Flat device for pipe and rod materials

A flat head and pipe rod technology, which is applied in the field of pipe and rod end face processing equipment, can solve the problems of not being able to meet the continuous mass production, the continuous online operation of the drawing machine, etc., and achieve a simple and reasonable structure, reduce labor intensity and work efficiency. high effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] The present invention will be further described in detail below in conjunction with the accompanying drawings and embodiments.

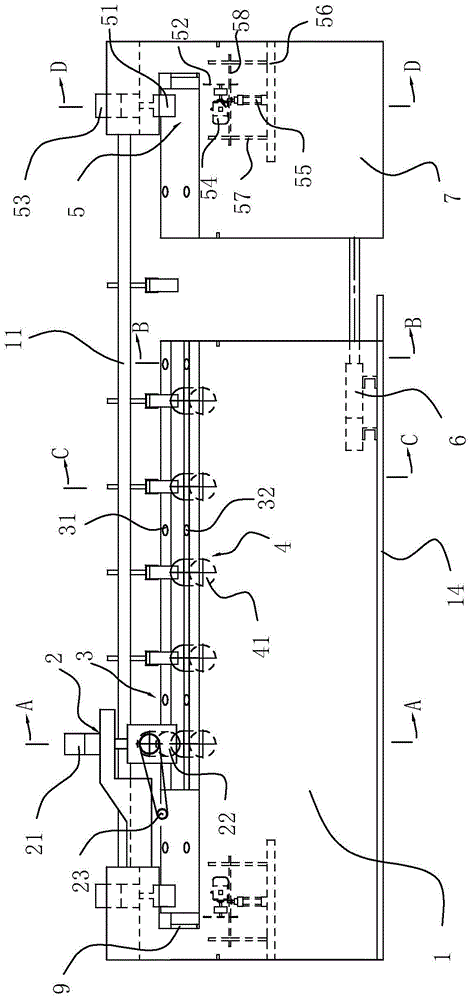

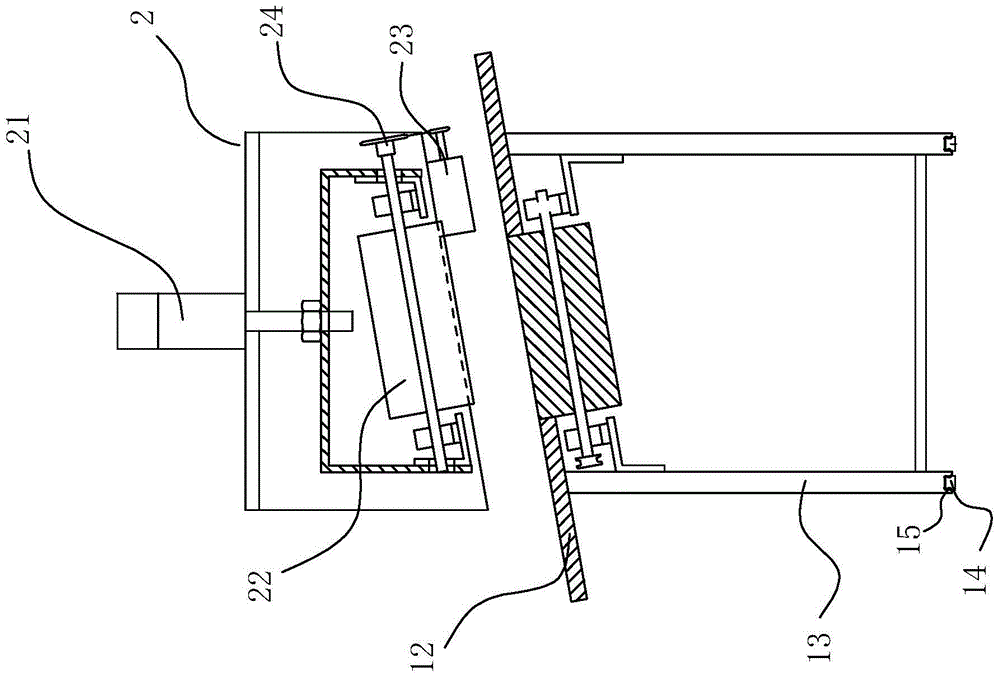

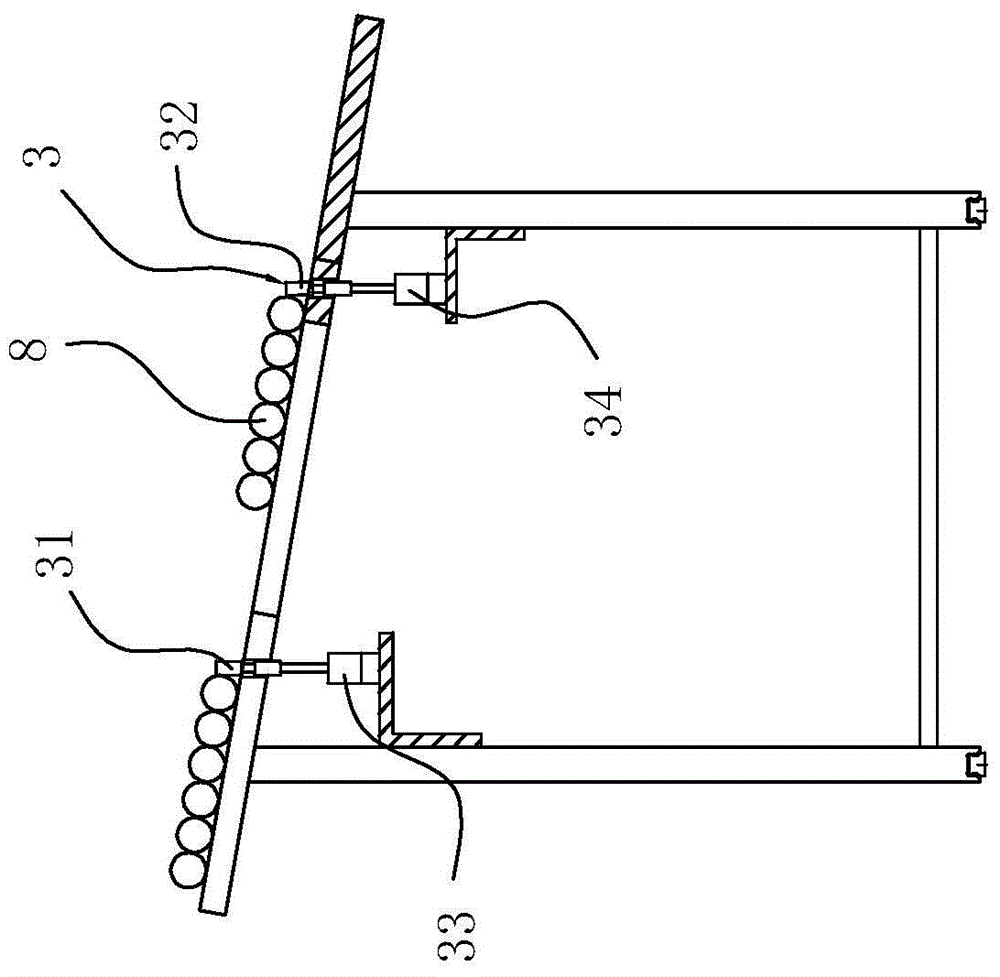

[0023] like Figure 1~5 As shown, the flat head device of the tube and bar in this embodiment includes a frame 1, and the frame 1 is integrated with the combined drawing machine to realize online flat head, and the frame 1 is provided with a fixed baffle 9 and a pressing wheel mechanism 2. The transmission mechanism 4, the discharge mechanism 3 and the sawing mechanism 5. The frame 1 includes a cross bar 11, an operation table 12, a support foot 13 and a slider 14. The operation table 12 is an inclined surface for easy discharge. The upper end is connected with the cutting place of the combined drawing machine. There are two front and rear chute 15, a total of 4, which are arranged at the bottom of the frame 1. Two support feet 13, a total of 4, are used to support the operation table 12. A reinforcement plate is provided between the supporti...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com