A kind of automatic sheet feeding machine equipment in shield tunneling machine

A piece feeding machine and equipment technology, applied in mining equipment, shaft equipment, wellbore lining, etc., can solve the problems that automatic feeding of segments cannot be realized, the distance of segment placement needs to be mastered manually, and the assembly machine cannot be snatched, etc. , to achieve the effect of simple structure, reduced handling process and high space utilization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

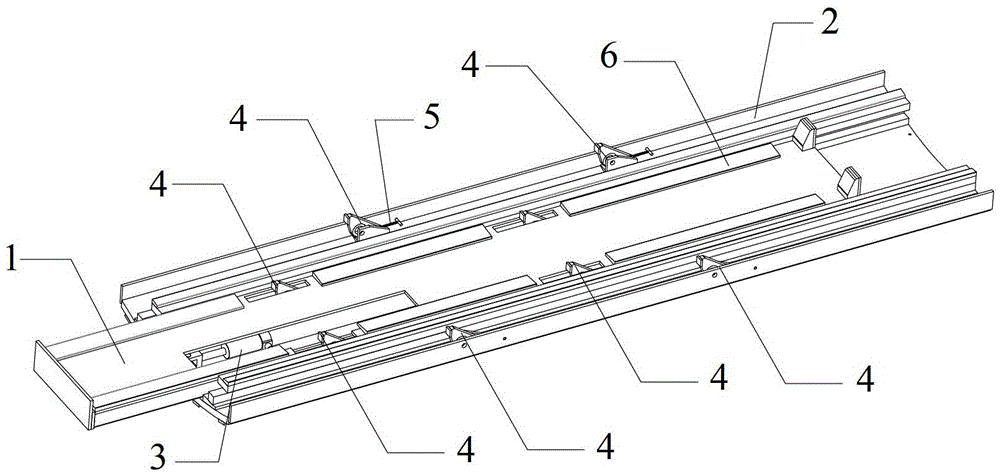

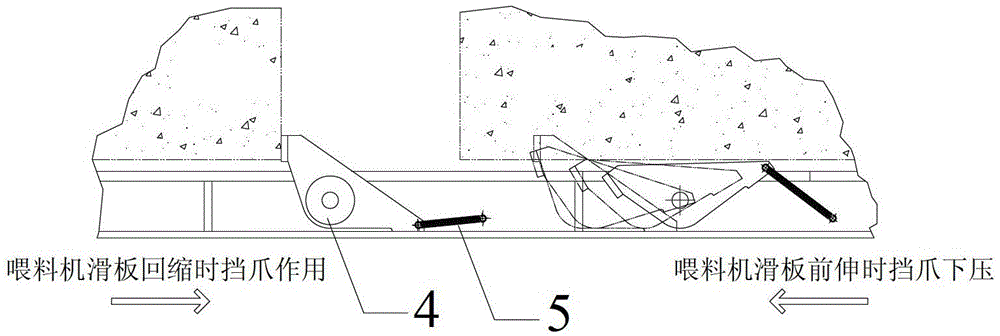

[0020] A kind of automatic sheet feeding machine equipment in shield, its structure is as figure 1 As shown, it is composed of an outer conveying platform 2 and an inner conveying platform 1 embedded in the outer conveying platform 2. Both sides of the outer conveying platform 2 and the inner conveying platform 1 are provided with backstop claws 4, and the backstop claws 4 are The return spring 5 is respectively connected with the outer conveying platform 2 or the inner conveying platform 1 for conveying the tube sheet to move forward.

[0021] The backstop claws 4 are arranged in pairs on both sides of the outer conveying platform 2 and the inner conveying platform 1 in parallel. The number of backstop claws 4 and the distance between each pair of backstop claws are determined according to the length and position of the conveyed tube sheet Through the sequential movement of each pair of reverse stop claws 4, the tube piece is transported to the designated position.

[0022] When t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com