A method for improving the electrochemical corrosion resistance of sn-based lead-free solder ultrasonic composite brazing aluminum and its alloy joints

A lead-free solder, corrosion performance technology, applied in welding equipment, metal processing equipment, manufacturing tools, etc., can solve the problems of limited improvement of corrosion resistance of joints, broken oxide film, poor corrosion resistance, etc., to improve the corrosion resistance Effect of electrochemical corrosion performance, reduction of potential difference, and improvement of corrosion resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

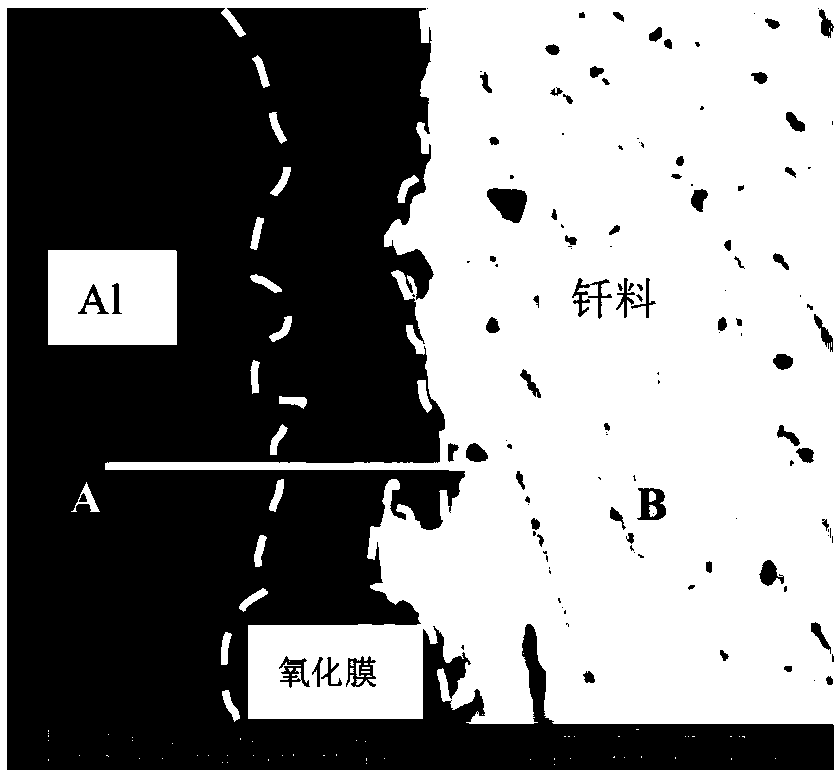

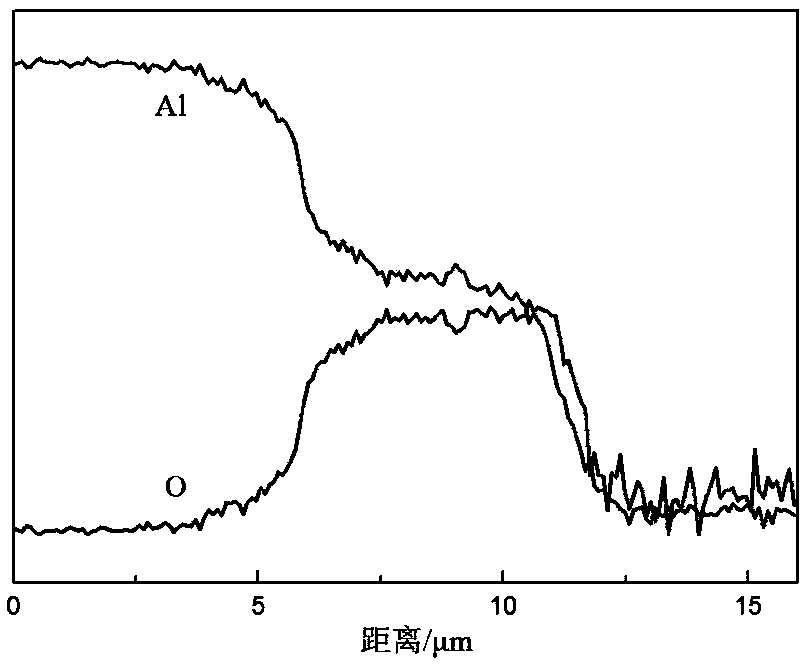

[0053] Embodiment 1: after the Al alloy is anodized, ultrasonic brazing is performed by using SnZnAgAl solder.

[0054] When performing anodic oxidation, use 15g / L oxalic acid aqueous solution as the electrolyte, and the current is 0.25A / dm 2 , the constant current mode is used for oxidation, the oxidation time is about 10 minutes, and the thickness of the thickened oxide film obtained is about 5 μm.

[0055] Table 1 is the chemical composition (weight percent) of low-temperature Sn-based active solder

[0056]

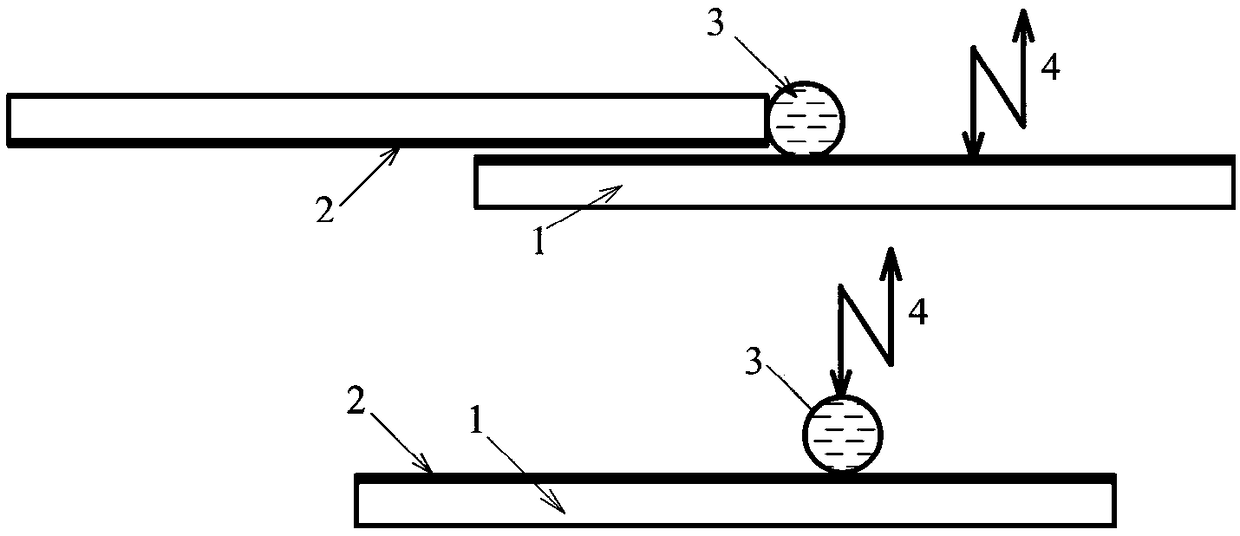

[0057] The welding method in the present embodiment is as follows:

[0058] Step 1, ultrasonically cleaning the oxidized Al alloy and solder in acetone for 10 minutes to remove surface oil stains;

[0059] Step 2, the welding process is carried out in the atmosphere, the solder is placed on the base metal, and the whole is heated to 240°C;

[0060] Step 3. After the solder is melted, use an ultrasonic soldering iron to apply ultrasound in the liquid solder, and ...

specific Embodiment approach 2

[0064] Embodiment 2: after micro-arc oxidation of Al alloy, ultrasonic brazing is performed by using SnBiZnAlTi solder.

[0065] During micro-arc oxidation, the solution is 15g / L sodium silicate aqueous solution, 2g / L potassium hydroxide aqueous solution, the frequency is 500Hz, and the current is 2A / dm 2 , the constant current mode is adopted, the oxidation time is 15min, and the thickness of the oxide film on the Al surface is increased to 40μm.

[0066] Table 2 is the chemical composition (weight percent) of low-temperature Sn-based active solder

[0067]

[0068] The welding method in the present embodiment is as follows:

[0069] Step 1, ultrasonically cleaning the oxidized Al alloy and solder in acetone for 10 minutes to remove surface oil stains;

[0070] Step 2. Assemble the aluminum alloy on the self-made jig in the form of a lap joint, place the brazing material on one side of the brazing seam gap, and the size of the brazing seam is 400 μm;

[0071] Step 3. Th...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com