Rare earth surface treatment agent for improving electrochemical corrosion resistance of copper foil surface and surface treatment process

A surface treatment agent and corrosion performance technology, applied in the field of electrolytic copper foil, can solve the problems of unsatisfactory electrochemical corrosion resistance, insufficient fine and uniform crystallization of the alloy layer, etc., to improve the electrochemical corrosion resistance and electrochemical resistance Corrosion, the effect of improving the uniformity of densification

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

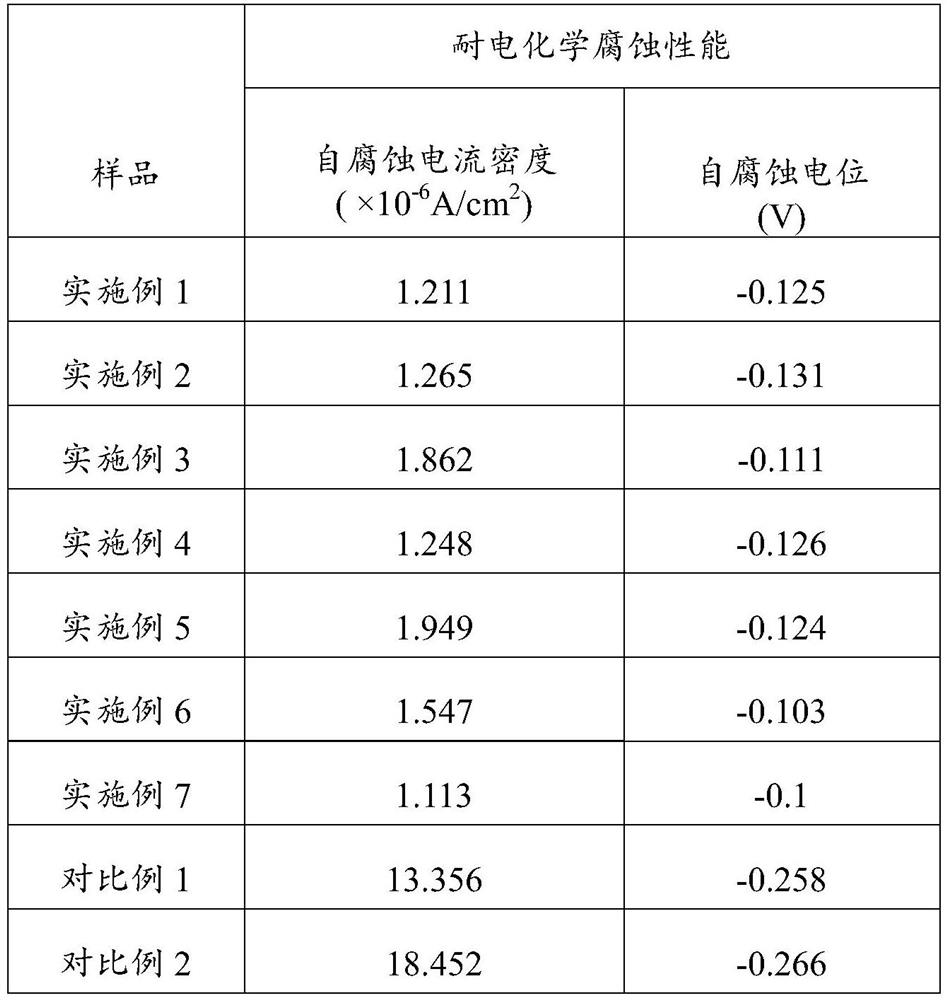

Examples

Embodiment 1

[0023] A rare earth surface treatment agent for improving the electrochemical corrosion resistance of copper foil surface, comprising the following components: potassium pyrophosphate 130g / L, zinc sulfate 10g / L, nickel sulfate 15g / L, sodium borate 10g / L, cerium sulfate 1g / L, Additive A 5mg / L. Wherein, the additive A is SPS, and the solvent of the surface additive is deionized water.

[0024] A surface treatment process for improving the electrochemical corrosion resistance of the surface of copper foil, comprising the following steps: placing the copper foil with a thickness of 12 μm after pickling, roughening, and curing treatment in an electrolytic cell containing the above-mentioned surface treatment agent, and controlling the process The condition pH is 9, the temperature is 35°C, and the current density is 1.5A / dm 2 , The electroplating time is 8s.

Embodiment 2

[0026] A rare earth surface treatment agent for improving the electrochemical corrosion resistance of copper foil surface, comprising the following components: potassium pyrophosphate 135g / L, zinc sulfate 8g / L, nickel sulfate 15g / L, sodium borate 12g / L, cerium sulfate 1g / L, Additive A 5mg / L. Wherein, the additive A is PEG, and the solvent of the surface additive is deionized water.

[0027] A surface treatment process for improving the electrochemical corrosion resistance of the surface of copper foil, comprising the following steps: placing the copper foil with a thickness of 12 μm after pickling, roughening, and curing treatment in an electrolytic cell containing the above-mentioned surface treatment agent, and controlling the process Conditions pH is 9.5, temperature is 38°C, current density is 2A / dm 2 , The electroplating time is 6s.

Embodiment 3

[0029] A rare earth surface treatment agent for improving the electrochemical corrosion resistance of copper foil surface, comprising the following components: potassium pyrophosphate 140g / L, zinc sulfate 8g / L, nickel sulfate 15g / L, sodium borate 10g / L, lanthanum sulfate 1g / L, Additive A 5mg / L. Wherein, the additive A is SPS, and the solvent of the surface additive is deionized water.

[0030] A surface treatment process for improving the electrochemical corrosion resistance of the surface of copper foil, comprising the following steps: placing the copper foil with a thickness of 12 μm after pickling, roughening, and curing treatment in an electrolytic cell containing the above-mentioned surface treatment agent, and controlling the process The condition pH is 10, the temperature is 42°C, and the current density is 2.5A / dm 2 , The electroplating time is 5s.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com