Novel high-corrosion-resistance lid maker die material equipment

A high corrosion resistance, mold material technology, applied in the direction of manufacturing tools, metal sawing equipment, metal processing equipment, etc., can solve the problems of reduced work efficiency, low degree of automation, increased labor intensity, etc., to achieve simple structure of the device, easy to use Simple, labor-saving and financial-saving effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

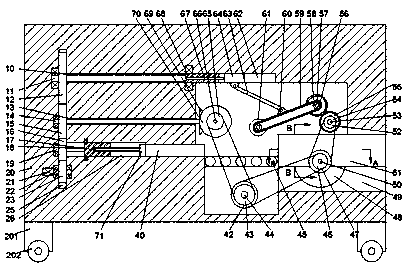

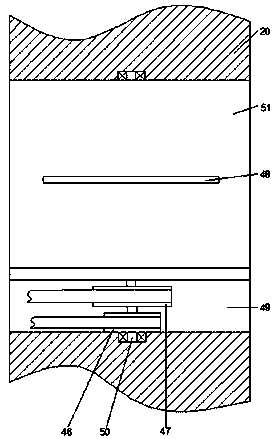

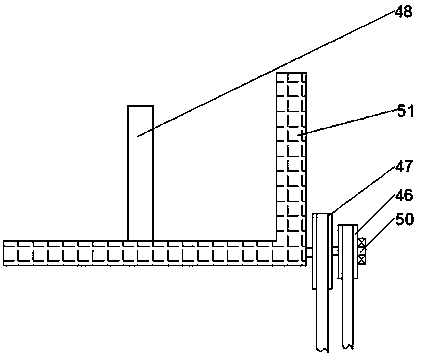

[0019] like Figure 1-3 As shown, a novel high-corrosion-resistant cap making machine mold material equipment of the present invention includes a body 20, a motor 21 is provided inside the body 20, and a motor 21 located in the body 20 is provided on the right side of the motor 21. The first installation groove 25, the first installation groove 25 is provided with the first steering shaft 22 that is rotatably matched to the bottom of the left and right end walls, and the extension of the left end of the first steering shaft 22 is connected with the power of the motor 21, so that The left end of the first steering shaft 22 of the first installation groove 25 is fixedly connected with the first toothed gear 23, and the right side of the first installation groove 25 is provided with a first through cavity 26 communicating with each other. A second steering shaft 19 is rotationally connected between a through cavity 26 and the first installation groove 25, and the second steering ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com