Multi-cutter swivel stone material multi-machine cutoff production line

A technology of production line and knife rotary shaft, which is applied in the field of multi-machine joint cutting production line of stone with multi-knife rotary shaft, can solve the problem that there is no large-scale joint cutting production line capable of continuously producing and processing ultra-long and ultra-wide slab stone, so as to save consumption, The effect of improving material yield and reducing cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0033] The embodiments are further described below in conjunction with the accompanying drawings.

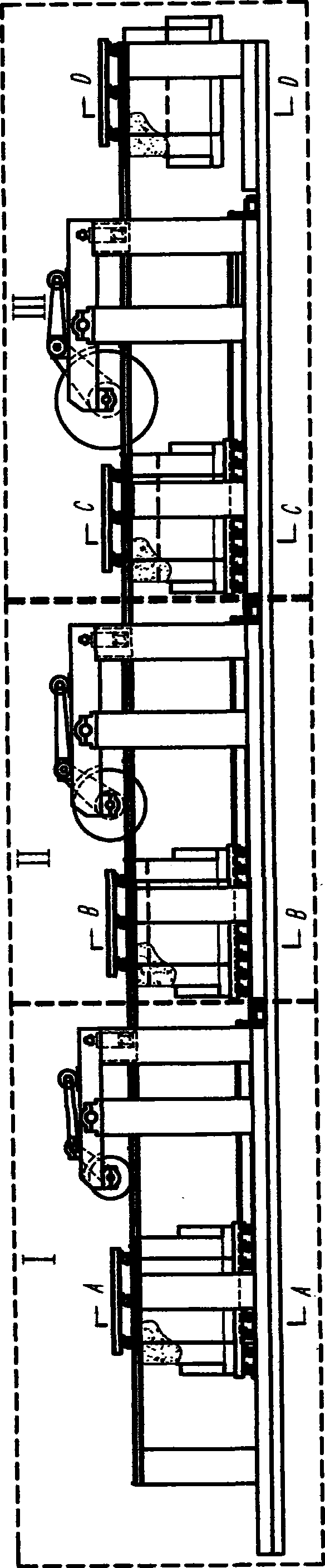

[0034] refer to figure 1 , is a schematic diagram showing the basic structure of the whole production line, taking three processing areas as an example. The three processing areas I, II, and III are marked in the figure, and the cutting lines A-A, B-B, C-C, and D-D in each area are shown.

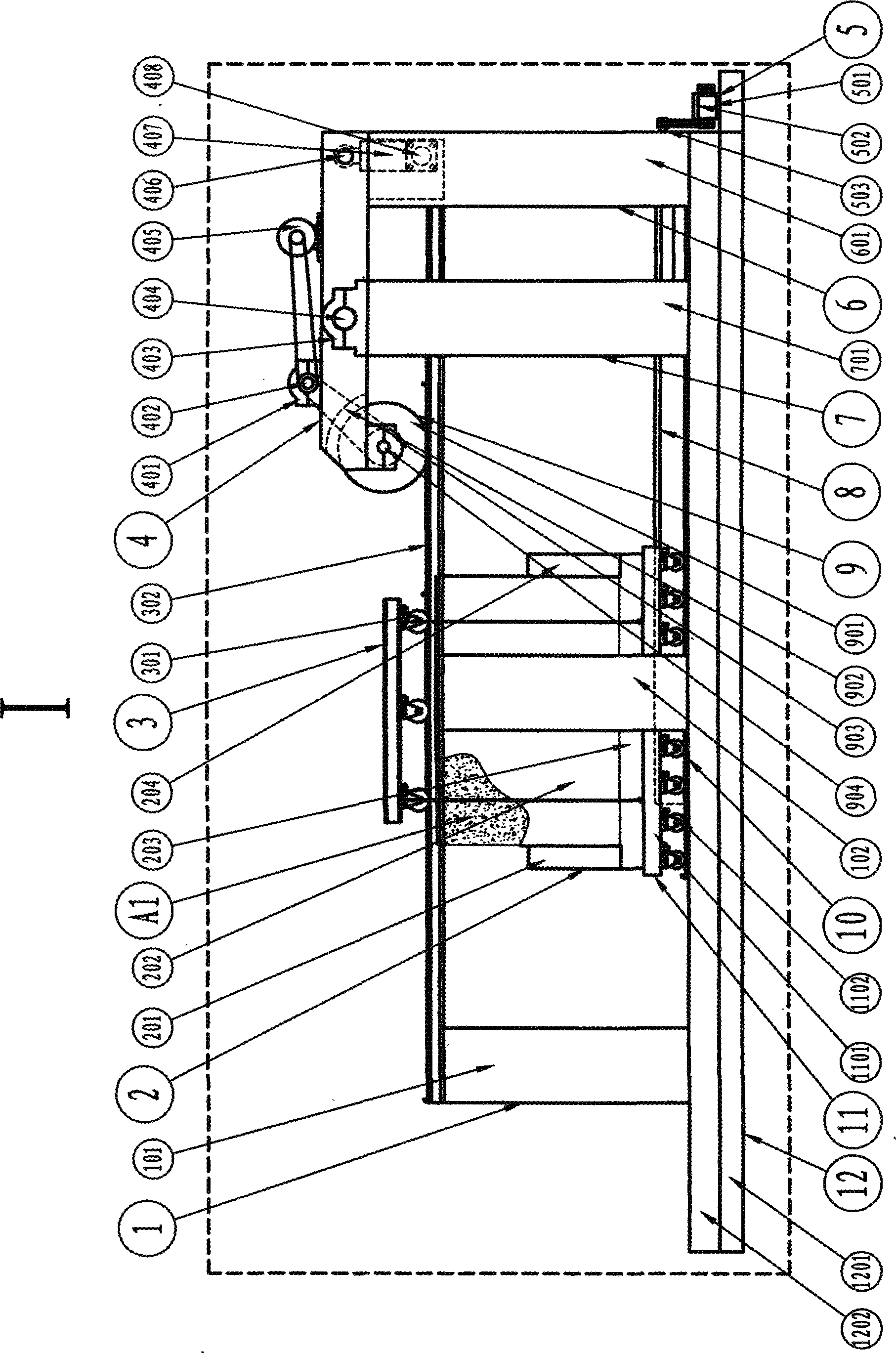

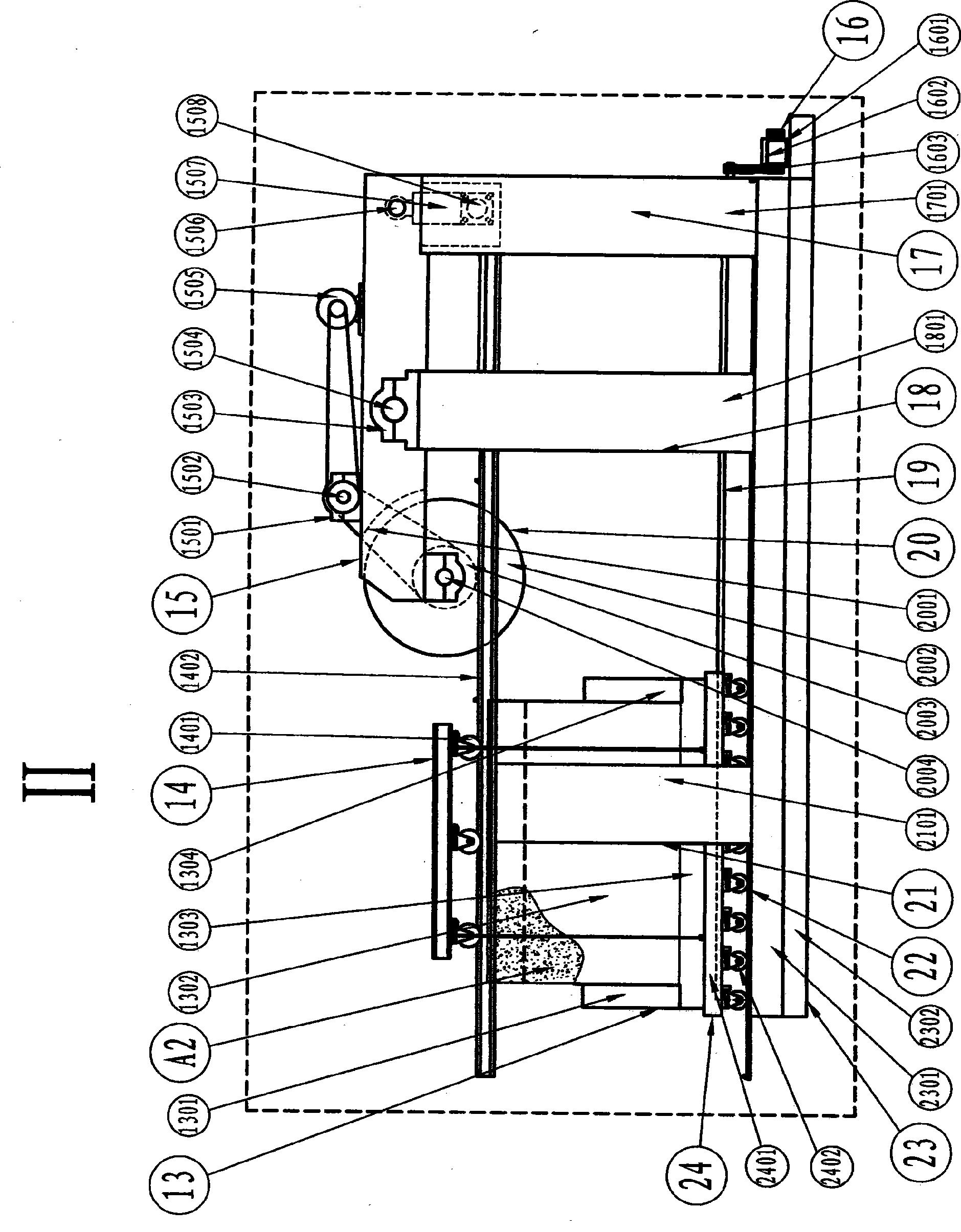

[0035] refer to figure 2, 1- There are 101, 102, 103, 104 four load-bearing columns of the driving crane. The figure shows that the front two are 101, 102, and there are two behind; 2-the fixture assembly, 201-the front end of the fixture is pressed and fixed Plate, 202-the fixed reference plate on the left side of the fixture, 203-the bottom plate of the fixture. 204-The rear end of the fixture is pressed and fixed on the reference plate, 205-The fixed reference plate on the right side of the fixture, A1-Stone processing parts; 3-Traffic crane assembly, 301-Traffic crane wheel group, 302...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com