Electrode plate of electric double layer capacitor (EDLC) and preparation method thereof

A technology of supercapacitors and electrode sheets, applied in the manufacture of hybrid capacitor electrodes and hybrid/electric double-layer capacitors, etc., can solve the problems of reduced working voltage, electrochemical corrosion of EDLC metal parts, etc., to reduce internal resistance and improve electrochemical resistance. Corrosion ability, effect of stable working voltage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

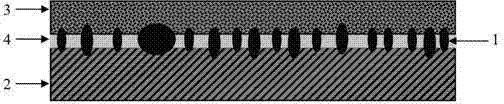

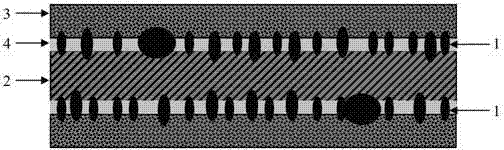

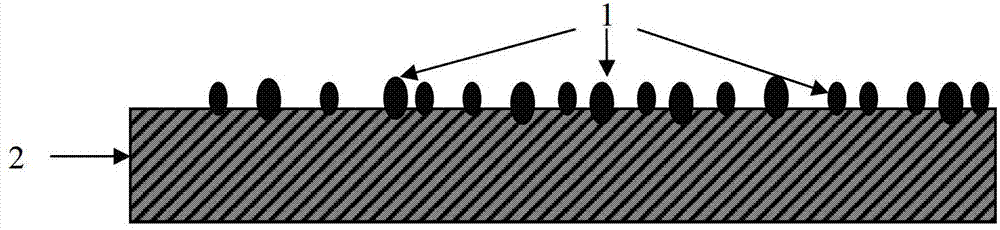

Image

Examples

Embodiment 1

[0033] Pitch-based spherical activated carbon may contain 0.5%wt impurities such as iron oxides and other iron compounds. Impurities form oxygen-containing functional groups on the surface of activated carbon, such as carbonyl, hydroxide, ether, etc. Iron compounds and oxygen-containing functional group impurities increase the self-discharge of EDLC and shorten the lifetime.

[0034] Impurities can be removed by the following method: Pitch-based spherical activated carbon is acid-washed with carboxylic acid and then filtered, the filter residue is collected, and the filter residue is heated from 600°C to 1200°C under the protection of inert gas. The heating process can remove the oxygen-containing functional groups on the surface and increase the graphitization of nano-carbon powder to enhance conductivity. After treatment, the specific surface area is ≥2000m 2 / g, activated carbon with a pore size of 1nm to 3nm. Use 600-mesh and 800-mesh sieves to screen activated carbon w...

Embodiment 2

[0041] The pitch-based spherical activated carbon is acid-washed with carboxylic acid and then filtered, the filter residue is collected, and the filter residue is heated from 600°C to 1200°C under the protection of an inert gas. After treatment, the specific surface area is ≥2000m 2 / g, activated carbon with a pore size of 1nm to 3nm. Use 1000 mesh and 1340 mesh sieves to screen activated carbon with a particle size of 10-13 μm as the electrode active material.

[0042] Weigh deionized water and ethanol with a volume ratio of 1:2, mix well, add PTFE solution, stir well, add acetylene black, and continue stirring. The solid content in the mixed solvent is 4wt%. After mixing evenly, add the treated activated carbon and grind it with a mortar. The ground electrode material was pressed into a 100 μm sheet with a roller press. The mass fractions of electrode active material, acetylene black and PTFE are 85%, 10% and 5%.

[0043] A 23 μm thick aluminum foil is selected as the ...

Embodiment 3

[0048] In this embodiment, a current collector without surface treatment is used, and the electrode material is directly coated on the current collector without using conductive glue, and other processes are completely consistent with Embodiment 2.

[0049] The pitch-based spherical activated carbon is acid-washed with carboxylic acid and then filtered, the filter residue is collected, and the filter residue is heated from 600°C to 1200°C under the protection of an inert gas. After treatment, the specific surface area is ≥2000m 2 / g, an electrode active material with an average particle size of 10 μm and a pore size of 1 nm to 3 nm.

[0050] Weigh deionized water and ethanol with a volume ratio of 1:2, mix well, add PTFE solution, stir well, add acetylene black, and continue stirring. The solid content in the mixed solvent is 4wt%. After mixing evenly, add the treated activated carbon, and the mass fractions of the electrode active material, acetylene black and PTFE are 85%,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com