Stone mosaic brick and method for making same

A mosaic and stone brick technology, applied in the field of stone, can solve the problems of inability to use dry hanging installation, complicated manufacturing process and high manufacturing cost, and achieve the effects of simple manufacturing process, low manufacturing cost and wide application.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

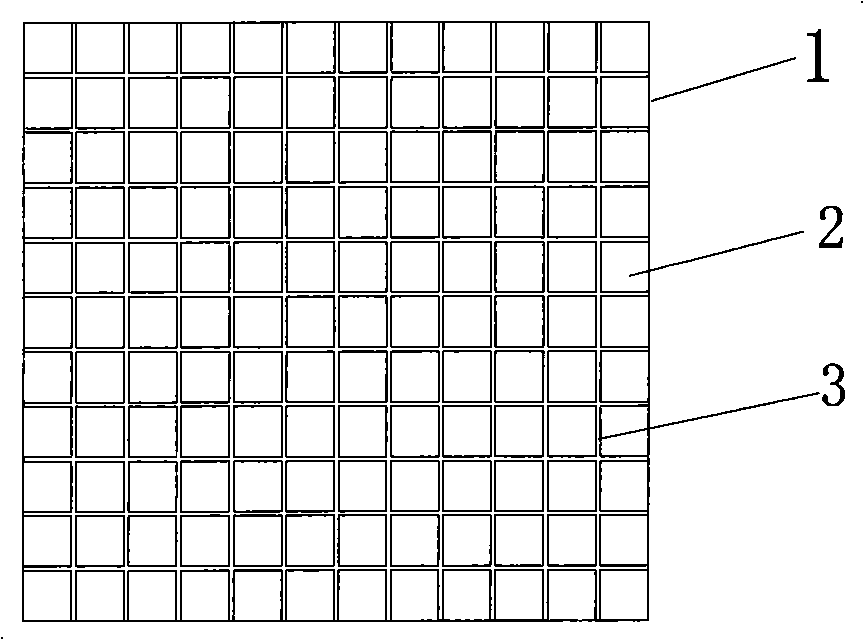

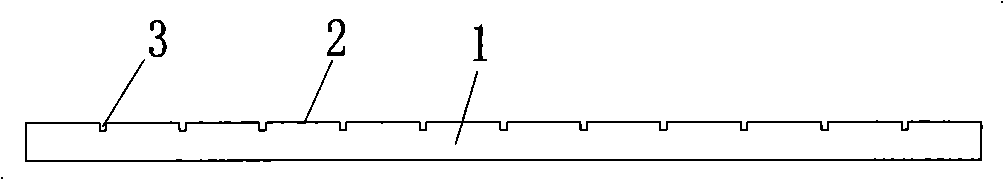

[0030] see figure 1 and 2 , a square mosaic pattern 2 given according to the design requirements on the marble stone brick 1 with a length and width of 300mm and a thickness of 25mm, using stone saw blades with a thickness of 2mm to form a saw blade group, and cutting the mosaic pattern particles according to the schedule Arrange the spacing of the saw blades according to the size, draw the slit 3 of the mosaic pattern particles according to the mosaic pattern, and obtain the stone mosaic brick. The slits constitute mosaic pattern particles, showing the effect of mosaic pattern particles.

[0031] In order to ensure that the stone brick 1 is not easy to break, the depth of the scratched seam 3 is 2 mm.

[0032] Since the stone saw blades with a thickness of 2mm are used to form a saw blade group, the spacing of the saw blades is arranged according to the particle size to be cut, and the slit 3 of the mosaic pattern particle effect can be drawn out, so as to ensure that the p...

Embodiment 2

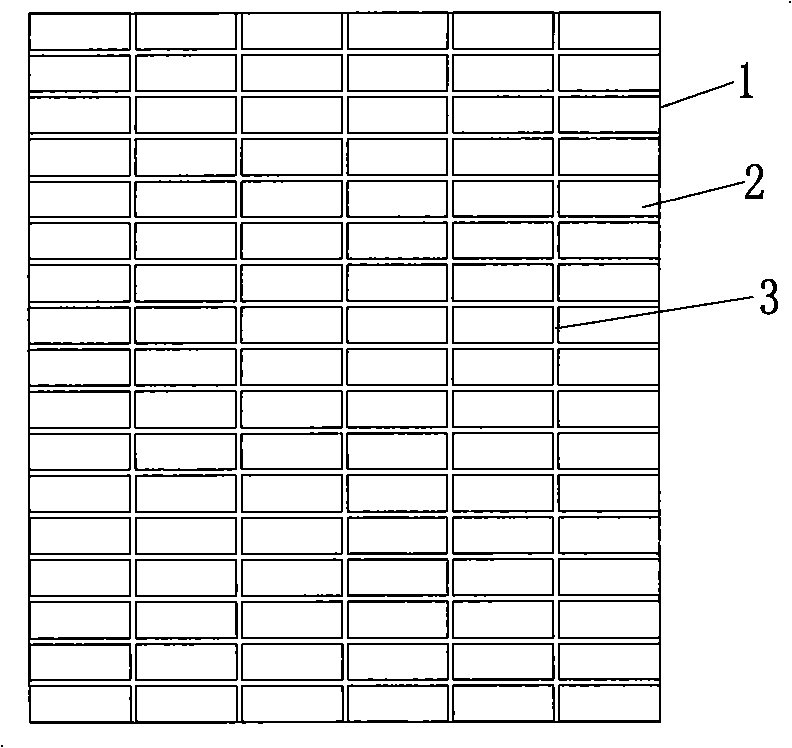

[0034] see image 3 , similar to Example 1, the difference is that the stone brick adopts granite stone brick 1, the size of stone brick 1 is 500mm in length, 400mm in width, and 50mm in thickness, the depth of scratch 3 is 3-4mm, and the square mosaic pattern is changed to Rectangular mosaic pattern 2.

Embodiment 3

[0036] Similar to Example 1, the difference is that the stone bricks are slate bricks, the size of the stone bricks is 400mm in length, 300mm in width, and 30mm in thickness, the depth of the scratches is 2.5-2.8mm, and the square mosaic pattern is changed to a circular mosaic pattern.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com