Breaking hammer with shearing device

A technology of shearing device and breaking hammer, applied in construction maintenance, earth mover/shovel, construction, etc., can solve problems such as troublesome operation of workers, troublesome excavator bucket shoveling garbage, failure to cut off in time, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

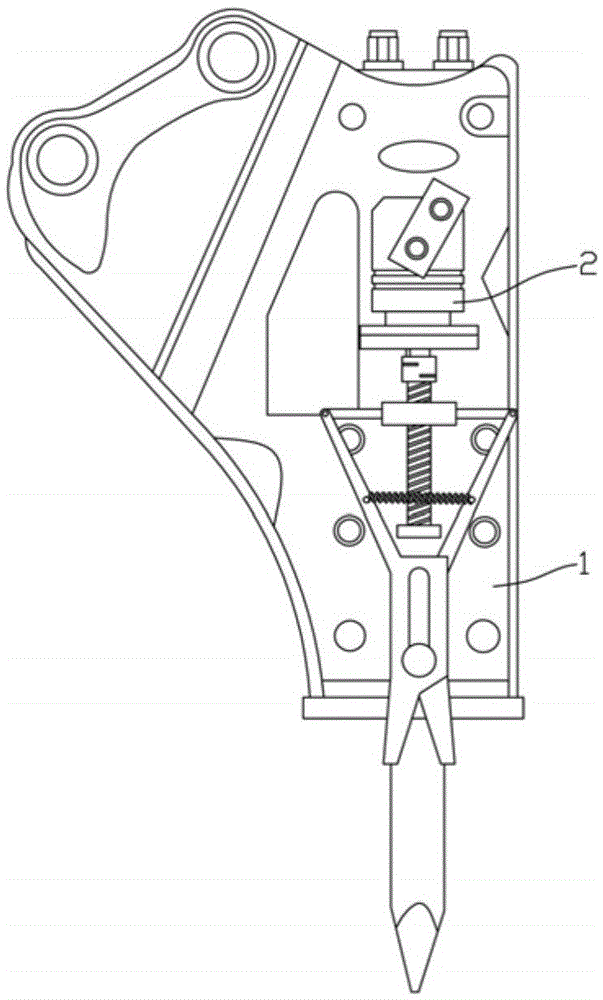

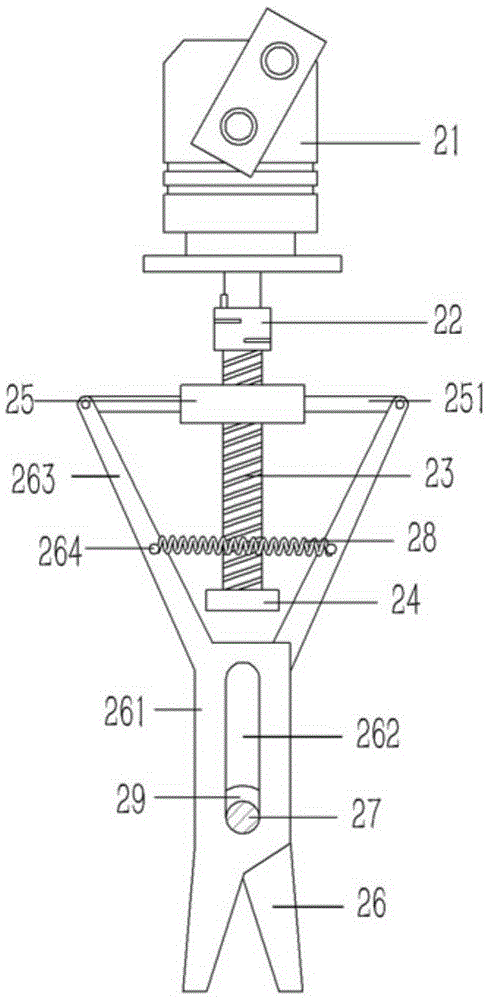

[0014] Example: see figure 1 , 2 As shown, a breaker with a shearing device includes a breaker 1, and a shearing mechanism 2 is fixedly connected to the breaker 1;

[0015] The shearing mechanism 2 includes a hydraulic motor 21 fixed on the side wall of the breaker 1. The rotating shaft of the hydraulic motor 21 is connected with the upper end of a vertical screw 23 through a coupling 22, and the lower end of the screw 23 is hinged on the base 24, the base 24 is fixed on the side wall of the breaker 1, and the lower side of the base 24 is provided with a shear knife, which is composed of two staggered and symmetrical blades 26, and the blade 26 is formed into a rectangular piece extending upward. body 261, a vertical guide groove 262 is formed on the rectangular piece body 261, the guide grooves 262 of the two blades 26 overlap together, and a guide column 27 is inserted in the guide groove 262, and the guide column 27 is fixed on the side wall of the breaker 1 Above, the up...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com