Fully-automatic continuous bag type modified atmosphere packaging machine

A fully automatic, packaging machine technology, applied in the direction of pressurization/gasification packaging, etc., can solve problems such as the inability to meet the requirements of gas composition distribution accuracy, the product production and application limitations of enterprises, and the difficulty in realizing continuous packaging processes. Achieve the effect of simple structure, fast and convenient adjustment, and high replacement rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] The specific implementation manner of the present invention will be described below in conjunction with the accompanying drawings.

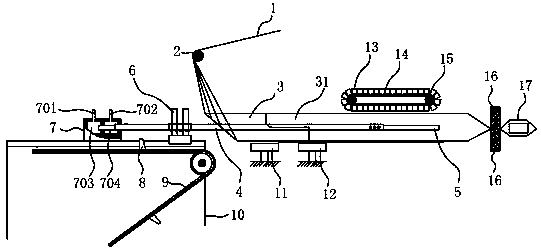

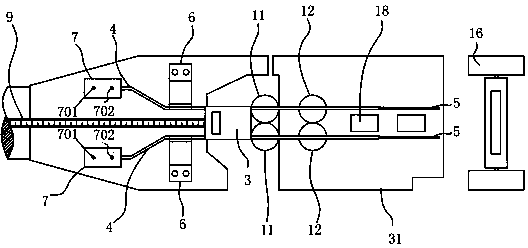

[0024] Such as figure 1 , figure 2 As shown, the fully automatic continuous bag-type modified atmosphere packaging machine of the present invention includes a frame 10, on which a supply chain 9 is arranged, a group of trachea connectors 7 and a group of trachea fixing devices 6 are used to feed the chain 9 It is symmetrically arranged on the frame 10 for the center.

[0025] The specific structure of the trachea connector 7 is as follows:

[0026] A pumping cavity 703 and an inflatable cavity 704 are respectively opened in the trachea connector 7, the pumping cavity 703 is connected to the pumping pipeline 702, and the gas-filling cavity 703 is connected to the inflation pipeline 701;

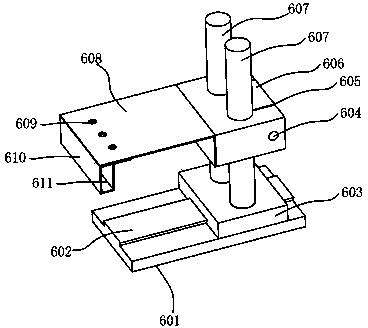

[0027] Such as image 3 As shown, the specific structure of the trachea fixing device 6 is as follows:

[0028] It includes a base 601, and a flange...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com