Patents

Literature

49results about How to "Improves electrochemical corrosion resistance" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

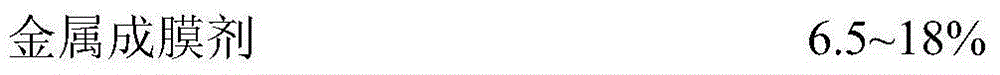

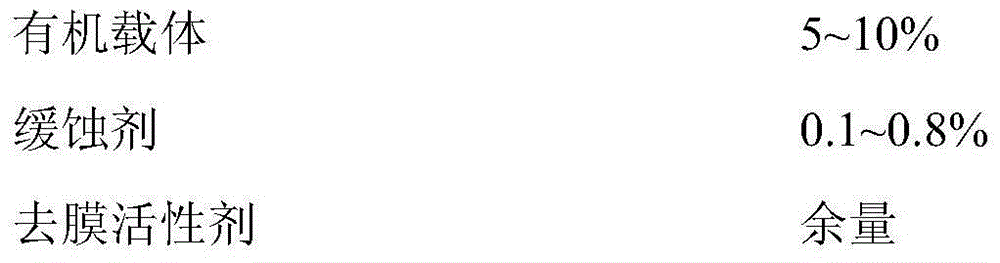

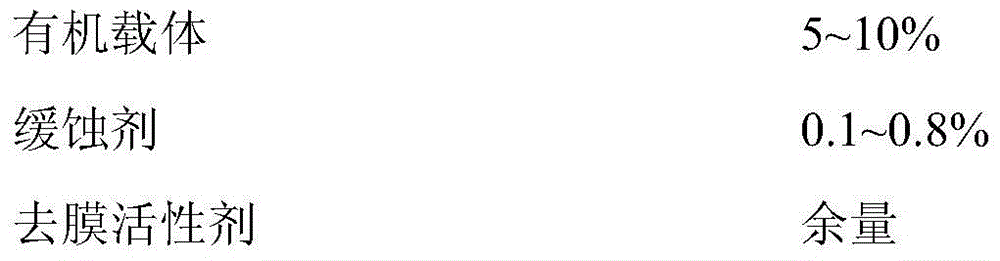

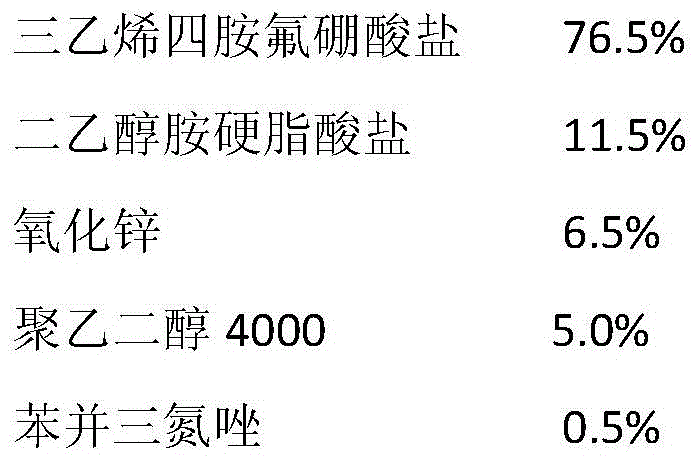

Cleaning-free solid-state scaling powder for aluminum low-temperature soldering and preparing method

ActiveCN104607826AFacilitate spreadingBarrier against electrochemical corrosionWelding/cutting media/materialsSoldering mediaActive agentAluminium

The invention discloses cleaning-free solid-state scaling powder for aluminum low-temperature soldering and a preparing method. According to the weight percentage, the cleaning-free solid-state scaling powder comprises raw materials of 6.5%-18% of metal film-forming agents, 5%-18% of organic carriers, 0.1%-1.8% of corrosion inhibition agents and the allowance of film removing active agents. The film removing active agents are composite salt of organic amine and acid. The cleaning-free solid-state scaling powder is suitable for lead-free solder wires with solid-state scaling powder contained in a core, and the powder can be used for automatic welding, manual soldering iron welding or flame spraying welding. The core-contained solder wires prepared with the scaling powder have the advantages that tinning speed is high, splashing is low, irritating smoke is avoided, post-welding residues do not have corrosiveness, a welding point has great electrochemical corrosion resistance, a contact service time is long, the wires are suitable for assembling welding of an aluminum coated layer circuit board and an aluminum soldering pin electronic element and brazing of an aluminum electric cable wire, an aluminum radiator and aluminum heat exchanging equipment.

Owner:SOUTH CHINA UNIV OF TECH

Rust-preventing aluminum alloy

The invention discloses a rust-proof aluminum alloy, which not only comprises 51 to 97.95 weight percent of aluminum, 0.01 to 2 weight percent of manganese, 0.01 to 2 weight percent of magnesium, and 0.01 to 3 weight percent of copper, but also comprises 1 to 19 weight percent of chromium, 0.01 to 9 weight percent of nickel, 0.01 to 4 weight percent of silicon, and 1 to 47.95 weight percent of aluminum oxide. The aluminum oxide forms a corundum-like substance in an aluminum alloy body to obviously improve the overall corrosion resistance and wear resistance of the aluminum alloy.

Owner:冷博

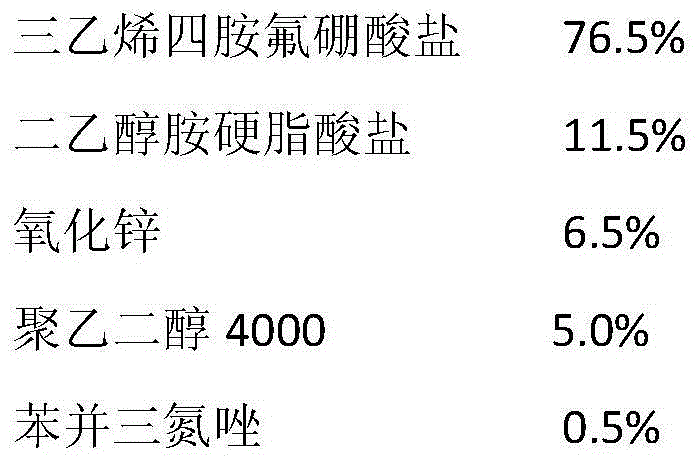

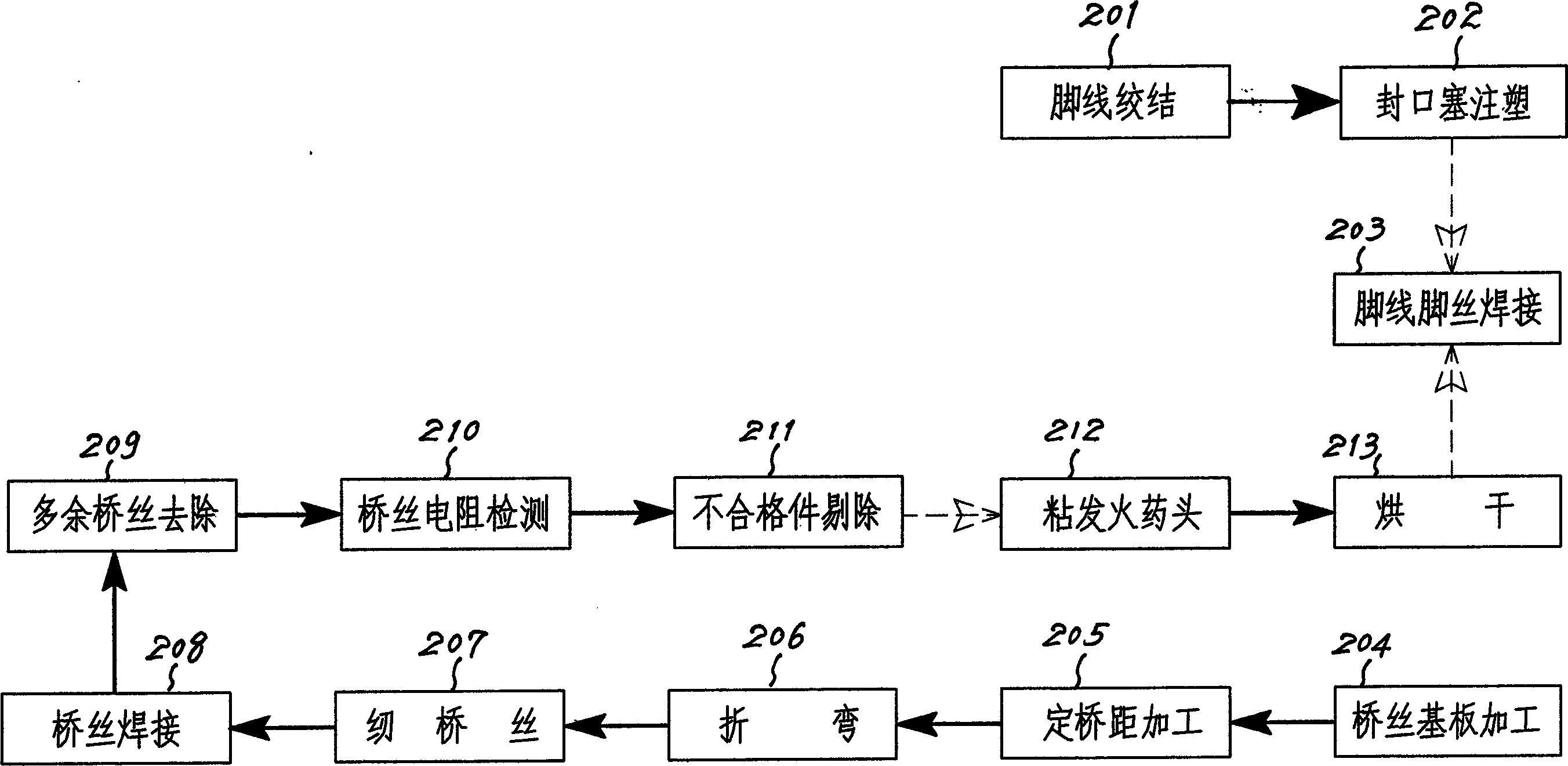

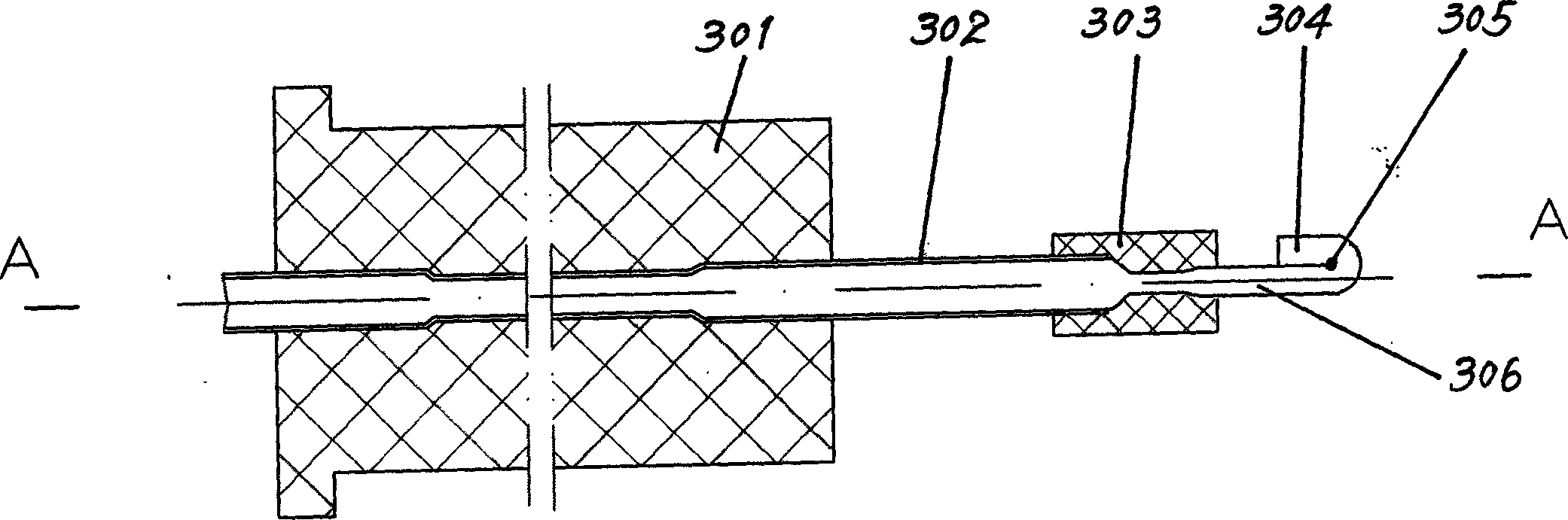

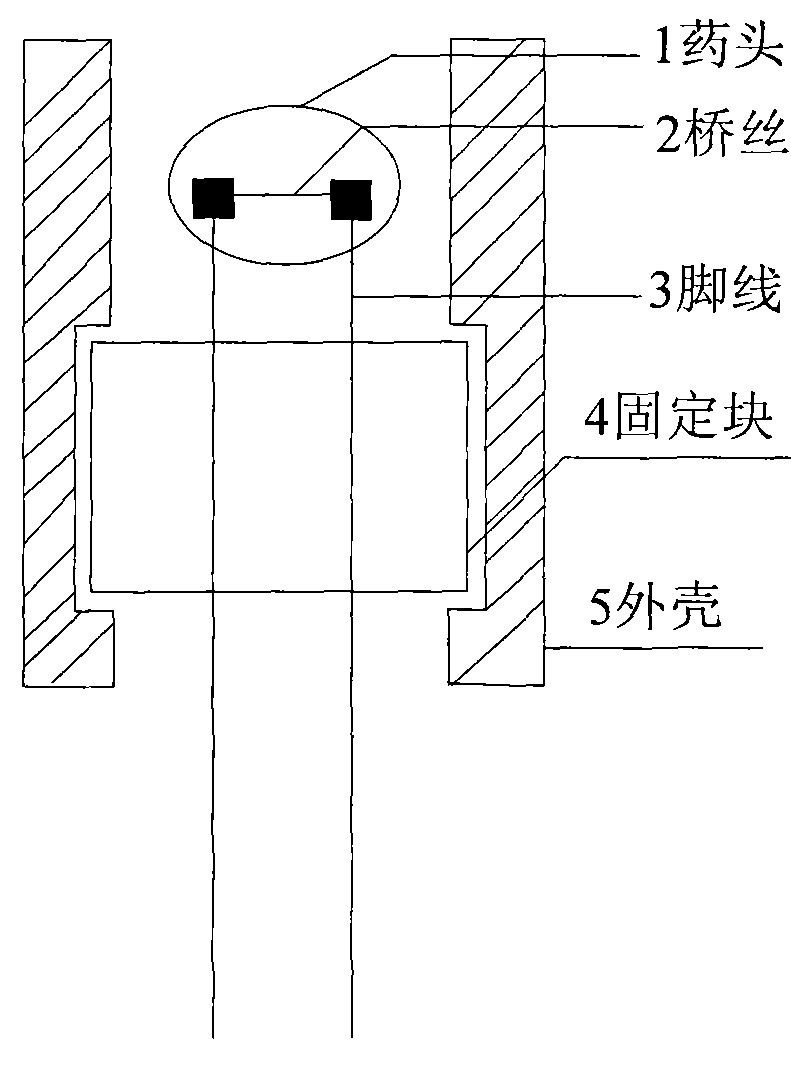

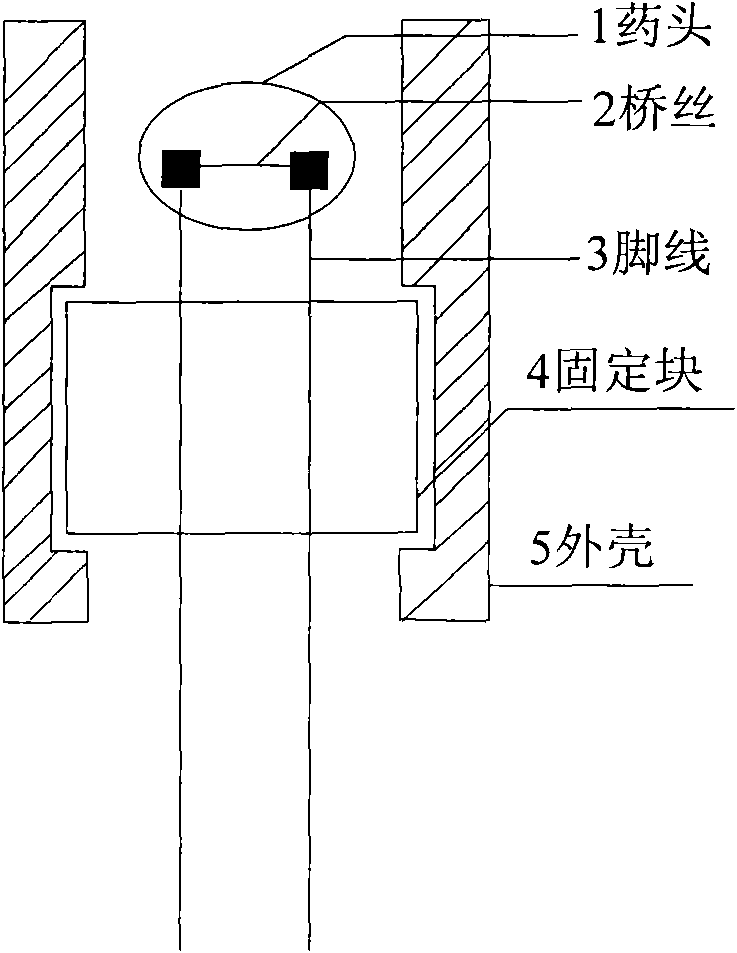

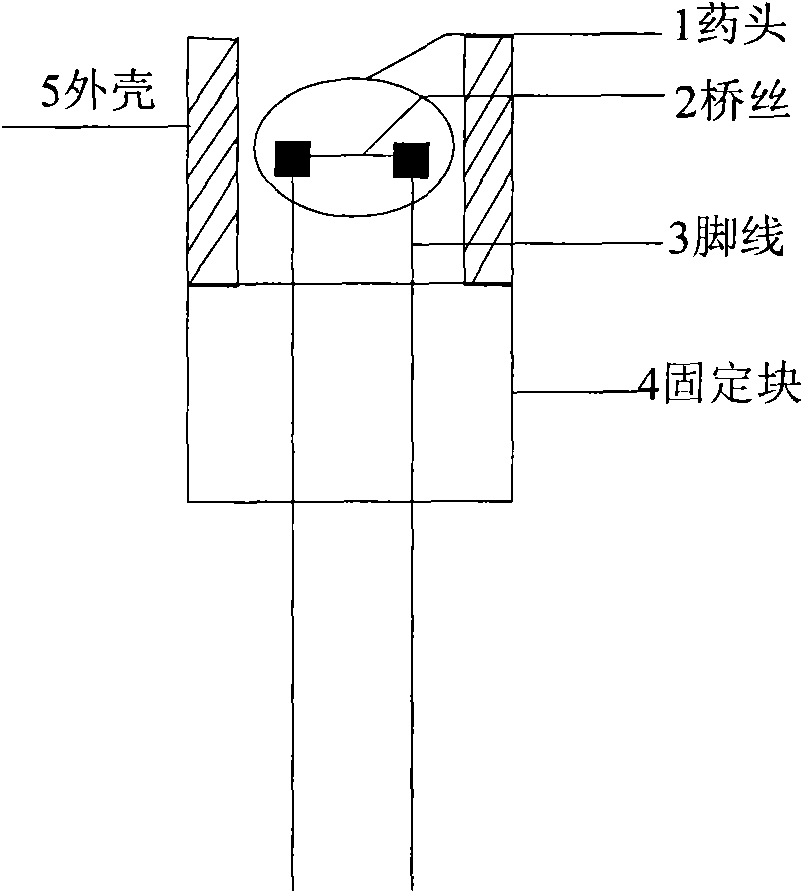

Electric detonator initiator

The electric detonator initiator includes bridge filaments, pin wires, span determinator and sealing plug. The pin wires are integral with the base board for the bridge filaments, and each piece of pin wires is formed with one section of pin wire from the sealing plug to the bridge filament welding end and is variable flat cross section structure. The pin wires have their flat parts inside sealing plug, span determinator and welding end. Both the sealing plug and the span determinator are linked structure with several parts. The present invention has simple production process, and the electric detonator initiator has small dispersion of bridge filaments and high side rigidity.

Owner:顾杨

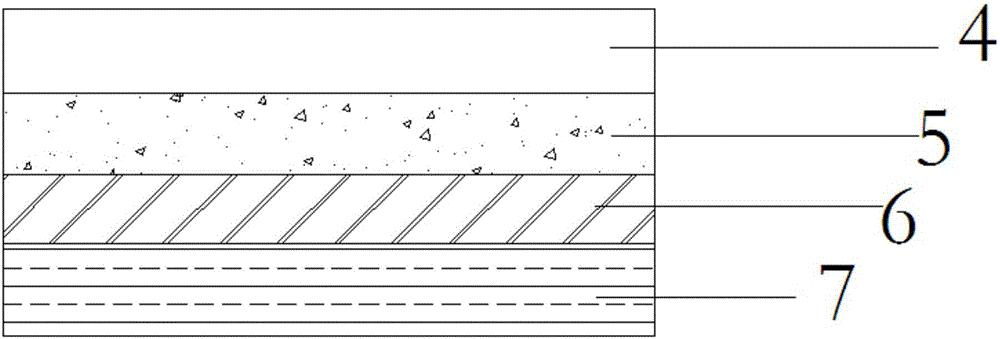

Electrode plate of electric double layer capacitor (EDLC) and preparation method thereof

InactiveCN103198929ALower internal resistanceExtended service lifeHybrid capacitor electrodesHybrid/EDL manufactureCapacitanceAdhesive

The invention belongs to the technical field of electric double layer capacitor manufacturing, and relates to an electrode plate of an electric double layer capacitor (EDLC) and a preparation method thereof. According to the electrode plate of the EDLC and the preparation method thereof, conductive carbon granules are embedded in one surface or two surfaces of a current collector, and the surface is bonded with electrode material through conductive adhesive; the electrode material is formed by electrode active substance, conductive agent and adhesive agent; the conductive adhesive is formed by conductive agent and rubber, and the rubber is capable of preventing current collector from being corroded electrochemically in electrolyte; and the current collector is made of aluminum foil as thick as 20um-30um, and the conductive carbon granules are embedded on the surface of the current collector with a high purity graphite bar by means of electrical spark discharge. The electrode active substance is active carbon like asphalt base ball, the specific surface area of the electrode active substance is larger than or equal to 2000m<2> / g, the grain size is 10um-23um, and the bore diameter is 1nm-3nm. By means of the electrode plate of the EDLC and the preparation method thereof, internal resistance of the EDLC is decreased, the electrochemical corrosion resistance of the EDLC current collector is improved, service life of the EDLC is prolonged, and working voltage is stabilized.

Owner:CHANGCHUN JLU KENUO TECH CO LTD

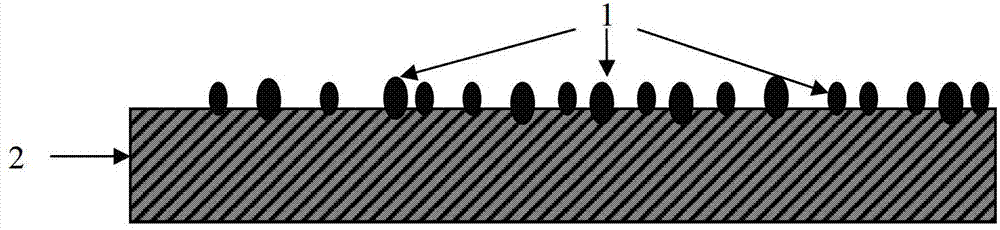

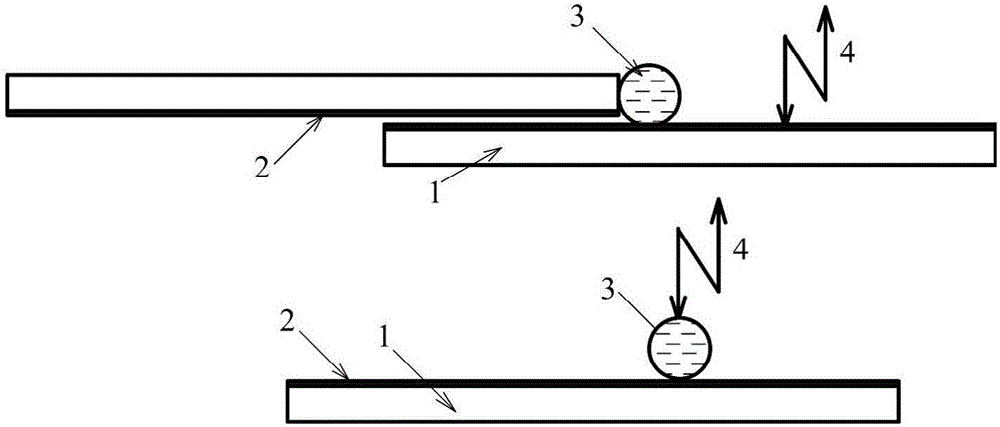

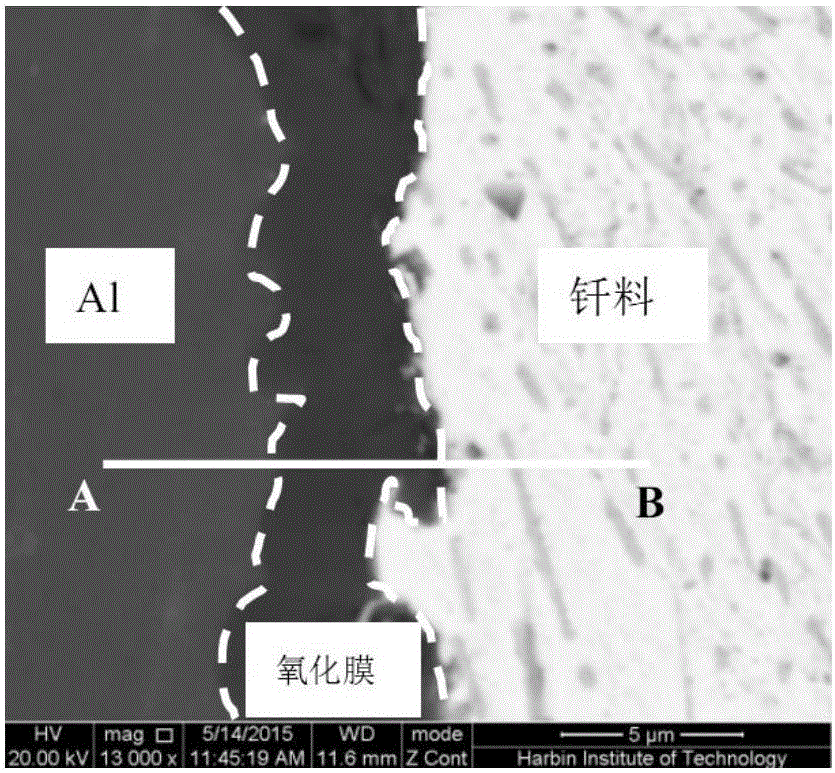

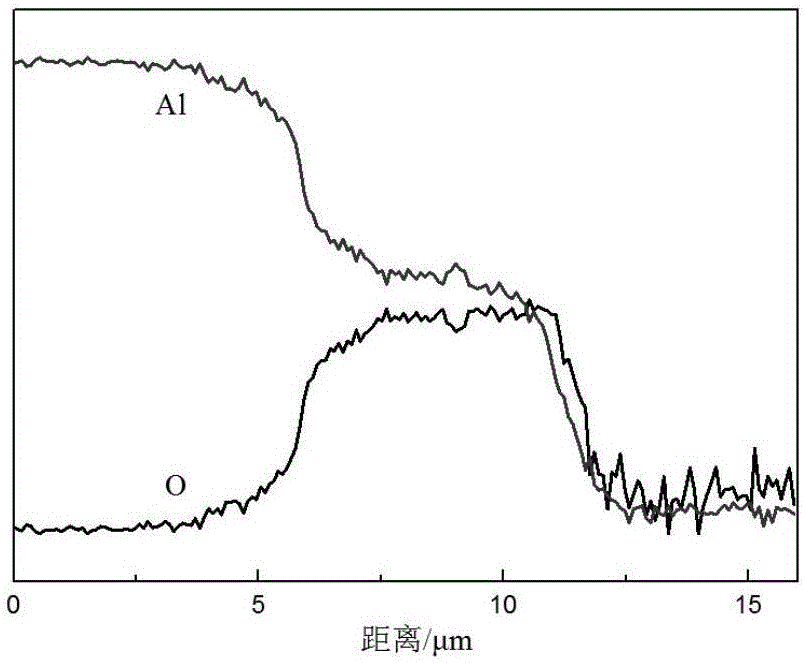

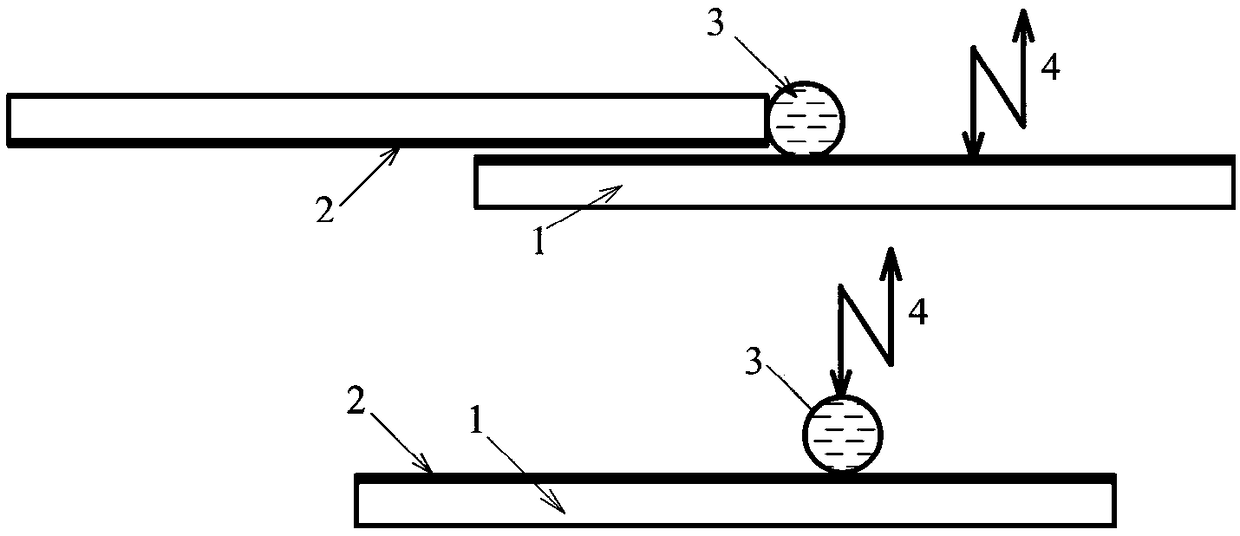

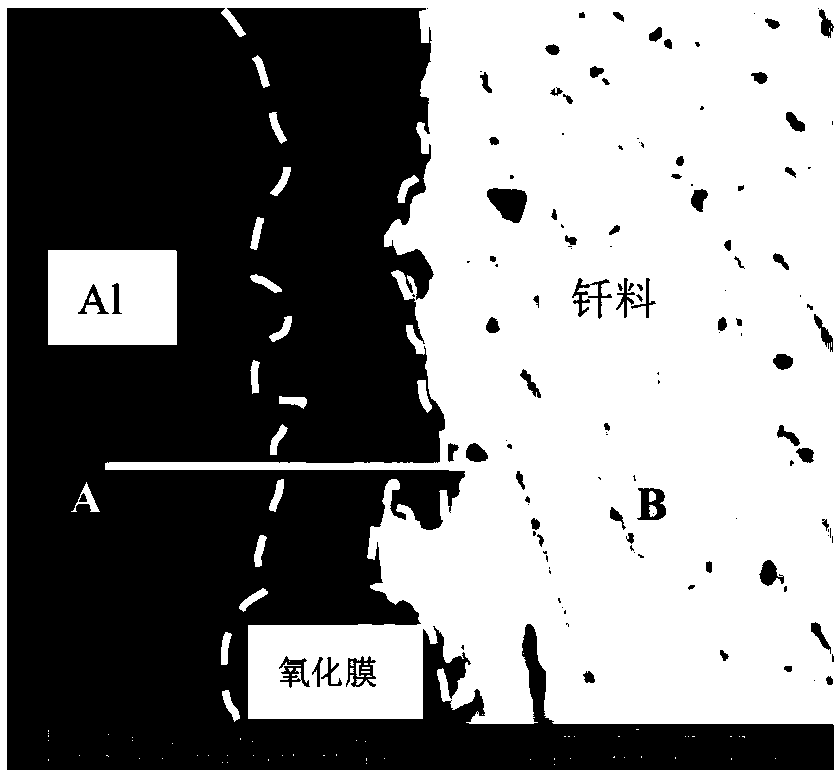

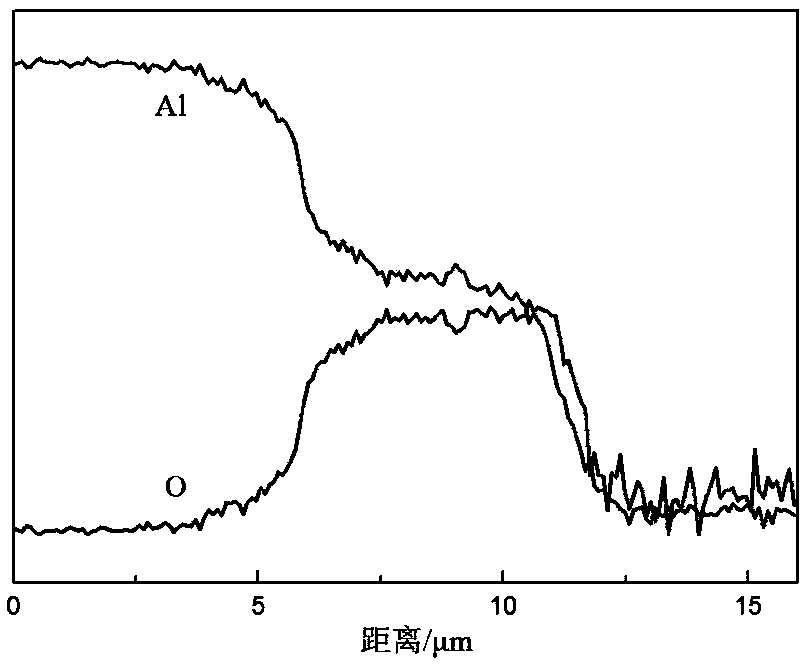

Method for improving electrochemical corrosion resistance of Al and Al alloy connector formed through ultrasound-combined brazing adopting Sn-based lead-free brazing filler metal

ActiveCN106270888AImproves electrochemical corrosion resistanceImprove barrier propertiesSoldering apparatusElectrochemical responseMicro arc oxidation

The invention discloses a method for improving the electrochemical corrosion resistance of Al and Al alloy connector formed through ultrasound-combined brazing adopting Sn-based lead-free brazing filler metal, and belongs to the technical field of brazing. According to the method, oxidation films are prepared on the surface of the Al and the surface of the Al alloy correspondingly, an electrochemical reaction between the element Sn in brazing filler metal alloy and the element Al in a base material is blocked, and the problem that the electrochemical corrosion resistance of the Al and the Al alloy connector formed through ultrasound-combined brazing adopting the Sn-based lead-free brazing filler metal is poor is solved. An anodic oxidation mode or a micro-arc oxidation mode is firstly utilized, and the oxidation films are prepared on the surface of the Al and the surface of the Al alloy correspondingly; and then the Sn-based lead-free active brazing filler metal is adopted for conducting ultrasound-combined brazing on the Al and the Al alloy. By adoption of the method, the electrochemical corrosion resistance of the Al and the Al alloy connector is remarkably improved.

Owner:HARBIN INST OF TECH

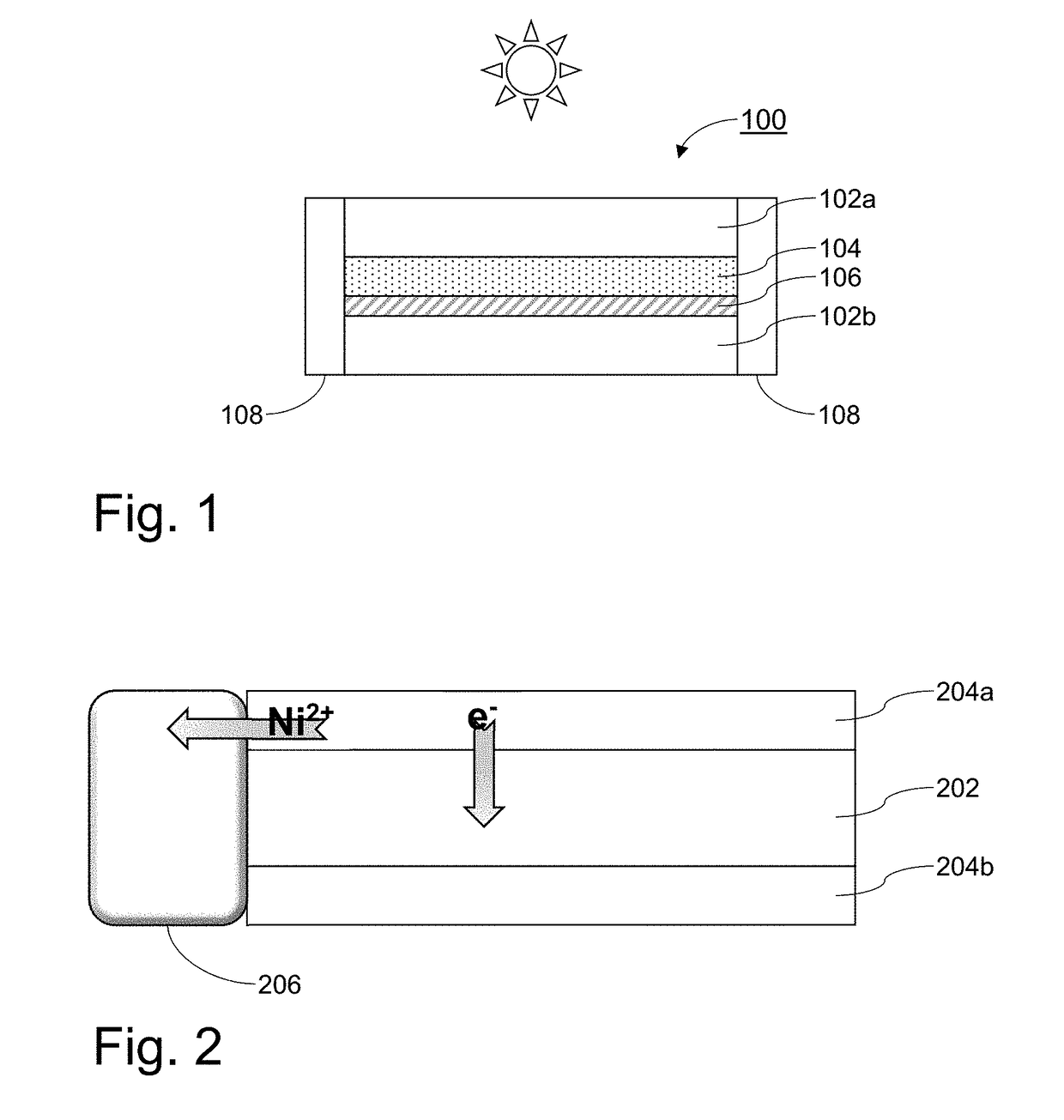

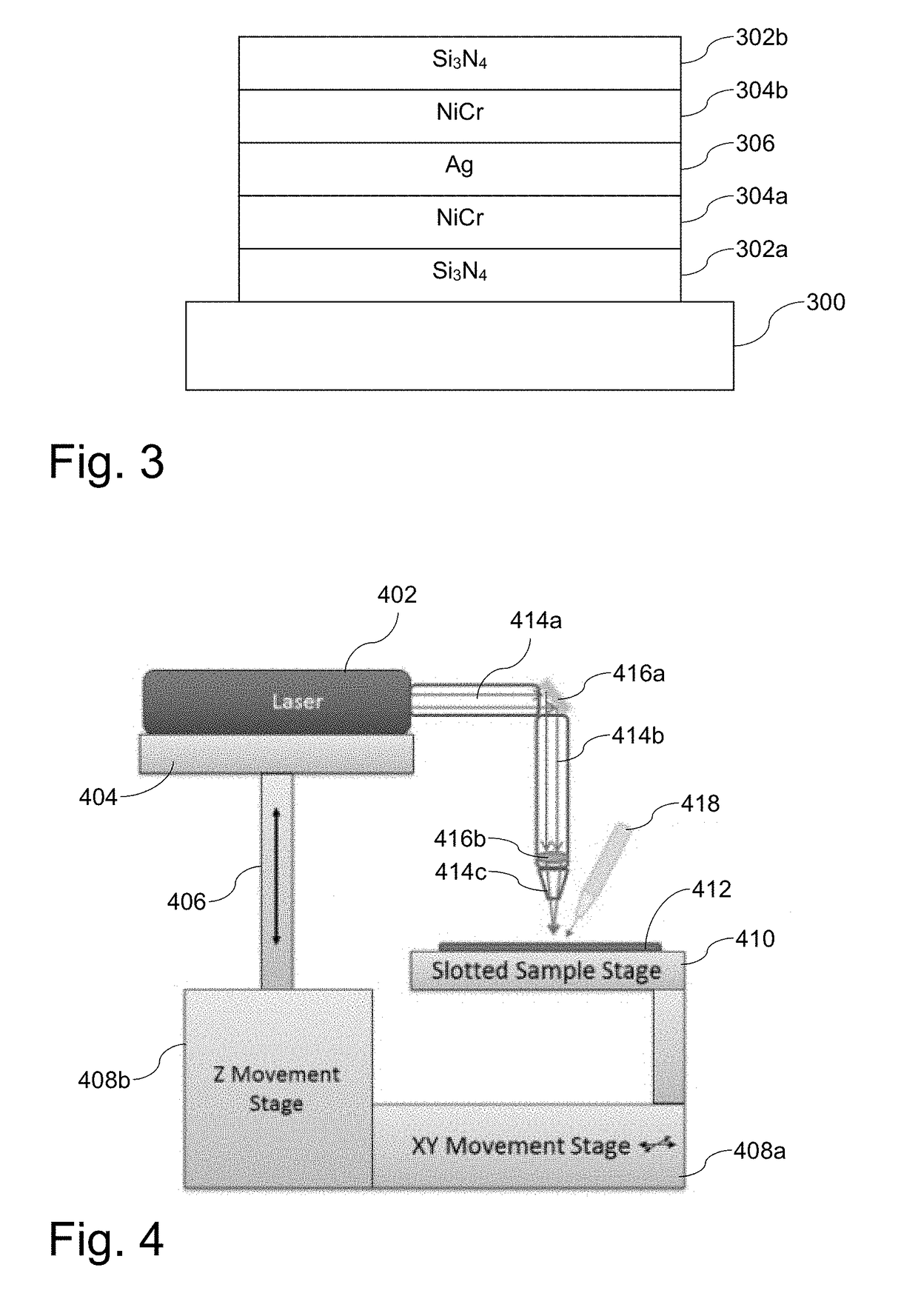

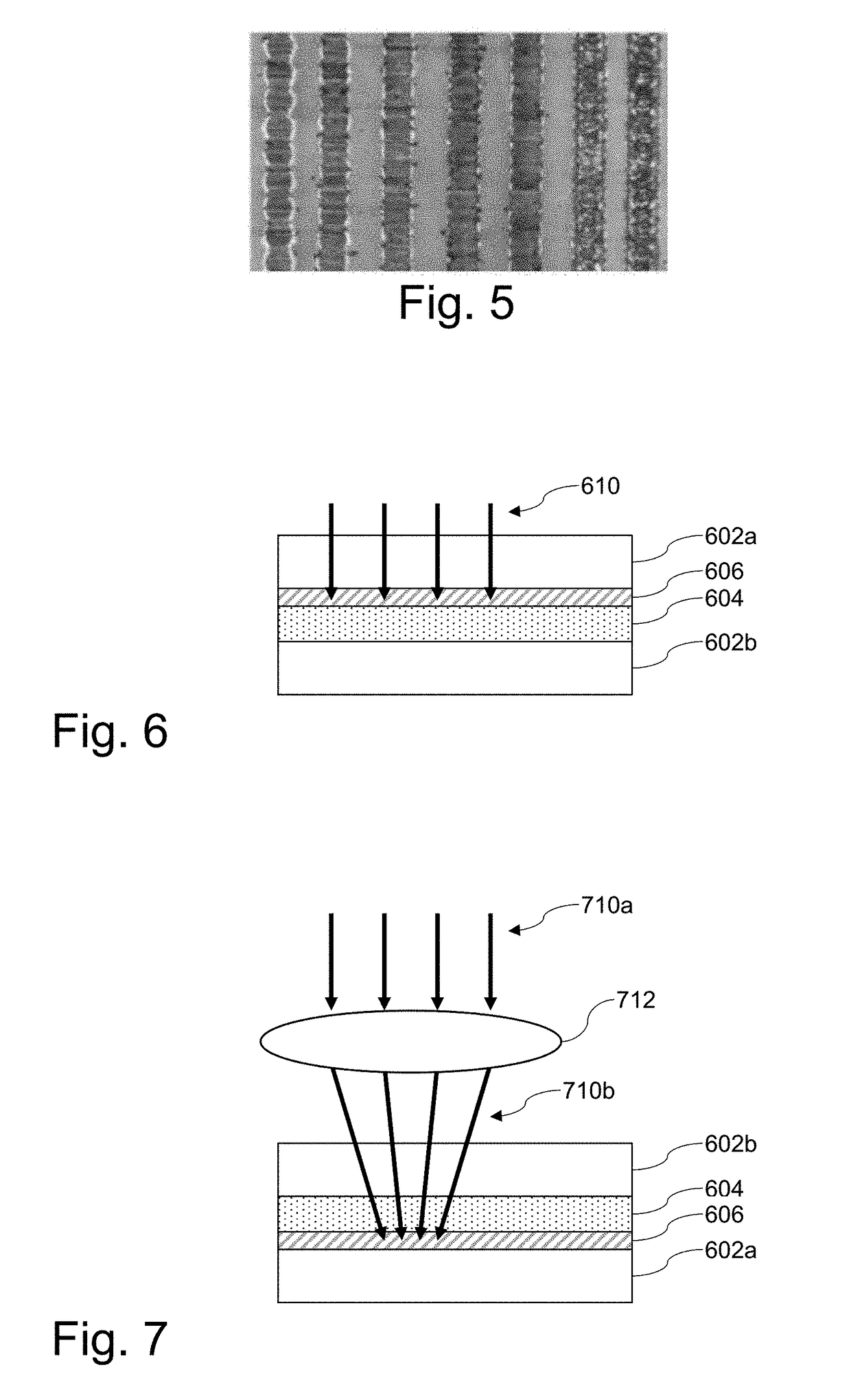

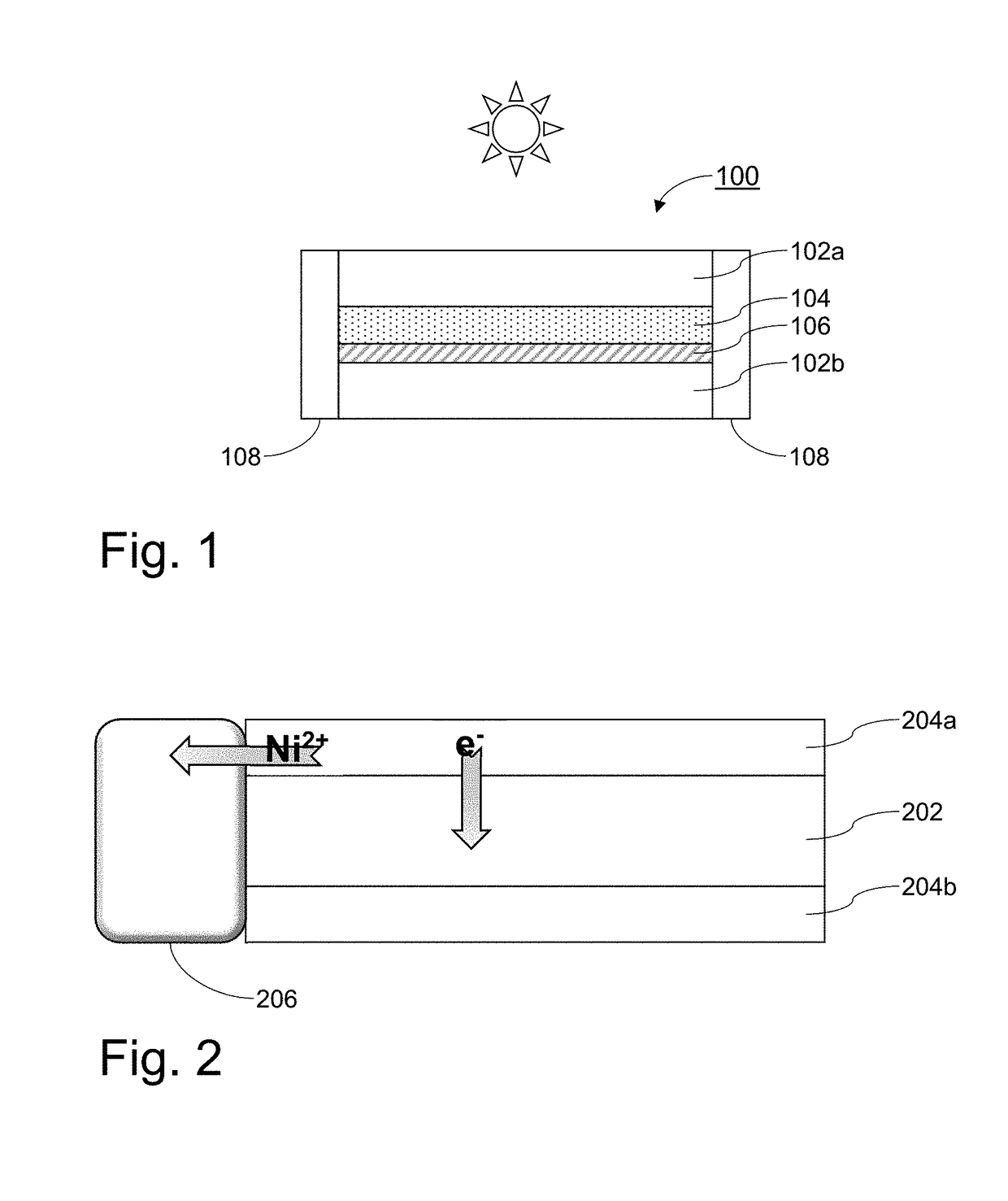

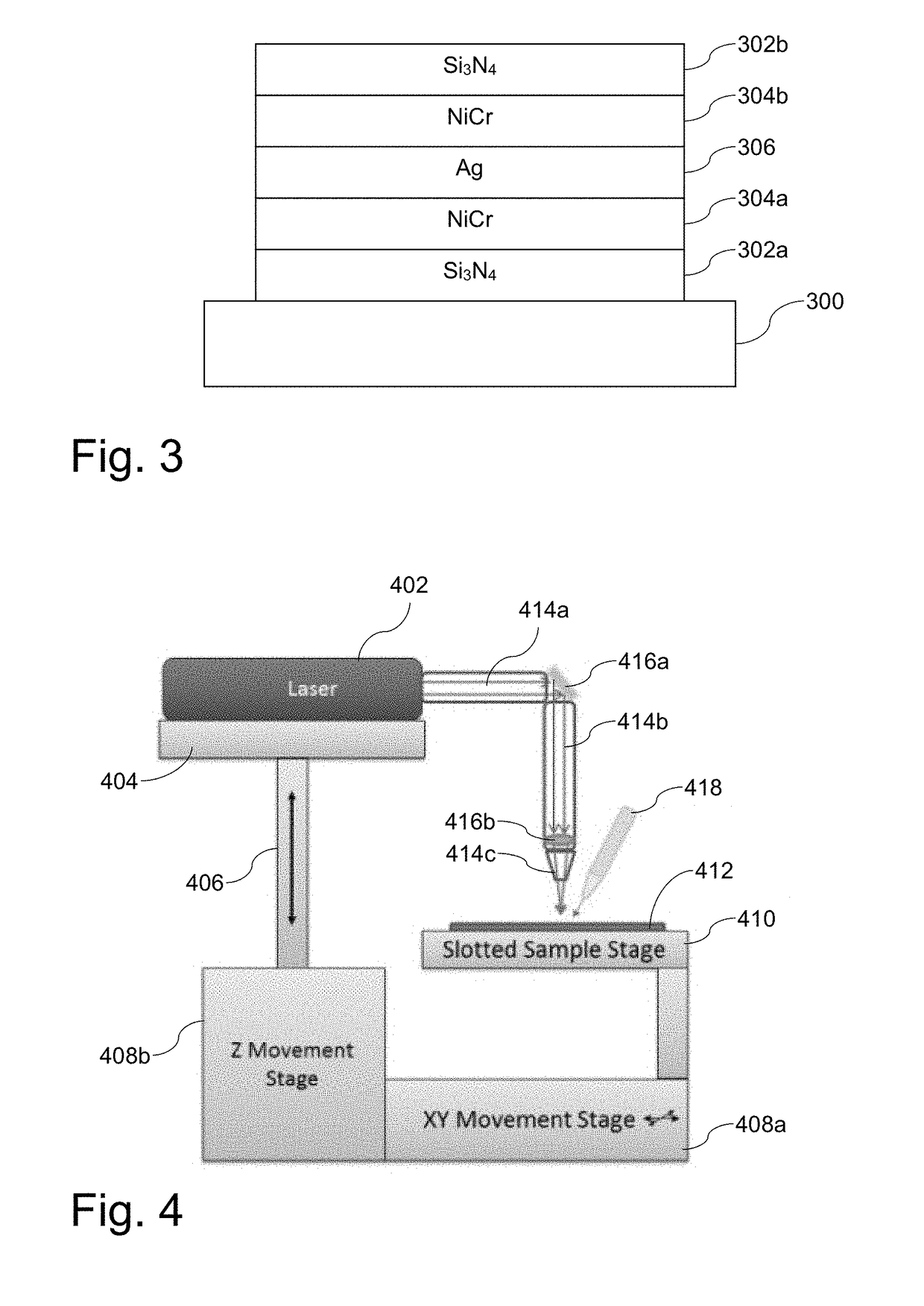

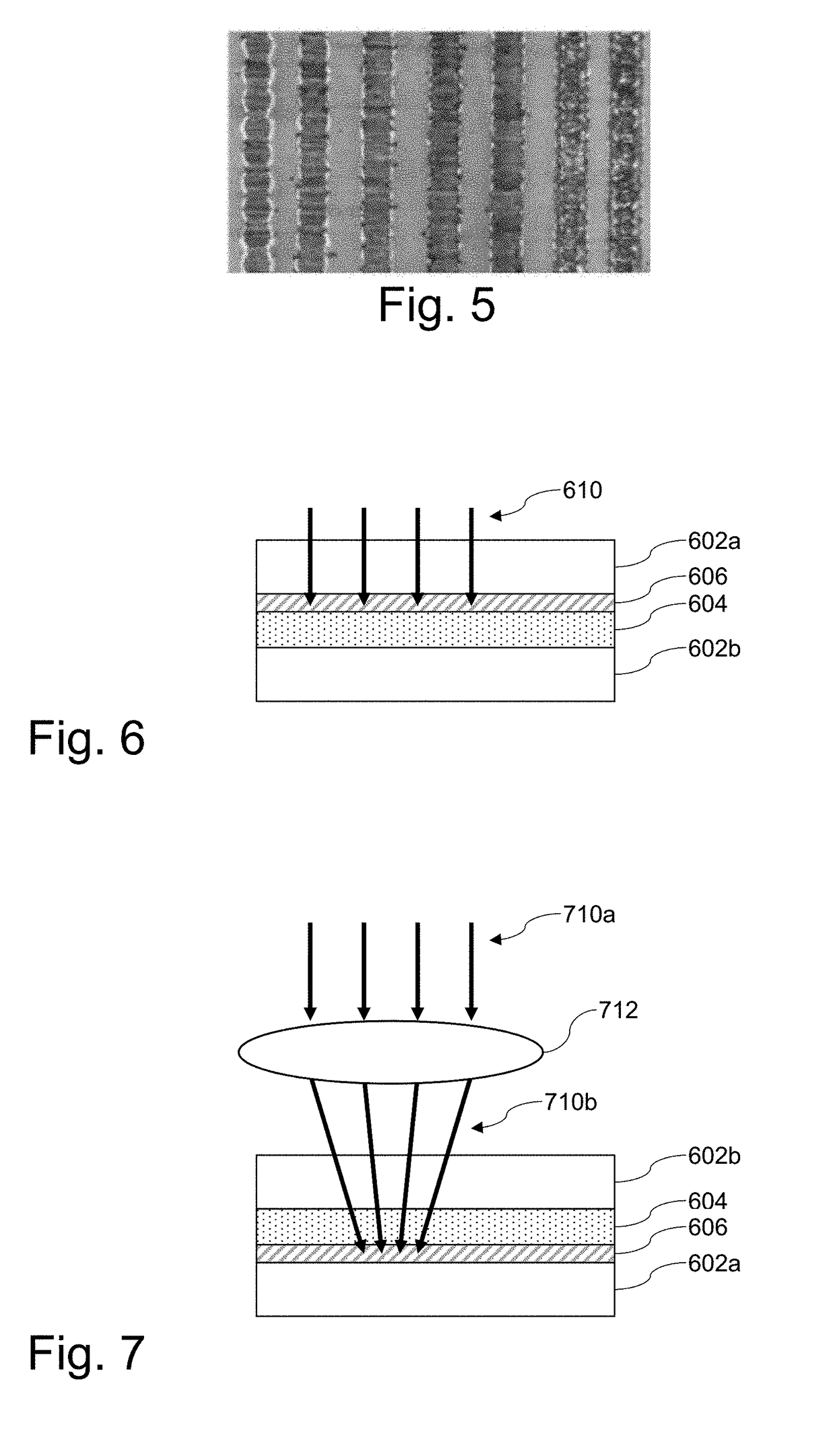

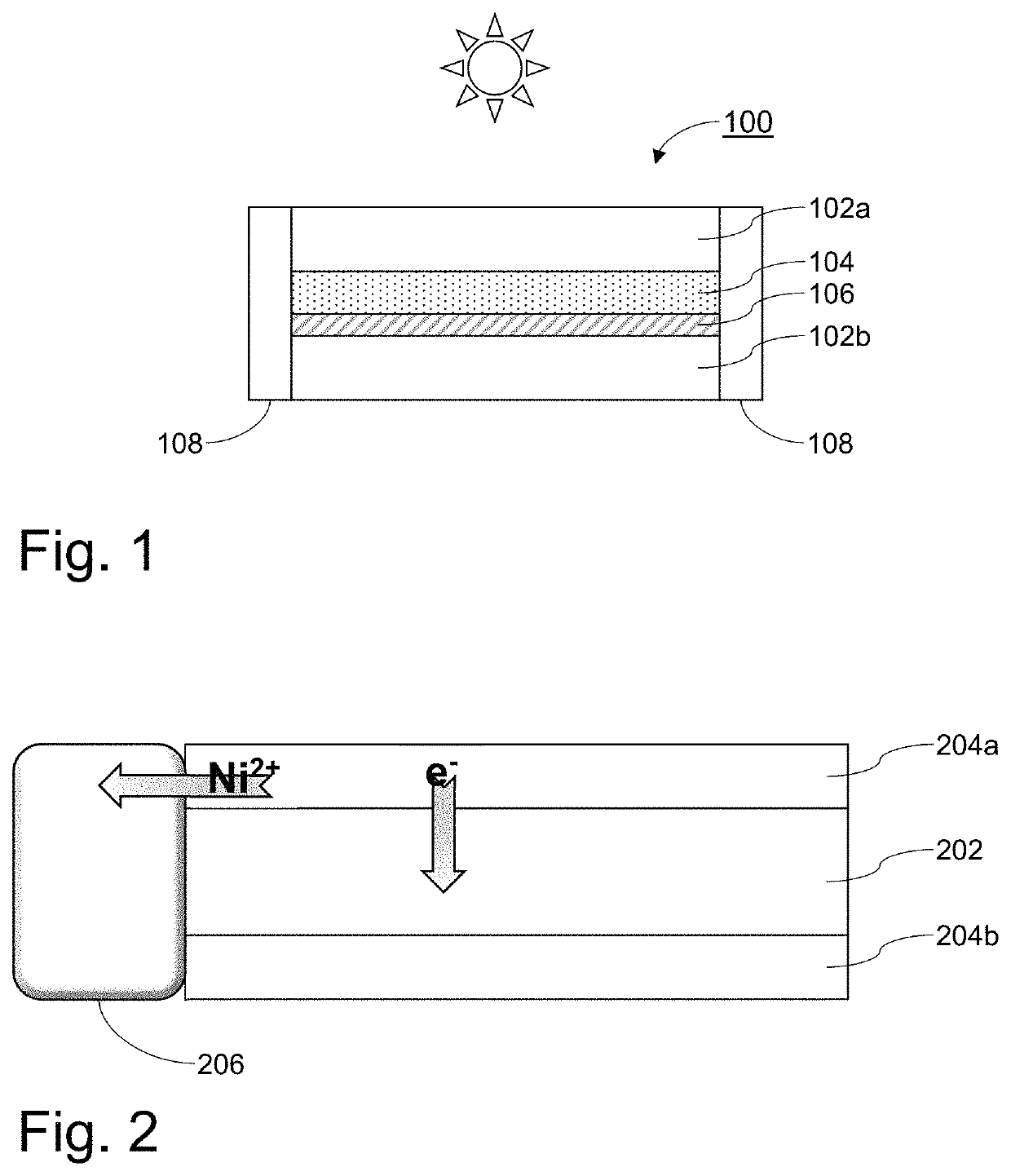

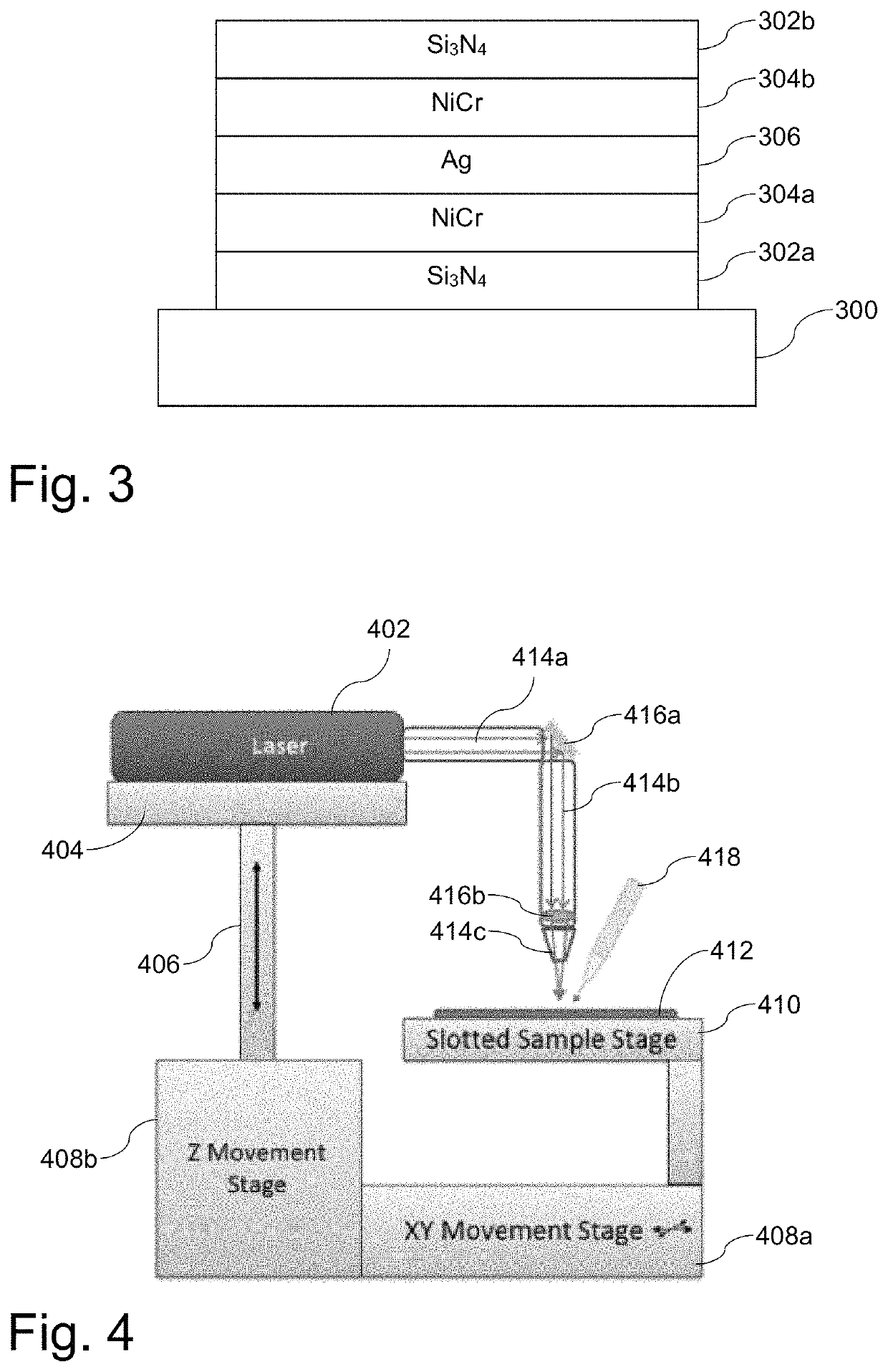

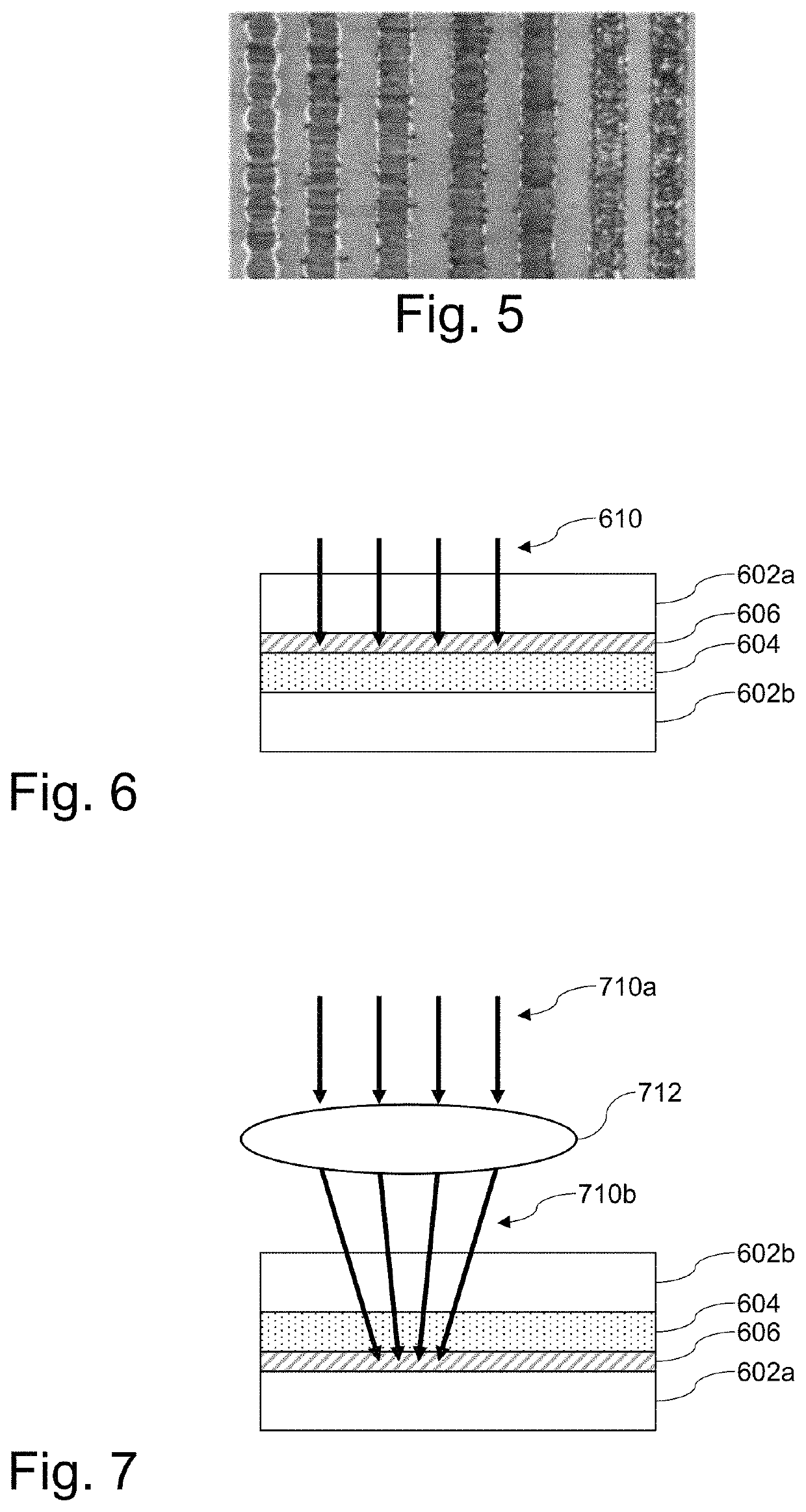

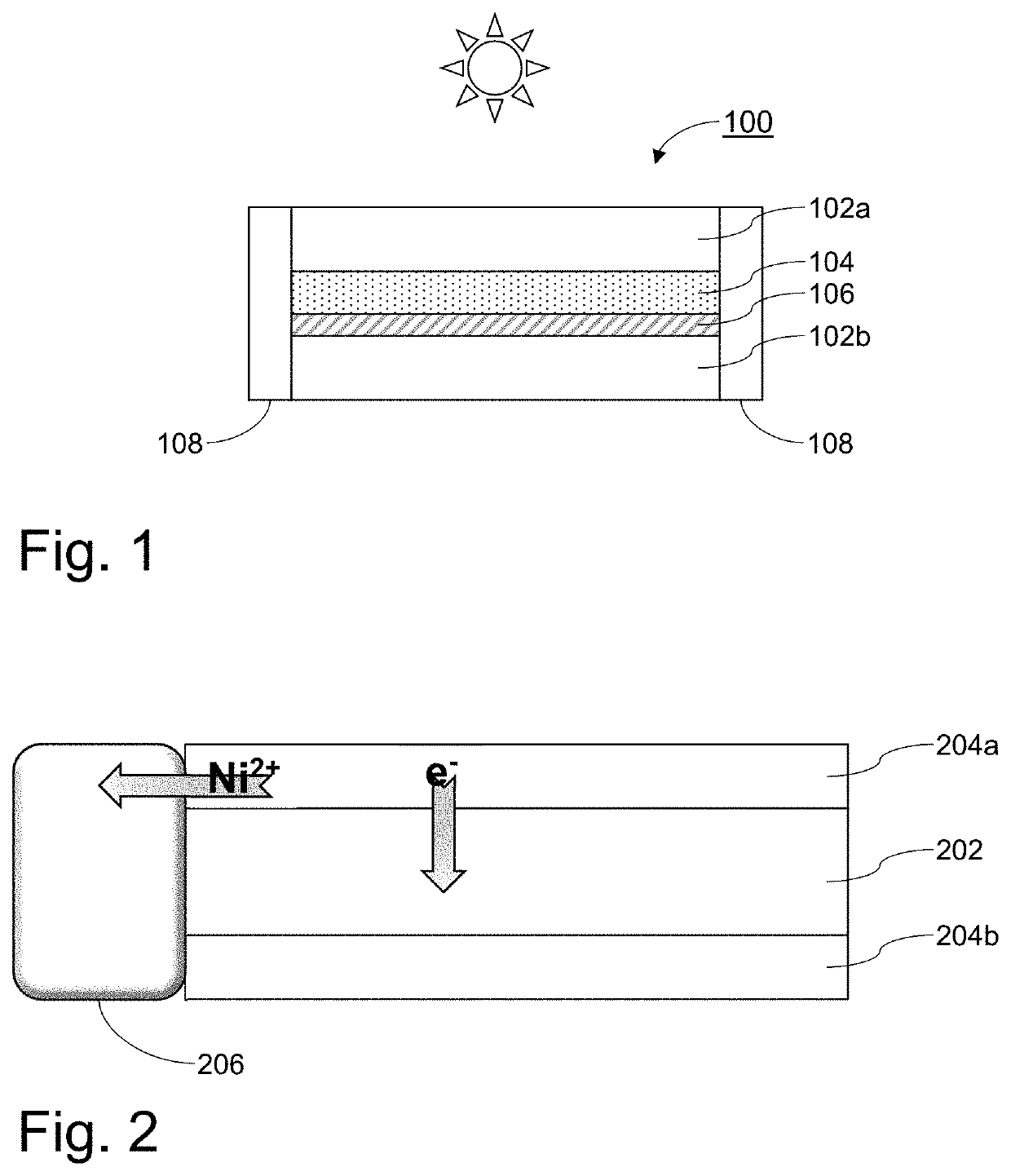

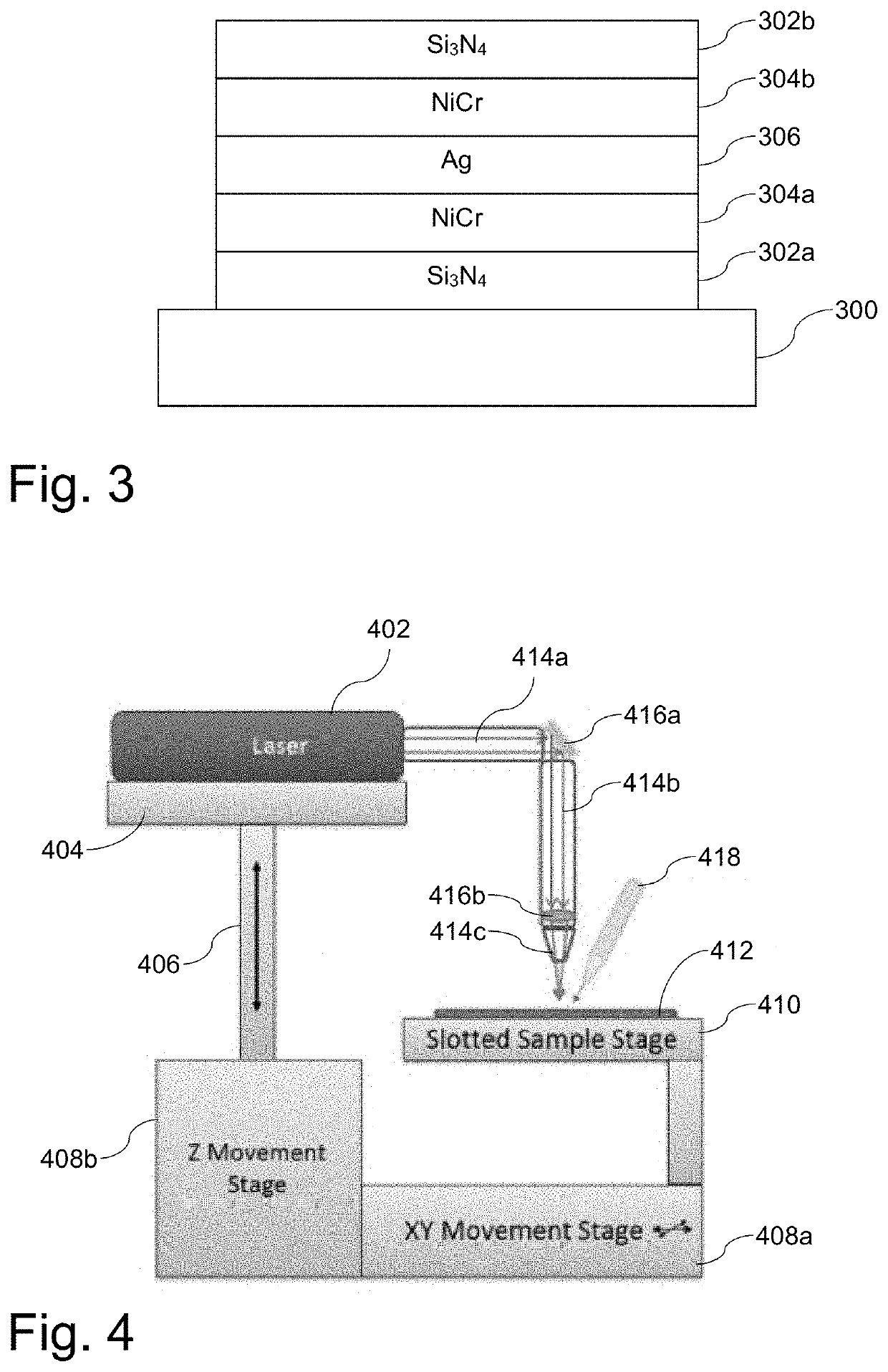

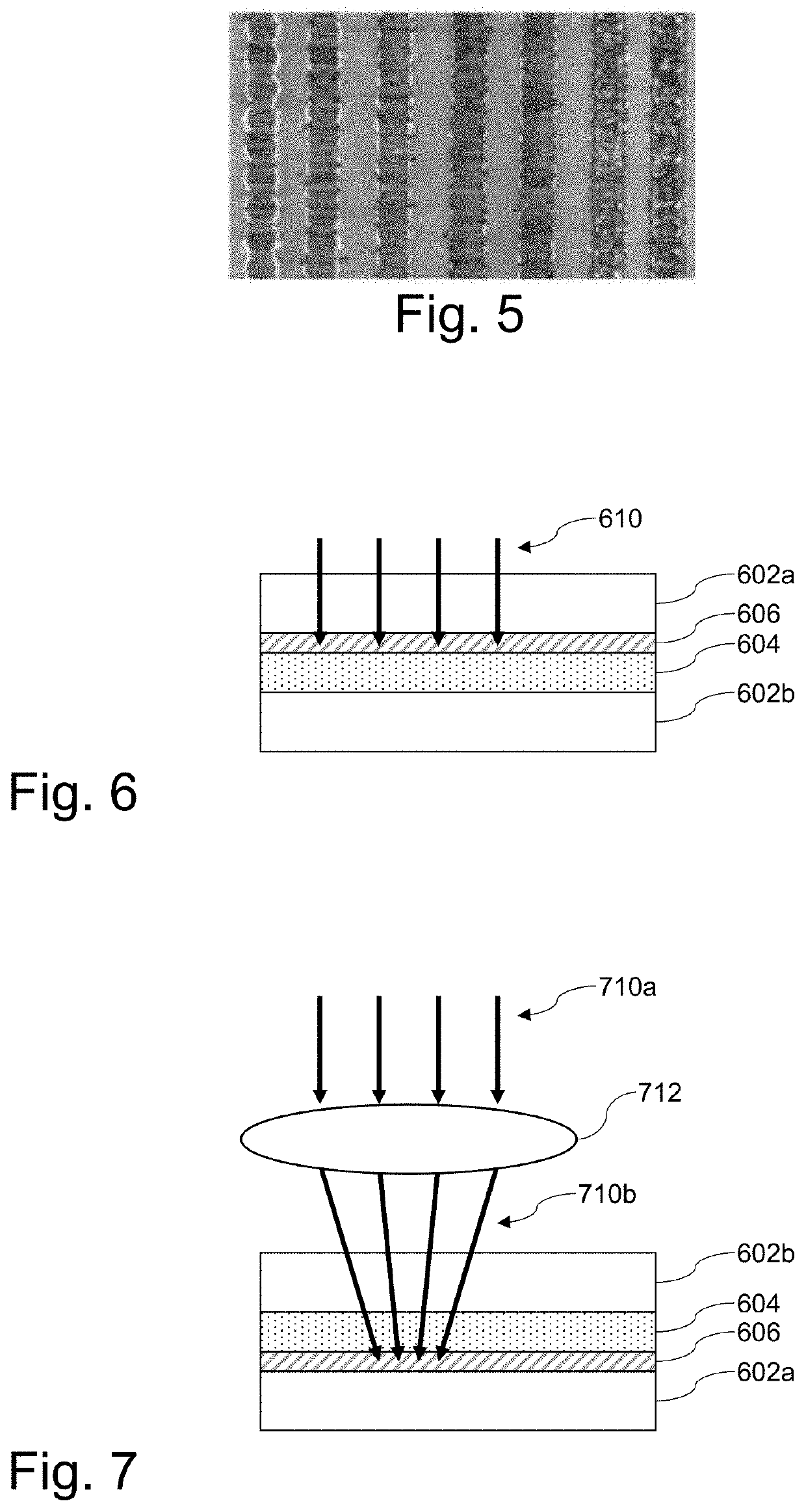

Techniques for laser ablation/scribing of coatings in pre- and post-assembled insulated glass units, and/or associated methods

ActiveUS20190009371A1Improves electrochemical corrosion resistanceReduce dispersionLaser beam welding apparatusInsulated glazingLow emissivity

Certain example embodiments of this invention relate to techniques for laser ablating / scribing peripheral edges of a coating (e.g., a low-emissivity, mirror, or other coating) on a glass or other substrate in a pre- or post-laminated assembly, pre- or post-assembled insulated glass unit, and / or other product, in order to slow or prevent corrosion of the coating. For example, a 1064 nm or other wavelength laser may be used to scribe lines into the metal and / or metallic layer(s) in a low-emissivity or other coating provided in an already-laminated or already-assembled insulated glass unit or other product, e.g., around its periphery. The scribe lines decrease electron mobility from the center of the coating to the environment and, thus, slow and sometimes even prevent the onset of electrochemical corrosion. Associated products, methods, and kits relating to same also are contemplated herein.

Owner:GUARDIAN GLASS LLC

Reduction annealing and heat plating process of band steel continuous heat plating rare earth aluminium zinc alloy

InactiveCN102121089AGood chemical resistanceImproves electrochemical corrosion resistanceHot-dipping/immersion processesFurnace typesRare earthShielding gas

The invention discloses a reduction annealing and heat plating process of band steel continuous heat plating rare earth aluminium zinc alloy, comprising a reduction annealing process and a heat plating process of the band steel continuous heat plating rare earth aluminium zinc alloy. In the invention, through determining that the rare earth aluminium zinc alloy is a band steel plating layer, the wetting property of the aluminium zinc alloy to the surface of band steel and the fluidity of a zinc solution can be enhanced by the rare earth; a best electrochemical protective membrane is formed on the surface of the band steel plating layer; through dividing the reduction heating segment into a front segment and a rear segment, the recrystallization temperature of the band steel can be rapidly raised, and the surface of the band steel is reduced to be smooth; and through respectively arranging an air inlet and an air outlet at the bottom of a hot tensioning segment and / or a cooling segment, and the top of the front reduction heating segment, a dew point value is lowered, and the protective gas in a furnace is improved, thus the band steel before entering a zinc pot has an active surface. By utilizing the technical scheme, the technique of band steel continuous heat plating zinc is further promoted, thus obviously improving the chemical corrosion resistance and electrochemical corrosion resistance of the heat plating zinc band steel, and playing a positive role in broadening the application fields such as the automobile industry and the like of the heat plating zinc band steel made in China.

Owner:HANGZHOU YONGFENG STEEL CONSTR

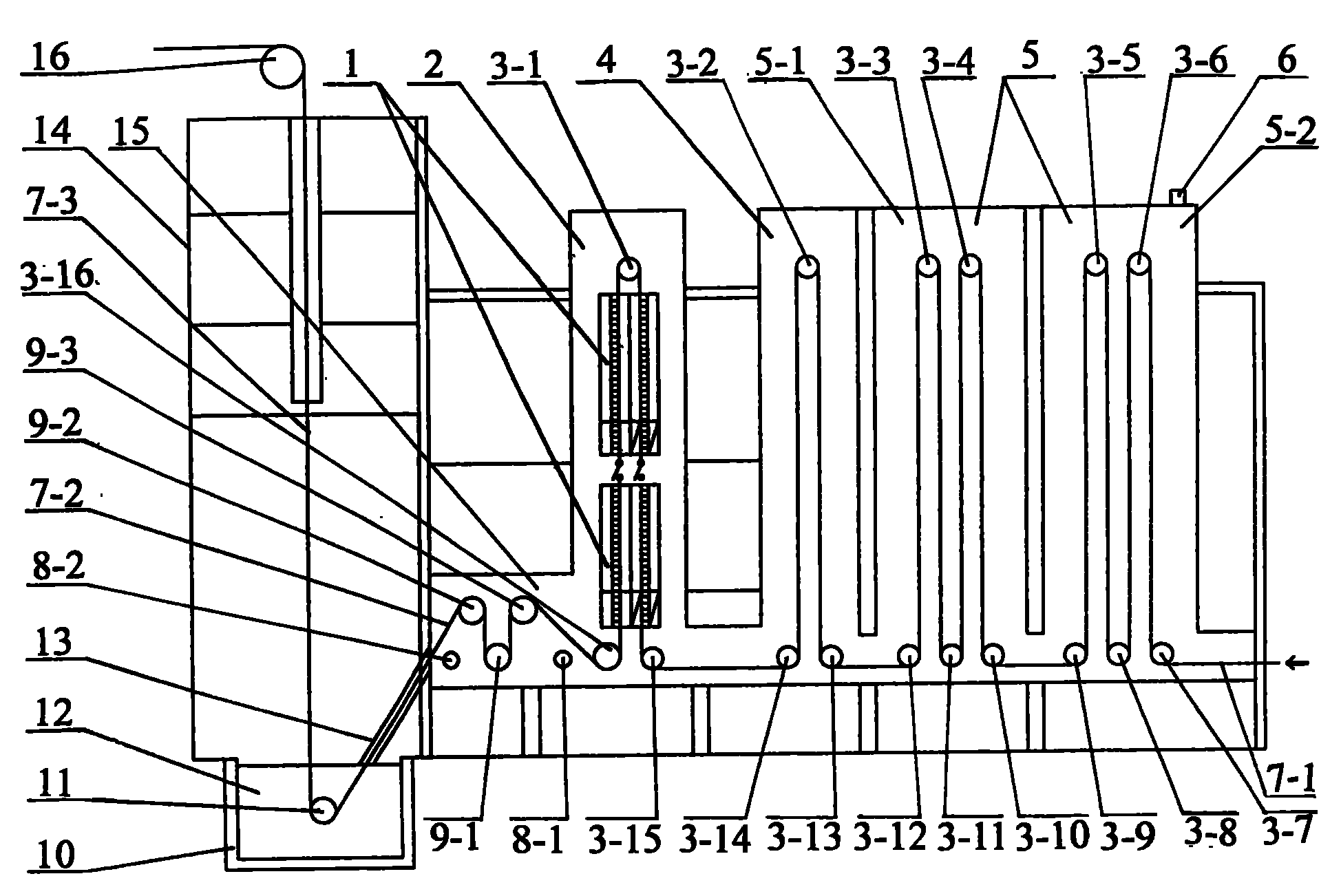

Bridging fibril welding set for digital electronic detonator

InactiveCN101811224AIncrease contact areaImprove welding qualityWelding/soldering/cutting articlesMetal working apparatusDetonatorElectron

The invention discloses a bridging fibril welding set for a digital electronic detonator, which comprises two metal leg wires, a medicament head, a fixing block and an outer shell, wherein the two metal leg wires are positioned in the outer shell and extend outside the outer shell, and one end of the metal leg wires is used for welding bridging fibrils while the other ends are used for connecting an ignition circuit of the detonator; two ends of the two metal leg wires are flaky; the fixing block are positioned in the outer shell and is used for fixing the metal leg wires; and an inner wall of the outer shell is provided with a groove of which the shape is matched with that of the fixing block. The bridging fibril welding set improves the welding reliability and realizes automated welding operation. After welding, the electrical conductivity is good, and the resistance coefficient is ultra-low or is approximate to zero. The fixing block and the outer shell are integrated through injection molding to realize integration, and adopt anti-static polyvinyl chloride to prevent static electricity. The leg wires of the detonator are fixed in the fixing block to avoid short circuiting between the leg wires.

Owner:北京维深数码科技有限公司

Tension-resistant and wear-resistant wire for electric power

InactiveCN105924702AGood weather resistanceImprove insulation performanceRubber insulatorsPlastic/resin/waxes insulatorsCopper wireWear resistant

The invention relates to a tension-resistant and wear-resistant wire for electric power. The wire comprises a conductor wire core, a polyethylene insulating layer, a fluoroplastic insulating layer, a flame-retardant dacron woven reinforcing layer and a wear-resistant outer sheath layer in sequence from inside to outside, wherein the conductor wire core is formed by twisting a plurality of tin-plated round copper wires. The wear-resistant outer sheath layer is prepared from, by weight, 40-60 parts of butadiene-styrene rubber, 20-40 parts of chloroprene rubber, 23-26 parts of fluoroether rubber, 0.1-15 parts of graphene, 13-15 parts of phenolic resin, 1-10 parts of a silane coupling agent, 12-15 parts of semi-reinforcing furnace black, 10-12 parts of calcined clay, 1-2 parts of magnesium chloride, 1-5 parts of magnesium powder, 5-7 parts of nano-molybdenum disulfide (MoS2), 1-10 parts of an anti-aging agent, 0-20 parts of a plasticizer and 1-5 parts of an accelerant. The wire has excellent corrosion resistance, high temperature resistance, wear resistance, tear resistance and tensile resistance.

Owner:郭秀珍

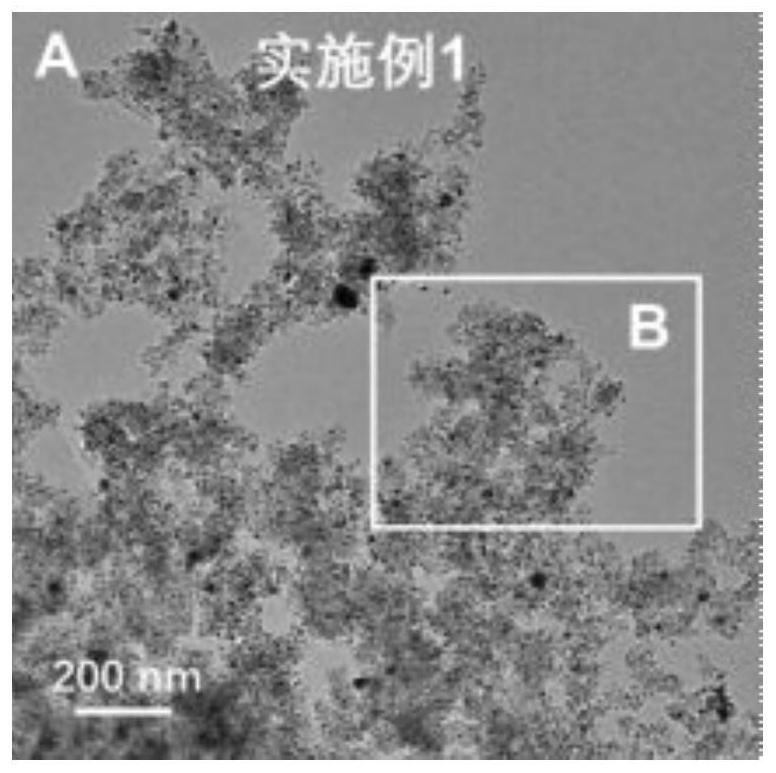

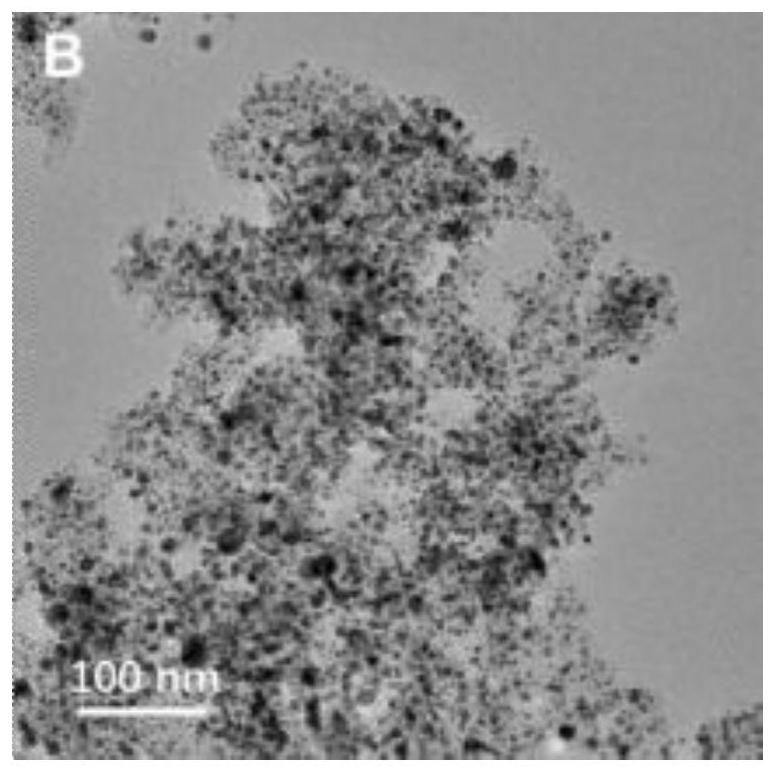

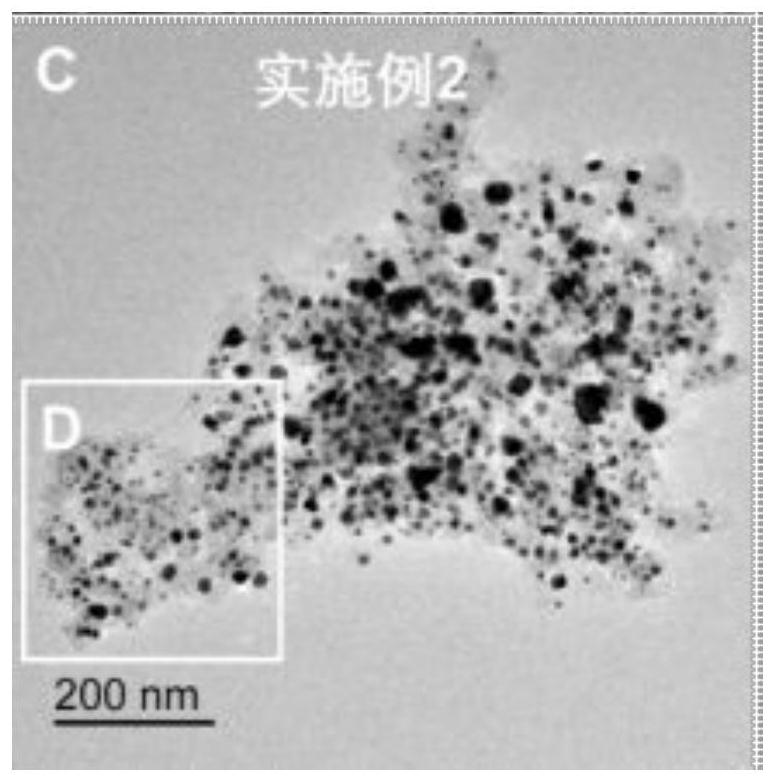

Graphitized carbon carrier for hydrogen fuel cell, preparation method of graphitized carbon carrier and cell catalyst of graphitized carbon carrier

ActiveCN113506885AInking degree is goodGood ink uniformityCell electrodesPtru catalystElectrical battery

The invention discloses a graphitized carbon carrier for a hydrogen fuel cell, a preparation method of the graphitized carbon carrier and a cell catalyst of the graphitized carbon carrier. The preparation method comprises the following steps: pretreating the carbon carrier; dispersing and anchoring transition metal ions, adding transition metal salt, auxiliaries and the like in the process, and performing ultrasonic stirring; carrying out catalytic graphitization on the carbon carrier, and keeping the temperature between 700 DEG C and 1000 DEG C; and catalytically purifying the graphitized carbon carrier. According to the graphitized carbon carrier for the hydrogen fuel cell, the auxiliaries are added in the preparation process of the carbon carrier, metal ions are assisted to be more uniformly dispersed on the surface of the carbon carrier, the uniformity of the catalytic graphitization degree of the surface of the carbon carrier is further improved, the electrochemical corrosion resistance of the carbon carrier is improved, and the durability of a catalyst is enhanced; and the auxiliary agent is converted into a carbon-containing substance in the heating process and serves as a physical barrier to hinder agglomeration and growth of metal particles. According to the carbon carrier, the graphitization temperature of a carbon material is remarkably reduced, the technical index of high-temperature roasting equipment is reduced, and the uniformity of the graphitization degree of the surface of the catalytic graphitization carbon carrier is better.

Owner:SINOCAT ENVIRONMENTAL TECH

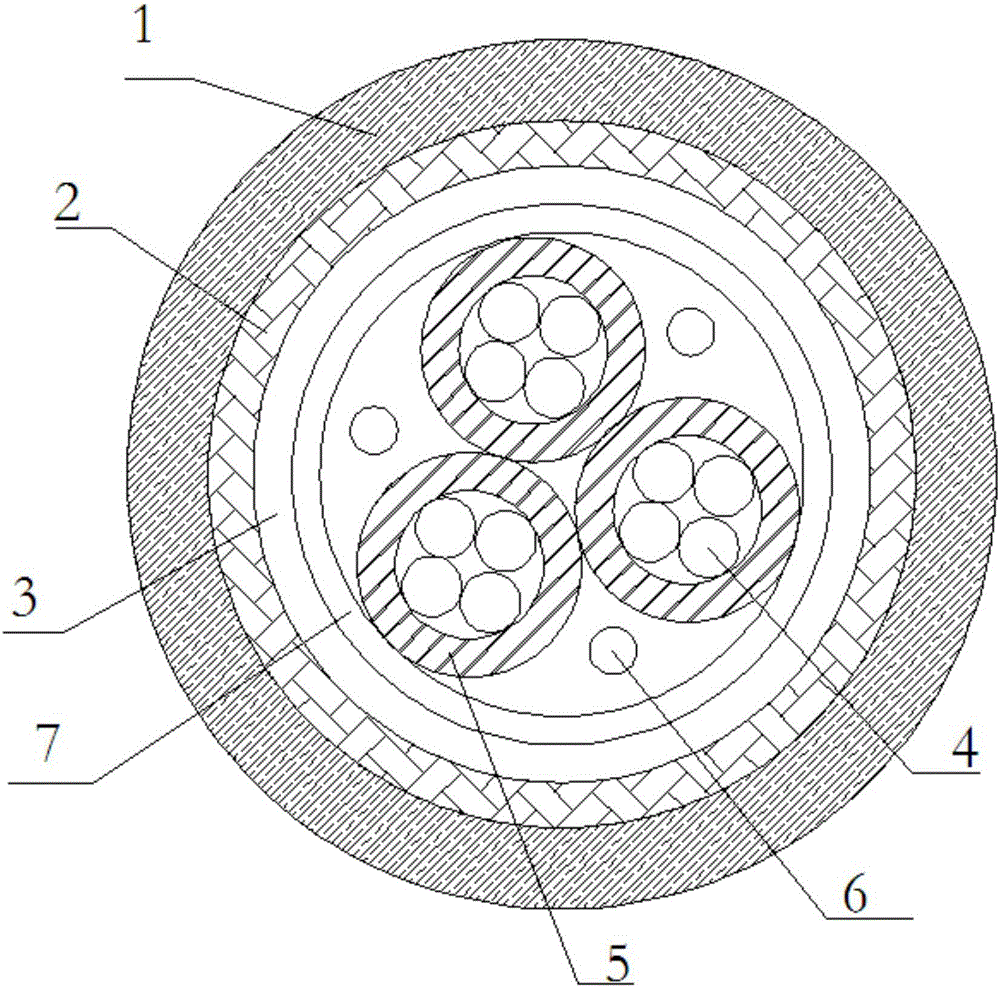

Electric wear-resistant anti-corrosion cable

InactiveCN105788747AImprove anti-aging propertiesImprove weather resistancePower cables with screens/conductive layersInsulated cablesWear resistantAluminium

The invention relates to an electric wear-resistant anti-corrosion cable, and the cable comprises a cable core, an alloy lead sheath shielding layer, and a wear-resistant anti-corrosion layer. A steel belt is disposed between the wear-resistant anti-corrosion and the alloy lead sheath shielding layer, and two surfaces of the steel belt are coated with anti-corrosion paint. A waterproof layer is disposed between the alloy lead sheath shielding layer and the cable core, and a filling layer is disposed between the cable core and the waterproof layer. The cable core comprises a conductor and an insulating layer wrapping the conductor. The above structure and the design of the wear-resistant anti-corrosion layer enable the aging, wear-resistant and anti-corrosion performances of the cable to be higher, and prolonging the service life of the cable.

Owner:郭秀珍

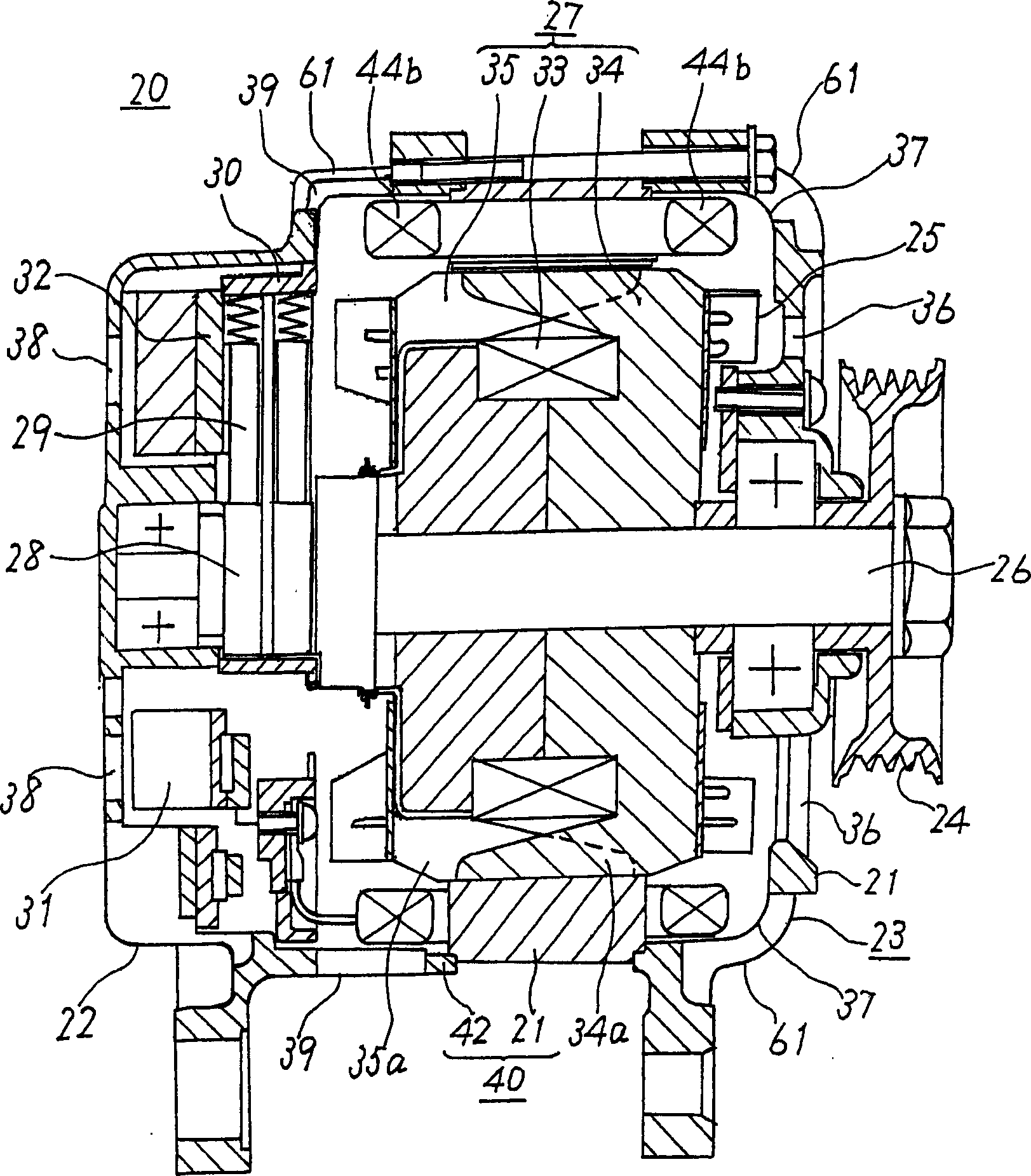

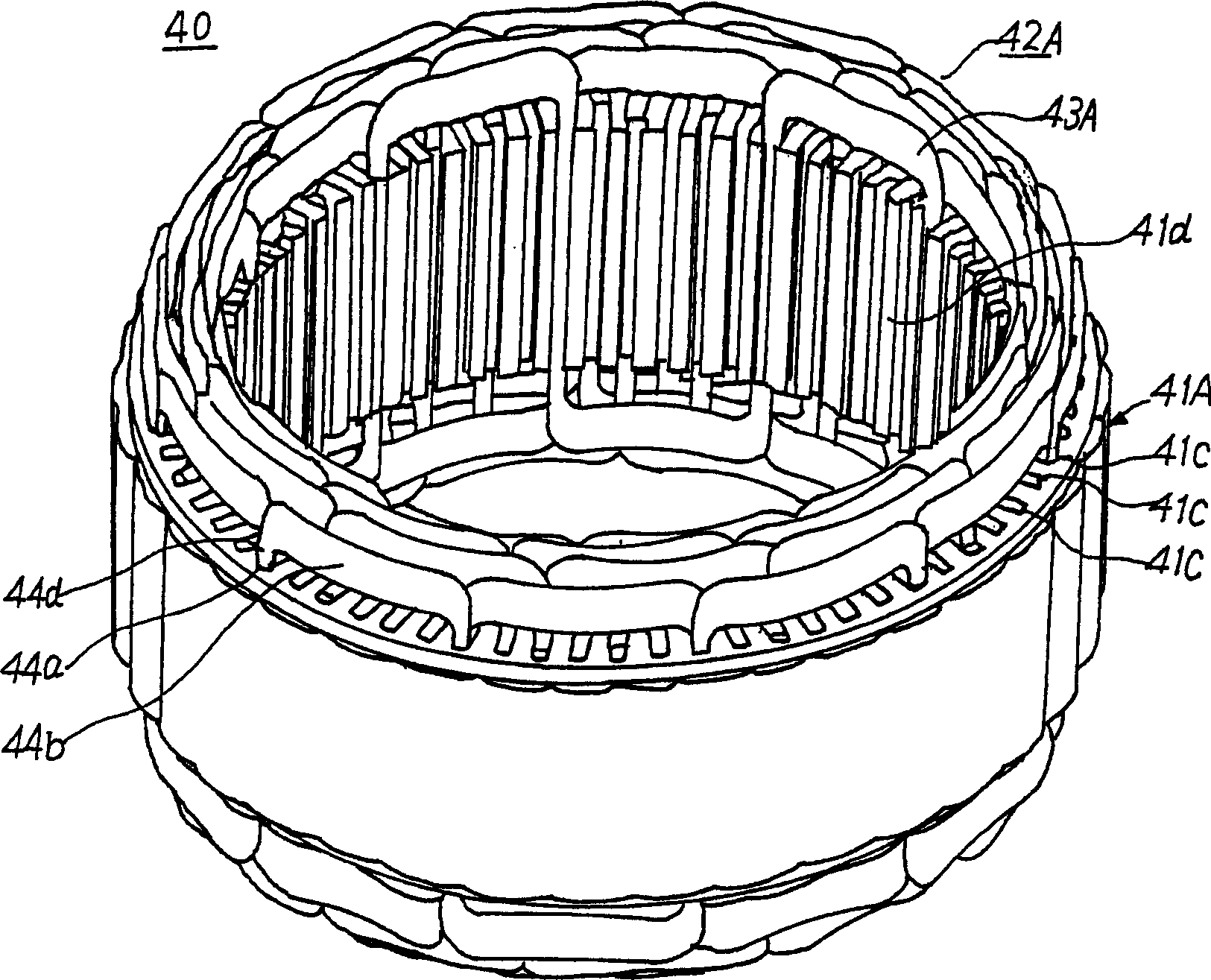

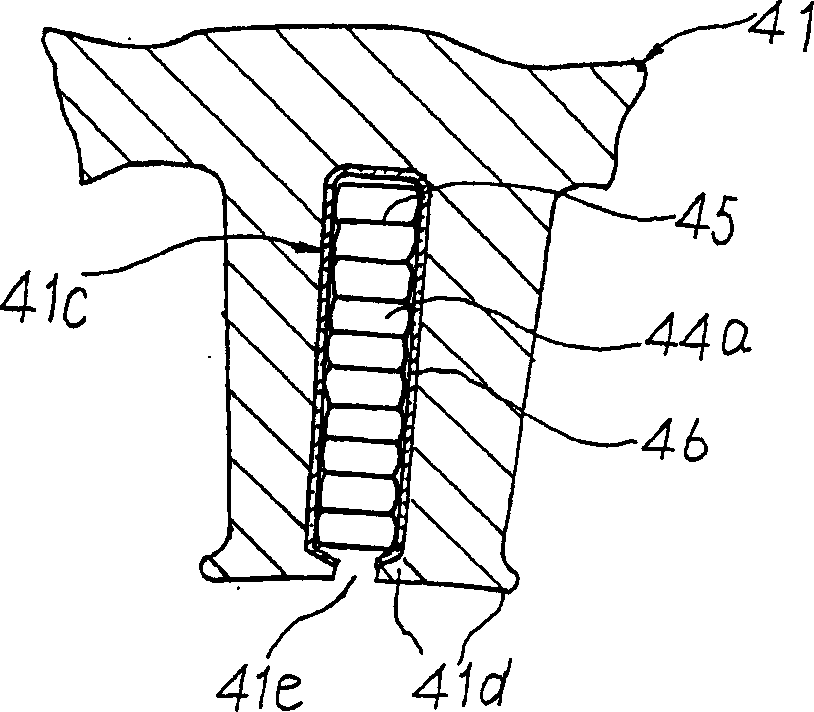

AC generator for vehicle

ActiveCN1809951AReduce axial heightGuaranteed insulation performanceWindings insulation shape/form/constructionWindings conductor shape/form/constructionInsulation layerEngineering

The invention discloses inductor which forms the coil patterns on the predetermined layer in the overlapped plural insulation layers. The coil pattern is formed on at least two insulation layers and the coil patterns are electrically connected. The constitution improves the inductor Q value without a large-size.

Owner:MITSUBISHI ELECTRIC CORP

A kind of no-clean solid flux for aluminum low-temperature soldering and its preparation method

ActiveCN104607826BEfficient removalNo corrosionWelding/cutting media/materialsSoldering mediaActive agentElectrochemical corrosion

The invention discloses cleaning-free solid-state scaling powder for aluminum low-temperature soldering and a preparing method. According to the weight percentage, the cleaning-free solid-state scaling powder comprises raw materials of 6.5%-18% of metal film-forming agents, 5%-18% of organic carriers, 0.1%-1.8% of corrosion inhibition agents and the allowance of film removing active agents. The film removing active agents are composite salt of organic amine and acid. The cleaning-free solid-state scaling powder is suitable for lead-free solder wires with solid-state scaling powder contained in a core, and the powder can be used for automatic welding, manual soldering iron welding or flame spraying welding. The core-contained solder wires prepared with the scaling powder have the advantages that tinning speed is high, splashing is low, irritating smoke is avoided, post-welding residues do not have corrosiveness, a welding point has great electrochemical corrosion resistance, a contact service time is long, the wires are suitable for assembling welding of an aluminum coated layer circuit board and an aluminum soldering pin electronic element and brazing of an aluminum electric cable wire, an aluminum radiator and aluminum heat exchanging equipment.

Owner:SOUTH CHINA UNIV OF TECH

Formula of strip steel rare-earth zinc aluminum alloy coating

InactiveCN102121087AImprove the technical level of continuous hot-dip galvanizingPrevent peelingHot-dipping/immersion processesTectorial membraneRare earth

The invention discloses a formula of a strip steel rare-earth zinc aluminum alloy coating for determining the strip steel coating and the basic materials of the strip steel coating and the proportion of the basic materials of the strip steel coating. By determining the strip steel coating as the strip steel rare-earth zinc aluminum alloy coating, the rare earth plays a role in enhancing the mobility of molten zinc and improving the infiltration property of the zinc aluminum alloy on the surface of the strip steel; and by determining the proportion of the strip steel rare-earth zinc aluminum alloy coating, the rare earth can also promote the zinc and aluminum elements to form an optimal electrochemical protective film on the surface of the strip steel coating. According to the technical scheme, the purposes of improving the chemical corrosion resistance and the electrochemical corrosion resistance of the galvanized strip steel and the adhesiveness of the zinc aluminum alloy and the steel base and avoiding peeling of the strip steel coating are fulfilled, the continuous hot galvanizing technology level of the strip steel is further promoted, the corrosion resistance of the hot galvanized strip steel is remarkably improved, and a condition is created for expanding the domestic hot galvanized strip steel to the application fields of automobile industry and the like.

Owner:HANGZHOU YONGFENG STEEL CONSTR

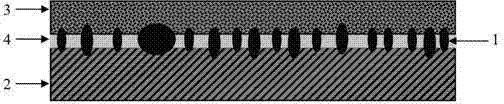

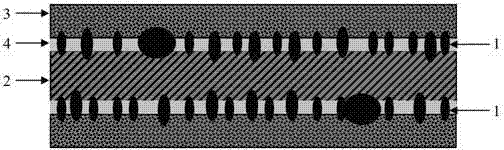

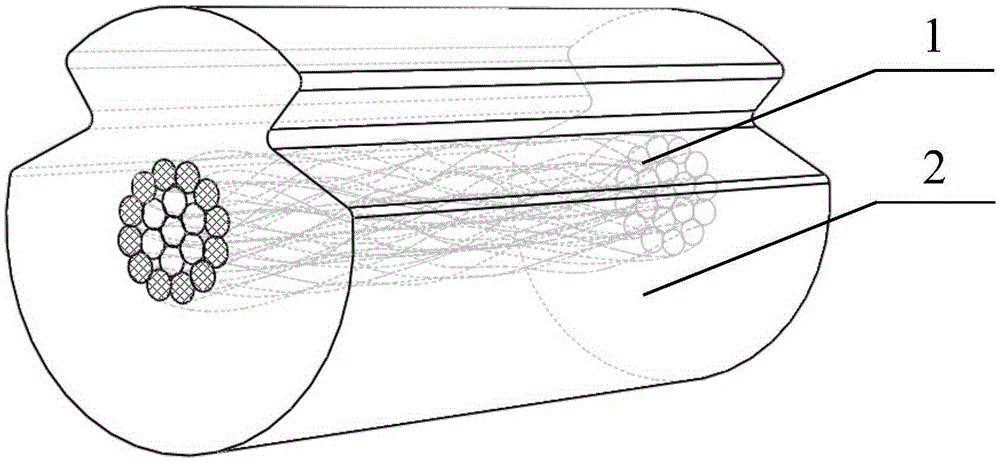

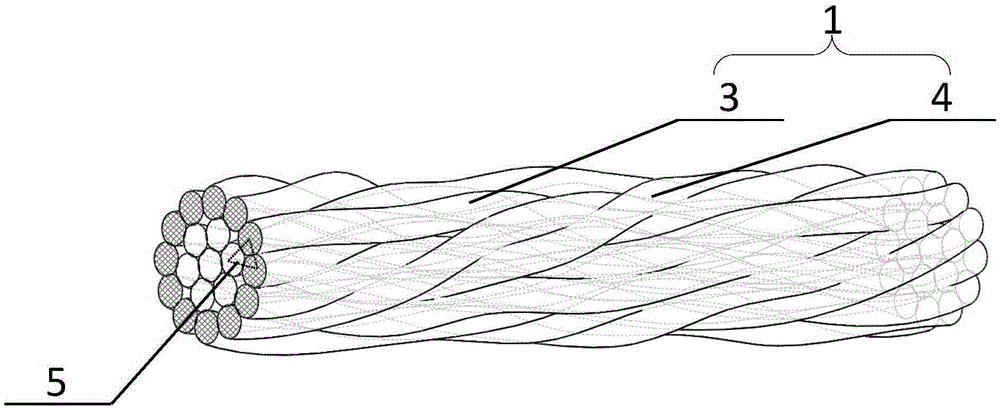

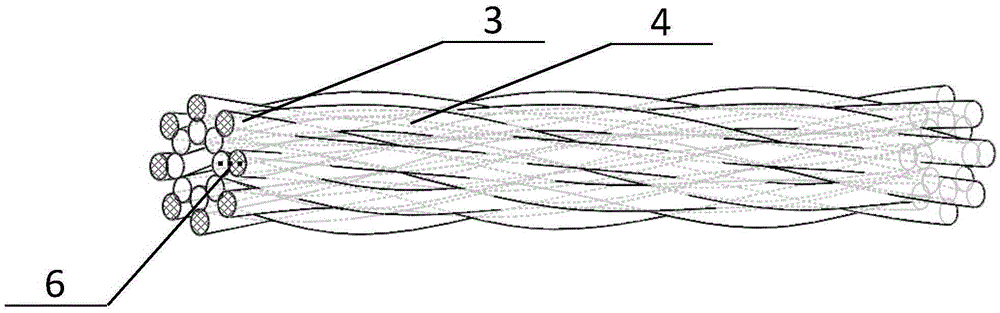

Enhancement core of fiber-reinforced copper-based composite material contact line

The embodiment of the invention provides an enhancement core of a fiber-reinforced copper-based composite material contact line. The enhancement core is composed of copper alloy wires and carbon fiber bundles. The enhancement core axially comprises a plurality of repeated feature circulation segments. The radial section of each feature circulation segment comprises a substructure formed by arranging one or more carbon fiber bundles and one or more copper alloy wires in a staggered manner. Due to the fact that the carbon fiber has the beneficial effects of being large in tensile strength, high in modulus and the like, the enhancement core has the larger tensile strength, potential difference does not exist between the carbon fiber and copper or between the carbon fiber and added alloy elements, the whole corrosion resistance of the contact line can be improved, and the enhancement core has the higher electrochemical corrosion resistance performance.

Owner:CHINA RAILWAYS CORPORATION +2

Lead alloy deslagging agent and application method thereof

The invention discloses a lead alloy deslagging agent which is prepared by uniformly mixing bamboo charcoal powder, sodium hydroxide, sodium nitrate, sulfur powder, pulverized coal and pine wood powder by a mechanical grinding and stirring way. The deslagging agent is prepared from the following components in percent by weight: 20-40% of bamboo charcoal powder, 5% of sodium hydroxide, 5% of sodiumnitrate, 3% of sulfur powder, 20-40% of pulverized coal and 20-40% of pine wood powder. When a lead alloy for a storage battery grid is prepared, the prepared deslagging agent is added into electrolytic lead to be reacted with molten lead of the electrolytic lead, so that lead slag is separated and impurities are removed. By preparing the alloy from the deslagging agent, the lead slag rate can bereduced by over 50%, and the alloy is low in impurity content and good in flowability of molten lead. The prepared lead is used for pouring the grid, and the grid is formed well, and is high in rateof finished products and high in corrosion resistance.

Owner:江苏海宝电池科技有限公司

A kind of sintered flux for submerged arc welding of x100 pipeline steel and preparation method thereof

InactiveCN105149817BIncrease alkalinityImproves electrochemical corrosion resistanceArc welding apparatusPipeline systemsToxic materialHuman health

The invention aims at providing sintering flux for submerged-arc welding of X100 pipeline steel and a preparation method for the sintering flux. By means of the sintering flux, the technical problem that many toxic substances and acid or corrosive gas produced due to incomplete combustion, which can easily occur during welding of the X100 pipeline steel, of the sintering flux containing halogen elements have potential threats to human health and the environment is solved. Meanwhile, the alkalinity is improved, so that the low-temperature impact toughness of weld metal is improved. Besides, the electrical conductivity during welding is enhanced, and the electrochemical corrosion resistant performance of welded joints is improved. The sintering flux comprises chemical components of, 45-55 wt.% of MgO, 3-5 wt.% of Al2O3, 5-10 wt.% of CaO, 5-8 wt.% of SiO2, 2-3 wt.% of MnO, 8-10 wt.% of TiO2, 3-5 wt.% of FeO, 2-3 wt.% of ZrO2, 5-10 wt.% of Na2O and 3-4 wt.% of K2O.

Owner:上饶市荣昌焊接材料有限公司

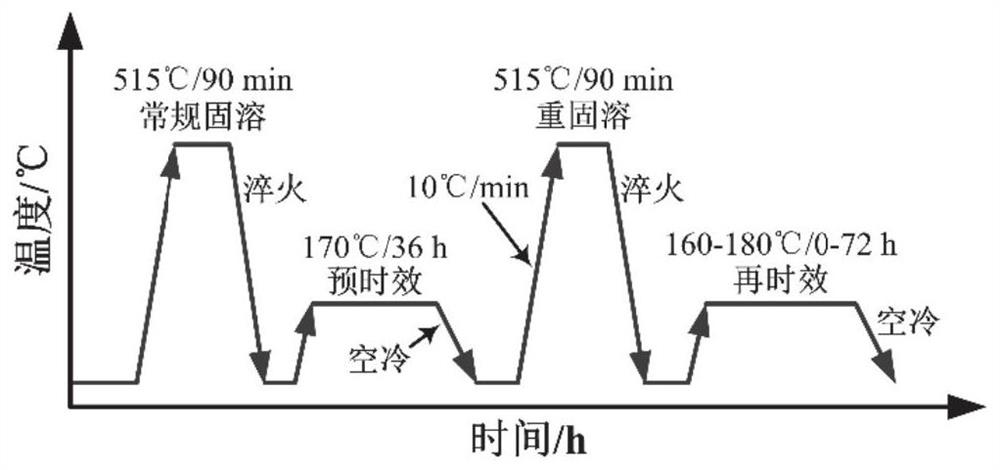

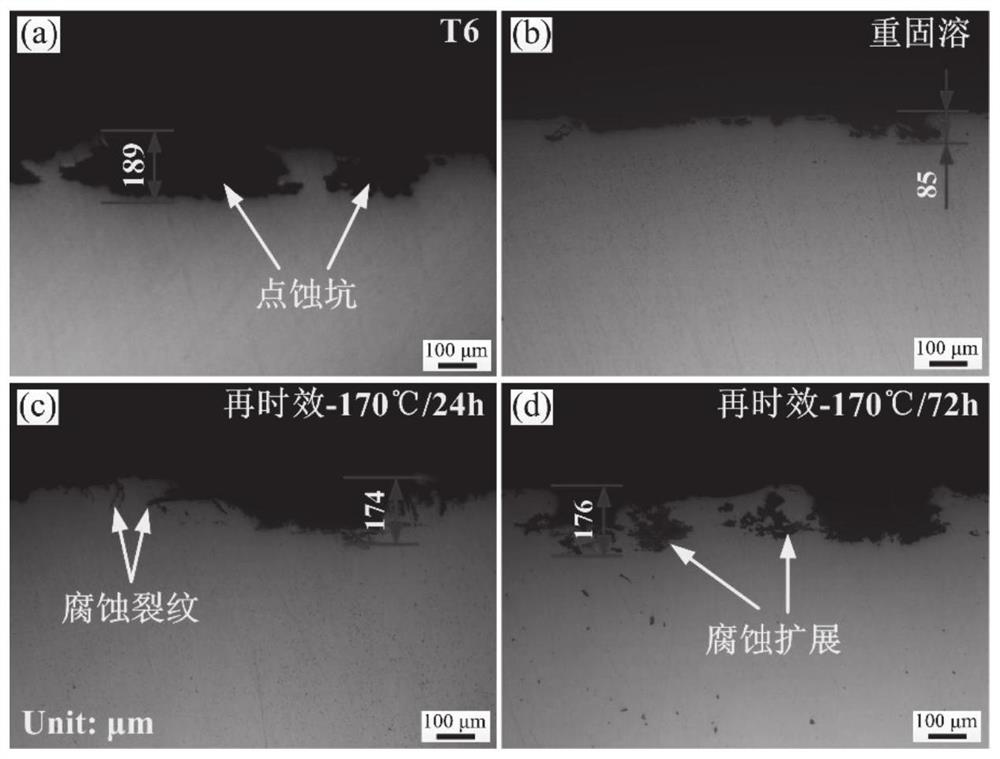

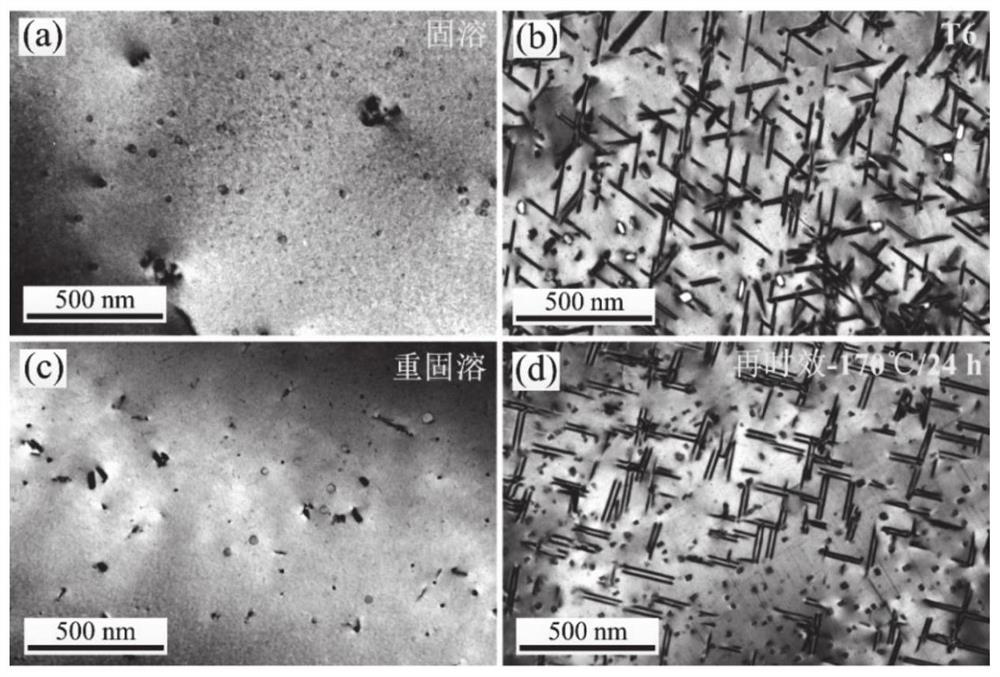

Heat treatment method for pre-aging, re-solid-solution and re-aging of Al-Cu-Li alloy

ActiveCN112281092AReduce the effect of strengtheningHigh strengthSolution treatmentHeat conservation

The invention discloses a heat treatment method for pre-aging, re-solid-solution and re-aging of an Al-Cu-Li alloy, belongs to the field of material heat treatment, and aims to perform conventional solid-solution, pre-aging, re-solid-solution and re-aging treatment on an Al-Cu-Li alloy extruded plate by controlling a heat treatment process system and parameters thereof. The conventional solid solution and re-solid solution treatment temperature is 515 + / -10 DEG C, heat preservation is performed for 60-90 min, then water quenching is performed, and the quenching transfer time is shorter than 5s. The pre-aging and re-aging treatment temperature is 160-180 DEG C, heat preservation is performed for 24-48 hours, and the product is taken out for air-cooling. The strength of the alloy can be reduced through re-solid-solution treatment, the plasticity of the alloy is improved, and correction and reprocessing processes are facilitated. The re-aging treatment can effectively regulate and control the variety, density and distribution of precipitated phases, thereby enhancing the strength of the alloy. In addition, due to coarsening of discontinuous grain boundary precipitated phases in the alloy and increasing of the copper content, on the premise that the strength of the alloy is basically not lost, the stress corrosion resistance, the intergranular corrosion resistance and the electrochemical corrosion resistance are improved, and the plasticity of the alloy is improved. The process is simple and feasible and is not limited by the thickness of the plate.

Owner:SHANDONG UNIV

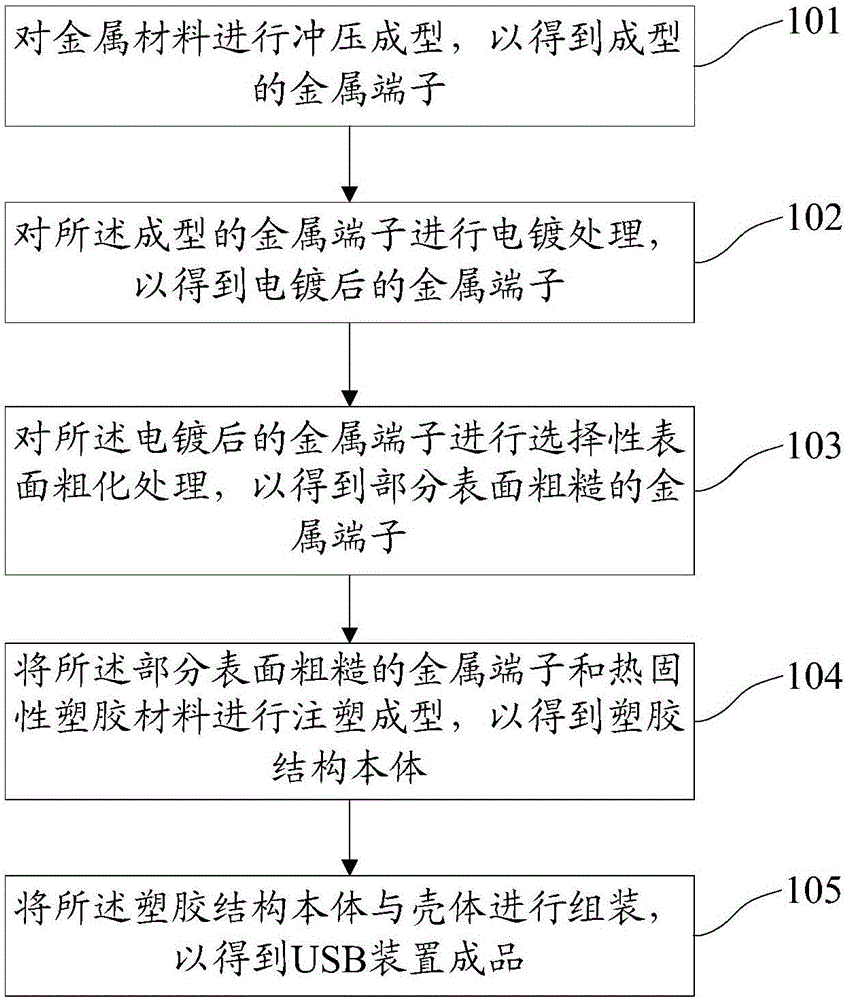

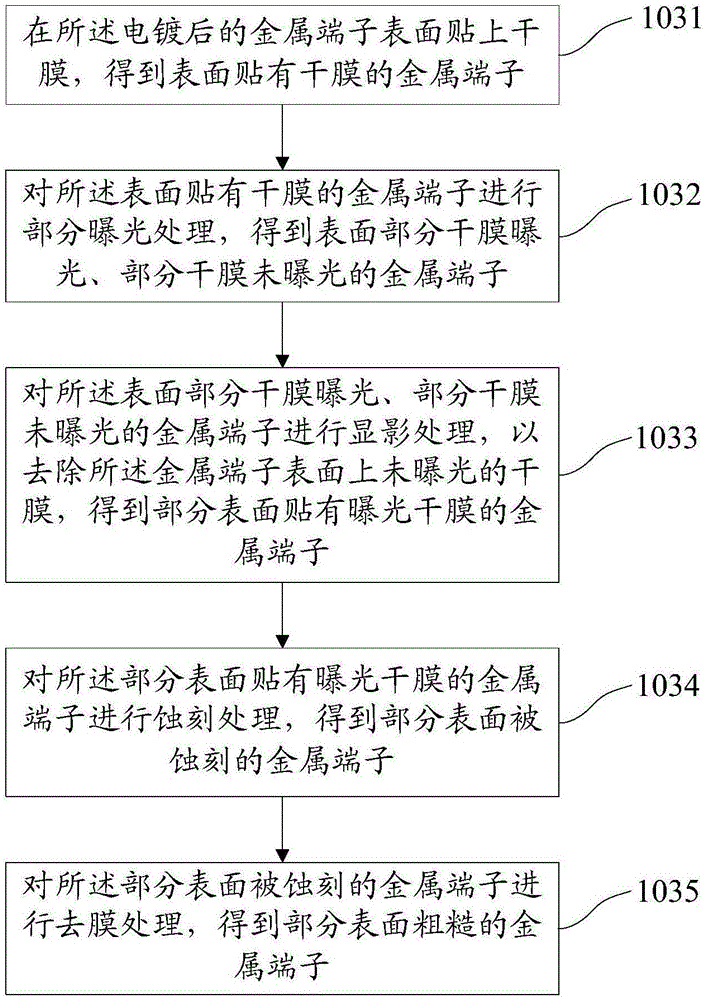

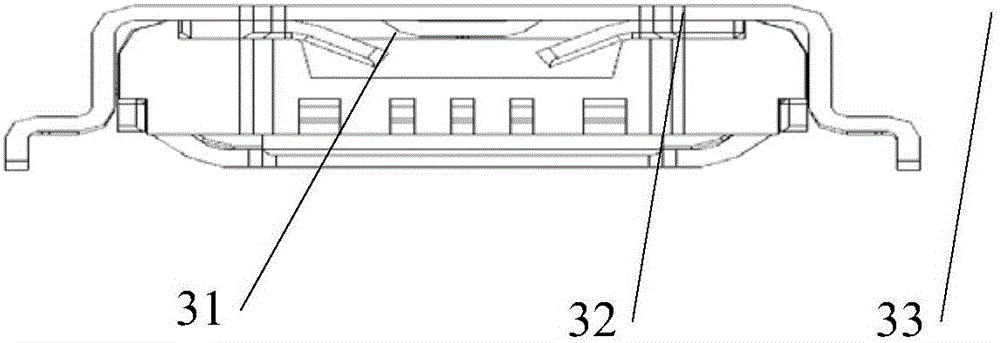

Machining method for USB device, USB device and mobile terminal

ActiveCN106835222AImproves resistance to galvanic corrosionReduce failureDomestic articlesCoatingsMetallic materialsElectroplating

The embodiment of the invention provides a machining method for a USB device, the USB device and a mobile terminal. The machining method for the USB device particularly includes the steps that metal materials are subjected to punching forming, so that a formed metal terminal is obtained; the formed metal terminal is subjected to electroplating treatment, and the electroplated metal terminal is obtained; the electroplated metal terminal is subjected to selective surface roughing treatment, and the metal terminal with part of the surface being rough is obtained; and the metal terminal with part of the surface being rough and thermoset plastic materials are subjected to injection molding, and a plastic structure body is obtained; and the plastic structure body and a shell are assembled, so that the USB device finished product is obtained. The electrochemical corrosion resistance of the USB device can be improved, and failures of the USB device caused by electrochemical corrosion are reduced.

Owner:VIVO MOBILE COMM CO LTD

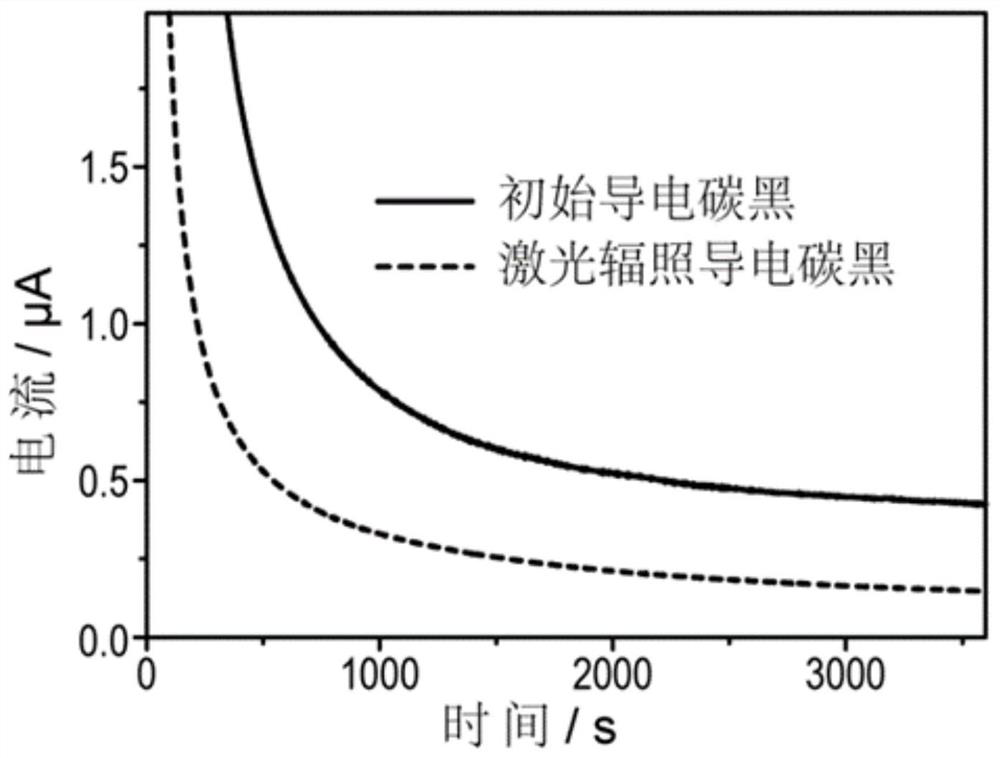

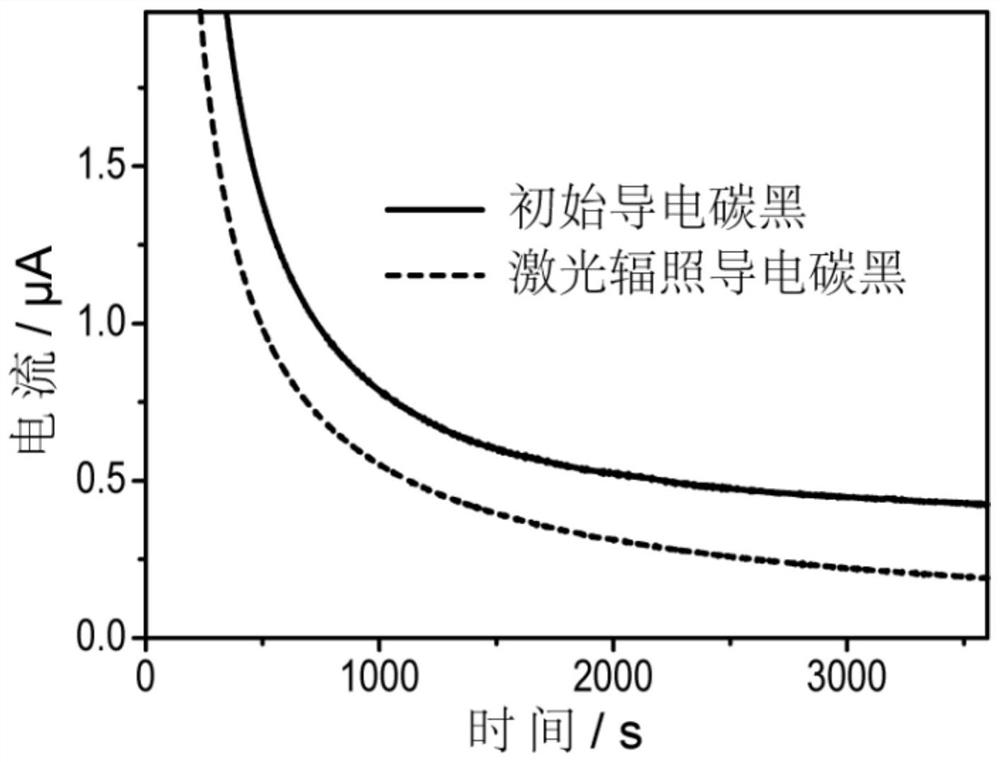

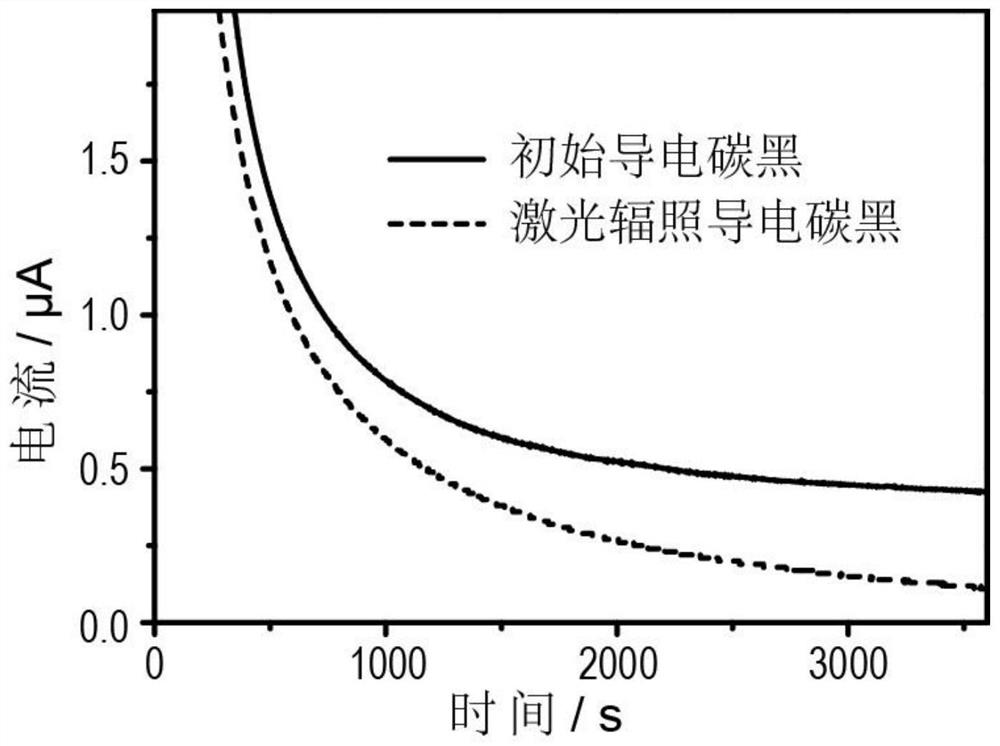

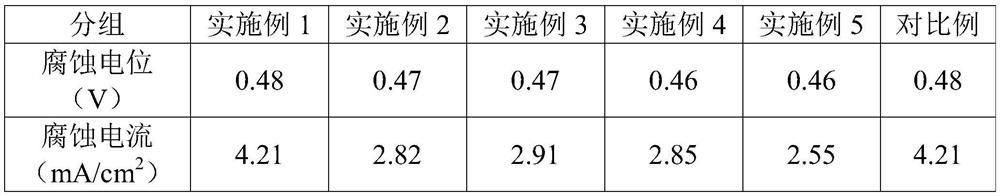

Method for improving electrochemical corrosion resistance of conductive carbon black

InactiveCN112679995AImproves electrochemical corrosion resistanceCorrosion current reductionCell electrodesPigment physical treatmentPtru catalystFluid phase

The invention discloses a method for improving electrochemical corrosion resistance of conductive carbon black, which comprises the following two steps: step 1, mixing the conductive carbon black with an alcohol solvent, and stirring for a period of time to enable the conductive carbon black to be uniformly dispersed in the alcohol solvent; and 2, irradiating the conductive carbon black alcoholic solution by using non-focused pulse laser, and stirring the solution in the irradiation process. Compared with initial conductive carbon black, the conductive carbon black subjected to laser irradiation treatment has lower corrosion current under the condition of high potential and shows higher electrochemical corrosion resistance, and the method is simple, quick, efficient and easy for batch production, has a wide application prospect in the field of proton exchange membrane fuel cell catalysts, and further has a wide application prospect in the field of proton exchange membrane fuel cell catalysts. The application field of the liquid-phase laser irradiation technology is expanded, and meanwhile, a new design thought is provided for improving the electrochemical corrosion resistance of the conductive carbon black.

Owner:安徽枡水新能源科技有限公司

Method for forming high-strength, high-toughness and high-corrosion-resistance copper-based alloy through selective laser melting

ActiveCN112647075AImproves electrochemical corrosion resistanceIncreasing energy efficiencyMetallic material coating processesSelective laser meltingAlloy

The invention relates to a method for forming a high-strength high-toughness high-corrosion-resistance copper-based alloy by selective laser melting. The method is characterized by comprising the following steps: (1) slicing a copper-based alloy part CAD (Computer-Aided Design) model layer by layer, and generating a series of selective laser areas to melt and form a two-dimensional scanning track according to slice contour information; and (2) stacking the special copper-based alloy powder point by point, line by line and layer by layer to form a three-dimensional solid copper-based alloy by adopting a selective laser melting method according to the generated scanning track. The copper-based alloy prepared by adopting the selective laser melting method has a biphasic heterogeneous microstructure, so that structural performance integrated design and manufacturing of the high-strength high-toughness high-corrosion-resistance copper-based alloy can be realized in one step; and the problems that a conventional method such as multi-pass rolling after fusion casting is complex in process, multi-step forming exists, and personalized and flexible manufacturing cannot be met are solved.

Owner:JINAN UNIVERSITY

Wear-resistant electrician bag for power systems

InactiveCN105778188ALight in massImprove wear resistanceOther accessoriesWear resistantElectric power system

The invention relates to a wear-resistant electrician bag for power systems, which comprises a bag body, a shoulder strap and a waist strap, the bag body consists of an internal wear-resistant layer, a non-woven fabric layer, a waterproof layer and an external wear-resistant layer from the inside to the outside, the internal wear-resistant layer is made of a thin thermoplastic elastic rubber layer, the waterproof layer is a polyvinyl chloride waterproof layer, and the material components of the external wear-resistant layer are as follows: 40 to 60 parts by weight of styrene-butadiene rubber, 20 to 40 parts by weight of chloroprene rubber, 23 to 26 parts by weight of fluoroether rubber, 0.1 to 15 parts by weight of graphene, 13 to 15 parts by weight of phenol-formaldehyde resin, 1 to 10 parts by weight of silane coupling agent, 12 to 15 parts by weight of semi-reinforcing furnace black, 10 to 12 parts by weight of calcined clay, 1 to 5 parts by weight of magnesium powder, 5 to 7 parts by weight of nanometer molybdenum disulfide (MoS2), 1 to 10 parts by weight of anti-aging agent, 4 to 8 parts by weight of zinc oxide and 1 to 5 parts by weight of accelerant. Besides high wear resistance, the electrician bag also has the characteristics of dampproofness, light weight, wear resistance, high temperature resistance, weather resistance and high insulating property.

Owner:郭秀珍

Techniques for laser ablation/scribing of coatings in pre- and post-laminated assemblies, and/or associated methods

ActiveUS20190009501A1Improves electrochemical corrosion resistanceReduce dispersionMirrorsLaminationInsulated glazingLow emissivity

Certain example embodiments of this invention relate to techniques for laser ablating / scribing peripheral edges of a coating (e.g., a low-emissivity, mirror, or other coating) on a glass or other substrate in a pre- or post-laminated assembly, pre- or post-assembled insulated glass unit, and / or other product, in order to slow or prevent corrosion of the coating. For example, a 1064 nm or other wavelength laser may be used to scribe lines into the metal and / or metallic layer(s) in a low-emissivity or other coating provided in an already-laminated or already-assembled insulated glass unit or other product, e.g., around its periphery. The scribe lines decrease electron mobility from the center of the coating to the environment and, thus, slow and sometimes even prevent the onset of electrochemical corrosion. Associated products, methods, and kits relating to same also are contemplated herein.

Method of making insulated glass window units

ActiveUS11148228B2Reduce dispersionSmooth movementLaser beam welding apparatusInsulated glazingLow emissivity

Certain example embodiments of this invention relate to techniques for laser ablating / scribing peripheral edges of a coating (e.g., a low-emissivity, mirror, or other coating) on a glass or other substrate in a pre- or post-laminated assembly, pre- or post-assembled insulated glass unit, and / or other product, in order to slow or prevent corrosion of the coating. For example, a 1064 nm or other wavelength laser may be used to scribe lines into the metal and / or metallic layer(s) in a low-emissivity or other coating provided in an already-laminated or already-assembled insulated glass unit or other product, e.g., around its periphery. The scribe lines decrease electron mobility from the center of the coating to the environment and, thus, slow and sometimes even prevent the onset of electrochemical corrosion. Associated products, methods, and kits relating to same also are contemplated herein.

Owner:GUARDIAN GLASS LLC

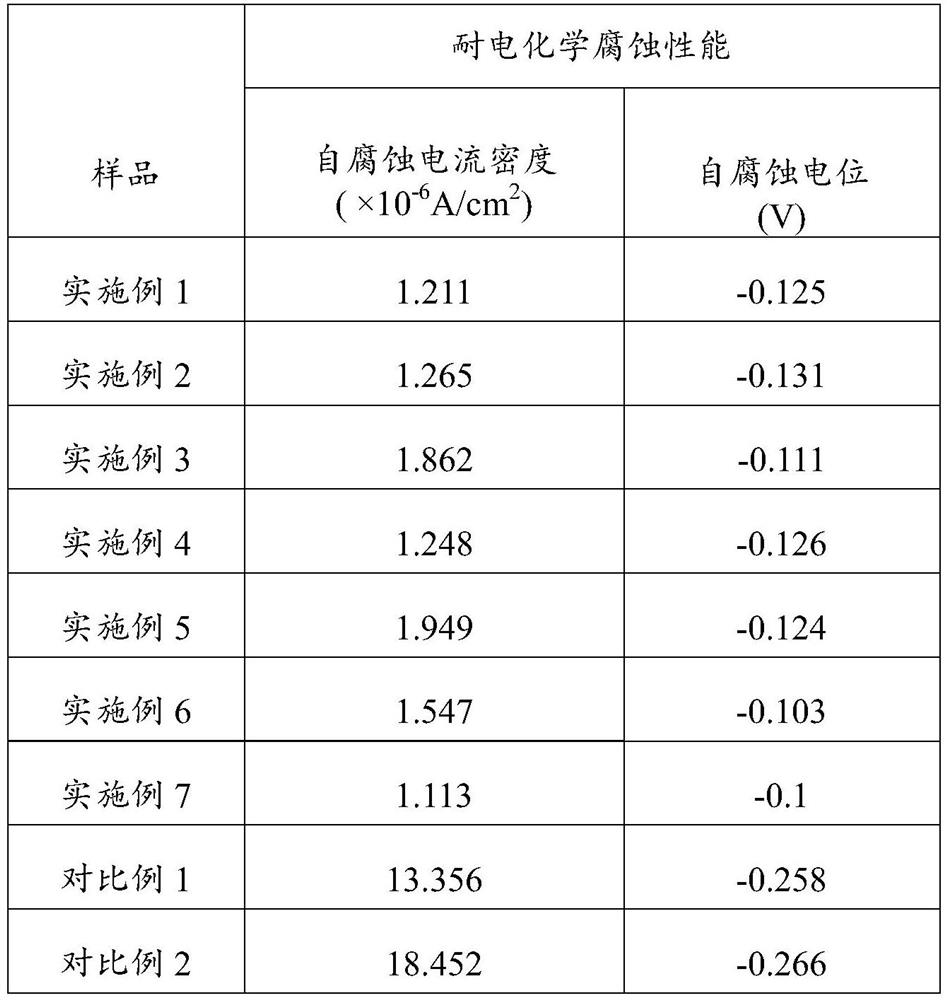

Rare earth surface treatment agent for improving electrochemical corrosion resistance of copper foil surface and surface treatment process

ActiveCN114108042AImprove resistance to galvanic corrosionImproves electrochemical corrosion resistanceCellsRare-earth elementElectrolysis

The invention relates to the technical field of electrolytic copper foils, and discloses a rare earth surface treating agent for improving the electrochemical corrosion resistance of the surface of a copper foil, the rare earth surface treating agent comprises the following components: potassium pyrophosphate, zinc sulfate, nickel sulfate, metalloid salt, an additive A and rare earth salt, and the electrochemical corrosion resistance of the surface of the copper foil can be effectively improved. According to the method, a Zn-Ni-metalloid element (Si, As and B)-rare earth element (La, Ce, Pr and Nd) quaternary alloy coating is electrolytically deposited on the surface of the copper foil, so that the electrochemical corrosion resistance of the surface of the copper foil is improved. The metalloid can enable the coating to be in an amorphous state, so that the electrochemical corrosion resistance of the coating is improved; the rare earth element has characteristic adsorption, can effectively improve the compactness uniformity of the microstructure of the plating layer, and can also effectively improve the electrochemical corrosion resistance of the plating layer.

Owner:SHANDONG JINBAO ELECTRONICS

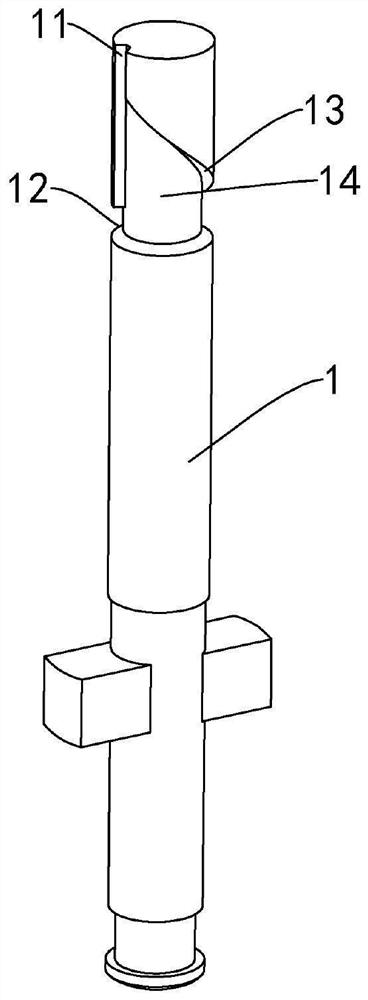

A plunger coupling for an obtuse-angle oil groove of a high-pressure oil pump

ActiveCN112761839BReduce impactExtended service lifePositive displacement pump componentsFuel injecting pumpsEngineeringPlunger

The present invention proposes a plunger coupling for an obtuse-angle oil tank of a high-pressure oil pump, the plunger coupling includes a plunger body, the plunger body is a cylindrical metal rod, and an oil outlet groove is provided on the side of one end of the plunger body along the axial direction One end of the oil outlet groove communicates with the end of the plunger body, and the other end is closed. The closed end of the oil outlet groove is provided with an annular groove along the circumference of the plunger body, and one side of the end of the oil outlet groove communicates with the end of the plunger body A chute is provided along the surface of the plunger body. One end of the chute communicates with the oil outlet groove, and the other end communicates with the annular groove. The area enclosed by the chute, the annular groove and the oil outlet groove forms a special-shaped groove with the same depth. The angle formed by the side walls of the chute, the annular groove and the oil outlet groove and the bottom surface of the corresponding groove body is an obtuse angle. The structure of the oil groove of the plunger coupling part of the invention is more reasonable, and at the same time, the surface of the oil groove after treatment has better mechanical properties and electrochemical properties, and has good application prospects.

Owner:CHANGJIANG WUHAN WATERWAY ENG CO

Techniques for laser ablation/scribing of coatings in pre- and post-laminated assemblies, and/or associated methods

Certain example embodiments of this invention relate to techniques for laser ablating / scribing peripheral edges of a coating (e.g., a low-emissivity, mirror, or other coating) on a glass or other substrate in a pre- or post-laminated assembly, pre- or post-assembled insulated glass unit, and / or other product, in order to slow or prevent corrosion of the coating. For example, a 1064 nm or other wavelength laser may be used to scribe lines into the metal and / or metallic layer(s) in a low-emissivity or other coating provided in an already-laminated or already-assembled insulated glass unit or other product, e.g., around its periphery. The scribe lines decrease electron mobility from the center of the coating to the environment and, thus, slow and sometimes even prevent the onset of electrochemical corrosion. Associated products, methods, and kits relating to same also are contemplated herein.

Owner:GUARDIAN GLASS LLC

Environment-friendly passivation solution for aluminum alloy and preparation method thereof

InactiveCN112481610ASimple processEasy to operateMetallic material coating processesMischmetalPolymer modified

The invention discloses an environment-friendly passivation solution for an aluminum alloy. The environment-friendly passivation solution for the aluminum alloy is characterized by comprising the following components in percentage by mass: 0.05 to 0.11 percent of potassium hexafluorohafnium oxide, 0.03 to 0.05 percent of sodium fluoborate, 0.06 to 0.13 percent of amphoteric organic ion trimethoxysilylpropyl polyurethane polymer, 0.01 to 0.02 percent of modified rare earth metal organic framework and the balance of water. The invention further discloses a preparation method of the environment-friendly passivation solution for the aluminum alloy. The environment-friendly passivation solution for the aluminum alloy disclosed by the invention is remarkable in passivation effect, high in stability, uniform and compact in passivation film, high in corrosion resistance, good in environmental protection property, high in adhesive force and good in film forming property.

Owner:杨汉松

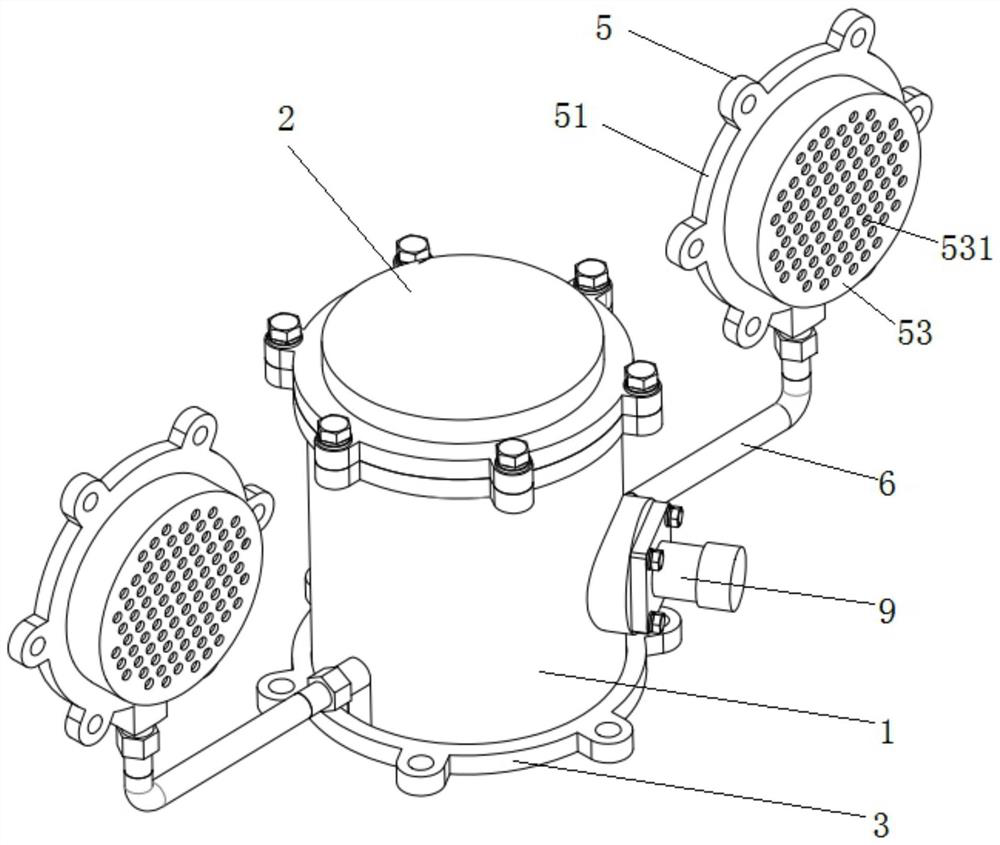

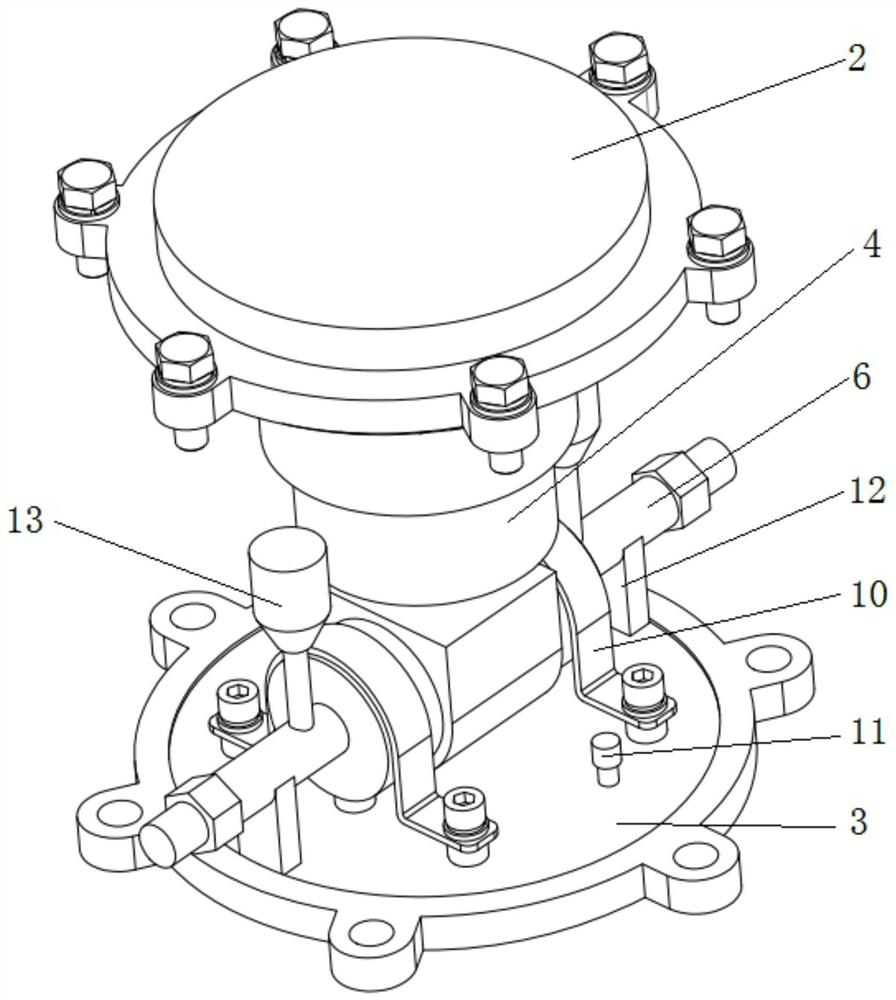

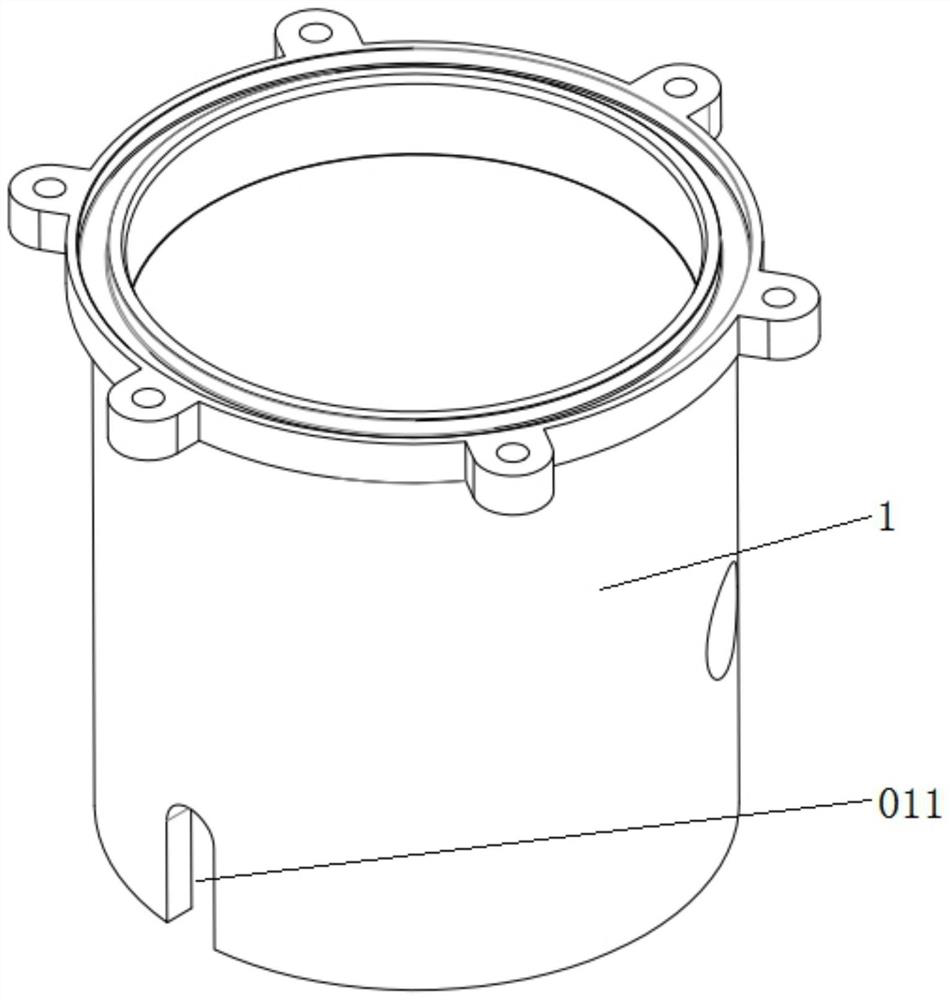

High-pressure-resistant and corrosion-resistant remote transmission differential pressure sensor

PendingCN114646421AHigh water pressure resistanceImprove seawater corrosion resistancePressure difference measurement between multiple valvesCapillary TubingStructural engineering

The invention discloses a high-pressure-resistant and corrosion-resistant remote transmission differential pressure sensor. The sensor comprises a cylinder, wherein the two ends of the cylinder are open; the cylinder cover is fixed at the top of the cylinder body; the cylinder bottom is fixed at the bottom of the cylinder body; the measuring assembly is arranged in the cylinder body and is fixedly connected with the cylinder bottom; the two pressure tapping accessories are located on the two sides of the cylinder respectively and connected with the two pressure measuring ends of the measuring assembly. The pressure tapping accessory comprises a mounting flange, a diaphragm and a protective cover; the diaphragm is fixed on the surface of the mounting flange, the protective cover is fixedly connected with the mounting flange, and the diaphragm is arranged in the protective cover; a plurality of through holes are formed in the surface of the protective cover; the capillary tube is wrapped with a layer of protective sleeve; the two capillary tubes are connected to the two pressure measuring ends of the measuring assembly respectively. One end of the capillary tube penetrates through the side wall of the cylinder and is fixedly connected with the pressure measuring end of the measuring assembly, and the other end is fixedly connected with the diaphragm. The pressure difference sensor can be used for deep sea operation, has high pressure resistance and corrosion resistance, and is accurate in measured data.

Owner:中国船舶集团有限公司第七零七研究所九江分部

A method for improving the electrochemical corrosion resistance of sn-based lead-free solder ultrasonic composite brazing aluminum and its alloy joints

ActiveCN106270888BImproves electrochemical corrosion resistanceImprove barrier propertiesSoldering apparatusElectrochemical responseMicro arc oxidation

Owner:HARBIN INST OF TECH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com