Feeding structure for stone cutter

A technology of stone cutting machine and feeding mechanism, which is applied in the direction of stone processing tools, stone processing equipment, work accessories, etc., can solve the problem that the rock cannot be prevented from shaking up and down, and achieve the effect of adding blocks and cutting, and the speed is stable and slow

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 example

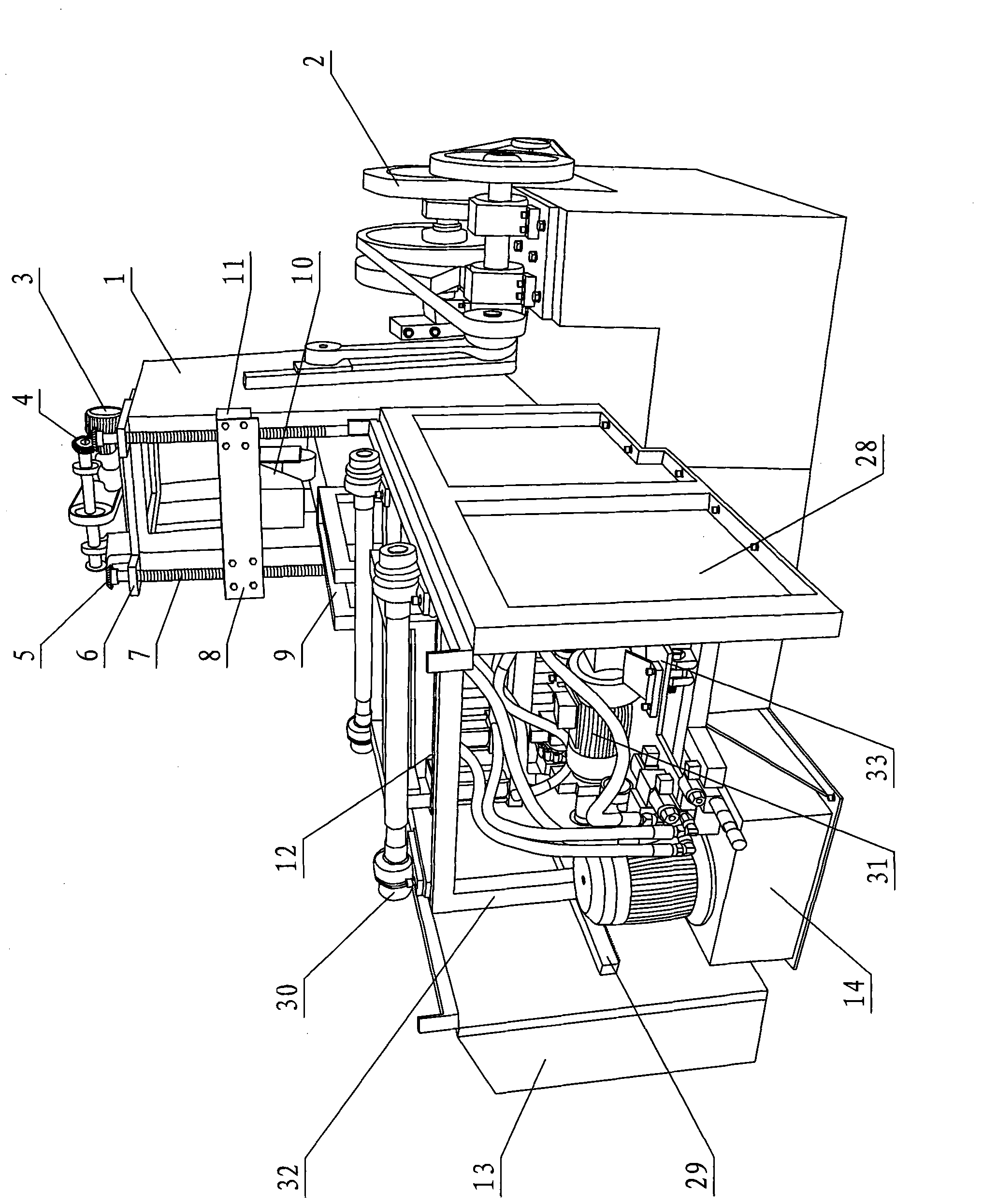

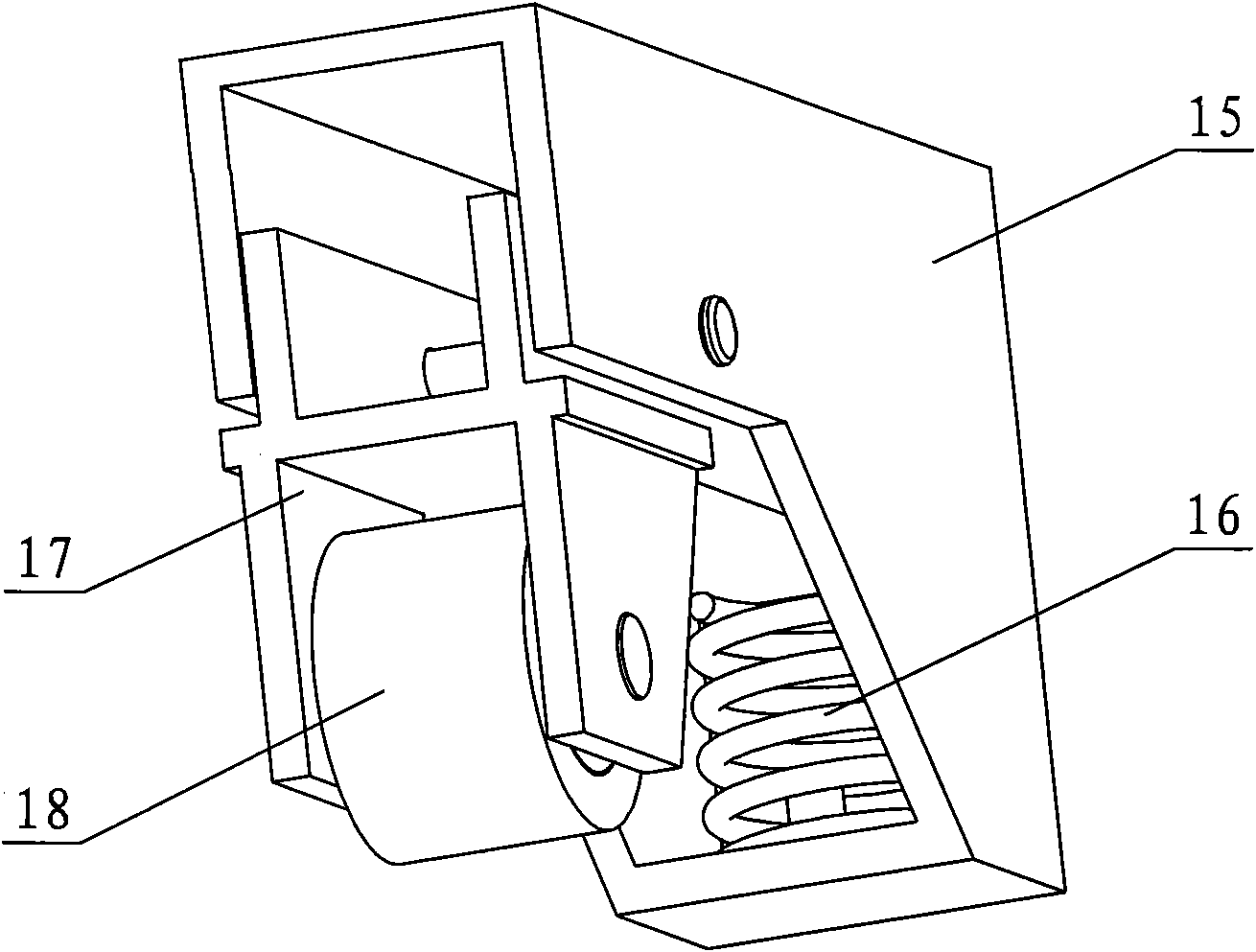

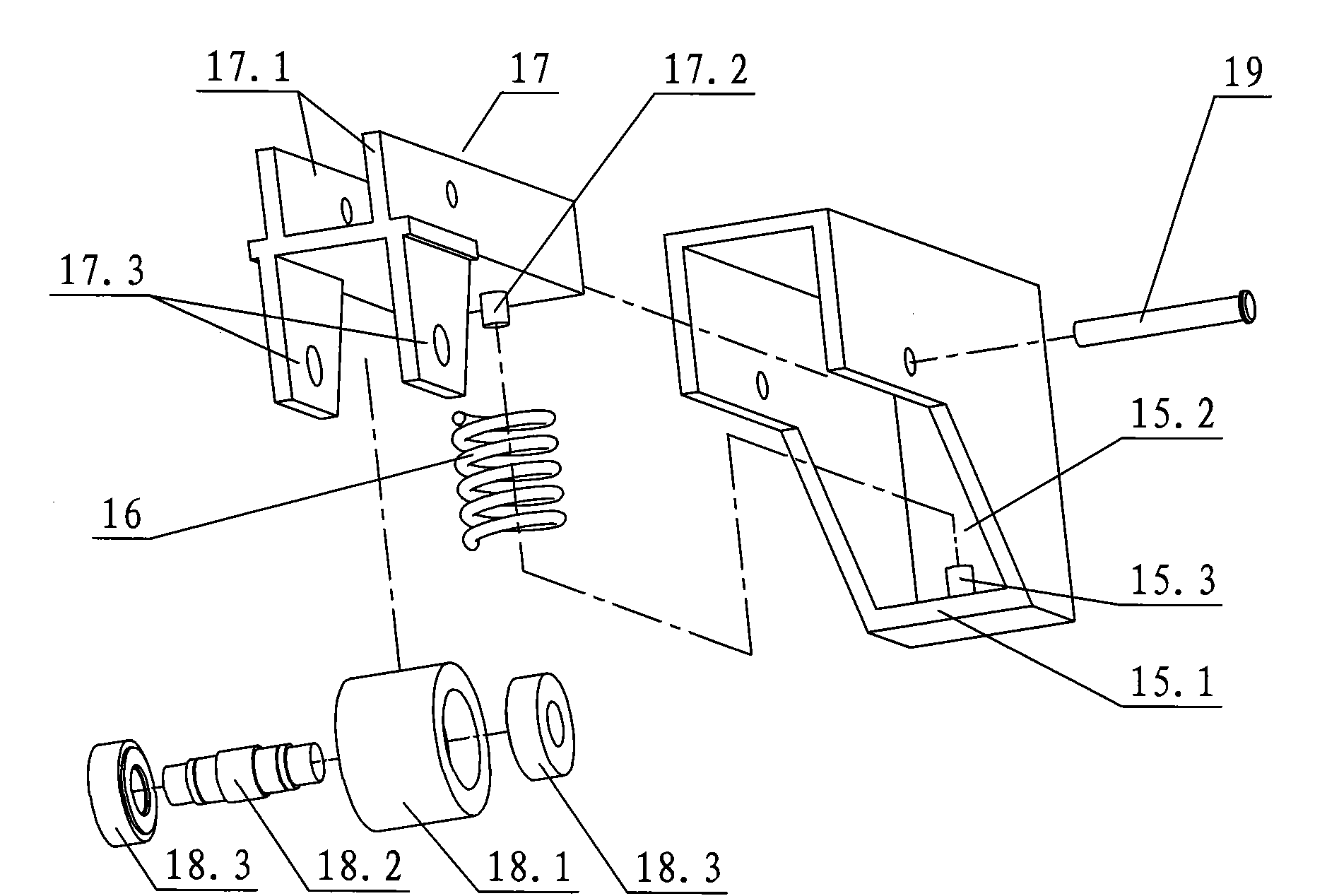

[0034] see figure 1 , Figure 11-Figure 13 , the feeding structure of the stone cutter includes a feeding mechanism 12 arranged at the rear of the frame 1 and capable of moving back and forth, a receiving part 21 for placing stones is arranged in front of the feeding mechanism, a cutting part is arranged in front of the receiving part, and a cutting part Connected with the main drive mechanism 2, the rear of the frame is provided with a rack 29 transversely, and the feeding mechanism is provided with a forward gear 40 driven by a forward motor 44 and a reverse gear 39 driven by a reverse motor 31. The forward gear and the reverse gear are respectively It is connected with the front lifting mechanism and the rear lifting mechanism, so that the forward and backward gears are engaged with or disengaged from the rack through the lifting movement.

[0035] The left and right sides of the rear portion of the frame 1 corresponding to the feeding mechanism 12 are provided with fixed ...

no. 2 example

[0048] see Figure 7 , the top surface of the movable seat 17' is provided with hinged ears hinged with the fixed seat 15' at least in the middle front, and the front end of the bottom surface is provided with a roller shaft seat connected with the pressing roller 18; the fixed seat is connected with the frame through a lifting mechanism, and the upper part is provided with There is a fixed seat top plate 15.4'; the elastic member is a tension spring 16', and the upper and lower ends are connected with the fixed seat top plate 15.4' and the rear end top surface of the movable seat respectively. Other unmentioned parts are the same as the first embodiment.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com