Handheld sealing machine capable of preventing wrong heating

A handheld, mis-heating technology, applied in the directions of external support, packaging sealing/fastening, transportation packaging, etc., can solve the problems of complex structure, poor safety, human injury, etc., and achieve simple and convenient closing operation, reliable performance, and manufacturing cost. low effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

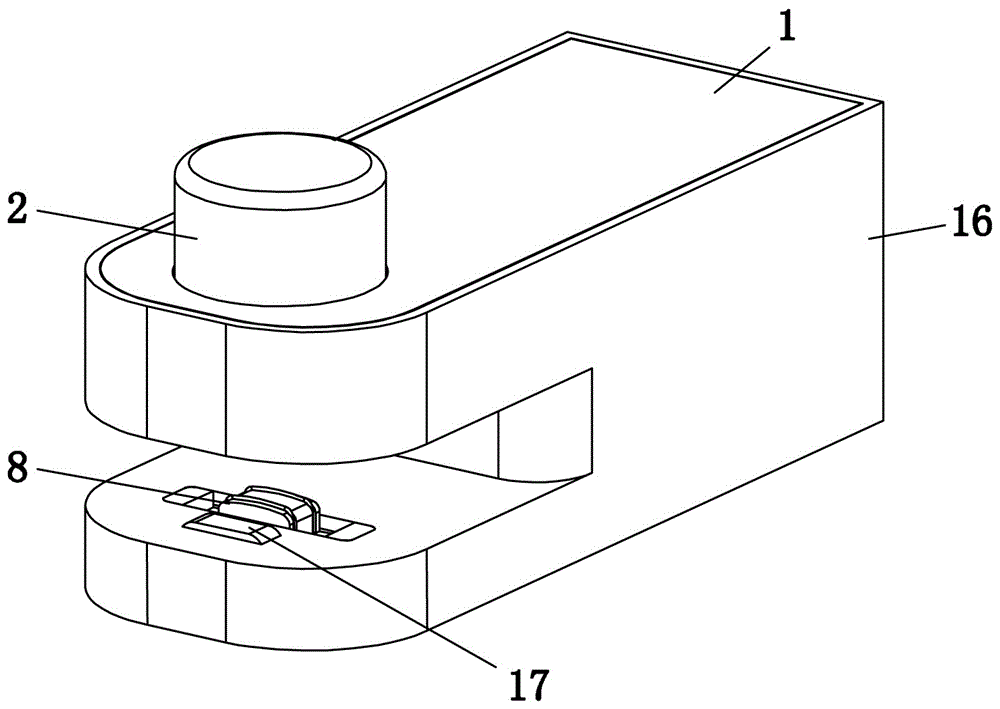

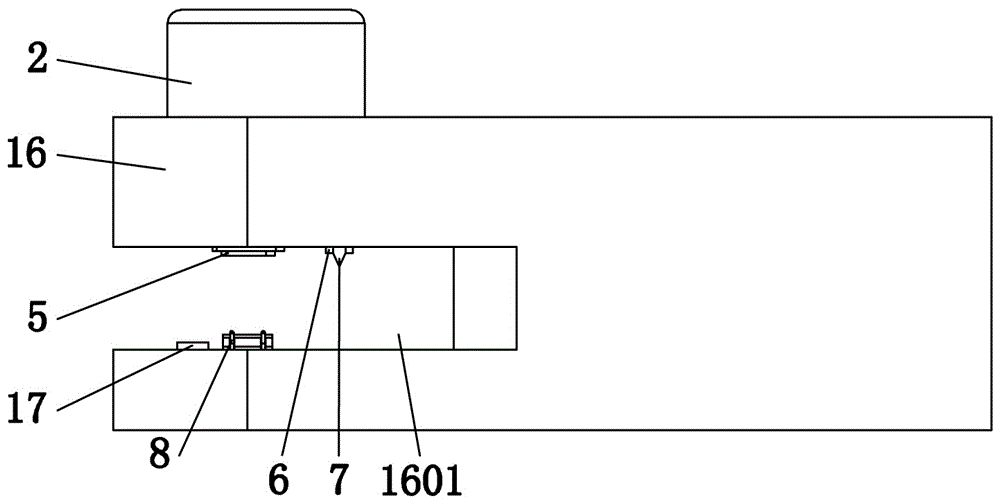

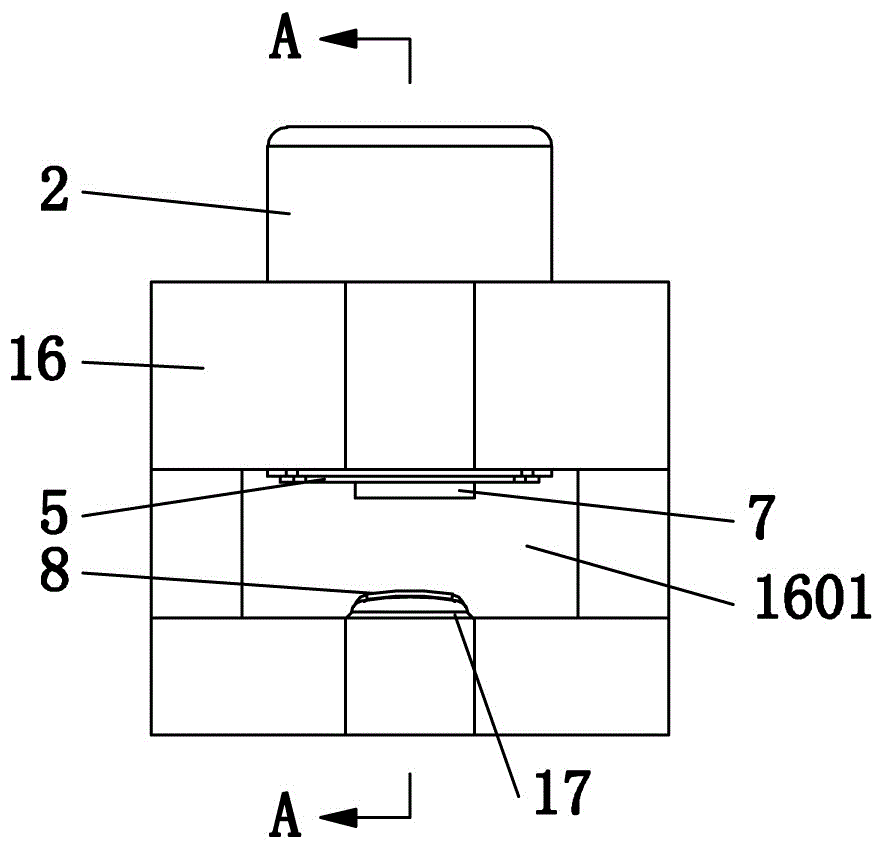

[0030] Example 1, see Figure 1 to Figure 8 As shown, as a basic implementation, a handheld sealing machine capable of preventing false heating includes a casing 16, an electric heating module 8, a pressure contact assembly, and a power supply module 14. The casing 16 is provided with an opening slot 1601 and a pressure contact The components and the electric heating module 8 are respectively arranged on the upper and lower sides of the opening slot 1601. The power supply module 14 is arranged in the casing 16 and is electrically connected to the electric heating module 8 through a switch mechanism; the pressure contact assembly is elastically reset up and down in the direction of the electric heating module 8 Movement setting, the pressing contact assembly is provided with a touch contact 201 for the touch switch mechanism; the pressing contact assembly is movably adjusted and matched with the casing 16, and the touch contact is realized by adjusting the relative position of th...

Embodiment 2

[0044] The second embodiment is different from the first embodiment: see Picture 9 As shown, the electric heating module 8 is a heating sheet, and the heating sheet is integrally stamped and formed into two heating strips 801. By setting different thicknesses and / or widths, the two heating strips have two working states of high temperature and low temperature respectively. . According to different sealing effects, different combinations of electric heating modules 8 are set, which has a wider application range.

Embodiment 3

[0045] The third embodiment is different from the first embodiment: see Picture 10 As shown, the electric heating module 8 is a heating sheet, and the heating sheet is integrally stamped and formed with two heating strips 801, and there is a connecting strip 802 between the two heating strips 801; by setting different thicknesses and / or widths, The two heating strips have two working states of high temperature and low temperature respectively. According to different sealing effects, different combinations of electric heating modules 8 are set, which has a wider application range.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com