Electric wear-resistant anti-corrosion cable

A corrosion-resistant and corrosion-resistant layer technology, applied in the direction of power cables, insulated cables, cables, etc. with shielding layer/conductive layer, to achieve high weather resistance, excellent impact resistance, and good elasticity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

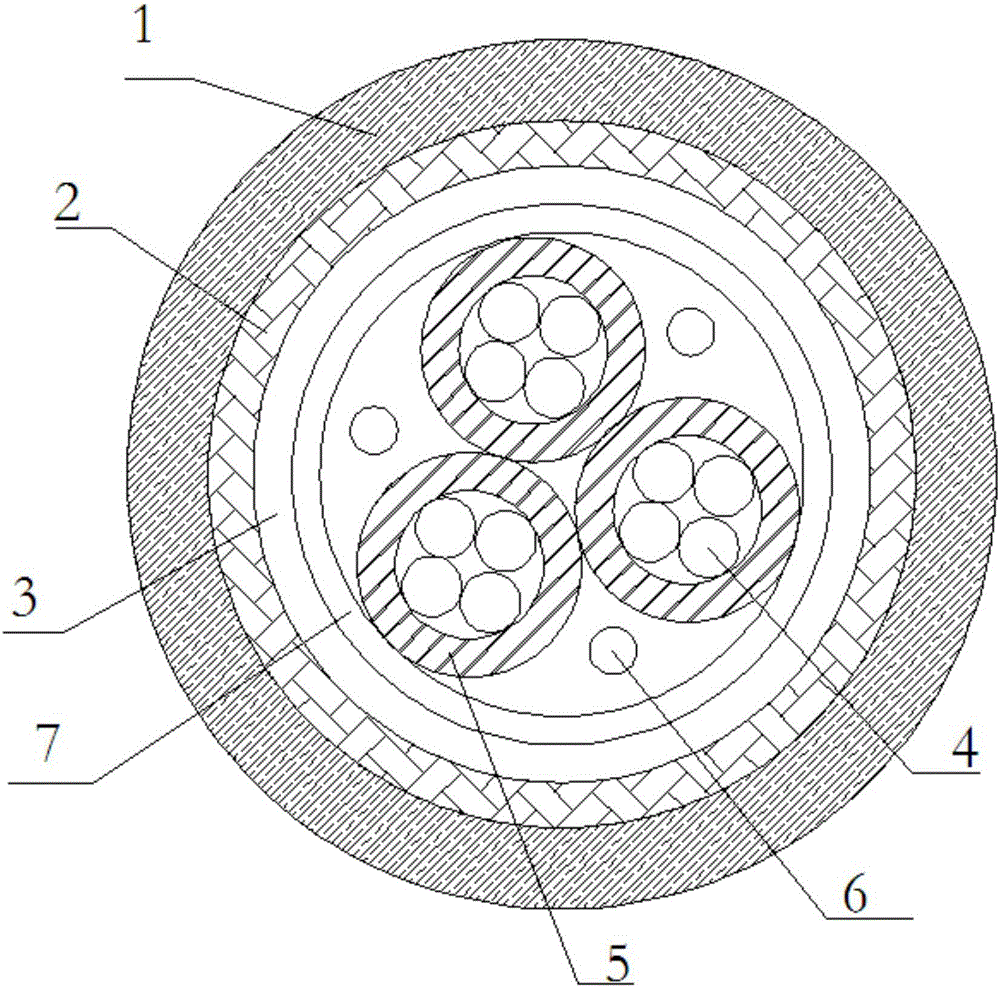

[0033] A wear-resistant and corrosion-resistant cable for electric power, with a structure such as figure 1 As shown, it consists of 3 cable cores, an alloy lead sheath shielding layer 3 and a wear-resistant and corrosion-resistant layer 1, and a steel strip 2 is arranged between the wear-resistant and corrosion-resistant layer 1 and the alloy aluminum sheath shielding layer 3, and the steel strip 2 Both sides are coated with anti-corrosion paint, a waterproof layer 7 is set between the alloy lead sheath shielding layer 3 and the 3 cable cores, a filling layer 6 is set between the 3 cable cores and the waterproof layer 7, and the 3 cable cores are evenly arranged on the filling layer 6, the cable core includes a conductor 4 and an insulating layer 5 covering the conductor;

[0034] The waterproof layer 7 is a polyvinyl chloride waterproof layer, the thickness of the wear-resistant and corrosion-resistant layer is 2 mm, the material used for the shielding layer of the alloy lea...

Embodiment 2

[0044] The wear-resistant and corrosion-resistant cable for electric power as described in embodiment 1, the difference is that:

[0045] The thickness of the wear-resistant and corrosion-resistant layer is 1.5mm, and the raw material components of the wear-resistant and corrosion-resistant layer are as follows, all in parts by weight:

[0046] 58 parts of styrene-butadiene rubber, 32 parts of neoprene rubber, 23 parts of fluoroether rubber, 5 parts of graphene, 5 parts of phenolic resin, 698 parts of silane coupling agent Si, 15 parts of semi-reinforced furnace black, 12 parts of calcined clay, 2 parts of magnesium chloride parts, magnesium powder 4 parts, nano molybdenum disulfide (MoS 2 ) 7 parts, phenylenediamine derivatives anti-aging agent 8 parts, plasticizer 6 parts, accelerator NS 4 parts.

[0047] The material for the wear-resistant and corrosion-resistant layer is prepared according to the following method, and the steps are as follows:

[0048] (1) Molybdenum dis...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com