A kind of no-clean solid flux for aluminum low-temperature soldering and its preparation method

A no-cleaning, soldering technology, applied in welding equipment, welding media, manufacturing tools, etc., can solve the problems of poor electrochemical corrosion resistance of low-temperature active solder joints, fast tinning speed, and low moisture absorption. Achieve the effect of improving solder joint reliability, promoting spreading, and increasing solder joint life.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

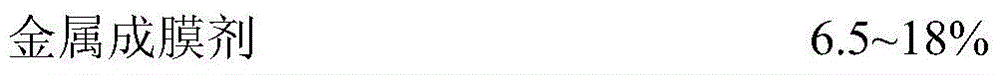

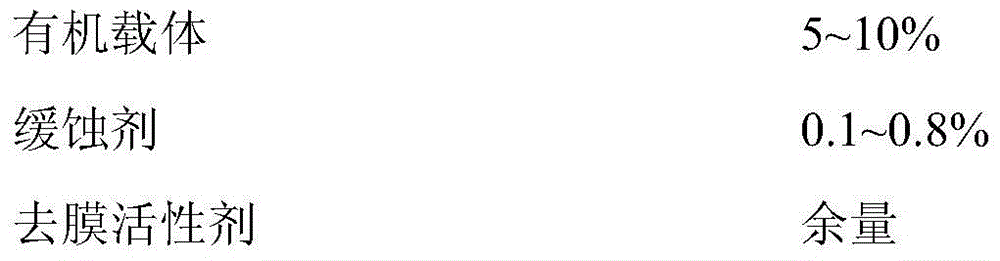

[0048] A no-clean solid flux used for aluminum low-temperature soldering, the raw material formula components are as follows:

[0049]

[0050] Preparation method: prepare triethylenetetramine, diethanolamine and alcohol as an organic amine alcohol solution with a weight ratio of 1:2, and prepare an acid alcohol solution with a weight ratio of fluoroboric acid, stearic acid and alcohol with a weight ratio of 1:3. Titrate the organic amine alcohol solution with an acid alcohol solution in the kettle to pH = 7 and let it stand for 24 hours; put the organic amine hydrochloride alcohol solution in a polytetrafluoroethylene evaporating dish, heat it to 135±5°C and continue at 90r / min Stir at a high speed until the alcohol and water are removed, and cool to obtain a solid mixture of triethylenetetraamine fluoroborate and diethanolamine stearate; take the above-mentioned mass fraction of organic amino acid salt in a reaction kettle and heat it to 110±5°C , add zinc oxide to the li...

Embodiment 2

[0052] A no-clean solid flux used for aluminum low-temperature soldering, the raw material formula components are as follows:

[0053]

[0054] Preparation method: prepare hydroxyethylethylenediamine, triethanolamine and alcohol as an organic amine alcohol solution with a weight ratio of 1:3, and prepare an acid alcohol solution with a weight ratio of fluoroboric acid, hydrofluoric acid and alcohol with a weight ratio of 1:5, Titrate the organic amine alcohol solution with acid alcohol solution to pH = 7 in the reaction kettle and let it stand for 48 hours; put the organic amine hydrochloride alcohol solution in a polytetrafluoroethylene evaporating dish, heat it to 135±5°C and continuously heat it for 60r Stir at a speed of 1 / min until the alcohol and water are removed, and cool to obtain a solid mixture of hydroxyethylethylenediamine fluoroborate and triethanolamine hydrofluoride; take the above-mentioned mass fraction of organic amino acid salt in a reaction kettle, and h...

Embodiment 3

[0056] A no-clean solid flux used for aluminum low-temperature soldering, the raw material formula components are as follows:

[0057]

[0058] Preparation method: hydroxydiethylethylenediamine, ethylenediamine and alcohol are prepared into an organic amine alcohol solution with a weight ratio of 1:1, and adipic acid, fluoroboric acid and alcohol are prepared into an acid alcohol solution with a weight ratio of 1:4 , Titrate the organic amine alcohol solution with an acid alcohol solution in the reaction kettle to pH = 7 and then place it for 24 hours; place the organic amine hydrochloride alcohol solution in a polytetrafluoroethylene evaporating dish, heat it to 135±5°C and continuously Stir at a speed of 80r / min until the alcohol and water are removed, and cool to obtain a solid mixture of hydroxydiethylethylenediamine adipate and ethylenediamine fluoroborate; take the above mass fraction of organic amino acid salt in the reaction kettle , heated to 110±5°C, adding zinc o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com