Reduction annealing and heat plating process of band steel continuous heat plating rare earth aluminium zinc alloy

A zinc-aluminum alloy and strip steel technology, applied in hot-dip galvanizing process, metal material coating process, heat treatment furnace, etc., can solve problems such as rough surface of strip steel, unsatisfactory wettability, and poor fluidity of zinc liquid

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

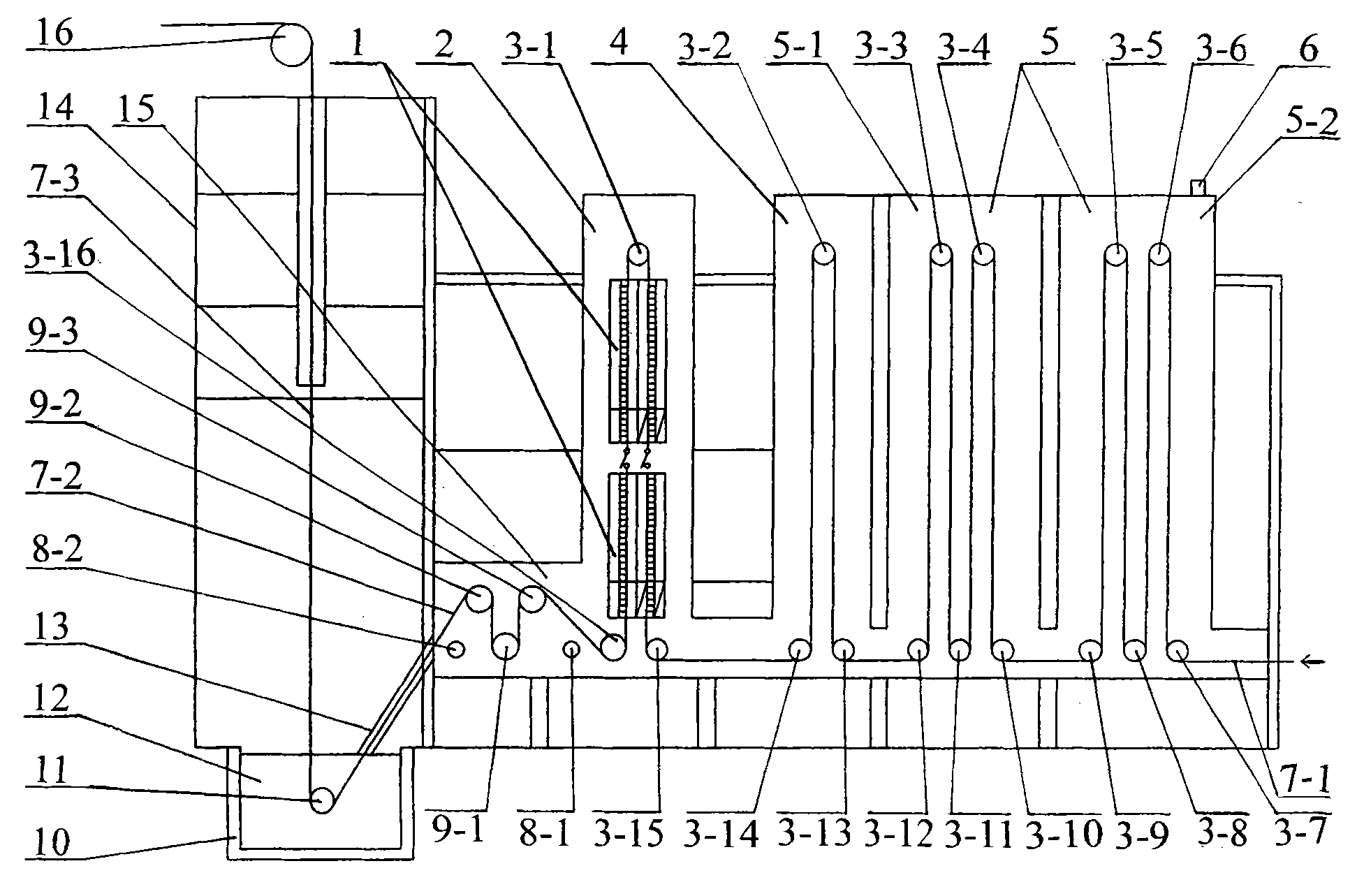

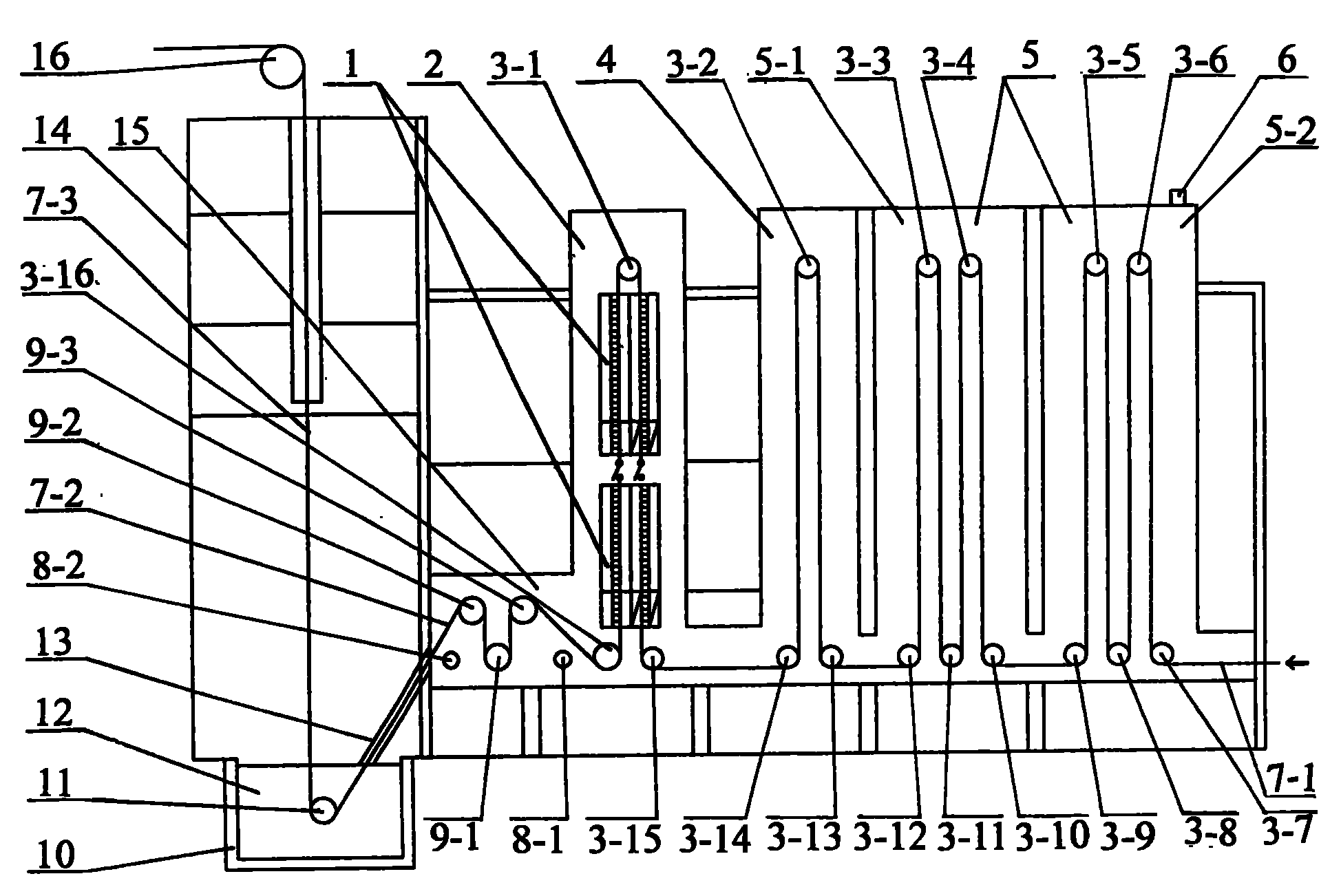

[0018] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

[0019] As shown in the figure, the reduction annealing and hot-dip process of continuous hot-dip rare earth zinc-aluminum alloy on strip steel includes the reduction annealing process of continuous hot-dip rare earth zinc-aluminum alloy on strip steel and the hot-dipping process of continuous hot-dip rare earth zinc-aluminum alloy on strip steel Craft two parts.

[0020] The reduction annealing process of continuous hot-dip rare earth zinc-aluminum alloy on strip steel is divided into reduction heating section 5 and reduction soaking section including pre-reduction heating section 5-2 and post-reduction heating section 5-1 as shown in the figure. 4. It is carried out in a reduction annealing furnace with a cooling section 2 of a cooler 1 and a thermal tension section 15 structure. The main process content includes the strip steel reduction annealing pro...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com