Electric detonator initiator

An electric detonator and foot wire technology, used in detonators, electric fuzes, fuzes, etc., can solve the problems of low material utilization rate of refined galvanized thin steel strips, speed up the corrosion rate of welded joints, and reduce resistance stability. The effect of improving electrochemical corrosion resistance, reducing manufacturing process links and reducing scrap rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

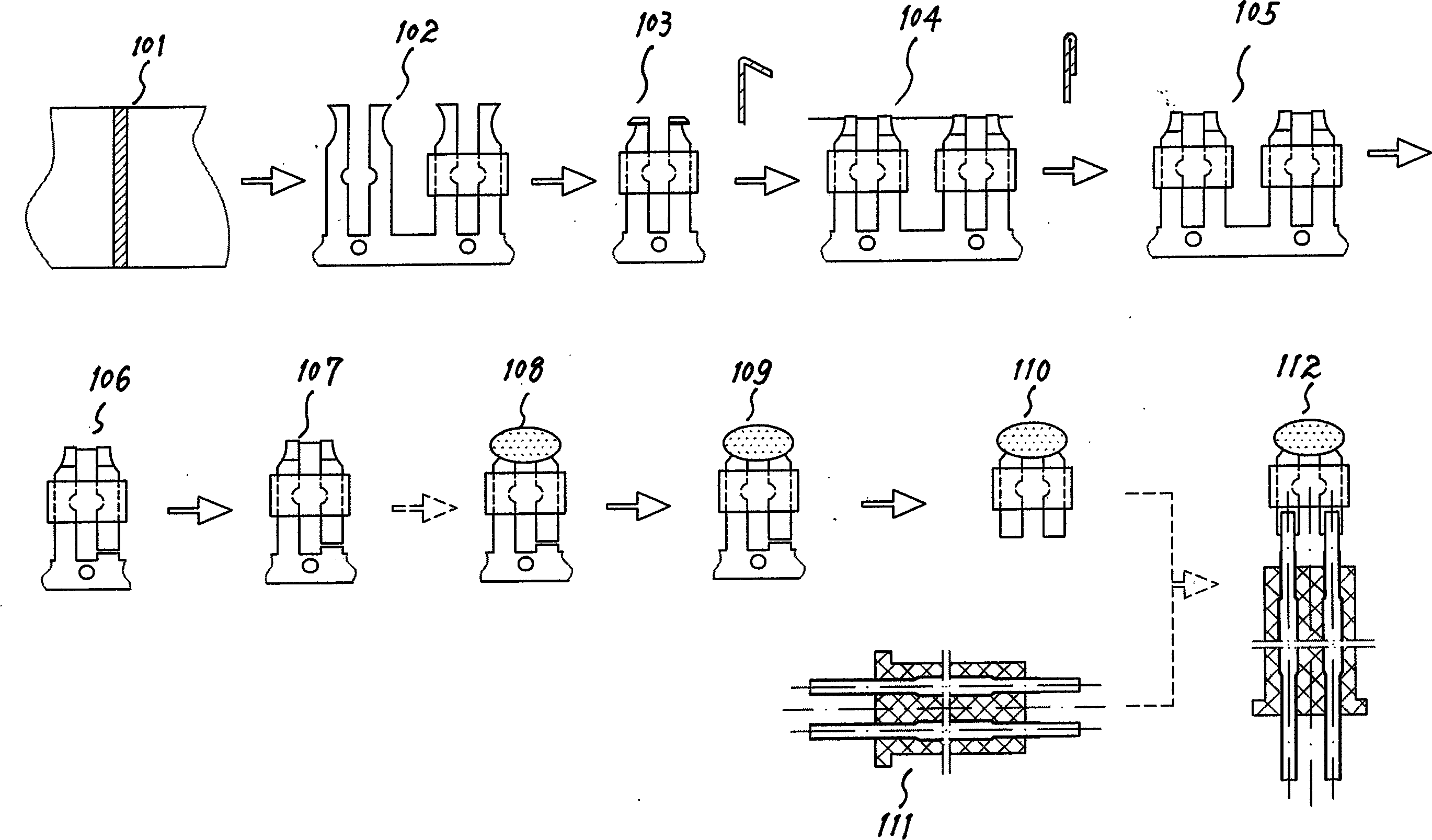

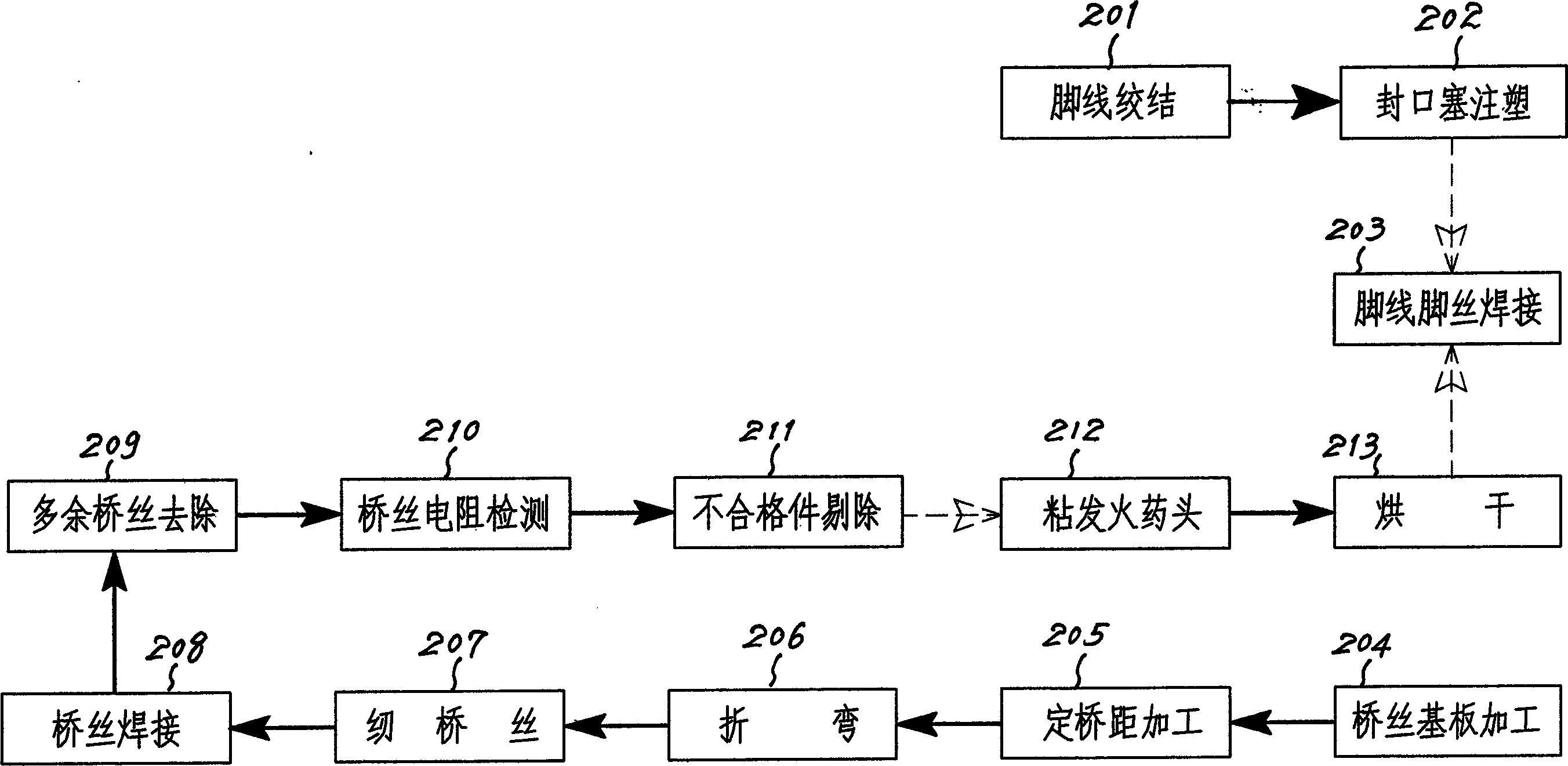

[0022] The present invention will be described in further detail below in conjunction with the accompanying drawings and specific embodiments.

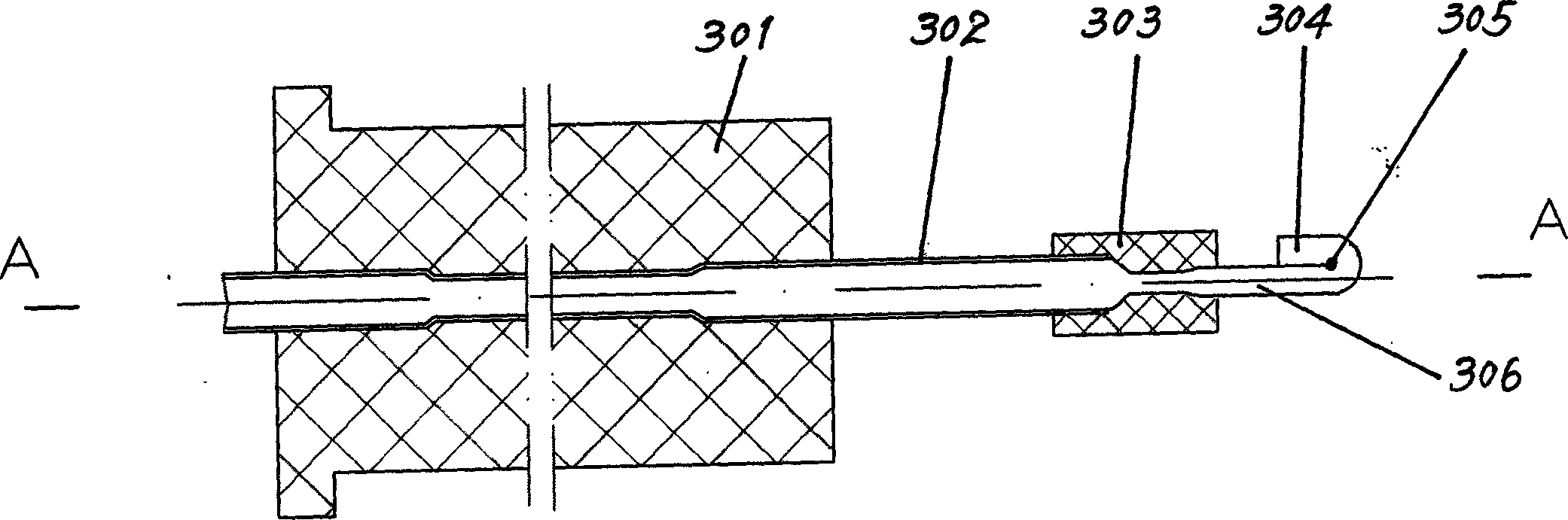

[0023] like Figure 3-1 and Figure 3-2 As shown, the electric detonator ignition device of the present invention includes a bridge wire 305, a foot wire 304 with a plastic sheath 302, a bridge distance fixing device 303 and a sealing plug 301, and the base wire 304 and the bridge wire 305 are integrated structure, so that a foot wire 304 from the sealing plug 301 to the welding end of the bridge wire 305 forms a foot wire, and the foot wire is a variable cross-section structure, and the sections are flat. In the ignition device of the electric detonator of the present invention, the segments shown in the legs are flat sections, and the flat sections are located in the sealing plug 301 section of the legs, the bridge distance fixing device 303 section and the welding end 306 respectively. It can be seen that the fundamental differen...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com