Gantry type stone cutter

A cutting machine, gantry-type technology, applied in the direction of stone processing tools, stone processing equipment, work accessories, etc., can solve the problems of poor stability of the lifting column, prone to irregular shaking, etc., to increase stability, improve cutting accuracy and sawing. The life of the film, the effect of solving the shaking

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] The specific implementation manners of the embodiments of the present invention will be described below with reference to the accompanying drawings.

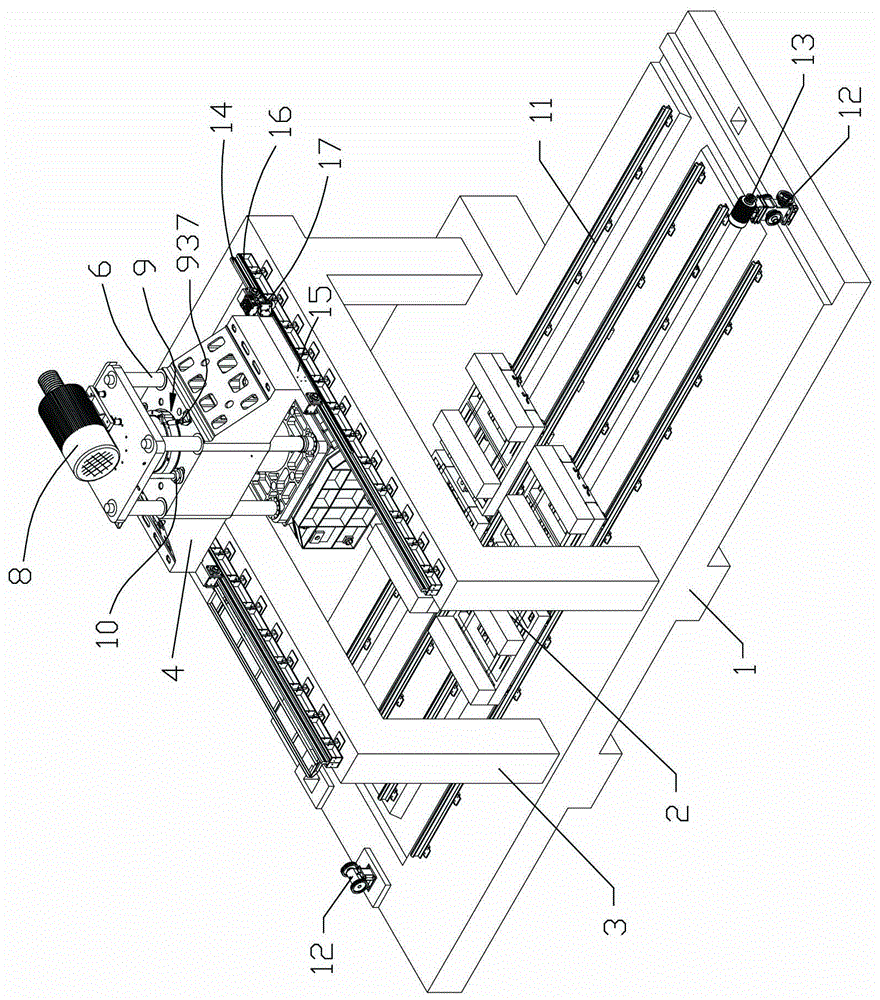

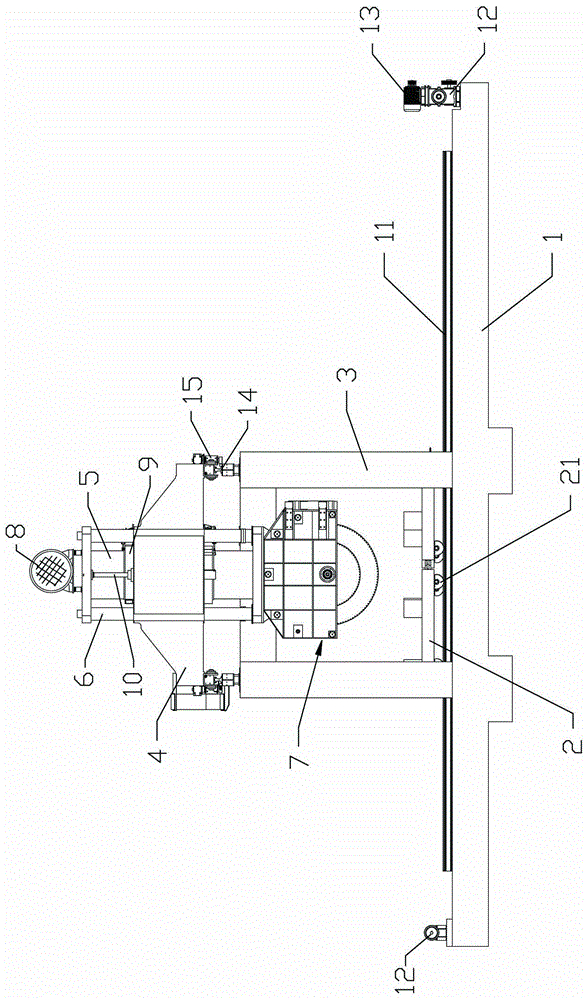

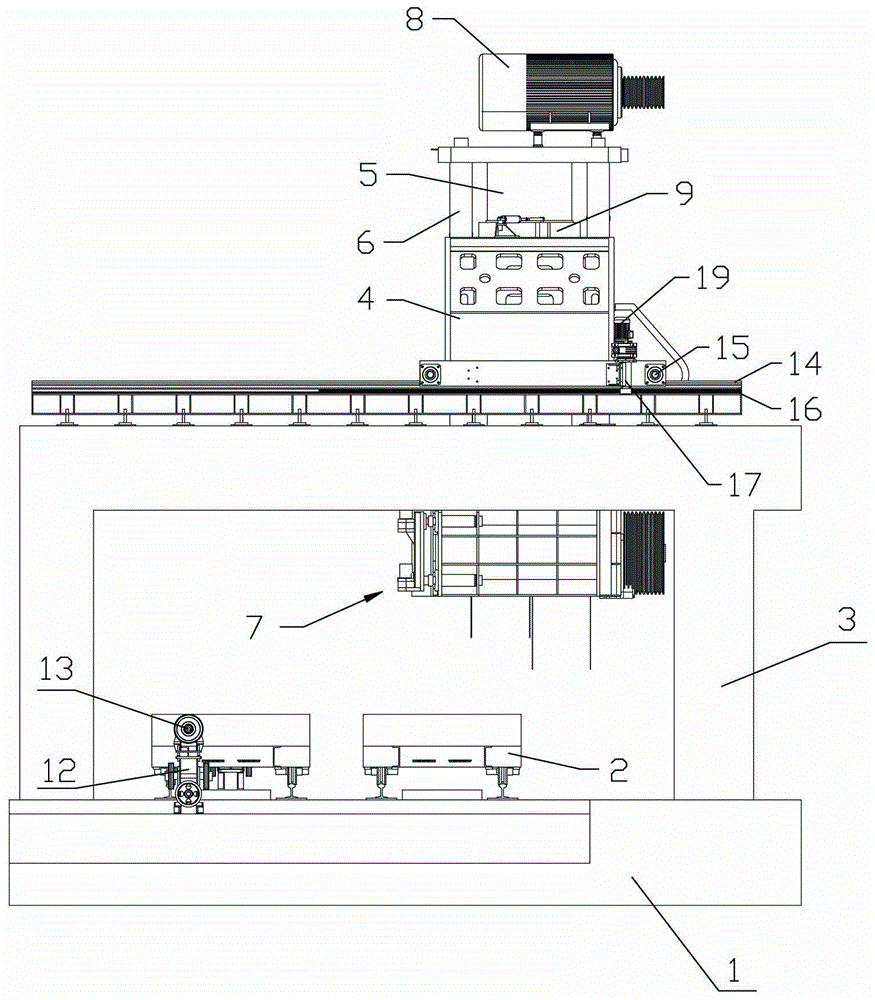

[0030] refer to Figure 1 to Figure 4 , a gantry-type stone cutting machine, including a base 1, the base 1 is provided with a trolley 2 that can move along the X-axis direction of the base 1, and the base 1 is fixedly connected with two parallel support seats 3 parallel to each other at intervals. Two parallel support bases 3 are erected with a gantry 4 that can move along the Y-axis direction of the base 1 on the parallel support base 3 , and the gantry 4 is provided with a lifting column 5 that can be lifted up and down in the Z-axis direction of the gantry 4 and A plurality of lifting auxiliary columns 6, the lifting column 5 and the lower part of the lifting auxiliary column 6 are respectively fixedly connected to a combined saw machine 7, and the upper parts of the lifting column 5 and the lifting auxiliary column 6...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com