Method for improving electrochemical corrosion resistance of conductive carbon black

A technology of conductive carbon black and corrosion performance, which is applied in the direction of battery electrodes, circuits, electrical components, etc., and can solve the problems of high cost and high energy consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0022] First, mix 50㎎ conductive carbon black with 20mL ethanol, stir for 10min to disperse the conductive carbon black evenly in the ethanol;

[0023] Subsequently, the ethanol solution of conductive carbon black was irradiated by a non-focused pulsed laser, and the solution was still stirred during the irradiation process. The wavelength of the pulsed laser is 1064nm, the spot diameter is 7mm, the pulse width is 7ns, the frequency is 10Hz, and the energy density is 400mJ / cm 2 , the irradiation time is 15min.

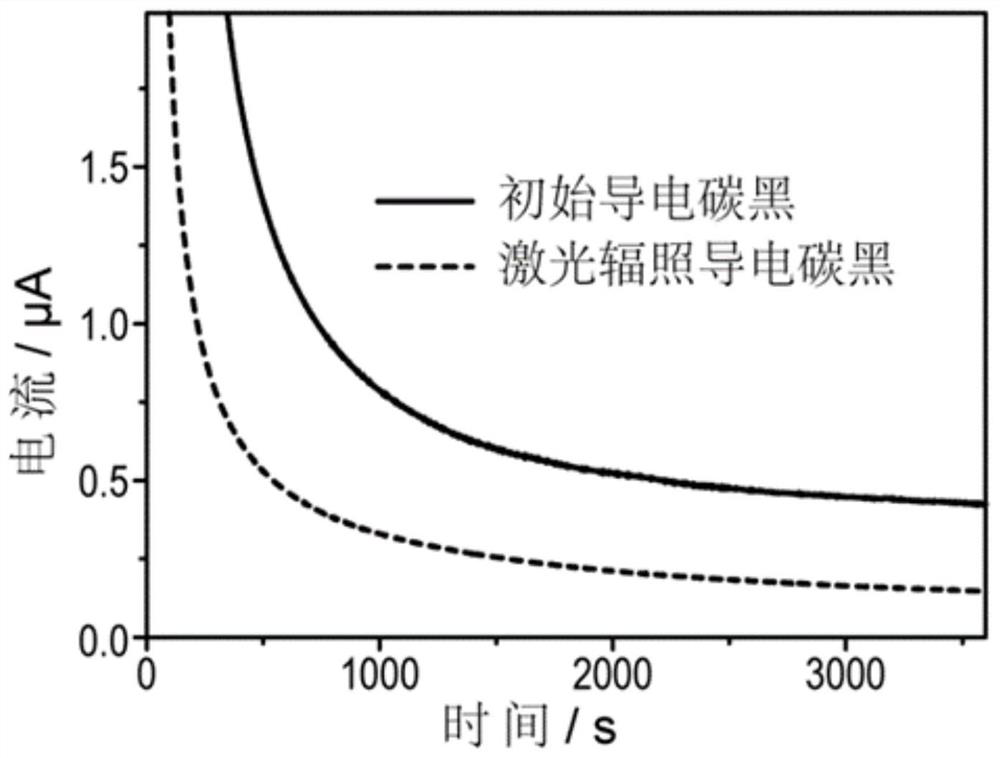

[0024] figure 1 Shown are the corrosion current versus time curves of initial conductive carbon black and laser-irradiated conductive carbon black. At a potential of 1.2V (vs. NHE), no water decomposition reaction will occur, and the reaction that occurs at this time is mainly a carbon corrosion reaction. Therefore, the corrosion current at this potential can be used to measure the electrochemical corrosion resistance of conductive carbon black ability. Depend on ...

Embodiment 2

[0026] First, mix 35㎎ conductive carbon black with 20mL ethanol, stir for 10min to make conductive carbon black evenly dispersed in ethanol;

[0027] Subsequently, the ethanol solution of conductive carbon black was irradiated by a non-focused pulsed laser, and the solution was still stirred during the irradiation process. The wavelength of the pulsed laser is 1064nm, the spot diameter is 7mm, the pulse width is 7ns, the frequency is 10Hz, and the energy density is 300mJ / cm 2 , the irradiation time is 10min.

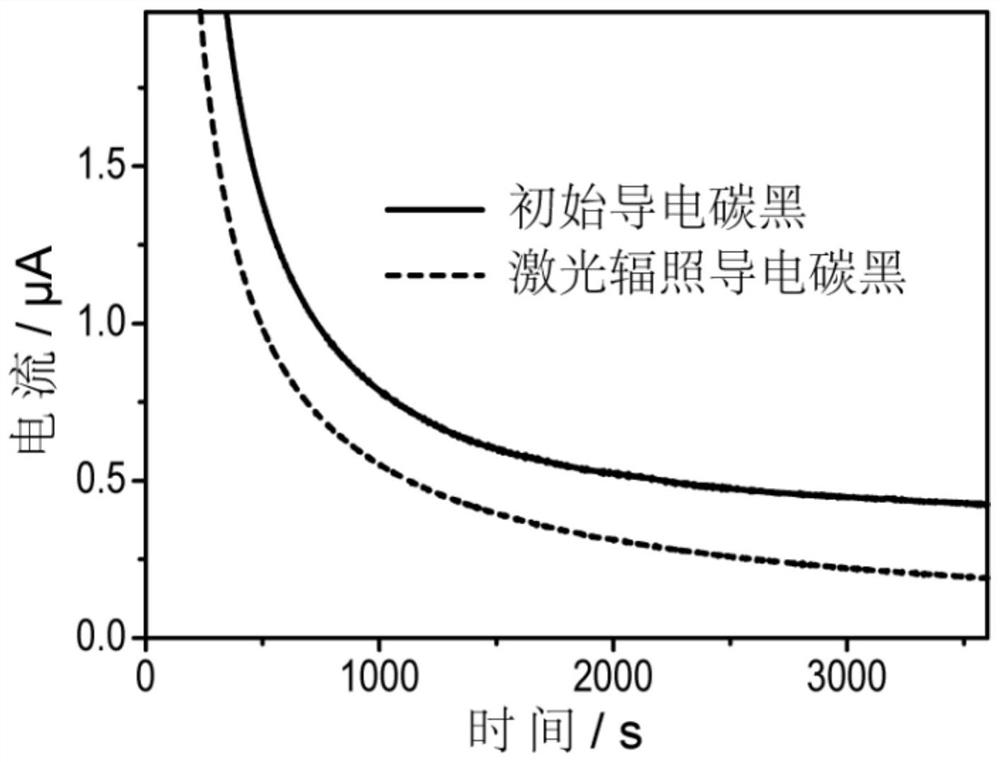

[0028] figure 2 Shown are the corrosion current versus time curves of initial conductive carbon black and laser-irradiated conductive carbon black. Depend on figure 2 It can be seen that during the whole test process, compared with the initial conductive carbon black, the laser irradiated conductive carbon black has a lower corrosion current; after 3600s, the corrosion current of the initial conductive carbon black is 0.424μA, while the laser irradiated conductive c...

Embodiment 3

[0030] First, mix 150㎎ conductive carbon black with 20mL ethanol, stir for 10min to disperse conductive carbon black evenly in ethanol;

[0031] Subsequently, the ethanol solution of conductive carbon black was irradiated by a non-focused pulsed laser, and the solution was still stirred during the irradiation process. The wavelength of the pulsed laser is 1064nm, the spot diameter is 7mm, the pulse width is 7ns, the frequency is 20Hz, and the energy density is 800mJ / cm 2 , the irradiation time is 20min.

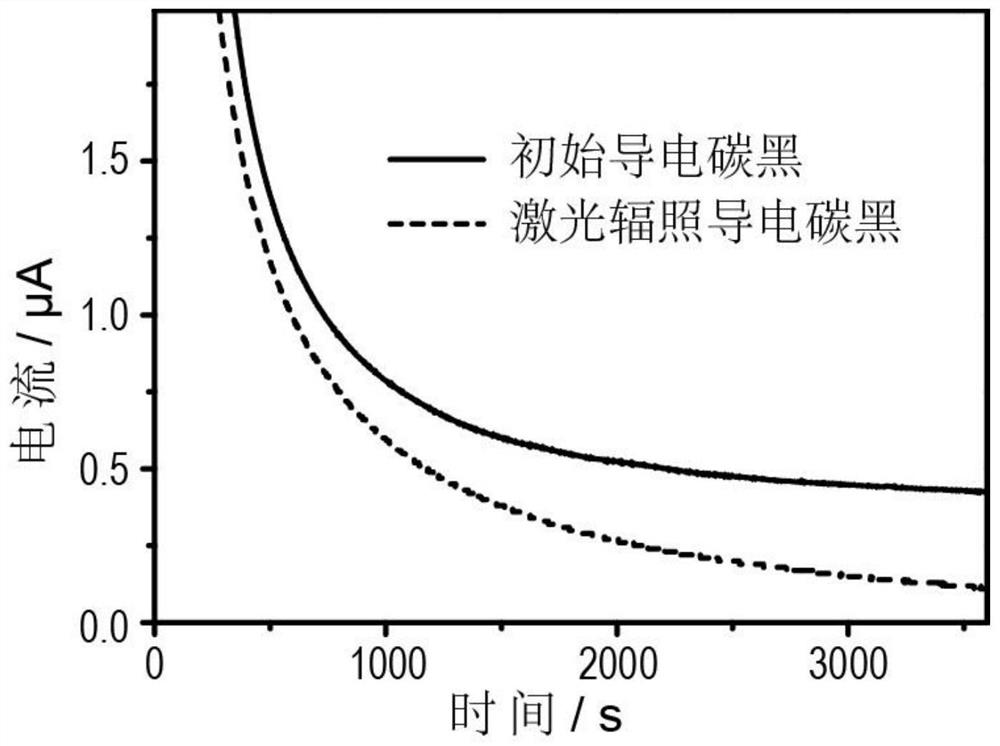

[0032] image 3 Shown are the corrosion current versus time curves of initial conductive carbon black and laser-irradiated conductive carbon black. Depend on image 3 It can be seen that during the whole test process, compared with the initial conductive carbon black, the laser irradiated conductive carbon black has a lower corrosion current; after 3600s, the corrosion current of the initial conductive carbon black is 0.424μA, while the laser irradiated conductive carbon b...

PUM

| Property | Measurement | Unit |

|---|---|---|

| wavelength | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| frequency | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com