Multichannel digitized intelligent unbalance loading error correcting and weighing sensor and weighing method thereof

A technology of load cell and eccentric load error, applied in the field of sensor structure, can solve the problems of destroying the anti-corrosion treatment layer of the load cell, labor and time-consuming accuracy, reducing protection effect, etc., and achieves ingenious structural design, improved correction accuracy, and compensation accuracy improved effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

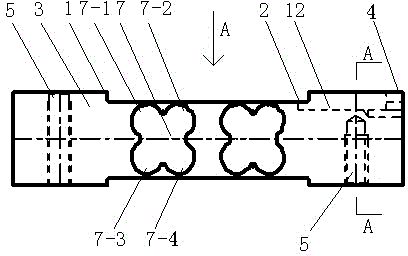

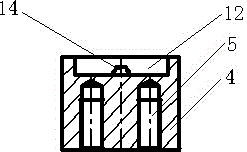

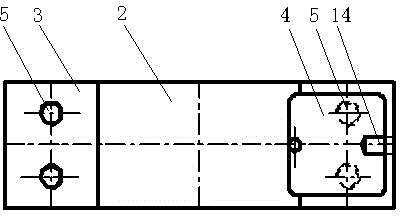

[0037]The multi-channel digital eccentric load error intelligent correction load cell of this embodiment includes an elastic body 1 made of aluminum alloy material. The elastic body 1 is composed of a beam 2 in the middle and a left fixing part 3 and a right fixing part 4 at both ends. The two fixing parts are integrated with the beam 2, the left fixing part 3 is formed with mounting holes 5, the lower surface of the right fixing part 4 is provided with mounting holes 5, and the upper surface of the right fixing part 4 is provided with a mounting hole for placing a circuit board 6. Groove 12, the inside of the beam 2 is provided with two through holes 7 through the beam 2, the position of the upper and lower surfaces of the beam 2 corresponding to the through holes 7 is the strain zone, and the upper and lower surfaces of the beam 2 are respectively provided with two groups Resistance strain device, each group of resistance strain devices is composed of four resistance strain g...

Embodiment 2

[0045] The difference between this embodiment and Embodiment 1 is that the cross-section of the through hole 7 is circular, and the position where the upper and lower surfaces of the beam 2 correspond to the circular through hole 7 is the strain zone, and the upper and lower surfaces of the beam 2 are respectively set There are two sets of resistance strain devices, and the installation positions of the resistance strain devices correspond to the positions of two adjacent circular through holes 7 .

Embodiment 3

[0047] The difference between this embodiment and Embodiment 1 is that the cross-section of the through hole 7 is square, the position where the upper and lower surfaces of the beam 2 correspond to the circular through hole 7 is the strain zone, and the upper and lower surfaces of the beam 2 Two sets of resistance strain devices are respectively provided, and the installation positions of the resistance strain devices correspond to the positions of two adjacent circular through holes 7 .

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com