Multifunctional dynamic precision test system

A technology of dynamic precision and test system, applied in the field of dynamic precision research test system, can solve the problems of not considering the influence and not having advantages, etc., to achieve the effect of easy analysis, powerful signal analysis and processing functions, and simple and friendly interface

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

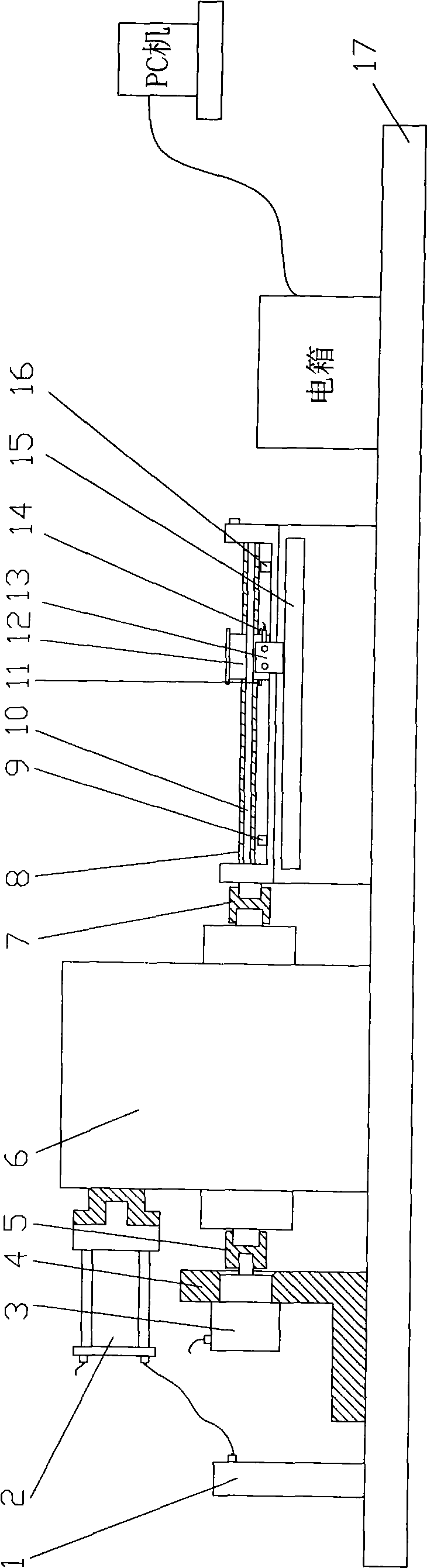

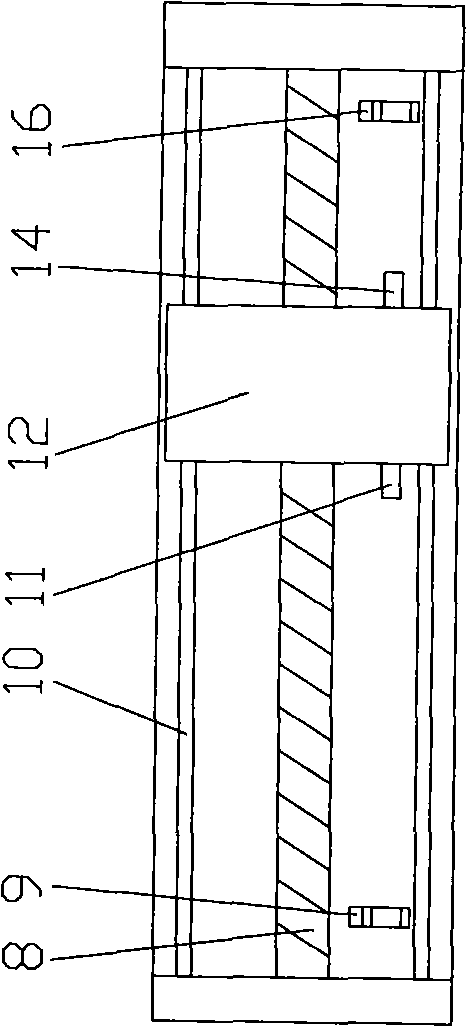

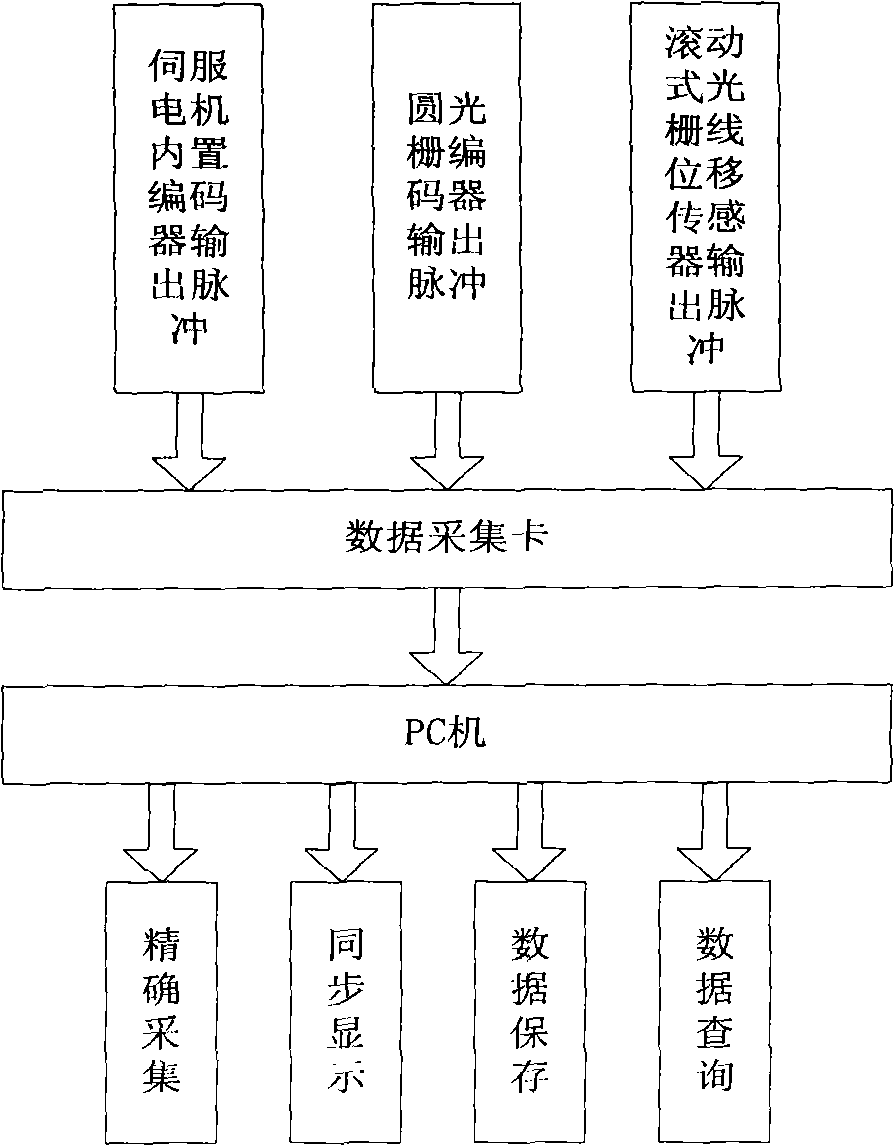

[0039] see figure 1 , figure 2 , the motion mechanism of the system is: a servo motor 2 controlled by a servo driver 1 is set to drive the reducer 6 to rotate. The reducer 6 is a two-stage helical gear reducer. The coupling 5 is connected with the circular grating encoder 3, and the other end is connected with the ball screw 8 through the bellows coupling 7, and the ball screw 8 and the nut realize rolling transmission through steel balls; It is connected with a worktable 12 that can slide axially along the linear guide rail 10. The worktable 12 is supported by the linear guide rails 10 located on both sides of the ball screw 8. The linear guide rail 10 is supported at both ends and suspended in the middle; The sensor 15 measures the displacement, wherein the reading head 13 is positioned and guided by ball bearings, with low friction and high sensitivity. The reading head 13 and the workbench 12 are connected by threads, and the rolling grating line displacement sensor 15 i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com