Graphitized carbon carrier for hydrogen fuel cell, preparation method of graphitized carbon carrier and cell catalyst of graphitized carbon carrier

A graphitized carbon and fuel cell technology, applied in battery electrodes, circuits, electrical components, etc., can solve the problem of limited improvement in the electrochemical corrosion resistance of carbon carriers, uneven distribution of metal particles, and the degree of graphitization on the surface of catalytic graphitized carbon carriers. Inhomogeneous and other problems, to achieve the effect of improving the resistance to electrochemical corrosion, good uniformity of the degree of graphitization, and stable catalytic effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

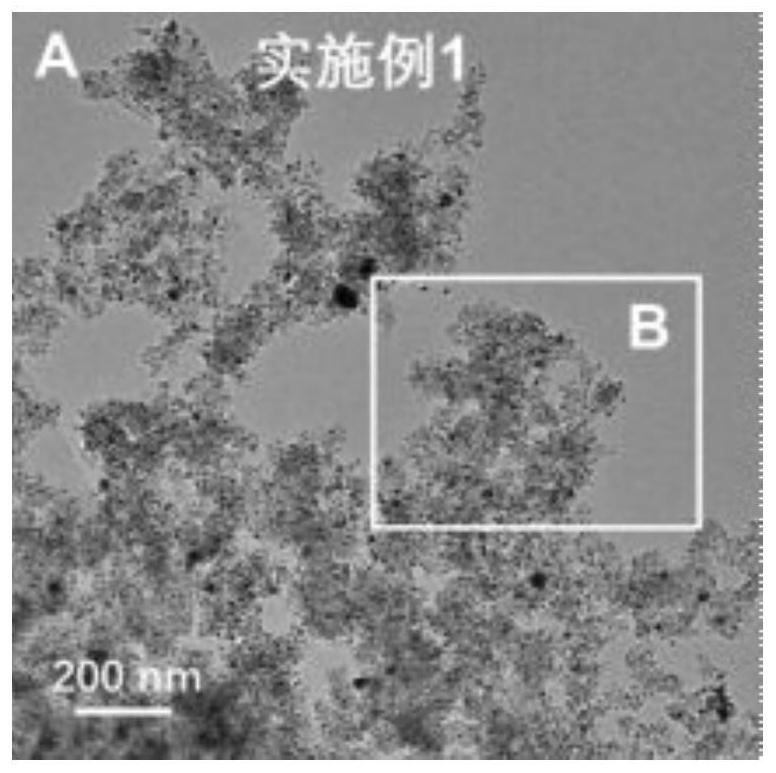

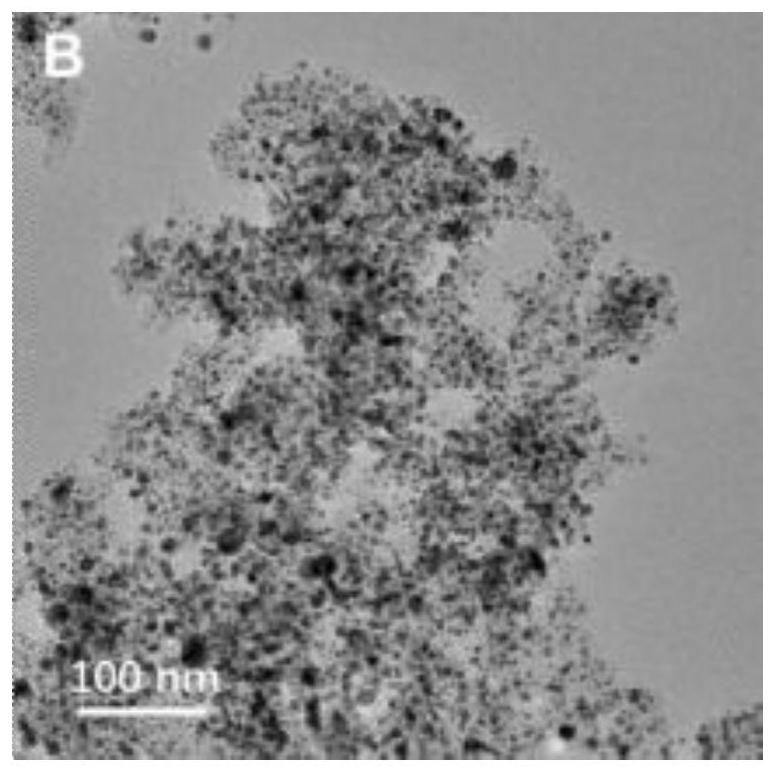

Embodiment 1

[0072] 1. Put 2g of original carbon carrier into the crusher, shear and crush for 10 minutes for later use;

[0073] 2. Take 1g of the sample in step 1, 5g of auxiliary agent aniline, 4g of cobalt nitrate and 200g of isopropanol and ultrasonically stir and mix for 1 hour, then reflux at 80°C for 5 hours;

[0074] 3. The product in step 2 was subjected to rotary evaporation to remove the solvent, and the rotary evaporation temperature was 60°C;

[0075] 4. Place the transition metal salt / carbon carrier mixture in step 3 in a tube furnace, blow nitrogen into it for 15 minutes, then heat it up to 300°C at a rate of 1°C / min and keep it warm for 30 minutes, then The heating rate was 5°C / min and the temperature was raised to 900°C for 3 hours. After cooling to room temperature, the pristine graphitized carbon support / transition metal mixture can be obtained

[0076] 5. Mix the original graphitized carbon support / transition metal mixture obtained in step 4 with a 1M sulfuric acid w...

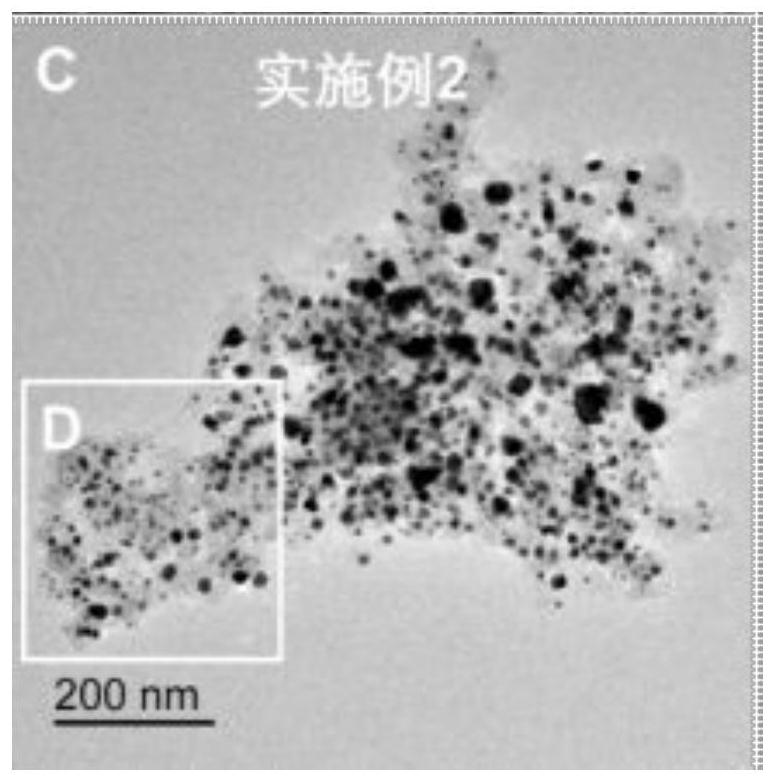

Embodiment 2

[0083] 1. Put 2g of original carbon carrier into the crusher, shear and crush for 10 minutes for later use;

[0084] 2. Take 1g of the sample in step 1, 4g of cobalt nitrate and 200g of isopropanol and ultrasonically stir and mix for 1 hour, then reflux at 80°C for 5 hours;

[0085] 3. The product in step 2 was subjected to rotary evaporation to remove the solvent, and the rotary evaporation temperature was 60°C;

[0086] 4. Place the transition metal salt / carbon carrier mixture in step 3 in a tube furnace, blow nitrogen into it for 15 minutes, then heat it up to 300°C at a rate of 1°C / min and keep it warm for 30 minutes, then The heating rate was 5°C / min and the temperature was raised to 900°C for 3 hours. After cooling to room temperature, the pristine graphitized carbon support / transition metal mixture can be obtained

[0087] 5. Mix the original graphitized carbon support / transition metal mixture obtained in step 4 with a 1M sulfuric acid washing solution, and then pickl...

Embodiment 3

[0093] 1. Put 2g of original carbon carrier into the crusher, shear and crush for 10 minutes for later use;

[0094] 2. Take 1g of the sample in step 1 and 200g of isopropanol and mix it ultrasonically for 1 hour, then reflux at 80°C for 5 hours;

[0095] 3. The product in step 2 was subjected to rotary evaporation to remove the solvent, and the rotary evaporation temperature was 60°C;

[0096] 4. Put the carbon carrier mixture in step 3 in a tube furnace, blow it with nitrogen for 15 minutes, then raise the temperature at a rate of 1 °C / min to 300 °C and keep it warm for 30 minutes, then at a rate of 5 °C Heat up to 900°C per minute and keep warm for 3 hours. After cooling to room temperature, the original graphitized carbon support can be obtained.

[0097] 5. Mix the original graphitized carbon carrier obtained in step 4 with a washing solution of 1M sulfuric acid, and then pickle at 85° C. for 4 hours. Then the acid-washed sample was washed with deionized water to neutr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com