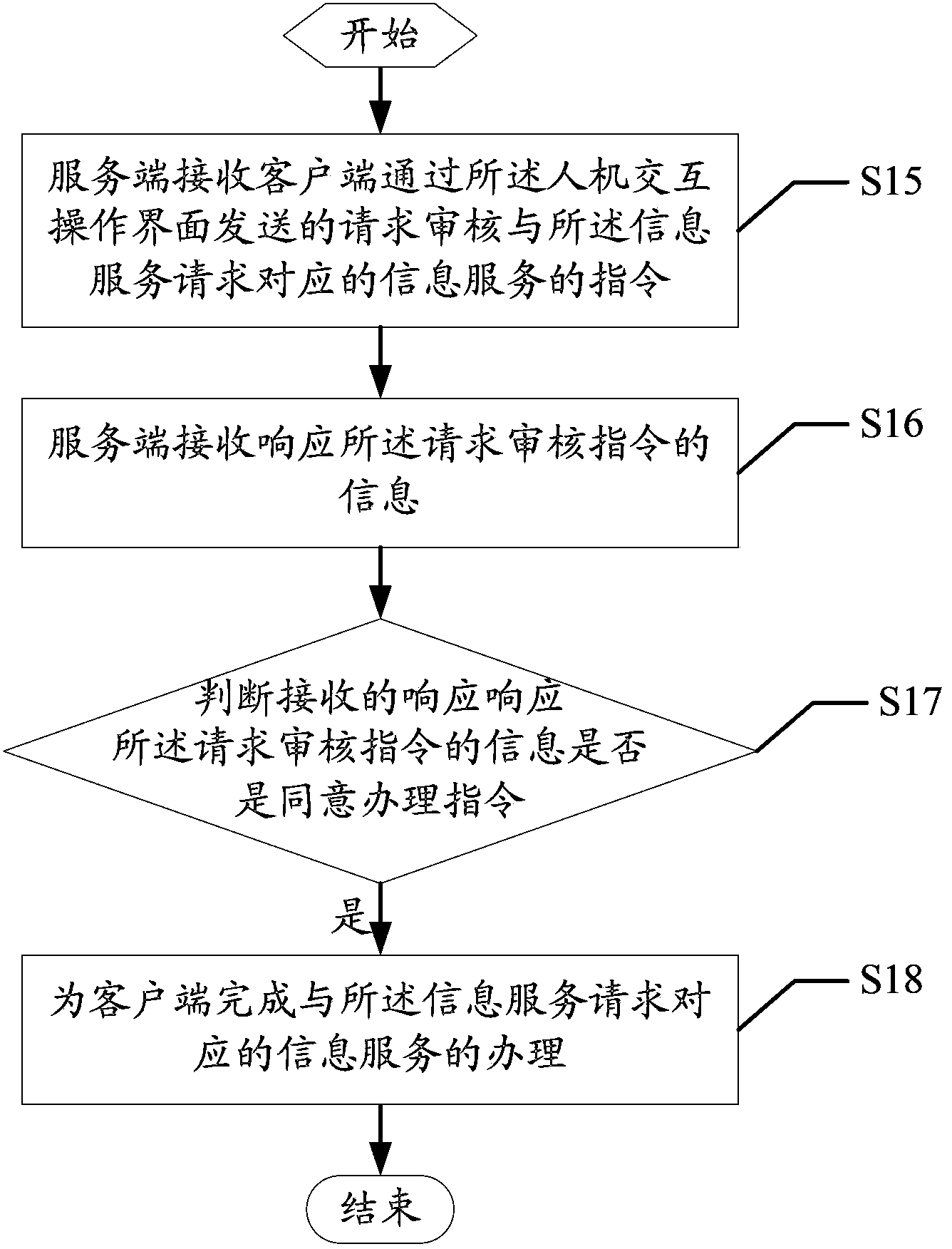

Method for controlling information service of client side and server side and server side

The invention discloses a method for controlling the information service of a client side and a server side. The method comprises the following steps: the server side receives an information service request and user identity information from the client side; the server side analyzes whether prestored filed information, corresponding to the acquired user identity information, of the information service exists; if the prestored filed information, corresponding to the acquired user identity information, of the information service exists, the server side responds to the received information service request and conducts the information service corresponding to the information service request for the client side. According to the method for controlling the information service of the client side and the server side, when the information service request and the user identity information sent by the client side are received, the information service corresponding to the information service request is conducted for the client side if the prestored filed information, corresponding to the acquired user identity information, of the information service exists, therefore, a user does not need to input relevant information needed for conducting the information service every time, the conducting processes of the information service are reduced, and the information service can be conducted quickly and conveniently.

Owner:SHENZHEN LONGRISE SCI & TECH

Method for improving recession of large blind hole

InactiveCN112165770AReduce manufacturing costImprove the quality of production productsSuperimposed coating processPrinted element electric connection formationLaser drillingDrill hole

The invention relates to a method for improving the recession of a large blind hole, which is used for filling the large blind hole with the blind hole diameter of more than or equal to 5mil and morethan or equal to 10mil on an inner layer anylayer, and comprises the following steps of: filling and leveling up the drilled large blind hole by adopting a whole plate electroplating mode after laserdrilling and chemical copper deposition; and then polishing and grinding the copper surface at the large blind hole in a manner of outer-layer patterning, copper reduction and plate grinding in sequence to improve the recession of the large blind hole. According to the method for improving the large blind hole recession, the flatness of the blind hole reaches 95% or above by optimizing an existingblind hole filling process, the large blind hole recession is greatly improved, the product quality is improved, meanwhile, the procedures of carrying, reworking and the like are omitted, the productquality is improved, and the production cost is effectively reduced.

Owner:VICTORY GIANT TECH HUIZHOU CO LTD

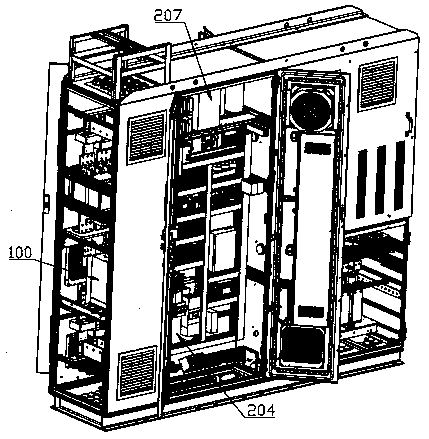

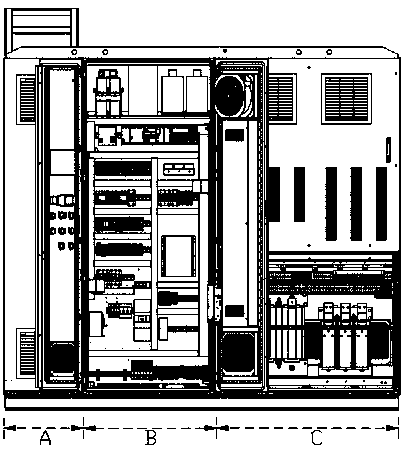

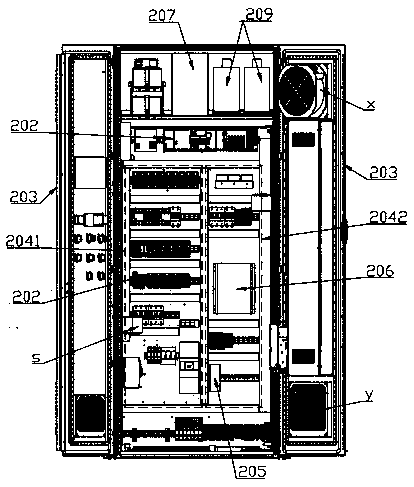

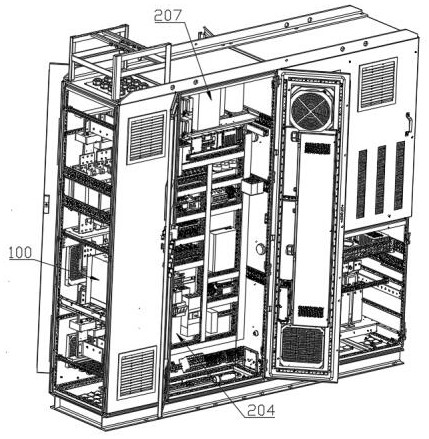

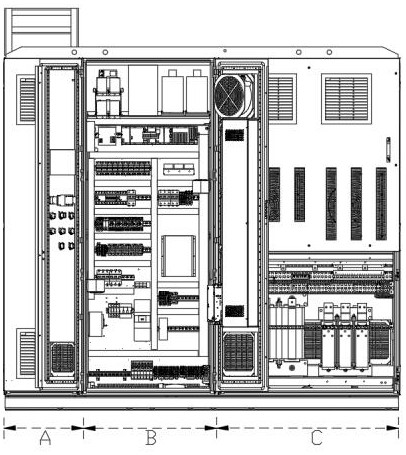

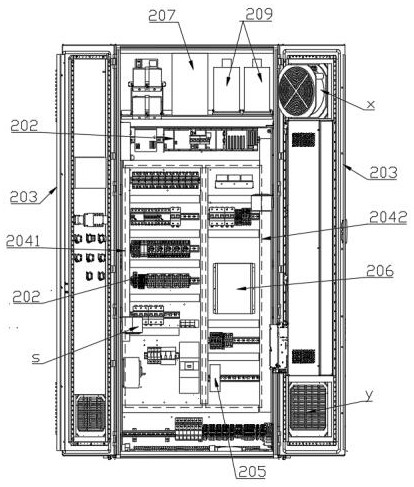

All-in-one machine for wind turbine generator set

ActiveCN110350586AHigh layout and installation efficiencyReduce installation difficultyClimate change adaptationSingle network parallel feeding arrangementsElectricityFrequency conversion

The invention discloses an all-in-one machine for a wind turbine generator set, and the all-in-one machine is characterized in that the all-in-one machine comprises a cabinet body, and a grid-connected unit, a main control power distribution unit and a frequency conversion unit are installed in the cabinet body; the grid-connected unit comprises a main circuit breaker; the main control power distribution unit comprises a three-phase transformer and a PLC; the input side of the three-phase transformer is electrically connected with any side of a main circuit breaker of the grid-connected unit,and the output side of the three-phase transformer forms a power supply of each power distribution loop; each input interface of the PLC is used for receiving various parameters, and each output interface of the PLC is electrically connected with a control coil of a contactor in each power distribution loop; the frequency conversion unit comprises a power grid side frequency converter, the input side of the power grid side frequency converter is used for being electrically connected with the alternating-current power grid, and the output side of the power grid side frequency converter is connected with the input side of the rotor side three-phase frequency converter. The all-in-one machine for the wind turbine generator set has the advantages of smaller size, lower manufacturing cost, safeand reliable structure and high cost performance.

Owner:CHONGQING KK QIANWEI WINDPOWER EQUIP

Large-capacity card storage equipment

PendingCN108910516ASmall change in lengthIncrease memory card capacityConveyor partsMechanical conveyorsEngineeringLarge capacity

Owner:GUANGZHOU MINGSEN TECH CO LTD

All-in-one machine for wind turbine

ActiveCN110350586BHigh layout and installation efficiencyReduce installation difficultyClimate change adaptationSingle network parallel feeding arrangementsFrequency changerControl power

The invention discloses an all-in-one machine for wind turbines, which is characterized in that it includes a cabinet body, and a grid-connected unit, a main control power distribution unit and a frequency conversion unit are installed in the cabinet; the grid-connected unit includes a main circuit breaker; the main control power distribution unit The unit includes a three-phase transformer and PLC. The input side of the three-phase transformer is electrically connected to any side of the main circuit breaker of the grid-connected unit. The output side of the three-phase transformer constitutes the power supply of each power distribution circuit; each of the PLC The input interface is used to receive various parameters, and each output interface of the PLC is used to electrically connect with the control coil of the contactor in each power distribution circuit; the frequency conversion unit includes a grid-side inverter, and the input side of the grid-side inverter is used to communicate with the above The AC grid is electrically connected, and the output side of the inverter on the grid side is used to connect with the input side of the three-phase inverter on the rotor side. The all-in-one machine for wind turbines of the present invention has the advantages of smaller volume, lower cost, safe and reliable structure, and high cost performance.

Owner:CHONGQING KK QIANWEI WINDPOWER EQUIP

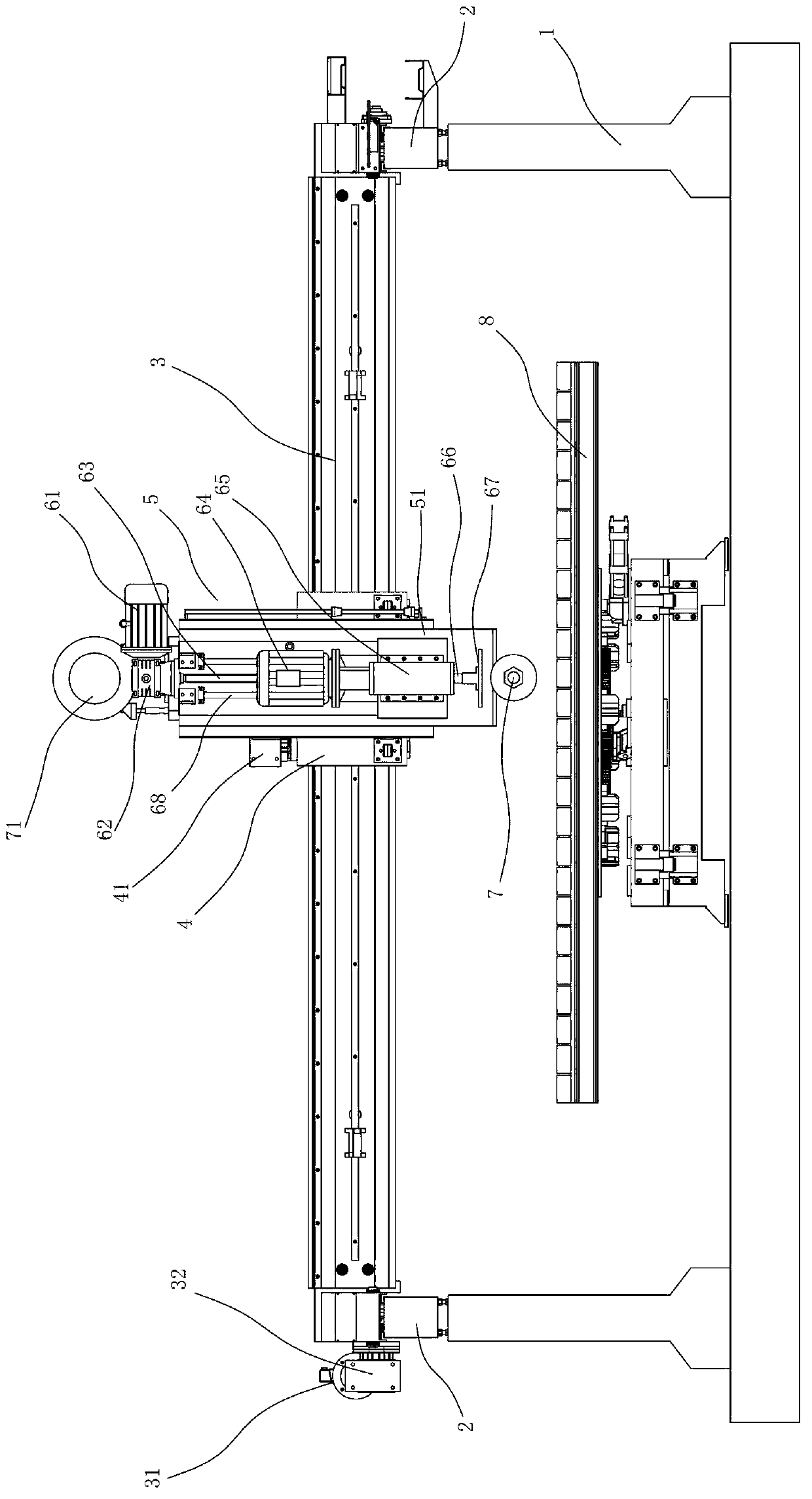

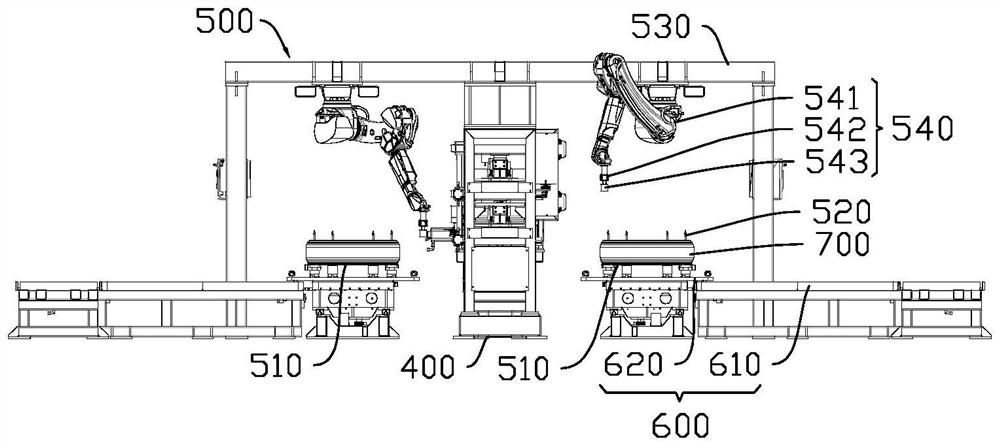

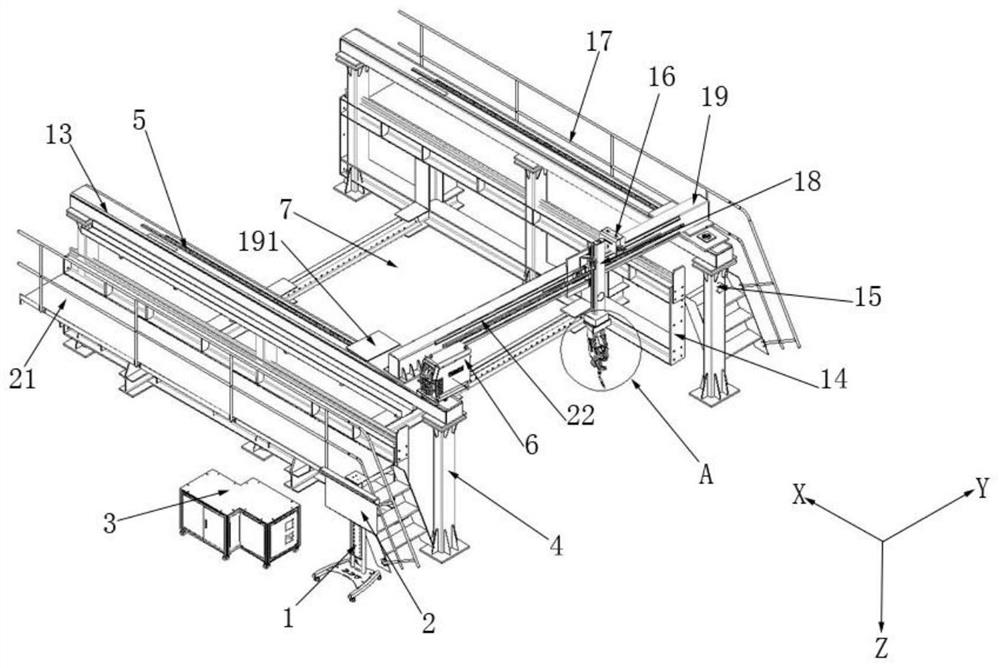

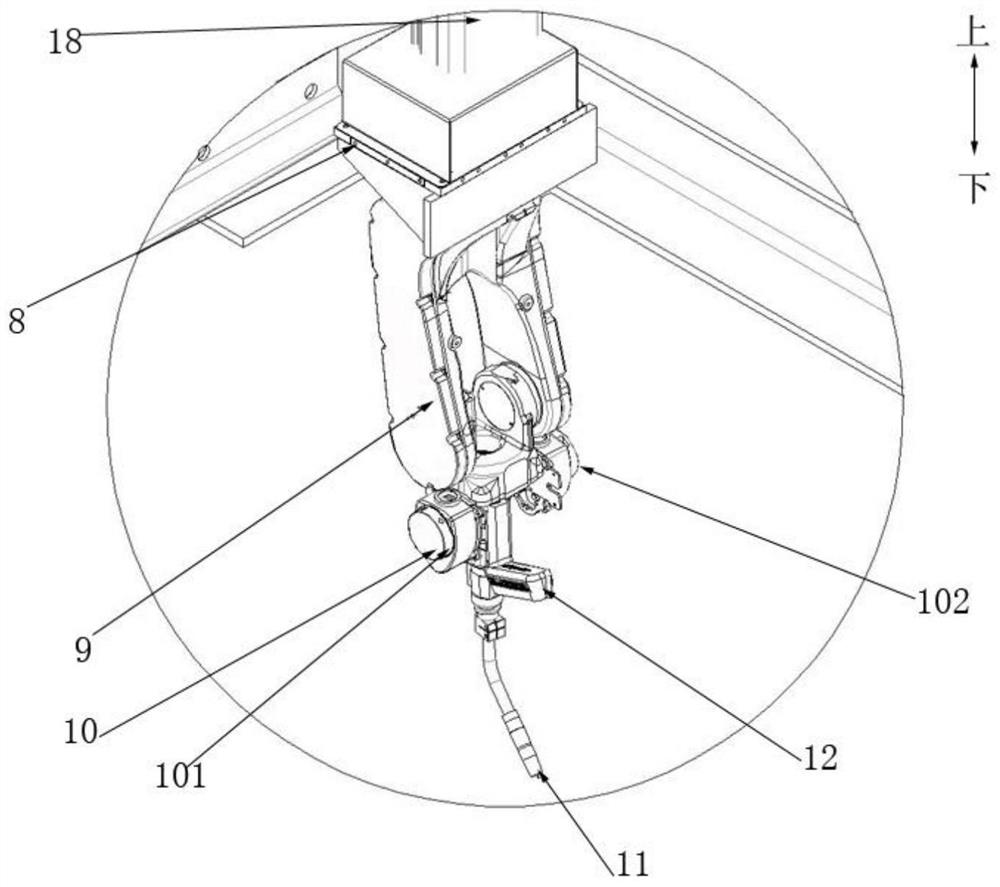

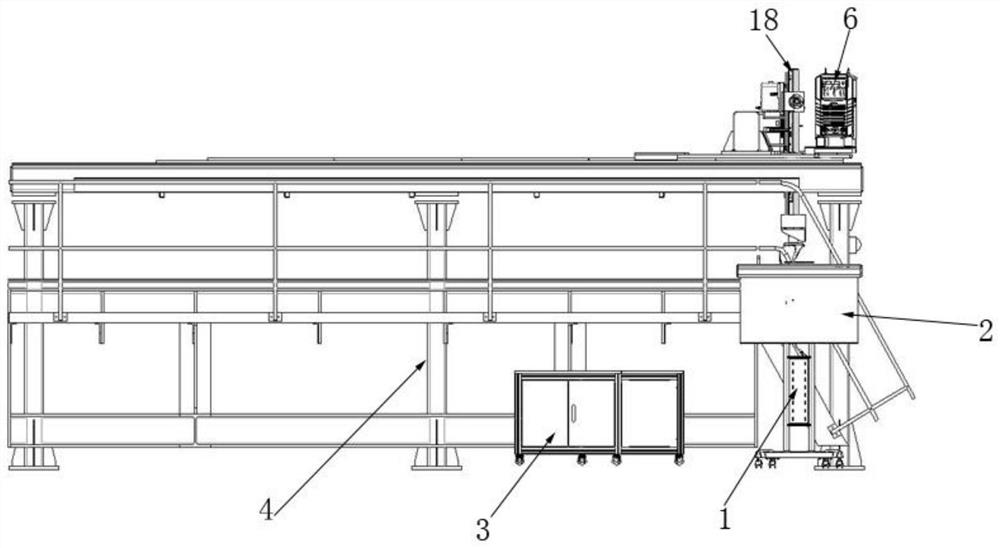

Six-degree-of-freedom automatic path optimization intelligent welding platform and method

PendingCN114769989ALarge space for exerciseHigh freedom of movementProgramme-controlled manipulatorGripping headsControl engineeringProcess engineering

The invention provides a six-degree-of-freedom automatic path optimization intelligent welding platform and method.The six-degree-of-freedom automatic path optimization intelligent welding platform comprises a welding platform system, the welding platform system is connected with a joist barrow system, and a robot is arranged on the joist barrow system; the intelligent control system controls the robot to conduct welding. Compared with the prior art, according to the six-degree-of-freedom automatic path optimization intelligent welding platform, the robot is arranged on the truss system, the platform system and the truss system are matched with each other to provide displacement in the X direction, the Y direction and the Z direction for the robot, and therefore the motion space of the robot is enlarged; the motion freedom degree and flexibility of the robot are improved, and mechanical dead angles are eliminated; and therefore, the robot can achieve welding of a welding seam with the large space span and the long length at a time, and the welding precision is improved.

Owner:江苏新控智能机器科技有限公司

A measuring tool for aluminum bar bending machine

ActiveCN105403118BAccurate measurementReliable measurementMechanical measuring arrangementsMeasurement deviceAluminum can

The invention discloses a measurement tool for an aluminum strip bender. The measurement tool comprises brake devices, an object carrying plate, a clamping device and measurement devices, wherein the end portions of the brake devices and the object carrying plate are connected with a slide rail, each brake device comprises a fixation support frame, each fixation support frame is successively provided with a limiting clamping groove, a second cantilever, an over beam and a base plate from top to bottom, each second cantilever is symmetrically distributed at the two sides of each fixation support frame, each limiting clamping groove is internally provided with a first cantilever, the two sides of each first cantilever are each provided with a limiting protruding strip, each limiting protruding strip is movably connected with each second cantilever, each first cantilever is rotationally connected with the corresponding limiting protruding strips through a fixation rod, the bottom of the front end of each first cantilever is provided with the clamping device, and the measurement devices are fixedly connected with the bottom of the object carrying plate. The structure is simple, the practicality is high, an aluminum strip can be clamped and positioned, the aluminum can also be loaded and carried, the labor intensity is reduced, the operation is simple and convenient, the safety is high, and the steps for measuring the aluminum strip are simplified.

Owner:嵊州博远铝业有限公司

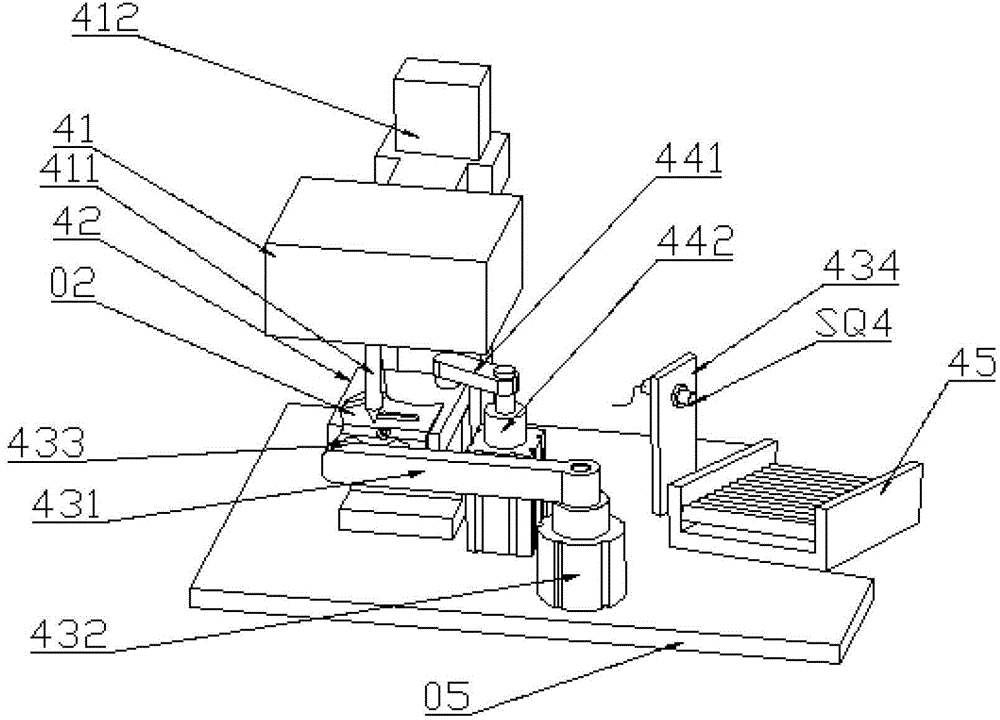

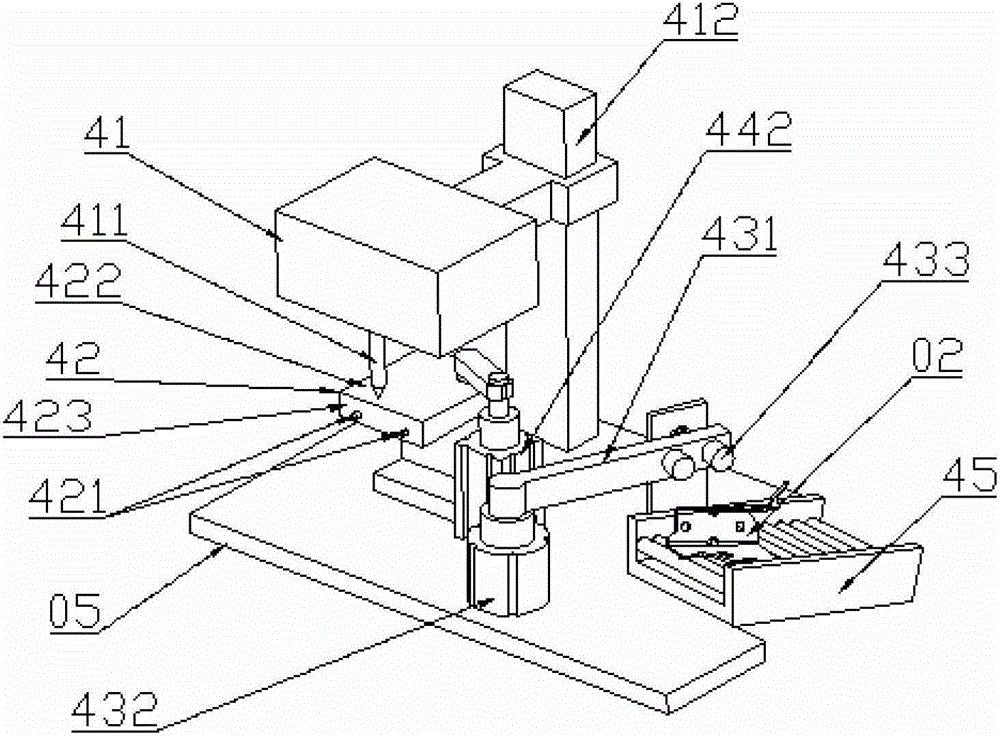

Automatic marking device, automatic marking welding system and its control circuit

InactiveCN103302998BReduce investmentReduce harmWelding/cutting auxillary devicesTypewritersEngineeringAssembly line

Owner:TIANJIN BOXIN AUTOMOBILE PARTS

Stone cutting production line

ActiveCN105196424BAvoid inaccurate distributionAvoid wear and tearEdge grinding machinesStone-like material working toolsProduction lineAgricultural engineering

The invention relates to a chipped ashlar cutting production line and belongs to the field of stone cutting equipment. The chipped ashlar cutting production line comprises a butting cutting machine, a chipped ashlar cutting chamfering machine and a mill which are connected in sequence through a transition frame, wherein the butting cutting machine comprises a main frame; a mine car is arranged on the main frame; horizontal walking mechanisms are arranged at the two ends of the main frame; an upper transverse beam is arranged between the two horizontal walking mechanisms; the upper transverse beam is provided with a vertical hoisting mechanism; the vertical hoisting mechanism is connected with a main beam; a main shaft box provided with a main shaft and an auxiliary main shaft box provided with an auxiliary main shaft are arranged under the main beam; the chipped ashlar cutting chamfering machine comprises a worktable; the worktable is provided with a plurality of cutting machines; a chamfering machine is arranged between the first cutting machine and the second cutting machine; and each of each cutting machine and each chamfering machine comprises the main shaft box provided with the main shaft and the auxiliary shaft box provided with the auxiliary main shaft. According to the equipment, butting, cutting and chamfering are carried out on a guide rail in a production process and machining is carried out on the same production line; and the equipment does not need to be transported, the machining precision is improved, the working amount is alleviated and the working efficiency is improved.

Owner:山东省滨州市鑫通机械有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com