Automatic marking device, automatic marking welding system and its control circuit

A control circuit and automatic technology, applied in the direction of auxiliary devices, welding equipment, welding equipment, etc., can solve the problem that the marking machine cannot realize automatic marking operation, and achieve the effect of high cost performance, cost reduction, and reduction of handling process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

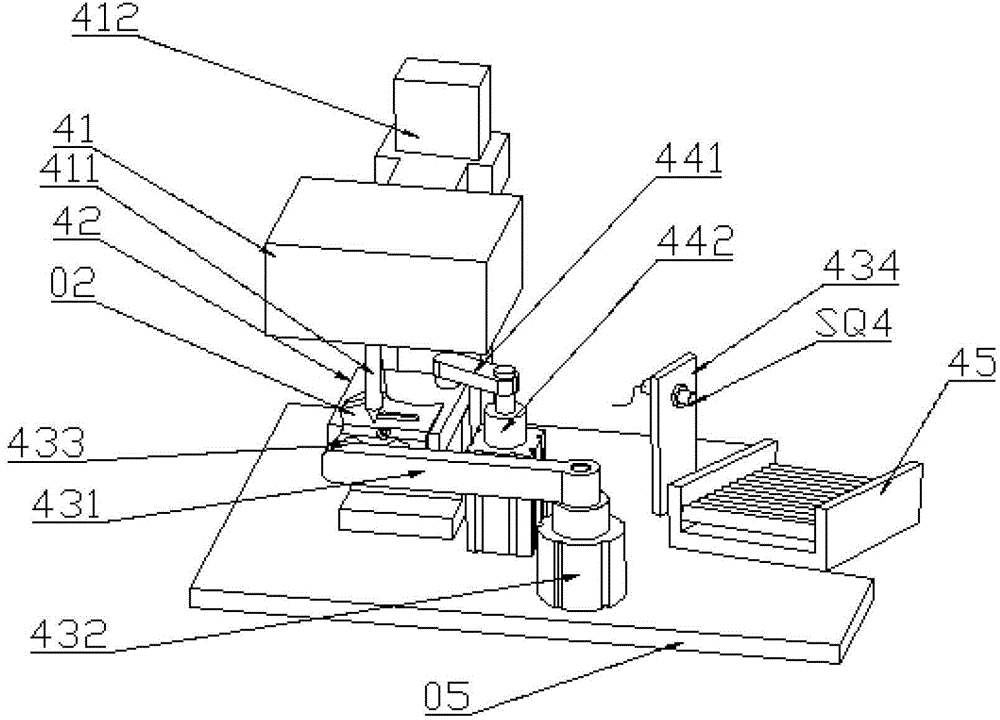

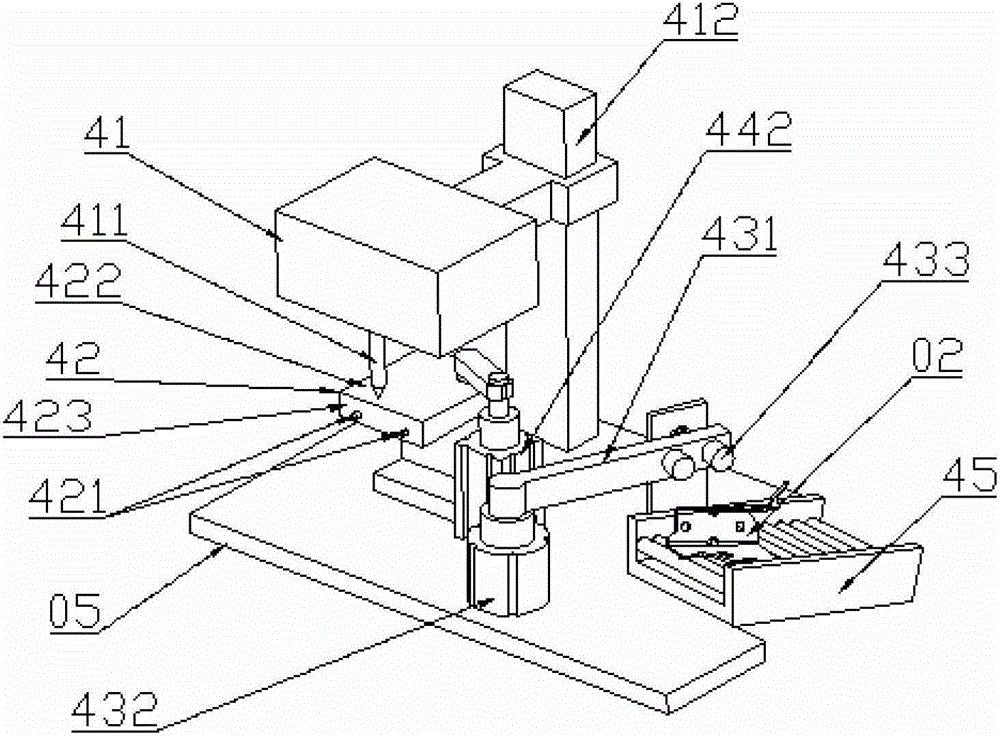

[0030] like figure 2 and image 3 As shown, the automatic marking device includes a marking machine 41 installed on a horizontal support platform, a workbench 42, a rotary pressing mechanism, a rotary unloading mechanism and a slideway 45;

[0031] Because the workpiece to be marked has two inner surfaces similar to the angle iron form that are substantially perpendicular to each other, the workbench has a placement portion for placing the workpiece to be marked, and the placement portion is also provided with two parts that are connected to the workpiece to be marked. The mutually perpendicular front faces 423 and upper end faces 422 correspond to the inner faces perpendicular to each other. The printing needle 411 of the printer is located above the upper end face 422 of the placement part of the workbench, and the printing needle can realize the extension and retraction of moving up and down. Reset action; also includes a reset detection travel switch SQ3 for detecting wh...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com