Machine vision systems for use with programmable material consolidation apparatus and systems

a technology of programmable material and machine vision, applied in the direction of program control, additive manufacturing process, instruments, etc., can solve the problems of conventional stereolithographic apparatus without machine vision system for ensuring, conventional stereolithographic apparatus without handling system, and cleaning equipment suitable for use with relatively delicate structures. achieve the effect of high level of precision

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

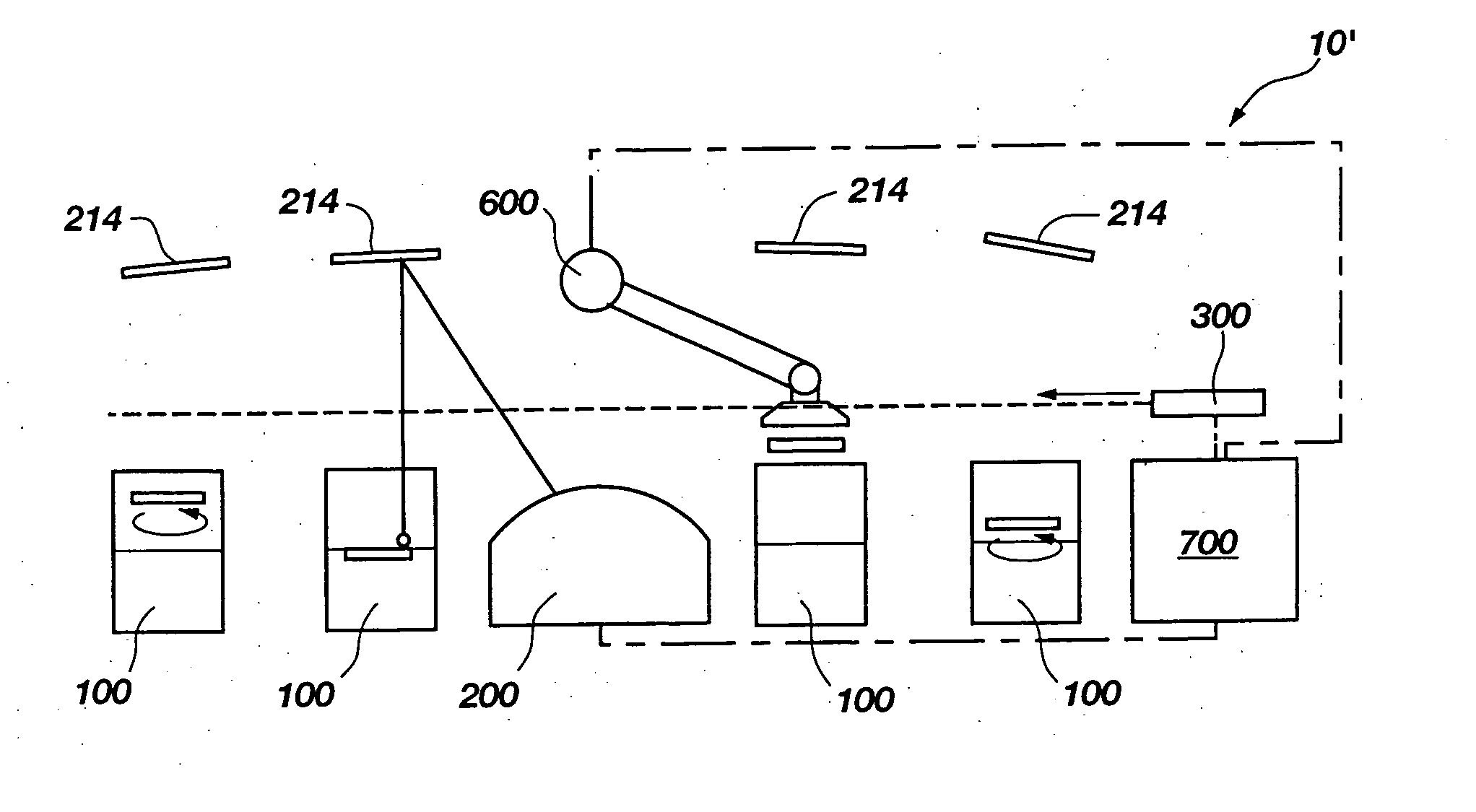

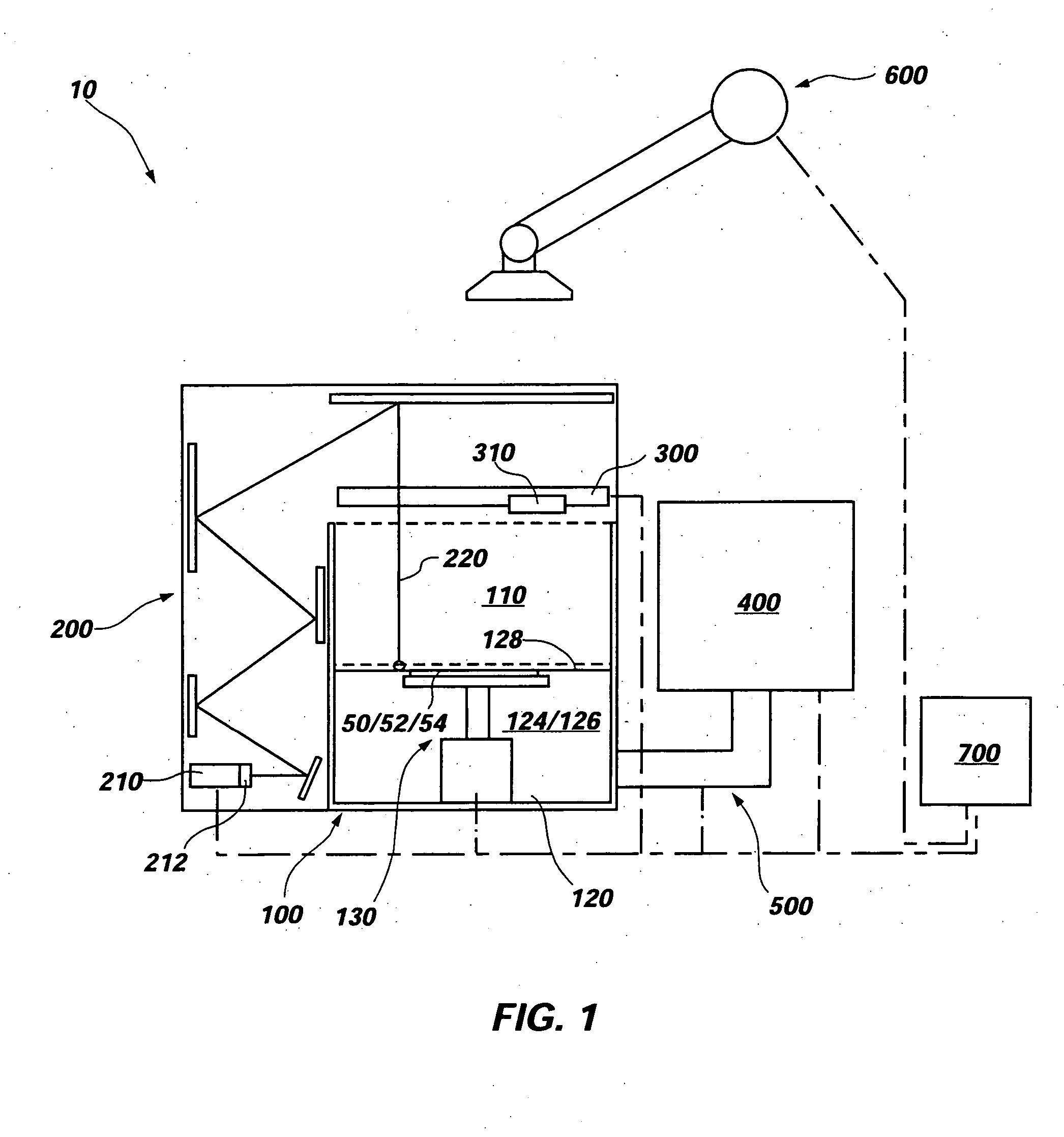

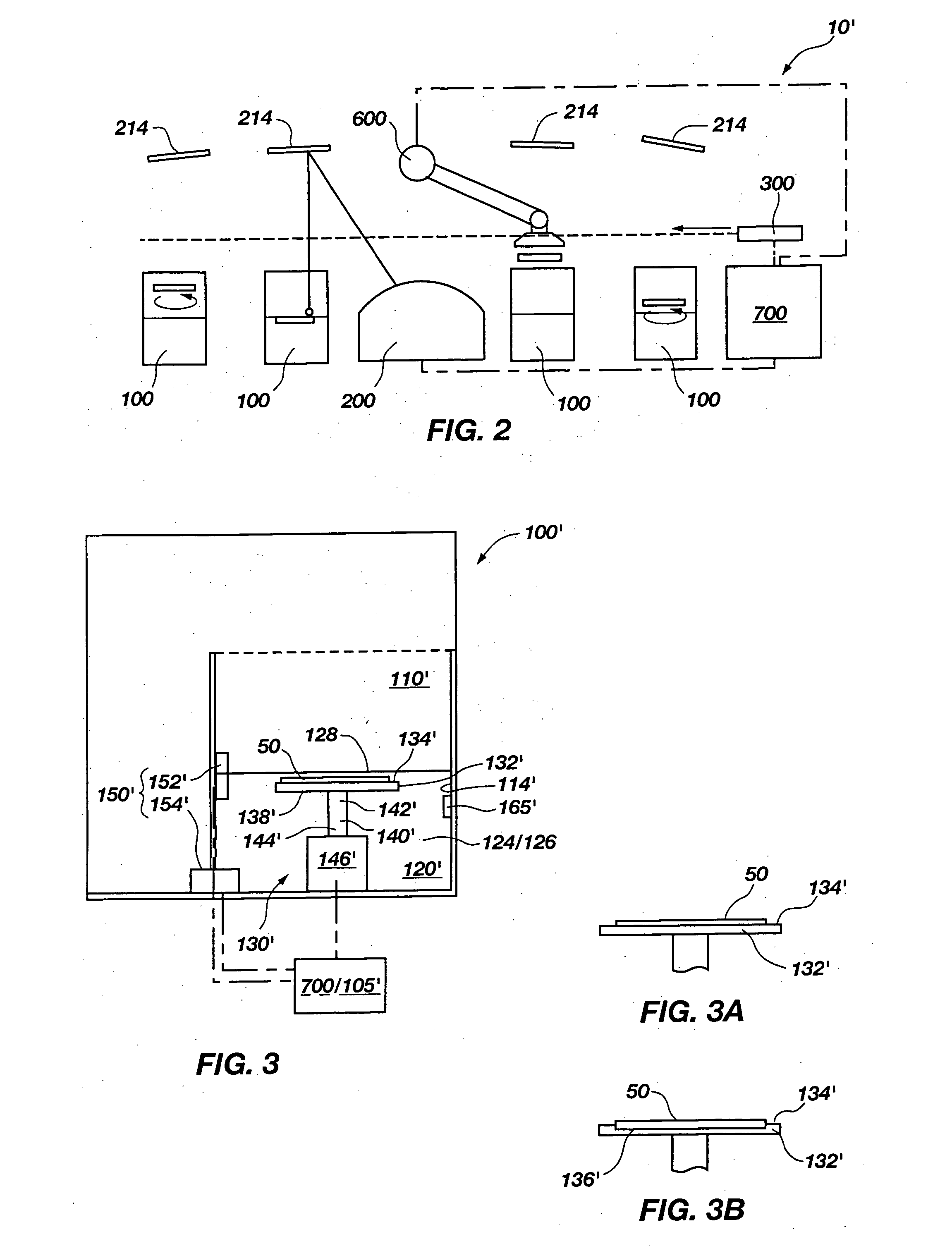

[0053] An exemplary stereolithographic apparatus 10 for fabricating features on semiconductor substrates 52, semiconductor devices 54 or associated components (e.g., lead frames, circuit boards, etc.) (not shown) or other fabrication substrates 50 is schematically depicted in FIG. 1. As shown, stereolithographic apparatus 10 includes a fabrication tank 100 and a material consolidation system 200, a machine vision system 300, a cleaning component 400, and a material reclamation system 500 that are associated with fabrication tank 100. The depicted stereolithographic apparatus 10 also includes a substrate handling system 600, such as a rotary feed system or linear feed system available from Genmark Automation Inc. of Sunnyvale, Calif., for moving fabrication substrates 50 from one system of stereolithographic apparatus to another. Features of one or more of the foregoing systems may be associated with one or more controllers 700, or processing elements, such as computer processors or ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| path length | aaaaa | aaaaa |

| size | aaaaa | aaaaa |

| pressures | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com