Mechanical part clamping equipment with cutting function

A technology for mechanical parts and clamping equipment, applied in the field of machining, can solve problems such as clamping only one of flat or curved workpieces, reducing work efficiency, etc., to achieve a wide range of applications, improve efficiency, and improve accuracy. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

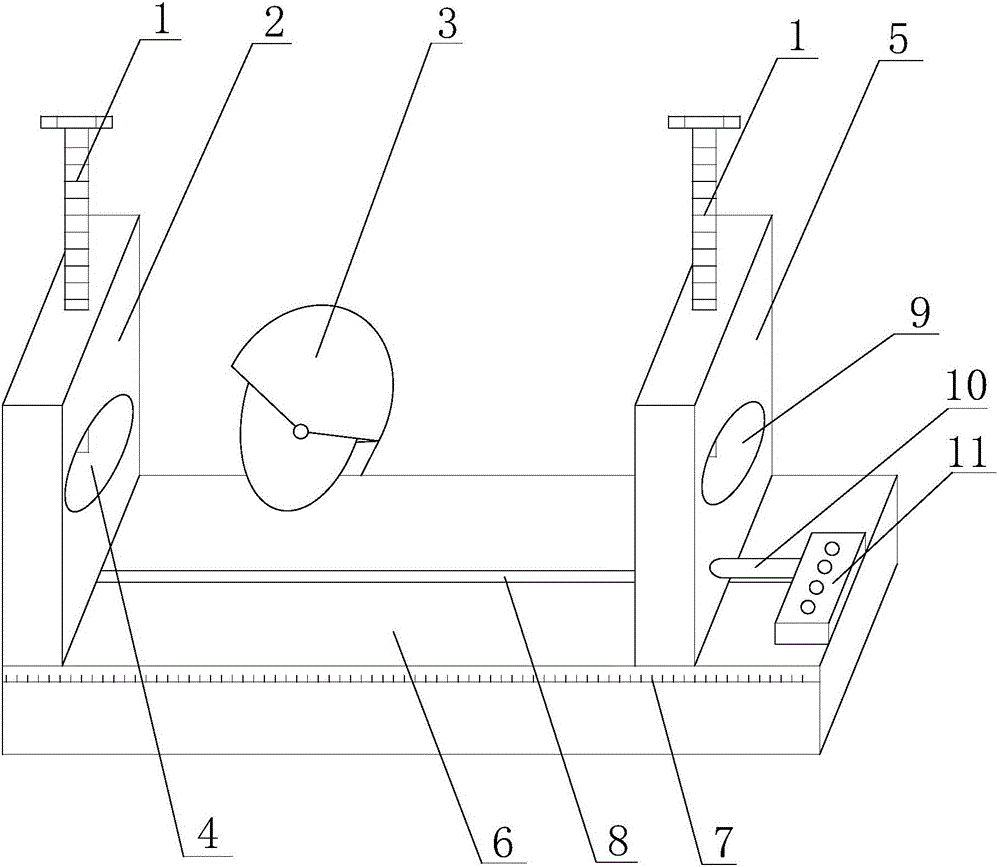

[0022] Such as figure 1 As shown, the mechanical part clamping device with cutting function of the present invention includes a base 6 and a cutting device 3. The base 1 is rectangular in shape, the side of the base 6 is provided with a slide rail, the cutting device 3 is connected to the slide rail, and the cutting device 3 can move in a horizontal direction along the slide rail. The cutting device 3 includes a saw disk, a motor, and a propulsion mechanism. The motors are respectively connected with the saw disk and the propulsion mechanism. The propulsion mechanism is the existing technology and can be driven by the motor to push the saw blade. Straight-line cutting, the top of the base 6 is provided with a first support platform 2 and a second support platform 5. The first support platform 2 and the second support platform 5 are both rectangular in shape. The first support platform 2 is provided with a blind hole 4, The hole 4 is located at the central position of the first ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com