A plunger coupling for an obtuse-angle oil groove of a high-pressure oil pump

A technology of high-pressure oil pump and obtuse oil, which is applied to pump elements, parts of pumping devices for elastic fluids, and parts of variable-capacity pumps, etc. , can not operate normally and other problems, to achieve the effect of improving metal components and electrochemical corrosion performance, prolonging life, and improving electrochemical corrosion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

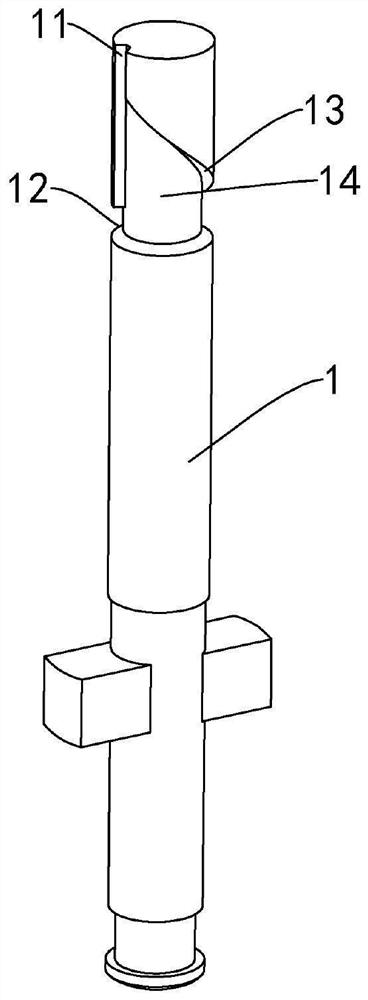

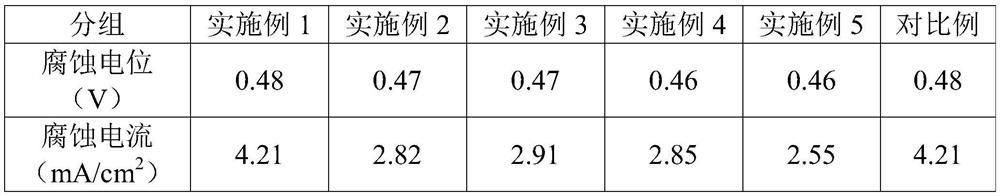

[0041] Process the plunger coupler in which the side walls of the inclined groove 13, the annular groove 12 and the oil outlet groove 11 form an angle of 110° with the bottom surface of the corresponding groove body.

Embodiment 2

[0043]Process the plunger coupling with the side wall of the chute 13, the annular groove 12, and the oil outlet groove 11 forming an angle of 120° with the bottom surface of the corresponding groove body. At the same time, the surface of the plunger body 1 is covered with iron sheets, and the The opening is filled with an appropriate amount of steel balls into the special-shaped tank body 14. The diameter of the steel balls is 0.1mm, and then the opening of the oil outlet tank 11 is closed, and the plunger body 1 is fixed on the vibration platform for vibration treatment. During the vibration process, in order to ensure that each Uniform shot blasting can be achieved in all directions. The plunger body 1 is set to rotate 20 revolutions per minute, the vibration frequency of the vibration platform is 100 Hz, and the vibration time is 30 minutes. After the treatment is completed, the iron sheet is removed to obtain the plunger coupling.

Embodiment 3

[0045] Process the plunger coupling with the side wall of the chute 13, the annular groove 12 and the oil outlet groove 11 forming an angle of 130° with the bottom surface of the corresponding groove body, and at the same time cover the surface of the plunger body 1 with iron sheet, and pass through The opening is filled with an appropriate amount of copper balls and nickel powder in the special-shaped tank body 14. The diameter of the copper balls is 0.5mm, and then the opening of the oil outlet tank 11 is closed, and the plunger body 1 is fixed on the vibration platform for vibration treatment. During the vibration process, In order to ensure uniform shot blasting in each direction, the plunger body 1 is set to rotate 20 revolutions per minute, the vibration frequency of the vibration platform is 200Hz, and the vibration time is 40min. After the treatment is completed, the iron sheet is removed to obtain the plunger coupling.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com